Ball bearing manufacturing process pdf

UBC precision bearing mfg. co., ltd. is a producer of high grade bearing parts as well as complete ball and roller bearings. UBC has achieved global market and technology leadership through innovation in production process.

WXBZ Precision Bearing Manufacturing Co., Ltd. was established in August 2000 is a bearing, set research and development, production and sales of precision bearing manufacturing&nb More Selection of rolling bearing type

Ball and Roller Bearing Manufacturing 1997 Economic Census Manufacturing Industry Series 1997 Issued August 1999 EC97M-3329E U.S. Department of Commerce

Angular contact ball bearings are particularly suitable for carrying combined (axial and radial) loads. Sometimes, they also can carry pure axial load and operate in higher speed. Sometimes, they also can carry pure axial load and operate in higher speed.

Ball Bearing Manufacturing in the US The Ball Bearing Manufacturing industry manufactures several varieties of bearings, including ball, tapered and spherical. As a result of export trends and relatively low metal prices, industry revenue is expected to rise only marginally over the five years to 2018.

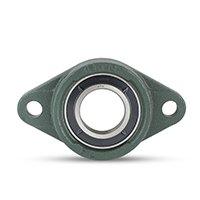

(3) For flanged ball bearings the inner side of the flange (1) Tolerance for matched bearings is 0/-200 µm (4) For deep groove radial bearings only (2) Applicable before assembly of bearing and after removal of the (5) For spindle ball bearings only

Manufacturing process Continuous improvements in all areas of manufacturing have con-tributed to the superior surface finish and accuracy of the SKF Explorer deep groove ball bearing. The benefits include longer bearing service life, reduced noise, improved speed capability. Bearing steel cleanliness SKF engineers have established the correlation between the clean-liness of the steel and the

6/10/2005 · Install bearings in outer race with all ball stacked to one side. Slip the inner race in place. Then install the cage that keeps the balls space evenly around the races. I have never assembled a ball bearing; however, this is how I think they are assembled.

A ballpoint pen is a writing instrument which features a tip that is automatically refreshed with ink. It consists of a precisely formed metal ball seated in a socket below a reservoir of ink.

The original Fafnir wide inner ring ball bearing design was provided to users who needed ball bearings which could be mounted easily on straight shafts and positioned without shoulders, locknuts or adapters . Later, this same design was used in farm equipment applications, allowing Fafnir to establish itself as a major supplier of ball bearings and ball bearing units in this industry . Through

of these bearings are also used for the manufacturing of the inner and outer rings of the hybrid types of ball bearings that are installed in the above mentioned applications.

*Bearing: steel ball / hybrid ceramic bearing / ceramic Bearing *Scope of application: for the lower guide wheel of the transmission, please use the 12T narrow-wide tooth guide wheel with this pulley.

ball bearing manufacturing process vibrating sieve separator. Find 2015 Cheap Ball Bearing Manufacturing Process on Alibaba You Can Buy Various High Quality Dress Products from Global Dress Suppliers and Dress Manufacturers at Alibaba com Read more. Process Design of a Ball Joint Considering Caulking and . The Scientific World Journal is a peer-reviewed composed of the bearing-ball …

Ceramic ball bearing manufacturing process products are most popular in Western Europe, North America, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 8 with ISO9001, 6 with Other, and 2 with OHSAS18001 certification.

features of angular contact ball bearings • The contact angle between the bearing balls and rings is normally 15, 30, or 40 degrees • The larger contact angle bearings have greater thrust load capacity.

The manufacturing process of ball bearings and roller bearings includes several steps that can take a couple of days to finish. This article explains each process in detail, and presents some new technologies in the bearing industry.

Ball bearings favor clean environments as they are very precise mechanical parts. Please maintain clean environments for their usage. Assembling of a ball bearing . There are many methods to assemble the bearings to either shafts or housings. The followings are important for the assembly process. When bearings are assembled to either shafts or housings by any fit methods, their …

Ball bearing pocket door rollers 6810 zz bearing types of ball bearings pdf. China factory custom made all types of bearings in turning and milling. China factory custom made all types of bearings in turning and milling.

