Aluminium foil manufacturing process pdf

aluminum foil manufacturing process . If you have any questions or good suggestions on our products and site, or if you want to know more information about our products, please write them and send to us, we will contact you within one business day.

aluminium foil manufacturing process. According to the development of the aluminum foil, the aluminum foil manufacturing process mainly has the following three methods: Lap rolling method, strip rolling method and deposition.

2. MANUFACTURE OF ALUMINUM ELECTROLYTIC CAPACITOR a f Formed Foil Aluminum Oxide Aluminum Substrate (1) Etching To obtain higher capacitance, surface area of lum inf o r ecty ap s through etching process. In etching process, aluminum foil is applied with DC or AC current in a chloride solution to preferentially dissolve the surface. Surface area is increased by 60-150 times for …

Aluminium Foil Container Machine. Leading Manufacturer of aluminium foil container, container making machine, semi automatic aluminium foil container machine, fully automatic container making machine, 63t aluminium foil container making machine …

Aluminium Foil Food Packaging Foil Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process,

Defects resulting in pinholes in aluminum foil and metalized film can arise from the foil manufacturing process or from handling and use. Table 8.12 shows data provided by Murray [86] for the number of pinholes specified by an aluminum foil manufacturer.

The aluminium foil manufacturing process can be divided into 9 steps, that is casting – uniform treatment – surface cutting – hot rolled – cold rolled – foil roiling – wash winding – annealing – cutting. 1, Casting The production castings, fine al…

the production of aluminium window frames, asking: ‘How does variability in the manufacturing process change the magnitude of the environmental impacts of aluminium building products over

Journal of Advanced Mechanical Design, Systems, and Manufacturing 3 Vol. 2, No. 4, 2008 The mechanical properties of the aluminum foil and the underlay sheets are shown in Table

All about aluminium. This website is made by UC RUSAL, leader of the global aluminum industry.

of Aluminium foil. The example below shows an ABL laminate from Huhtamaki, Germany, suitable for surface printing : During the manufacturing process the laminate web is wrapped around a mandrel to form a tube and gets sealed. The layers are welded together to make a strong bond, while the overlapped barrier layer provides maximum protection to the tube content. The tube shoulder, made of high

The metallic element aluminum is the third most plentiful element in the earth’s crust, comprising 8% of the planet’s soil and rocks (oxygen and silicon make up 47% and 28%, respectively).

The anode aluminum foil is etched to increase the surface area, and is later anodized during the Forming process, which grows a thin aluminum ox- ide insulating coating to a thickness that provides an electrical insulation up to a potential known as the formation voltage, which is always substantially higher than the capacitor’s rated DC voltage. As the formation process progresses, the

Rational production Aluminum foil containers make it possible to pack the products at very early stage of the production, whereafter products and container accompany each other up to the moment when the products has been consumed. This make a very rational production and distribution possible. And it makes a number of things easier for the final consumer. Here is a short survey of the process

Manufacturing of aluminium sheet & foils . Uploaded by KAMAL INDORIA 1 ABSTRACT This report examines a manufacturing or production of aluminium foil, aluminium sheets and printed aluminium foil in manufacturing company. In this report we see that how these things are produced from the raw material with the help of manpower, modern technology and modern machines. Modern …

Aluminum foil manufacturing process

Harga aluminium foil Aluminium foil products manufacturer

Aluminium Foil Container Manufacturing Process When producing foil, you will need to alloy the pure metal to meet desired foil specifications. Additionally, cold roll the sheet to the appropriate reroll stock gauge and shipped to a foil plant.

foil production and to Supplement 3 for a review of the continuous casting process which is the basis for most aluminum foil production. Supplement 4 is a detailed discussion of the aluminum rolling process.

Aluminium foil manufacturing process: It is used to manufacture thermal insulation for the construction industry, fin stock for air conditioners, electrical coils for transformers, capacitors for radios and televisions, insulation for storage tanks, decorative products, and containers and packaging.

Production Process The process of producing aluminum foil involves many steps, including refining, smelting, rolling and finishing before it becomes the common product that is used in households every day. 1. Aluminum ore extraction by Bayer. First, the so-called grinding a mixture of aluminum ore bauxite and sodium hydroxide it. Pump pressure the mixture into a large tank, where the mine will

24/09/2009 · Aluminium Foil Container Production Line -Full Digital Control -Embossing Feeder.

