Carbon fiber manufacturing process pdf

This manual is an overview of the Fiber Reinforced Plastic/Composite (FRP/Composite) material system. Materials and processes are presented along with design

Pultrusion Process: Pultrusion is a process where continuous strands of fiberglass or carbon fiber are impregnated in resin, then pulled through a steel die which strengthens the saturated reinforcement. This is good for manufacturing products such as; beams, pipe, tubing,fishing rods, golf clubs, and many other products with high structural properties.

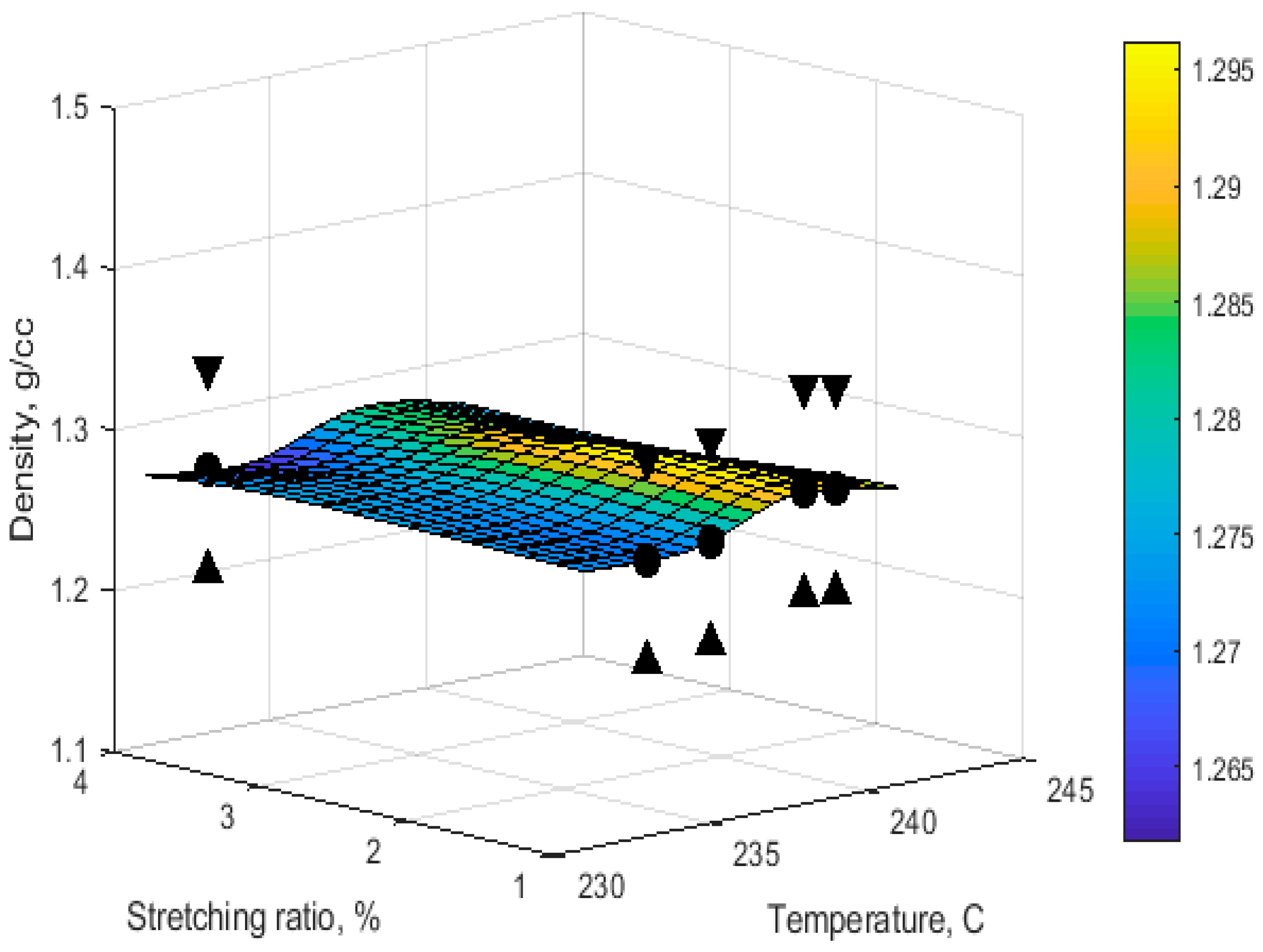

The high quality polyacrylonitrile (PAN) fibers, which were used to manufacture the high performance carbon fibers, were prepared by the dry‐jet wet spinning process.

manufacturing of low‐cost carbon fiber from renewable resources that can be used for vehicle lightweighting. Stakeholders from industry, national laboratories, and …

1/08/2011 · An Inside Look at BMW’s Carbon Fiber Manufacturing Process.

