Automated computer integrated manufacturing systems pdf

Automation, Production Systems, and Computer-Integrated Manufacturing is appropriate for advanced undergraduate/ graduate-level courses in Automation, Production Systems, and Computer-Integrated Manufacturing. The book should also be useful for practicing engineers and managers who wish to learn about automation and production systems technologies in modern manufacturing. Â This …

In a simplistic sense, a computer integrated manufacturing system does one or both of the following tasks: A methodology for understanding the state of a process or equipment, and reporting the related equipment performance, quality delivered and the process parameters for real-time continuous monitoring and analysis. Correcting the current state of the equipment/process to rectify any

Application of intelligent manufacturing systems and computer integrated manufacturing (CIM) has become the necessity to overcome the above issues while retaining the employment level and revenue of a country in today’s highly competitive global market. With the developments taking place in CIM and its related technologies, the application of CIM in manufacturing enterprises has become a

2. Computer Integrated Manufacturing (CIM) system has several key components: an automated storage and retrieval system (ASRS), at least one automated workstation such

unit iv flexible manufacturing system (fms) and automated guided vehicle system (agvs) me6703 computer integrated manufacturing systems syllabus Types of Flexibility – FMS – FMS Components – FMS Application & Benefits – FMS Planning and Control– Quantitative analysis in FMS – …

This unit of competency covers the evaluation of computer integrated manufacturing (CIM) systems. It includes hardware, controllers, networks and data handling for business, planning and control, manufacturing operations, automation safety, work health and safety (WHS) and risk management compliance, software and system integration.

Automation, Production Systems, and Computer-Integrated Manufacturing is appropriate for advanced undergraduate/ graduate-level courses in Automation, Production Systems, and Computer-Integrated

Answer: As defined in the text, computer-integrated manufacturing (CIM) denotes the pervasive use of computer systems to design the products, plan the production, control the operations, and perform the various information-processing functions needed in a

Vision-based Automated Inspection System in Computer Integrated Manufacturing F. L. Chen and C. T. Su Department of Industrial Engineering, National Tsing Hua University, Hsinchu, Taiwan, Republic of China The industrial application of an automated inspection system that aims to enhance the efficiency and flexibility of a computer integrated manufacturing system (CIMS) is proposed in this

Automation, Production Systems, and Computer-Integrated Manufacturing has 517 ratings and 40 reviews. This book provides the most advanced, comprehensive…

Therefore, CAPP system is a critical element in total system integration of automated design and manufacturing environment. This paper provides an overview of CAPP system and its approaches. Also, it presents the techniques that are used to integrate CAPP systems with other computer-based systems. Finally, some of the well-known CAPP systems will be discussed.

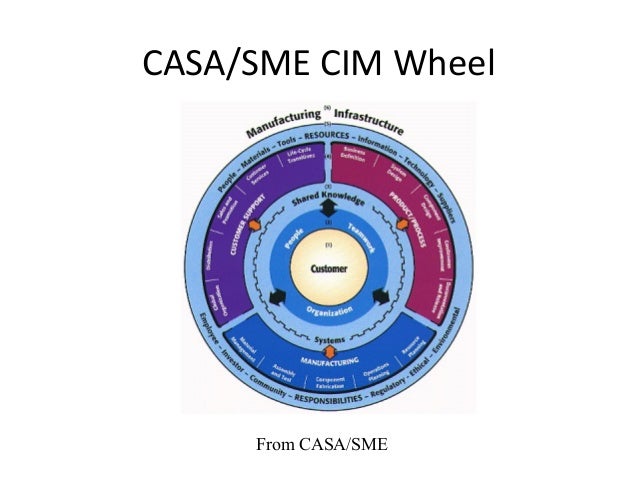

The idea of “Digital Manufacturing” was prominent the 1980s, when Computer Integrated Manufacturing was developed and promoted by machine tool manufacturers and the Computer and Automated Systems Association and Society of Manufacturing Engineers (CASA/SME). “CIM is the integration of total manufacturing enterprise by using integrated systems and data communication …