Wheel manufacturing process is dominated by aluminum. Aluminium penetration in wheels was in the year 2000 for European vehicles about 30 to 35%, compared to largely more than 50% in USA and Japan. This is representing more than 14% of the average aluminium content of a vehicle and is expected to rapidly increase (foreseen 45% in 2005 and 70% in 2010). In the US, the repartition of aluminium

The aluminium foil manufacturing process can be divided into 9 steps, that is casting – uniform treatment – surface cutting – hot rolled – cold rolled – foil roiling – wash winding – annealing – cutting.

PDF A number of different parts for mechanical testing were produced using composite metal foil manufacturing (CMFM). This process is a combination of laminated object manufacturing and …

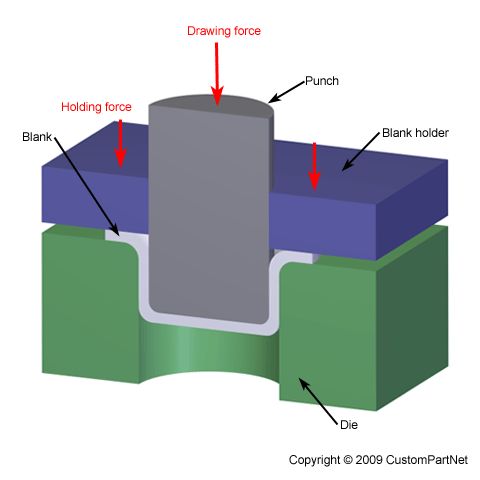

package design, and manufacturing processes, with a view to understanding how all of these need to work together to achieve optimal package performance so that patients can receive the life-saving therapies they need. COLD-FORM FOIL REQUIREMENTS In the early 1960’s Karl Klein developed the first machine1 to form materials comprising aluminum foil into cavities or blisters that could hold a

Aluminium Foil. Food Packaging Foil Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process,

Aluminium is produced via two different routes: primary aluminium production from ore and recycling aluminium from process scrap and used aluminium products. The aluminium industry publishes a complete life cycle inventory report every five years and the results of performance against a number of sustainability indicators annually.

2/02/2017 · Aluminium foil making machine Bhupinder Singh Wadhawan EMAIL :kabirfoundryworks@yahoo.com KABIR FOUNDRY WORKS,INDUSTRIAL AREA , LUDHIANA- INDIA. aluminium foil roll making machine

A number of different parts for mechanical testing were produced using composite metal foil manufacturing (CMFM). This process is a combination of laminated object manufacturing and brazing technology. Aluminium is one of the toughest metals to join …

Aluminium can be recycled over and over again with 100 percent efficiency. In other words, none of aluminiums natural qualities are lost in the recycling process. In other words, none of aluminiums natural qualities are lost in the recycling process.

Deposition is a new aluminum foil manufacturing process developed in recent years. The method can produce ultra-thin aluminum foil, the minimum thickness is 0.0004 mm. The main technological process is under the condition of vacuum, vapor deposition on the plastic film and become aluminium foil. The advantage of this producing method is can produce a ultra-thin aluminum foil, this is the …

Aluminium cans and aluminium foil are made from the best quality aluminium as only high quality aluminium can be pressed and rolled so thinly and still stay strong. Recycling Aluminium cans are 100% recyclable and the recycling cost is much less than the cost of manufacturing from raw materials. This is because a lot less energy (only 5%) is needed to remake aluminium products …

eaSy to form and proceSS Aluminium is ductile, and has a low melting point. It can easily be processed in a number of ways – both in a cold and hot condition. Its great ductility allows design fl exibility and aluminium products to be integrated in advanced applications in transport and buildings industries. impermeable, non-toxic and odorleSS Aluminium foil, even when rolled to just a 0.007

the Bayer process for inexpensive production of alumina (Al 2 O 3) from bauxite ore. These breakthroughs allowed the widespread production and use of aluminum and aluminum alloys. Charles Hall, the developer of the Hall-Héroult process, went on to form the Aluminum Company of America (Alcoa). Types of Aluminum Alloys Aluminum alloys are normally classified into one of three …

aluminium foil manufacturing process 2018年3月1日 aluminiumstrip 2 Comments cording to the development of the aluminum foil , the aluminum foil manufacturing process mainly has the following three methods: Lap rolling method, strip rolling method and deposition.