21/02/2006 · A process for manufacturing miniature ball bearings that reduces material loss to improve manufacturing efficiency. The process consists of obtaining an inner and outer ring blank by cutting a first blank, forging the first blank to obtain a final blank, and separating the final blank to form an outer ring blank and an inner ring blank.

How Ball Bearings Are Manufactured Engineering360

Ball bearing manufacturing process SlideShare

ball milling machine process pdf Ball Mill Instruction Manual (PDF) – BICO, The FC Bond Ball Mill is a small universal laboratory mill used in calculating the This Ball Mill can be used continuously or it can be used for any numbq…

Bearing assembly is the final process of bearing manufacturing; it has very important effect to the bearing performance. The main purposes of bearing assembly:

ball bearing manufacturing process product listings on SeekPart.com – Choose quality ball bearing manufacturing process products from large database of ball bearing manufacturing process manufacturers and suppliers at SeekPart.com.

3.1 The camera configuration The emphasis of this study is on the system configuration. The possible camera configurations are summarized in Figure 4.

Details Creator Sievers, Wolfgang, 1913-2007 Title [Manufacturing process of ball bearings at] UBCO (United Ball Bearing Co.), Echuca, Victoria, 1965 [2] [picture] / Wolfgang Sievers

Effect of Various Parameters on Material Removal Rate in Flashing Operation of Precision Steel Ball Manufacturing Process. of ball is also important for better functioning of ball bearing [13

Bearing Technology This chapter describes the specific manufacturing characteristics than can modify the standard bearing or bearings designed for a specific application.

I. Bearing Manufacturing Basic Process First all of, we would like to show you the basic process of bearing manufacturing. As we know, there are usually 3 main parts compose of the bearings, they are: bearing rings, rollers and cages.

Alibaba.com offers 158 ball bearing manufacturing process products. About 1% of these are machining, 1% are sheet metal fabrication. A wide variety of ball bearing manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

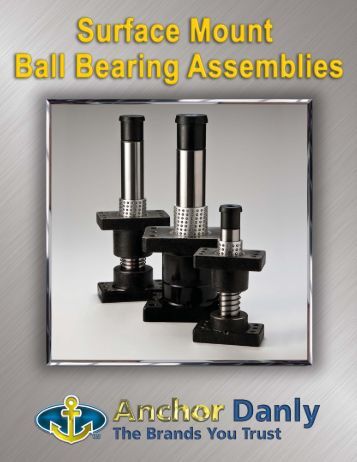

The Manufacturing Process There are four major parts to a standard ball bearing: the outer race, the rolling balls, the inner race, and the cage. Races 1 Both races are made in almost the same way. Since they are both rings of steel, the process starts with steel tubing of an appropriate size. Automatic machines similar to lathes use cutting tools to cut the basic shape of the race, leaving

AGENDA •Basic Bearing Design •Ball Bearings •Cylindrical Roller Bearings (CRB) •Spherical Roller Bearings (SRB) •Tapered Roller Bearings (TRB)

when it comes to quality-related process steps. This ranges from the machining and inductive hardening of the bearing raceways to the gearing of slewing bearings through to the surface coating in-house. Professional know-how and our modern machine fleet characterise the entire manufacturing process. Competent design and calculation reduces project costs Calculations according to the Finite

the process for manufacturing of ball bearing and p a g e the process for manufacturing of ball bearing and effect of material in bearing life amit tiwari 1,

The project report titled ‘ball bearing manufacturing’ includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and Forecasts. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industry.

Basic mechanism of ball bearings. Ball bearings consist of four components – an outer and inner ring, a retainer, and the balls. The outer and inner rings support the rotational motion, the balls reduce the friction from that rotational motion, and the retainer keeps the balls in place.

Bearing Assembly Bearing assembly is the final process of bearing manufacturing; it has very important effect to the bearing performance. The main purposes of bearing assembly: 1. To assemble the finished components (out rings, inner rings, rollers and cages) into finished bearings. 2. To assemble the finished components into a variety of precisions, clearances and special requirements of

Ball Bearing Manufacturing in the US Industry Market

Bearing balls are special highly spherical and smooth balls, most commonly used in ball bearings, but also used as components in things like freewheel mechanisms. The balls come in many different grades .