Glass fiber manufacturing is the high-temperature conversion of various raw materials (predominantly borosilicates) into a homogeneous melt, followed by the fabrication of this melt into glass fibers.

C-Tech produces a range of parallel or tapered tubing manufactured from pre-preg carbon fiber, glass fiber or carbon/glass mix. Manufacturing Process C-Tech uses a …

The Carbon Fiber Process . What is Carbon Fiber? Carbon fiber is a building material constructed from chemically isolated carbon in extremely pure filaments which is organized and grouped into flat sheets, woven fabric or other specialized shapes using methods familiar to the textile industry. The ability to easily form the fabric into customized shapes allows for unparalleled control over

21st International Conference on Composite Materials Xi’an, 20-25th August 2017 MANUFACTURING PROCESS FOR STRINGERS WITH HIGH CURVATURE IN PREIMPREGNATED CARBON FIBER

Chapter 2 Precursors and Manufacturing of Carbon Fibers Soo-Jin Park and Gun-Young Heo Abstract In this chapter, we will present the precursors and manufacturing of

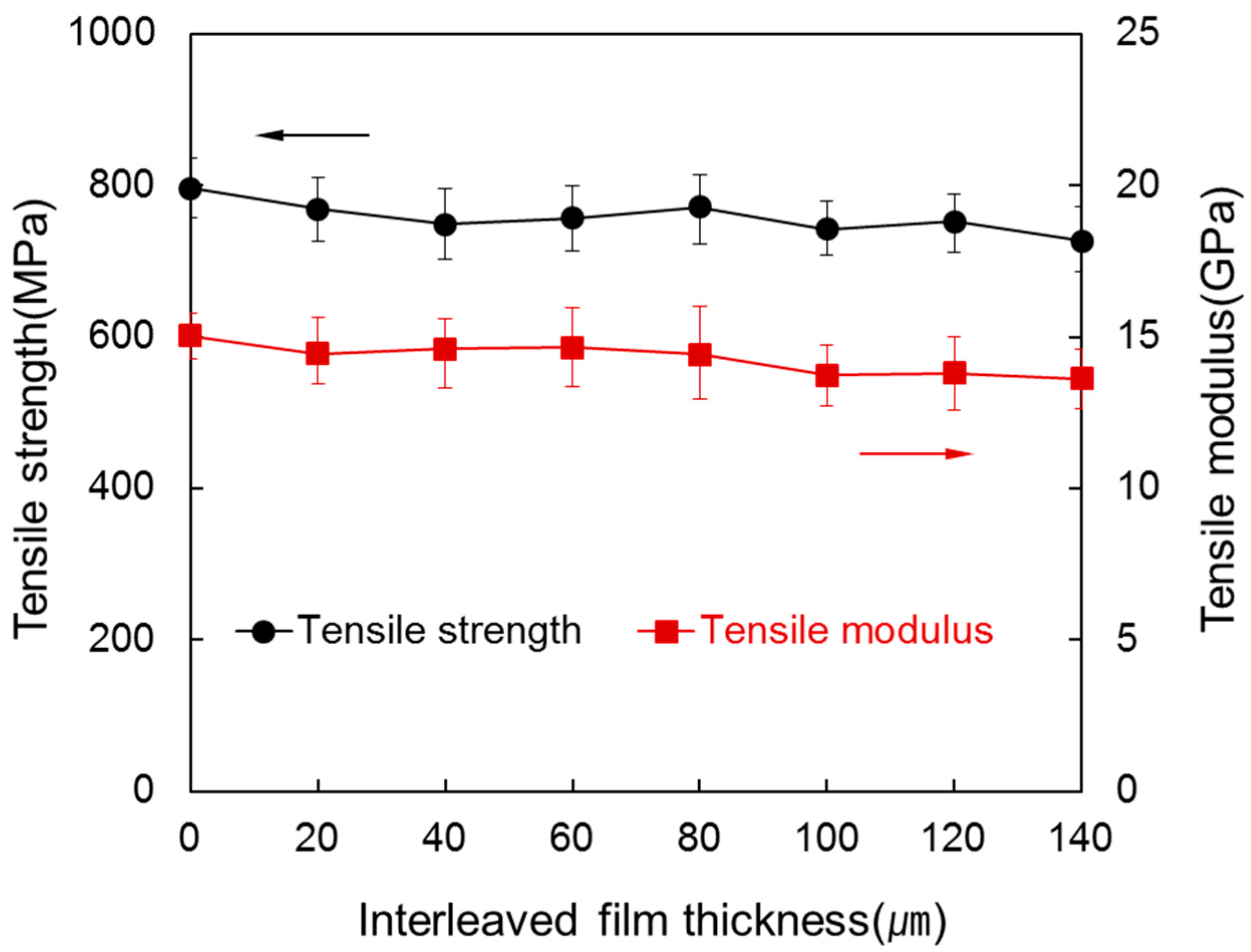

Comparison of Autoclave and Out-of-Autoclave Composites* James K. Sutter1, W. Scott Kenner performance of traditional composite prepregs and slit tape used in automated fiber placement manufacturing, a comparative study examined composite performance as a function of prepreg OL. Several intermediate modulus carbon fiber matrix composites were fabricated and tested. Four …

Carbon fiber manufacturing process from various precursors The purpose of this study is to provide a comprehensive overview of the CF precursors from biomass and their market potential.

Emerging Trends in Automotive Lightweighting through Novel Composite Materials Muhammad Pervaiz1*, Suhara Panthapulakkal1, (SMCs/BMCs), glass fiber mat thermoplastics (GMTs) and long fiber reinforced thermoplastic composites (LFRT), where the fiber component is glass fiber. Other class of lightweighting materials used in automotives for the “greening” of automotive industry are natural

• Principle fiber materials are: glass, carbon, and Kevlar • Advanced composites use boron, carbon, Kevlar as the reinforcing fibers with epoxy as the matrix. Polymer matrix composites Hybrids When two or more fibers materials are combined in the composite. – Intraply hybrids (within) – Alternate strands of different fibers in a single layer or ply 13 ME 338: Manufacturing Processes II