Computer Integrated Manufacturing is a course that applies principles of rapid prototyping, robotics, and automation. This course bui lds upon the computer solid modeling skills developed in …

flexible manufacturing systems (FMS), and automated materials handling (AMH); and computer-aided techniques for management— e.g., management information systems (MIS) and computer-aided planning (CAP). When systems for design, manufacturing, and man-agement are used together in a coordinated system, the result is computer-integrated manufacturing (CIM). The context for this …

suitable for automated manufacturing system designers and maintenance personnel, and those pursuing engineering or related qualifications and careers. Prior experience in the application of computing technology, mathematics, scientific principles and techniques, electrical principles and techniques, programming of computers and controllers, methods, processes and mechanical …

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR COMPUTER-INTEGRATED MANUFACTURING ENVIRONMENTS . R.C. Dixon. 1 *, G.Bright. 2 & R. Harley. 3. 1.2 . …

COMPUTER TECHNIQUES AND APPLICATIONS OF AUTOMATED

training.gov.au MEM23122A – Evaluate computer integrated

Flexible manufacturing system consist of an integrated system of computerized numerically controlled (CNC) machine tool , automated material handling system operating under the controlled computer , workstation, storage etc. This paper highlights the merits, demerits, application of FMS and also overviewed of other aspect of FMS. Keyword:- Computer Numerical Control, FMS Layout, Flexibility

Computer-Integrated Manufacturing (CIM) is the manufacturing approach of using computers to control the entire production process. This integration allows individual processes to exchange information with each other and initiate actions. Through the integration of computers, manufacturing can be faster and less error-prone, although the main advantage is the ability to create automated

Automation, Production Systems, and Computer-Integrated Manufacturing, Third Edition, by Mikell P. Groover. 7/29 Computer-Aided Design (CAD)

Computer-integrated manufacturing Since about 1970 there has been a growing trend in manufacturing firms toward the use of computers to perform many of the functions related to design and production. The technology associated with this trend is called CAD/CAM, for computer-aided design and computer-aided manufacturing.

6 Origin The term ” CIM ” is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing,

automation-production-systems-and-computer-integrated-manufacturing-4th-edition.pdf – Automation, Production Systems, And Computer-Integrated Manufacturing (4th Edition) By Mikell P. Groover If you are searched for the book Automation, …

Overview. Computer-integrated manufacturing is used in automotive, aviation, space, and ship building industries. The term “computer-integrated manufacturing” is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing, and support functions of a manufacturing enterprise

380 Toward the Factory o/the Future H.-J. Bullinger, H. J. Warnecke (eds.) Computer Integrated and Automated Manufacturing Systems in Aircraft Manufacturing

Computer Integrated Manufacturing is the integration of the total manufacturing enterprise through the use of integrated systems and data communications coupled with new managerial philosophies that improve organizational and personnel efficiency.

world in the form of computer-integrated manufacturing systems (CIMS), which integrate the islands of automation in product.-design, cell level production, and plant level pro- …

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS Important Questions ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS Important questions Regulation 2013 Anna University free download. ME6703 Important questions COMPUTER INTEGRATED MANUFACTURING SYSTEMS free pdf download.

Computer-integrated manufacturing (CIM)is an umbrella term for the total integration of product design and engineer- ing, process planning, and manufacturing by means of complex computer systems. Less comprehensive computerized systems for production planning, inventory control, or scheduling are often considered part of CIM. By using these powerful com-puter systems to integrate all phases of

Automation, Production Systems, and Computer-Integrated Manufacturing, Third Edition, by Mikell P. Groover. 13 Parts Delivery at Workstations Typical parts delivery system at a workstation consists of the following hardware components: 1. Hopper – container for parts 2. Parts feeder – removes parts from hopper 3. Selector and/or orientor – to assure part is in proper orientation for assembly

Computer-integrated manufacturing (CIM) is a system consisting of software covering many business processes, including integration of automated assignment and reporting of factory floor operations through machine and material handling equipment sensors and software. CIM covers enterprise resource planning (ERP) modules in a manufacturing operation, including design, purchasing, inventory, shop