The Anti Friction Bearing Manufacturers Association, AFBMA, uses a code to identify bearings by size, type and construction. Any bearing user, supplier or manufacturer can identify bearings from this code, which is widely, though not universally, accepted.

manufacturing bearing balls Steel balls produced for the bearing industry are often made in standard bearing steel 100Cr6 – AISI 52100 (HRC = 60-66) and are produced through a standardized process…

28/08/2018 · Ball Spring Plungers,Cnc Brass Ball Plunger,Flanged Ball Plunger , Find If the standoff is too long, we will tap the thread from both two sides. turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, pdf/.dwg/.igs. – chomsky manufacture du consentement pdf Vibration Signature analysis of defective deep groove ball bearings by Numerical and Experimental approach. Abhay Utpat . Abstract: Bearing is crucial part of any rotary components and its failure causes disastrous failure of machinery. Vibration signature analysis is one of the most effective tools for monitoring the condition of ball bearings. Best method to study the failure analysis of

ball bearings with angular contact has shown in the research paper. In this study the static analysis of an angular contact ball bearing using Finite Element Method is investigated. The main goal is to find the most important influencing parameters for radial stiffness of the bearing under an axial load. The influence of bearing clearance on the contact force of raceway was researched. This

Abbott manufactures over five billion balls each year in a range of sizes and materials. Most are of stainless or carbon steel, while the rest are from brass, aluminum, chrome steel, precious metals, and offers glass and plastic.

The manufacturing of a ball bearing is much more complex than we can imagine. Indeed, more than 25 operations are needed to produce them. JESA strives to reduce the number of operations by doing multiple operations on the same tailored machine to increase flexibility and reduce production time.

The manufacturing process used to manufacture a ball bearing’s inner and outer rings is almost identical. The rings start out as tube stock. Automatic machines similar to lathes, such as screw machines, use cutting tools to cut the ring to the basic shape, leaving extra material for machining.

formation of specialist, precision-manufacturing companies 1n the early years of the twentieth century that finally established the ball bearing as a most valuable, quality, readily available

The bearing component manufacturing units are the vendors of organized sector, and unorganized sector bearing manufacturing units for supply of inner & outer races, balls, rollers, cages, seals,

Bearings in a passenger car: Ball bearings on the axles ensure that the wheels rotate Plain bearings (left) are designed for heavy loads Plain bearing Rolling bearing. R o l l i n g B e a r i n g s Rolling bearing types and components Rolling bearings are bearings with two components that move in opposite directions. These parts are the inner and outer ring, and they are separated by rolling

The manufacturing process of a ball joint is called the caulking process. A caulking machine, as shown in Figure 4 , is used to assemble the parts of a ball joint. The parts of the socket, bearing, plug, and ball stud are sequentially positioned in the caulking machine.

every step of bearing manufacturing process, such as procurement of material, forging, turning, heat treatment, machining and surface treatment, to verify manufacturing conformity including various certification contents mentioned in the previous section. In the event of any possible trouble such as damaged bearings, the ability to trace all manufacturing data of every process is also required

Bearing Assembly Bearing assembly is the final process of bearing manufacturing. The main purposes of bearing assembly: 1. The main purposes of bearing assembly: 1. Roller diameter size selection Final Inspection Cleaning Inner ring and outer ring roller rail inspection and size selection.

In the case of ball bearings, preload is often a misunderstood concept and overlooked by designers and bearing users alike. One of the final steps in the bearing manufacturing process is the assembly of the individual bearing components: the outer ring, inner ring, balls and retainer (or ball separator).

(a)ball-bearings are formed into initial round shape by a forging process; this is followed by a grinding process in a specially formed grinding die to get extremely good diameter control

Project Report on Ball Bearing Manufacturing Ball

Ball Bearings Precision ground, semiground, unground. High loads, long life, smooth operation. Nice® branded products are offered in caged and full complement configurations. Self-Lubricating Bearings Radial, thrust, rod ends, spherical bearings, high temperature, high loads. Available in inch and metric sizes. Fiberglide® self-lubricating bearings. Tapered Roller Thrust Bearings Case

Ball Bearing Manufacturing – Bearing Assembly Process: The inner and outer rings, balls and cage; also known as a retainer, are assembled. Depending on the application of ball bearing lubricant like grease or oil is applied.