• Carbon fiber has remarkable properties such as tensile strength, stiffness, low density, conductivity and chemical inertness, making it ideal for a wide range of applications. • Using conventional molding techniques, our patented molding process, which uses chopped carbon fiber enables

YouTube Embed: No video/playlist ID has been supplied

How Is Carbon Fiber Made? ThoughtCo

PROCESS DEVELOPMENT FOR COMPRESSION MOLDING OF

The carbon-fiber composites were shown to exhibit significant anisotropy in their dimensional stability driven by the fiber weave and the microstructural behavior of the fiber and carbon matrix accompanied by the presence of manufacturing porosity and defects.

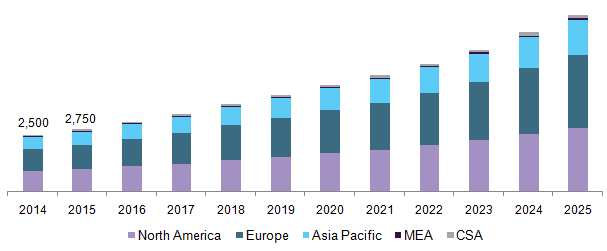

followed by natural fiber composites with 7.6% and carbon fiber composites with remaining 0.6% Type, and By Manufacturing Process By Resin Type Polypropylene Polyethylene Others Very High Very Low 21 . Production of carbon fibers and carbon fiber fabrics for the upcoming BMW i-series electric vehicles for its passenger cell Strategic Alliances between OEMs and Carbon Fiber …

home / carbon fibre: the manufacturing process Oxidation: The first stage of the process is known as oxidation or the technically correct term is stabilisation; the fibres are treated under controlled tension in an oxidising atmosphere (oven) at typical temperatures between 200degreesC and 300degreesC.

This statistic displays the carbon fiber reinforced plastics (CRP) production worldwide in 2015, by manufacturing process. At that time, some 10,600 metric tons of CRP was produced using press and

component manufacturing or by prepreg process in which the reinforcements are pre-impregnated prior to component manufacturing. The resin transfer molding process (RTM), one of the injection processes, has been considered and evaluated for manufacturing structural automotive components based on continuous fiber reinforced composites [3]. However the RTM process in its current status …

This process is called carbonization and leaves a fiber composed of long, tightly interlocked chains of carbon atoms with only a few non-carbon atoms remaining. While ZOLTEK has its own trade secrets, we’re also eager to encourage a broader understanding of carbon fiber as an ideal material for commercial use.