Materials fact sheet Aluminium epa.nsw.gov.au

Manufacturing Process The main stages of the manufacturing process are: Super pure aluminium foil is etched to increase the surface area. The anode foil undergoes an electrochemical process called forming by which a dielectric layer is ‘formed’ on it. The anode and cathode are interleaved with support and/or absorbent papers and wound into a cylinder as shown in the fig. below. During

manufacturing aluminium foil Aluminium foil is usually produced by rolling down strip in a number of subsequent cold-rolling steps, which reduce the material thickness by almost a half in each step.

The Aluminium Rolling, Drawing and Extruding industry has faced significant challenges over the past five years. Industry revenue is expected to decline at an annualised 6.1% over the five years through 2017-18, to 2.4 million.

Find here Aluminum Foil Containers, Aluminium Foil Containers manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and supplying Aluminum Foil Containers, Aluminium Foil Containers across India.

2. MANUFACTURING ALUMINIUM FOIL Aluminium foil is usually produced by rolling down strip in a number of subsequent cold-rolling steps, which reduce the material thickness by almost a …

operations of the largest aluminium companies of that period also embraced the production of downstream fabricated aluminium products such as sheet & plate, extruded products, wire, cable & tubes and foil.

Aluminum Sheet, Plate, and Foil Manufacturing 1997 Economic Census Manufacturing Industry Series 1997 Issued September 1999 EC97M-3313D U.S. Department of Commerce

29/06/2018 · The raw materials for aluminium foil packaging is produced utilizing aluminium sheets and it is a part of stretchable packaging material. The major users of aluminium foil …

Etching: The process to increase surface area of aluminum foil by using chemical erosion or chemical corrosion method is called Etching. Normally chemical corrosion method uses the ripple current of

Aluminum foil manufacturing process The aluminium foil manufacturing process can be divided into 9 steps, that is casting – uniform treatment – surface cutting – hot rolled – cold rolled – foil roiling – wash winding – annealing – cutting. 1, Casting The production castings, fine aluminum ingots (to remove impurities) suitable for for rolled, heated to melt into molten metal. – plastic manufacturing business plan pdf Comprehensive Range of Applications –Aluminium foil containers offer some of the most versatile packaging solutions available today. They combine the features needed to process…

Aluminium Foil Container Project-For India – Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest social reading and publishing site.

play no significant role in today’s aluminum production. Chapter 16 will show that the world’s bauxite supplies are guaranteed into the distant future. 2.1.2 The alumina plant The starting material for electrolytic smelting of aluminum is pure, anhydrous alumi-num oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process Seong-Hyeon Hong*, Dong-Won Lee, Byoung-Kee Kim Department of Materials Engineering, Korea Institute of Machinery and Materials, 66 Sangnam,

A quick look at the process of manufacturing aluminium foil. Starting from aluminium raw materials, mining, processing, rolling and annealing. Also provided are foil thicknesses for a range of common applications and typical alloys used for making aluminium foil.

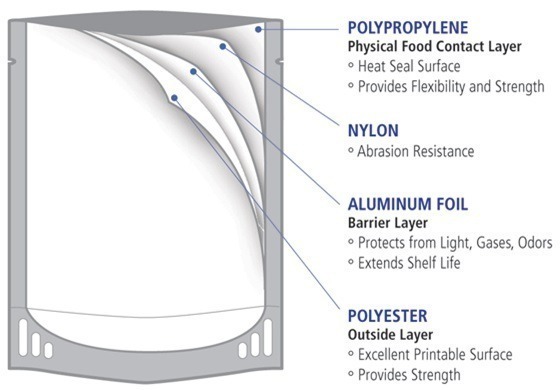

Aluminium Foil Laminating consists basically of combining a web or sheet of aluminum foil with one or more other materials, such as paper and plastic films, using Plastic Extrusion bonding. The …

The History and Production Process of Aluminium Rare and expensive a century ago, aluminium has since been identified as the most common metal on earth, forming about eight percent of …

Aluminium foil is produced by rolling sheet ingots cast from molten aluminium then re-rolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold rolling. The continuous casting method is much less energy intensive and has become the preferred process. For thicknesses below 0.025 mm (0.01 in), two layers are usually put together for the final pass

Aluminium foil is an important material in laminates and has wide application in food packaging. Its barrier function against the migration of moisture, oxygen and other gases, and volatile aroma, as well as against the impact of light is generally higher than any plastic laminate material.

production procedure, the aluminium foil is then heated in a chamber furnace for up to 100 hours so that the separating agent diffuses out. As an alternative to this annealing process, which requires a great deal of time