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS

– literature review on lean manufacturing pdf

Computer Integrated and Automated Manufacturing

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR

Computer Integrated Manufacturing for Fully Automated

good manufacturing practices for pharmaceuticals sixth edition pdf –

Computer Integrated Manufacturing for Fully Automated

Computer Integrated and Automated Manufacturing

The idea of “Digital Manufacturing” was prominent the 1980s, when Computer Integrated Manufacturing was developed and promoted by machine tool manufacturers and the Computer and Automated Systems Association and Society of Manufacturing Engineers (CASA/SME). “CIM is the integration of total manufacturing enterprise by using integrated systems and data communication …

This unit of competency covers the evaluation of computer integrated manufacturing (CIM) systems. It includes hardware, controllers, networks and data handling for business, planning and control, manufacturing operations, automation safety, work health and safety (WHS) and risk management compliance, software and system integration.

6 Origin The term ” CIM ” is both a method of manufacturing and the name of a computer-automated system in which individual engineering, production, marketing,

2. Computer Integrated Manufacturing (CIM) system has several key components: an automated storage and retrieval system (ASRS), at least one automated workstation such

22 replies on “Automated computer integrated manufacturing systems pdf”

Leave a CommentComputer Integrated Manufacturing is the integration of the total manufacturing enterprise through the use of integrated systems and data communications coupled with new managerial philosophies that improve organizational and personnel efficiency.

Computer Integrated Manufacturing Systems Engineering

Vision-based Automated Inspection System in Computer Integrated Manufacturing F. L. Chen and C. T. Su Department of Industrial Engineering, National Tsing Hua University, Hsinchu, Taiwan, Republic of China The industrial application of an automated inspection system that aims to enhance the efficiency and flexibility of a computer integrated manufacturing system (CIMS) is proposed in this

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR

training.gov.au MEM23122A – Evaluate computer integrated

Computer Integrated Manufacturing for Fully Automated

Computer-integrated manufacturing (CIM)is an umbrella term for the total integration of product design and engineer- ing, process planning, and manufacturing by means of complex computer systems. Less comprehensive computerized systems for production planning, inventory control, or scheduling are often considered part of CIM. By using these powerful com-puter systems to integrate all phases of

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR

380 Toward the Factory o/the Future H.-J. Bullinger, H. J. Warnecke (eds.) Computer Integrated and Automated Manufacturing Systems in Aircraft Manufacturing

Computer Integrated Manufacturing. Automation

Computer Integrated Manufacturing is a course that applies principles of rapid prototyping, robotics, and automation. This course bui lds upon the computer solid modeling skills developed in …

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR

In a simplistic sense, a computer integrated manufacturing system does one or both of the following tasks: A methodology for understanding the state of a process or equipment, and reporting the related equipment performance, quality delivered and the process parameters for real-time continuous monitoring and analysis. Correcting the current state of the equipment/process to rectify any

Computer Integrated Manufacturing. Automation

Vision-based automated inspection system in computer

The idea of “Digital Manufacturing” was prominent the 1980s, when Computer Integrated Manufacturing was developed and promoted by machine tool manufacturers and the Computer and Automated Systems Association and Society of Manufacturing Engineers (CASA/SME). “CIM is the integration of total manufacturing enterprise by using integrated systems and data communication …

training.gov.au MEM23122A – Evaluate computer integrated

In a simplistic sense, a computer integrated manufacturing system does one or both of the following tasks: A methodology for understanding the state of a process or equipment, and reporting the related equipment performance, quality delivered and the process parameters for real-time continuous monitoring and analysis. Correcting the current state of the equipment/process to rectify any

Computer Integrated Manufacturing. Automation

COMPUTER TECHNIQUES AND APPLICATIONS OF AUTOMATED

training.gov.au MEM23122A – Evaluate computer integrated

2. Computer Integrated Manufacturing (CIM) system has several key components: an automated storage and retrieval system (ASRS), at least one automated workstation such