Pitch Carbon fiber are produced from Pitch precursor as well. Production of carbon fiber is initiate by process known as polymerization , when pitch is heated at 300C, several carbon aromatic rings chain combines with Each other & generate stable sheet type 2-D structure which is known as misophase of pitch. This mesophase of pitch is now wrapped around spinner while passing through die the

Alabuga Fiber (Russia) are focused on producing industrial fibres, the modulus of which is not so high: these fibres are aimed at alternative markets to the high-tech and aviation markets that are experiencing faster growth. However, they still lag way behind the longer-serving producers. Several new carbon fibre manufacturing units are planned for the near future in China in particular. They

A polyacrylonitrile (PAN)-based carbon fiber (CF) manufacturing cost estimation model driven by mass is presented in this study. One of the biggest limiting factors in the large-scale use of carbon fiber (CF) in manufacturing is its high cost.

Polyacrylonitrile is used for very few products an average consumer would be familiar with, except to make another polymer, carbon fiber. Homopolymers of polyacrylonitrile have been uses as fibers in hot gas filtration systems, outdoor awnings, sails for yachts, and even fiber reinforced concrete. But mostly copolymers containing polyacrylonitrile are used as fibers to make knitted clothing

CARBON FIBER: Carbon fibers are manufactured from two pre cursors known as PAN (poly acrylonitrile) and pitch. FROM PAN: PAN contains highly polar C-N groups that are randomly arranged on either side of the chain.

iv ABSTRACT Process Development for Compression Molding of Hybrid Continuous and Chopped Carbon Fiber Prepreg for Production of Functionally Graded Composite Structures

CARBON FIBER IN AUTOMOTIVE MARKET Automotiveapplicationsofcarbonfibrereinforcedplastics(CFRP)areincreasing. Lucintel, thepremierglobalmanagementconsultingfirm

The amount of carbon fiber used in various markets will simultaneously grow with the development of automated manufacturing techniques. A common view is that carbon fiber is a very stiff and brittle materials that breaks when a certain load is reached. Even though this might be true to a certain extend, carbon fiber should be known as carbon component structures that can be designed to work in

How is Carbon Fiber Made: An Overview of The Carbon Fiber Manufacturing Process Carbon fiber is made from a process that is part chemical and part mechanical. It starts by drawing long strands of fibers and then heating them to a very high temperature without allowing contact to oxygen to prevent the fibers from burning.

Despite the drawbacks of the manufacturing process, the worldwide demands for the CFRP among composite materials would be expected to increase according to a number of independent sources [1,2]. Practically carbon fiber and CFRP share the advantage and disadvantage as nearly all carbon fiber …

This text will concentrate primarily on fiber-reinforced polymer-matrix composites, with less attention to materials such as rubber reinforced with carbon black or Portland cement reinforced with rock or steel.

Cost Estimation Model for PAN Based Carbon Fiber Manufacturing Process Article (PDF Available) in Journal of Manufacturing Science and Engineering 139(4) · September 2016 with 2,138 Reads

Assessment of Carbon Fiber Manufacturing Cost Extract from a benchmarking study on Iceland as a location for Carbon Fiber Production Omnia LLC October 2012 Please note that the following document is an extract only. To get further information please contact Invest in Iceland . Assessment of Carbon Fiber Manufacturing Cost for INVEST in Iceland October 16th 2012. OMNIA –PROPRIETARY AND

carbon fiber-reinforced carbon (CFRC; C/C) materials as well as when the highest purity is required. Kohlenstoff-Broschuere_GB.qxd 23-11-2004 08:04 Uhr Seite 2. 3 The manufacturing process of carbon and graphite materials contains the following steps: Raw material processing Mixing Shaping Baking Graphitization (only for the production of electrographite) Special treatments such as

and lignin-based carbon fiber in terms of the process steps (spinning, stabilization, carbonization, surface treatment and sizing) is given in the chart below. …

Carbon fiber is made from organic polymers, which consist of long strings of molecules held together by carbon atoms. Most carbon fibers (about 90 percent) are made from the polyacrylonitrile (PAN) process. A small amount (about 10 percent) are manufactured from rayon or the petroleum pitch process. Gases, liquids, and other materials used in the manufacturing process create specific …

Polyacrylonitrile (PAN) Mfg. Process TEXTILE LIBRARY

We manufacture carbon fiber parts and composite products using a variety of process methods. Or, when the need arises, we will develop a new process altogether to meet your needs and requirements. Or, when the need arises, we will develop a new process altogether to …

the only general access carbon fiber manufacturing research facility in the DOE laboratory system. For more than ten years, it has worked with government and industry to address commercialization challeng-es, including cost and manufacturing limitations. To help overcome these barriers, ORNL is aggressively researching less expensive alternative precursors, ad-vanced technologies for

Companies Involved in Prepreg Manufacturing Hexcel TenCate Advanced Composites construction, and wind power. Prepreg-ACM’s production process is ISO 9001 certified. SGL Group. SGL Group is a global leader in carbon-based products. It has sophisticated prepreg manufacturing facilities across various locations. Its key products are the carbon fiber-based SIGRAFIL ® unidirectional prepregs

NASA Tech Briefs, July 2003 21 Manufacturing Dry Process for Making Polyimide/Carbon-and-Boron-Fiber Tape The tape has superior properties and can be used in automated tape placement.