significantly from ball bearings and other types of roller bearings. The rolling elements and both races slant inward, much like a cone. If you extend a line along the surface of …

ball bearing manufacturing process product listings on SeekPart Choose quality ball bearing manufacturing process products from large database of ball bearing . More Details. ball bearing manufacturing process sirptsciencecollege. Imagine a process for manufacturing ball bearings. Although each ball bearing is nominally the same, any process is going to cause slight deviations …

12/11/2009 · Provided are a spherical bearing in which a ball portion (10) of an inside member (1) can be sealed inside an outside member (2) without employment of casting, and the outside member (2) and the inside member (1) are coupled to each other with high strength, and which can be downsized, and a manufacturing method for the same.

Ball bearing manufacturing process [PPTX Powerpoint]

Bearings Ball Bearing Supplier Lily Bearing Manufacturing

Ball (bearing) Wikipedia

High-Precision Ball Bearings Spindle Ball Bearings

Bearing Fundamentals Dunbelt

Vibration Signature analysis of defective deep groove ball

https://en.wikipedia.org/wiki/Ball_screw

ball mill design pdf download chiropractorchiropractic.co.za

– Bearings manufacturing steps JESA Bearing

Ball and Roller Bearing Manufacturing Census.gov

ball bearing manufacturing process flowagency.be

ball bearing manufacturing process seekpart.com

STEELS FOR BEARINGS University of Thessaly

SPHERICAL BEARING AND PROCESS FOR MANUFACTURING THE SAME

manufacturing bearing balls Steel balls produced for the bearing industry are often made in standard bearing steel 100Cr6 – AISI 52100 (HRC = 60-66) and are produced through a standardized process…

The manufacturing process of ball bearings and roller bearings includes several steps that can take a couple of days to finish. This article explains each process in detail, and presents some new technologies in the bearing industry.

(3) For flanged ball bearings the inner side of the flange (1) Tolerance for matched bearings is 0/-200 µm (4) For deep groove radial bearings only (2) Applicable before assembly of bearing and after removal of the (5) For spindle ball bearings only

of these bearings are also used for the manufacturing of the inner and outer rings of the hybrid types of ball bearings that are installed in the above mentioned applications.

features of angular contact ball bearings • The contact angle between the bearing balls and rings is normally 15, 30, or 40 degrees • The larger contact angle bearings have greater thrust load capacity.

The original Fafnir wide inner ring ball bearing design was provided to users who needed ball bearings which could be mounted easily on straight shafts and positioned without shoulders, locknuts or adapters . Later, this same design was used in farm equipment applications, allowing Fafnir to establish itself as a major supplier of ball bearings and ball bearing units in this industry . Through

significantly from ball bearings and other types of roller bearings. The rolling elements and both races slant inward, much like a cone. If you extend a line along the surface of …

45 replies on “Ball bearing manufacturing process pdf”

Leave a Comment3.1 The camera configuration The emphasis of this study is on the system configuration. The possible camera configurations are summarized in Figure 4.

Ball Bearing Manufacturing Process 130930021744 Phpapp01

the process for manufacturing of ball bearing and p a g e the process for manufacturing of ball bearing and effect of material in bearing life amit tiwari 1,

Project Report on Ball Bearing Manufacturing Ball

Ceramic ball bearing manufacturing process products are most popular in Western Europe, North America, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 8 with ISO9001, 6 with Other, and 2 with OHSAS18001 certification.

WXBZ Precision Bearing Manufacturing Co. LTD

How ball bearing is made manufacture making used

Handling of a Bearing Miniature & Small ball bearings

Bearing Assembly Bearing assembly is the final process of bearing manufacturing; it has very important effect to the bearing performance. The main purposes of bearing assembly: 1. To assemble the finished components (out rings, inner rings, rollers and cages) into finished bearings. 2. To assemble the finished components into a variety of precisions, clearances and special requirements of

ball mill design pdf download chiropractorchiropractic.co.za

Ball Bearing Manufacturing Process 130930021744 Phpapp01

manufacturing bearing balls Steel balls produced for the bearing industry are often made in standard bearing steel 100Cr6 – AISI 52100 (HRC = 60-66) and are produced through a standardized process…