COMPUTER TECHNIQUES AND APPLICATIONS OF AUTOMATED

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS

In a simplistic sense, a computer integrated manufacturing system does one or both of the following tasks: A methodology for understanding the state of a process or equipment, and reporting the related equipment performance, quality delivered and the process parameters for real-time continuous monitoring and analysis. Correcting the current state of the equipment/process to rectify any

training.gov.au MEM23122A – Evaluate computer integrated

Computer Integrated Manufacturing for Fully Automated

Automation, Production Systems, and Computer-Integrated Manufacturing is appropriate for advanced undergraduate/ graduate-level courses in Automation, Production Systems, and Computer-Integrated Manufacturing. The book should also be useful for practicing engineers and managers who wish to learn about automation and production systems technologies in modern manufacturing. Â This …

COMPUTER TECHNIQUES AND APPLICATIONS OF AUTOMATED

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS

Vision-based automated inspection system in computer

The idea of “Digital Manufacturing” was prominent the 1980s, when Computer Integrated Manufacturing was developed and promoted by machine tool manufacturers and the Computer and Automated Systems Association and Society of Manufacturing Engineers (CASA/SME). “CIM is the integration of total manufacturing enterprise by using integrated systems and data communication …

Computer Integrated Manufacturing for Fully Automated

INTRODUCTION revotechnologies.net

380 Toward the Factory o/the Future H.-J. Bullinger, H. J. Warnecke (eds.) Computer Integrated and Automated Manufacturing Systems in Aircraft Manufacturing

Computer Integrated Manufacturing Systems Engineering

COMPUTER TECHNIQUES AND APPLICATIONS OF AUTOMATED

world in the form of computer-integrated manufacturing systems (CIMS), which integrate the islands of automation in product.-design, cell level production, and plant level pro- …

training.gov.au MEM23122A – Evaluate computer integrated

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS

Answer: As defined in the text, computer-integrated manufacturing (CIM) denotes the pervasive use of computer systems to design the products, plan the production, control the operations, and perform the various information-processing functions needed in a

Computer Integrated Manufacturing. Automation

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS

This unit of competency covers the evaluation of computer integrated manufacturing (CIM) systems. It includes hardware, controllers, networks and data handling for business, planning and control, manufacturing operations, automation safety, work health and safety (WHS) and risk management compliance, software and system integration.

Vision-based automated inspection system in computer

ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS Important Questions ME6703 COMPUTER INTEGRATED MANUFACTURING SYSTEMS Important questions Regulation 2013 Anna University free download. ME6703 Important questions COMPUTER INTEGRATED MANUFACTURING SYSTEMS free pdf download.

Computer Integrated Manufacturing for Fully Automated

training.gov.au MEM23122A – Evaluate computer integrated

Computer Integrated Manufacturing Systems Engineering

flexible manufacturing systems (FMS), and automated materials handling (AMH); and computer-aided techniques for management— e.g., management information systems (MIS) and computer-aided planning (CAP). When systems for design, manufacturing, and man-agement are used together in a coordinated system, the result is computer-integrated manufacturing (CIM). The context for this …

training.gov.au MEM23122A – Evaluate computer integrated

unit iv flexible manufacturing system (fms) and automated guided vehicle system (agvs) me6703 computer integrated manufacturing systems syllabus Types of Flexibility – FMS – FMS Components – FMS Application & Benefits – FMS Planning and Control– Quantitative analysis in FMS – …

Vision-based automated inspection system in computer

Computer Integrated Manufacturing is a course that applies principles of rapid prototyping, robotics, and automation. This course bui lds upon the computer solid modeling skills developed in …

Computer Integrated Manufacturing Systems Engineering

Answer: As defined in the text, computer-integrated manufacturing (CIM) denotes the pervasive use of computer systems to design the products, plan the production, control the operations, and perform the various information-processing functions needed in a

training.gov.au MEM23122A – Evaluate computer integrated

ROBUST LOCALISATION OF AUTOMATED GUIDED VEHICLES FOR

Vision-based automated inspection system in computer

world in the form of computer-integrated manufacturing systems (CIMS), which integrate the islands of automation in product.-design, cell level production, and plant level pro- …

training.gov.au MEM23122A – Evaluate computer integrated

Computer Integrated Manufacturing Systems Engineering

Vision-based automated inspection system in computer

Comments are closed.