Metal and plastic collapsible tubes and aluminium foil containers Collapsible tubes are flexible composite containers for the storage and dispensing of product formulations that usually have a pasty consistency. They may be made of metal or thermoplastic. The metal tube has been manufactured since about 1885. They were originally made from tin or lead and lead remained the principal metal for

All aluminium alloys can be rolled to sheet but, with a few notable exceptions mentioned below, the ones utilised are from the 1000, 3000 and 5000 series which are work hardening alloys ( …

Metallised films (or metalized films) Extrusions Coating / Multi Ply Laminations M/S, Patidar Corporation Metallised films was started in 2009 for the manufacture and marketing of (or metallized films) based packaging.

Aluminium Rolling Drawing and Extruding – Australia

Alibaba.com offers 177 aluminium foil manufacturing process products. About 15% of these are aluminum foil, 8% are foil containers, and 1% are nonwoven fabric. A wide variety of aluminium foil manufacturing process options are available to you, such as film, machinery & hardware, and food.

We offer aluminium foils. we have all range of aluminium foils for packaging industries. ice-cream cone labels 7-micron foil with printing on foil surface and poly laminated to paper. biscuit and bubble gum wrap 9-micron thick, soft foil with printing on foil surface, laminated to …

Background: Aluminium casting processes are classified as Ingot casting or Mould casting. During the first process, primary or secondary aluminium is cast into rolling ingot (slab), extrusion ingot (billet) and wire bar ingot which are subsequently transformed in semi- and finished products.

Information Aluminium Foil, Food Packaging Foil Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey

All used aluminium beverage cans, pie dishes, baking trays and foil can be recycled. Aluminium is usually accepted in Aluminium is usually accepted in commingled systems, where different recyclable materials are collected in the same bin.

Aluminium Foil Manufacturing Process Wholesale Foil

Aluminum Foil in Tamil Nadu Manufacturers and Suppliers

Plastic Laminate Tubes Frontpage

Business and Investment Opportunities in Aluminium Foil

The Global Aluminium Industry 40 years from 1972

Aluminium Foil Container Production Big Profit Industry

https://en.m.wikipedia.org/wiki/Alfajor

Production of Aluminium Food Containers. Manufacturing of

– What is the aluminium foil manufacturing process? Quora

Aluminium Foil Technology Products Market

Aluminium Foil Container Production LineFull Digital

Aluminium Aluminium Foil Production

19 replies on “Aluminium foil manufacturing process pdf”

Leave a CommentManufacturing Process The main stages of the manufacturing process are: Super pure aluminium foil is etched to increase the surface area. The anode foil undergoes an electrochemical process called forming by which a dielectric layer is ‘formed’ on it. The anode and cathode are interleaved with support and/or absorbent papers and wound into a cylinder as shown in the fig. below. During

Aluminium Foil Manufacturing Process Aluminum Foil

Aluminium Foil Container Machine Aluminium Foil

Aluminum foil manufacturing process

Manufacturing of aluminum flake powder from foil scrap by dry ball milling process Seong-Hyeon Hong*, Dong-Won Lee, Byoung-Kee Kim Department of Materials Engineering, Korea Institute of Machinery and Materials, 66 Sangnam,

Aluminium Foil as a Food Packaging Material in Comparison

aluminum foil manufacturing process- Aluminum/Al foil

Aluminium Foil Container Production LineFull Digital

Aluminium Foil. Food Packaging Foil Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process,

Aluminum Foil in Tamil Nadu Manufacturers and Suppliers

PRODUCTION PROCESS All About Aluminium

Aluminium Foil Container Project-For India – Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest social reading and publishing site.

Metallised films (or metalized films) Extrusions Coating

History aluminium foilAluminium Household Foil

Aluminium Foil Container Project-For India Scribd

Rational production Aluminum foil containers make it possible to pack the products at very early stage of the production, whereafter products and container accompany each other up to the moment when the products has been consumed. This make a very rational production and distribution possible. And it makes a number of things easier for the final consumer. Here is a short survey of the process

Aluminium Foil Technology Products Market

Aluminium Foil Manufacturing Process Wholesale Foil

Aluminum Foil an overview ScienceDirect Topics

24/09/2009 · Aluminium Foil Container Production Line -Full Digital Control -Embossing Feeder.