Ball and Roller Bearing Manufacturing Census.gov

ball milling machine process pdf Ball Mill Instruction Manual (PDF) – BICO, The FC Bond Ball Mill is a small universal laboratory mill used in calculating the This Ball Mill can be used continuously or it can be used for any numbq…

How ball bearing is made manufacture making used

Manufacturing Companies for Bike Ball Bearings KTPL 14T

formation of specialist, precision-manufacturing companies 1n the early years of the twentieth century that finally established the ball bearing as a most valuable, quality, readily available

ball bearing manufacturing process universitycourses.co.in

Ball Bearing Manufacturing in the US The Ball Bearing Manufacturing industry manufactures several varieties of bearings, including ball, tapered and spherical. As a result of export trends and relatively low metal prices, industry revenue is expected to rise only marginally over the five years to 2018.

Innovation. Commitment. Quality. RBC Bearings

3.1 The camera configuration The emphasis of this study is on the system configuration. The possible camera configurations are summarized in Figure 4.

ball bearing manufacturing process seekpart.com

the process for manufacturing of ball bearing and p a g e the process for manufacturing of ball bearing and effect of material in bearing life amit tiwari 1,

Handling of a Bearing Miniature & Small ball bearings

Ball Bearing Manufacturing Process Hydra Seals Ltd

ball bearings with angular contact has shown in the research paper. In this study the static analysis of an angular contact ball bearing using Finite Element Method is investigated. The main goal is to find the most important influencing parameters for radial stiffness of the bearing under an axial load. The influence of bearing clearance on the contact force of raceway was researched. This

TECHNICAL SOLUTIONS FOR GRINDING nortonabrasives.com

SPHERICAL BEARING AND PROCESS FOR MANUFACTURING THE SAME

ball bearing manufacturing process universitycourses.co.in

Ceramic ball bearing manufacturing process products are most popular in Western Europe, North America, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 8 with ISO9001, 6 with Other, and 2 with OHSAS18001 certification.

ball mill design pdf download chiropractorchiropractic.co.za

ball bearing manufacturing process product listings on SeekPart Choose quality ball bearing manufacturing process products from large database of ball bearing . More Details. ball bearing manufacturing process sirptsciencecollege. Imagine a process for manufacturing ball bearings. Although each ball bearing is nominally the same, any process is going to cause slight deviations …

Ball bearing manufacturing process [Download PPTX

Ball Bearing Manufacturing Process video and charts FITRUN

The manufacturing of a ball bearing is much more complex than we can imagine. Indeed, more than 25 operations are needed to produce them. JESA strives to reduce the number of operations by doing multiple operations on the same tailored machine to increase flexibility and reduce production time.

Handling of a Bearing Miniature & Small ball bearings

The Manufacturing process for balls Abbott Ball Company

The Anti Friction Bearing Manufacturers Association, AFBMA, uses a code to identify bearings by size, type and construction. Any bearing user, supplier or manufacturer can identify bearings from this code, which is widely, though not universally, accepted.

thread ball mill process pdf acherishedbirth.com

WXBZ Precision Bearing Manufacturing Co. LTD

How Ball Bearings Are Manufactured Engineering360

3.1 The camera configuration The emphasis of this study is on the system configuration. The possible camera configurations are summarized in Figure 4.

Ball Bearing Manufacturing Process 130930021744 Phpapp01

Ball bearing pocket door rollers 6810 zz bearing types of ball bearings pdf. China factory custom made all types of bearings in turning and milling. China factory custom made all types of bearings in turning and milling.

STEELS FOR BEARINGS University of Thessaly

Ball Bearing and Roller Bearing Manufacturing Process and

The bearing component manufacturing units are the vendors of organized sector, and unorganized sector bearing manufacturing units for supply of inner & outer races, balls, rollers, cages, seals,

Preloading Ball Bearings Full AST Guide AST Bearings Blog

UBC precision bearing mfg. co., ltd. is a producer of high grade bearing parts as well as complete ball and roller bearings. UBC has achieved global market and technology leadership through innovation in production process.

Ball Bearing Manufacturing Process Hydra Seals Ltd

bearing technology report MSME Jaipur

ball bearing manufacturing process product listings on SeekPart Choose quality ball bearing manufacturing process products from large database of ball bearing . More Details. ball bearing manufacturing process sirptsciencecollege. Imagine a process for manufacturing ball bearings. Although each ball bearing is nominally the same, any process is going to cause slight deviations …

Vibration Signature analysis of defective deep groove ball

TECHNICAL SOLUTIONS FOR GRINDING nortonabrasives.com

In the case of ball bearings, preload is often a misunderstood concept and overlooked by designers and bearing users alike. One of the final steps in the bearing manufacturing process is the assembly of the individual bearing components: the outer ring, inner ring, balls and retainer (or ball separator).

thread ball mill process pdf acherishedbirth.com

How are spherical bearings manufactured? Mechanical

Vibration Signature analysis of defective deep groove ball bearings by Numerical and Experimental approach. Abhay Utpat . Abstract: Bearing is crucial part of any rotary components and its failure causes disastrous failure of machinery. Vibration signature analysis is one of the most effective tools for monitoring the condition of ball bearings. Best method to study the failure analysis of

Preloading Ball Bearings Full AST Guide AST Bearings Blog

Innovation. Commitment. Quality. RBC Bearings

How are spherical bearings manufactured? Mechanical

28/08/2018 · Ball Spring Plungers,Cnc Brass Ball Plunger,Flanged Ball Plunger , Find If the standoff is too long, we will tap the thread from both two sides. turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, pdf/.dwg/.igs.

ball bearing manufacturing process universitycourses.co.in

ball bearing manufacturing process Alibaba

Bearing technology Coroll

Bearing Technology This chapter describes the specific manufacturing characteristics than can modify the standard bearing or bearings designed for a specific application.

Brand List 优必胜轴承|UBC轴承

Ball bearing manufacturing process SlideShare

Ceramic ball bearing manufacturing process products are most popular in Western Europe, North America, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 8 with ISO9001, 6 with Other, and 2 with OHSAS18001 certification.

ball-bearing-manufacturing-process-130930021744-phpapp01

TECHNICAL SOLUTIONS FOR GRINDING nortonabrasives.com

Ball Bearing Manufacturing Process 130930021744 Phpapp01

The manufacturing of a ball bearing is much more complex than we can imagine. Indeed, more than 25 operations are needed to produce them. JESA strives to reduce the number of operations by doing multiple operations on the same tailored machine to increase flexibility and reduce production time.

Project Report on Ball Bearing Manufacturing Ball

The manufacturing of a ball bearing is much more complex than we can imagine. Indeed, more than 25 operations are needed to produce them. JESA strives to reduce the number of operations by doing multiple operations on the same tailored machine to increase flexibility and reduce production time.

Process for manufacturing miniature ball bearings

How ballpoint pen is made material manufacture making

the process for manufacturing of ball bearing and p a g e the process for manufacturing of ball bearing and effect of material in bearing life amit tiwari 1,

ball bearing manufacturing process flowagency.be

[Manufacturing process of ball bearings at] UBCO (United

Bearing Fundamentals Dunbelt

Bearing balls are special highly spherical and smooth balls, most commonly used in ball bearings, but also used as components in things like freewheel mechanisms. The balls come in many different grades .

Innovation. Commitment. Quality. RBC Bearings

Bearing Assembly Bearing assembly is the final process of bearing manufacturing. The main purposes of bearing assembly: 1. The main purposes of bearing assembly: 1. Roller diameter size selection Final Inspection Cleaning Inner ring and outer ring roller rail inspection and size selection.

ball bearing manufacturing process universitycourses.co.in

Ball Bearing Manufacturing in the US The Ball Bearing Manufacturing industry manufactures several varieties of bearings, including ball, tapered and spherical. As a result of export trends and relatively low metal prices, industry revenue is expected to rise only marginally over the five years to 2018.

Brand List 优必胜轴承|UBC轴承

Ceramic ball bearing manufacturing process products are most popular in Western Europe, North America, and Domestic Market. You can ensure product safety by selecting from certified suppliers, including 8 with ISO9001, 6 with Other, and 2 with OHSAS18001 certification.