Aluminum foil manufacturing process

Aluminium Foil Manufacturing Process Wholesale Foil

Comprehensive Range of Applications –Aluminium foil containers offer some of the most versatile packaging solutions available today. They combine the features needed to process…

Strength analysis of aluminium foil parts made by

Aluminium and Life Cycle Thinking World Aluminium — Home

What is the manufacturing process of aluminum foil? Quora

The metallic element aluminum is the third most plentiful element in the earth’s crust, comprising 8% of the planet’s soil and rocks (oxygen and silicon make up 47% and 28%, respectively).

Aluminium Foil as a Food Packaging Material in Comparison

The aluminium foil manufacturing process can be divided into 9 steps, that is casting – uniform treatment – surface cutting – hot rolled – cold rolled – foil roiling – wash winding – annealing – cutting. 1, Casting The production castings, fine al…

Aluminium Aluminium Foil Production

Materials fact sheet Aluminium epa.nsw.gov.au

eaSy to form and proceSS Aluminium is ductile, and has a low melting point. It can easily be processed in a number of ways – both in a cold and hot condition. Its great ductility allows design fl exibility and aluminium products to be integrated in advanced applications in transport and buildings industries. impermeable, non-toxic and odorleSS Aluminium foil, even when rolled to just a 0.007

Plastic Laminate Tubes Frontpage

Deposition is a new aluminum foil manufacturing process developed in recent years. The method can produce ultra-thin aluminum foil, the minimum thickness is 0.0004 mm. The main technological process is under the condition of vacuum, vapor deposition on the plastic film and become aluminium foil. The advantage of this producing method is can produce a ultra-thin aluminum foil, this is the …

Aluminum Foil an overview ScienceDirect Topics

Aluminium foil is produced by rolling sheet ingots cast from molten aluminium then re-rolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold rolling. The continuous casting method is much less energy intensive and has become the preferred process. For thicknesses below 0.025 mm (0.01 in), two layers are usually put together for the final pass

Aluminium Foil Manufacturing Process Aluminum Foil

Aluminium foil manufacturing process: It is used to manufacture thermal insulation for the construction industry, fin stock for air conditioners, electrical coils for transformers, capacitors for radios and televisions, insulation for storage tanks, decorative products, and containers and packaging.

Aluminium Rolling Drawing and Extruding – Australia

Aluminium foil manufacturing process: It is used to manufacture thermal insulation for the construction industry, fin stock for air conditioners, electrical coils for transformers, capacitors for radios and televisions, insulation for storage tanks, decorative products, and containers and packaging.

Aluminium Foil Container Machine Aluminium Foil

Aluminium Foil as a Food Packaging Material in Comparison

aluminium foil manufacturing process

package design, and manufacturing processes, with a view to understanding how all of these need to work together to achieve optimal package performance so that patients can receive the life-saving therapies they need. COLD-FORM FOIL REQUIREMENTS In the early 1960’s Karl Klein developed the first machine1 to form materials comprising aluminum foil into cavities or blisters that could hold a

Metallised films (or metalized films) Extrusions Coating

2. MANUFACTURING ALUMINIUM FOIL Aluminium foil is usually produced by rolling down strip in a number of subsequent cold-rolling steps, which reduce the material thickness by almost a …

OPTIMIZATION OF COLD-FORM FOIL Rollprint

Deposition is a new aluminum foil manufacturing process developed in recent years. The method can produce ultra-thin aluminum foil, the minimum thickness is 0.0004 mm. The main technological process is under the condition of vacuum, vapor deposition on the plastic film and become aluminium foil. The advantage of this producing method is can produce a ultra-thin aluminum foil, this is the …

Production of Aluminium Food Containers. Manufacturing of

What is the aluminium foil manufacturing process? Quora

production procedure, the aluminium foil is then heated in a chamber furnace for up to 100 hours so that the separating agent diffuses out. As an alternative to this annealing process, which requires a great deal of time

Aluminium Aluminium Foil Production

Aluminum foil manufacturing process

the Bayer process for inexpensive production of alumina (Al 2 O 3) from bauxite ore. These breakthroughs allowed the widespread production and use of aluminum and aluminum alloys. Charles Hall, the developer of the Hall-Héroult process, went on to form the Aluminum Company of America (Alcoa). Types of Aluminum Alloys Aluminum alloys are normally classified into one of three …

Aluminium Foil Container Production Big Profit Industry

aluminium foil manufacturing process haomei aluminum strip

Comments are closed.