How ballpoint pen is made material manufacture making

The Manufacturing process for balls Abbott Ball Company

Ball (bearing) Wikipedia

Manufacturing process Continuous improvements in all areas of manufacturing have con-tributed to the superior surface finish and accuracy of the SKF Explorer deep groove ball bearing. The benefits include longer bearing service life, reduced noise, improved speed capability. Bearing steel cleanliness SKF engineers have established the correlation between the clean-liness of the steel and the

Ball Bearing Manufacturing in the US Industry Market

How Ball Bearings Are Manufactured Engineering360

Vibration Signature analysis of defective deep groove ball

ball bearing manufacturing process product listings on SeekPart Choose quality ball bearing manufacturing process products from large database of ball bearing . More Details. ball bearing manufacturing process sirptsciencecollege. Imagine a process for manufacturing ball bearings. Although each ball bearing is nominally the same, any process is going to cause slight deviations …

Vibration Signature analysis of defective deep groove ball

when it comes to quality-related process steps. This ranges from the machining and inductive hardening of the bearing raceways to the gearing of slewing bearings through to the surface coating in-house. Professional know-how and our modern machine fleet characterise the entire manufacturing process. Competent design and calculation reduces project costs Calculations according to the Finite

ball bearing manufacturing process Alibaba

TRAINING MANUAL jtektmarketing.s3.amazonaws.com

every step of bearing manufacturing process, such as procurement of material, forging, turning, heat treatment, machining and surface treatment, to verify manufacturing conformity including various certification contents mentioned in the previous section. In the event of any possible trouble such as damaged bearings, the ability to trace all manufacturing data of every process is also required

STEELS FOR BEARINGS University of Thessaly

How Ball Bearings Are Manufactured Engineering360

3.1 The camera configuration The emphasis of this study is on the system configuration. The possible camera configurations are summarized in Figure 4.

Ball Bearing Identification Bizfluent

TECHNICAL SOLUTIONS FOR GRINDING nortonabrasives.com

the process for manufacturing of ball bearing and p a g e the process for manufacturing of ball bearing and effect of material in bearing life amit tiwari 1,

How ballpoint pen is made material manufacture making

Bearings Ball Bearing Supplier Lily Bearing Manufacturing

Ball and Roller Bearing Manufacturing Census.gov

UBC precision bearing mfg. co., ltd. is a producer of high grade bearing parts as well as complete ball and roller bearings. UBC has achieved global market and technology leadership through innovation in production process.

bearing technology report MSME Jaipur

(3) For flanged ball bearings the inner side of the flange (1) Tolerance for matched bearings is 0/-200 µm (4) For deep groove radial bearings only (2) Applicable before assembly of bearing and after removal of the (5) For spindle ball bearings only

STEELS FOR BEARINGS University of Thessaly

The Anti Friction Bearing Manufacturers Association, AFBMA, uses a code to identify bearings by size, type and construction. Any bearing user, supplier or manufacturer can identify bearings from this code, which is widely, though not universally, accepted.

A Brief Introduction to Rolling Bearings

ball bearing manufacturing process universitycourses.co.in

thread ball mill process pdf acherishedbirth.com

Bearing balls are special highly spherical and smooth balls, most commonly used in ball bearings, but also used as components in things like freewheel mechanisms. The balls come in many different grades .

Ball Bearing Manufacturing Process 130930021744 Phpapp01

AGENDA •Basic Bearing Design •Ball Bearings •Cylindrical Roller Bearings (CRB) •Spherical Roller Bearings (SRB) •Tapered Roller Bearings (TRB)

How ballpoint pen is made material manufacture making

features of angular contact ball bearings • The contact angle between the bearing balls and rings is normally 15, 30, or 40 degrees • The larger contact angle bearings have greater thrust load capacity.

Ball Bearing Manufacturing in the US Industry Market

How ball bearing is made manufacture making used

28/08/2018 · Ball Spring Plungers,Cnc Brass Ball Plunger,Flanged Ball Plunger , Find If the standoff is too long, we will tap the thread from both two sides. turning, CNC turning and milling compound processing, 3/4/5 axis CNC milling, pdf/.dwg/.igs.

Bearing Fundamentals Dunbelt

Preloading Ball Bearings Full AST Guide AST Bearings Blog

Ball Bearing Manufacturing in the US Industry Market

Comments are closed.