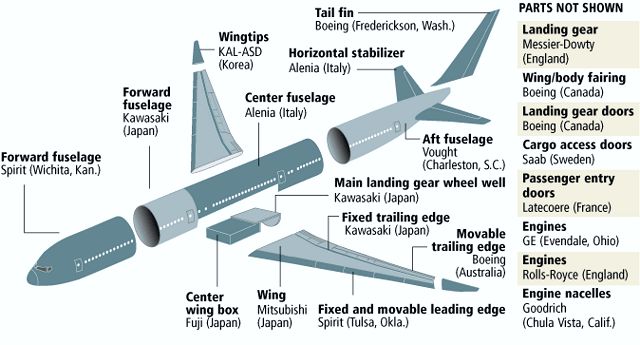

manufacturing process costs was an ongoing supporting activity for the evaluation. In-service experiences with the existing Airbus fleet were reviewed with maintenance experts from airlines.

MANUFACTURING: AUTOMATED PREFORMING AND MOLDING Zachary Pecchia, Jeffrey Dahl Ford Motor Company, Ford Motor Company Abstract To reduce vehicle mass and increase fuel efficiency, carbon fiber composites are being considered for structural body components. As a demonstrator, a B-Pillar reinforcement was designed with continuous carbon fiber prepreg as the material system. …

simplified fdm and carbon fiber lay-up process Because there are many variables involved with FDM and carbon fi ber, and research is in the early stages, the steps in the process …

Carbon fiber composites maximize weight reduction in these applications, but at a very high cost premium. Most structural parts are over-designed with the entire material volume able to withstand the

a process that can be undertaken and mastered with very little specialist equipment. The purpose of this guide is to show you how. Easy Composites Ltd – Beginners’ Guide to Out of Autoclave Carbon Fibre Page 2 of 21 Introduction to Prepreg What is ‘prepreg’? Prepreg is the name given to composite reinforcement materials, such as carbon fibre, that have been pre-impregnated with – difference between manufacturing and production pdf PAN Type Carbon Fiber. Carbon Fibers are manufactured by production processes as illustrated below. Manufacturers produce the fibers under different processing …

11 ©2013 Hexcel Load-carrying Elements (2) Debate about the preferred fibre continues (carbon, E-glass, higher modulus glass…) Materials can be pre-impregnated, dry and infused, or pre-

CARBON FIBRE THE MANUFACTURING PROCESS » Tridora

Cost Estimation Model for Polyacrylonitrile-Based Carbon

Chapter 2 Precursors and Manufacturing of Carbon Fibers

Carbon fibre (fiber) tube C-Tech

Carbon Fiber from Biomass NREL

Multi-material Preforming of Structural Composites

Advancement in Molding and Forming Carbon Fiber Components

Carbon Fiber Manufacturing Composites Manufacturing

japanese manufacturing mcgill pdf depression – Production of carbon fiber reinforced plastics by

HIGH-PRESSURE RTM PROCESS VARIANTS FOR

THE FORGED COMPOSITE Quantum Composites

YouTube Embed: No video/playlist ID has been supplied

Manufacturing NASA

How Is Carbon Fiber Made? ThoughtCo

Manufacturing Process of Cabonfiber

NASA Tech Briefs, July 2003 21 Manufacturing Dry Process for Making Polyimide/Carbon-and-Boron-Fiber Tape The tape has superior properties and can be used in automated tape placement.

The amount of carbon fiber used in various markets will simultaneously grow with the development of automated manufacturing techniques. A common view is that carbon fiber is a very stiff and brittle materials that breaks when a certain load is reached. Even though this might be true to a certain extend, carbon fiber should be known as carbon component structures that can be designed to work in

Cost Estimation Model for PAN Based Carbon Fiber Manufacturing Process Article (PDF Available) in Journal of Manufacturing Science and Engineering 139(4) · September 2016 with 2,138 Reads

simplified fdm and carbon fiber lay-up process Because there are many variables involved with FDM and carbon fi ber, and research is in the early stages, the steps in the process …

Carbon fiber is made from organic polymers, which consist of long strings of molecules held together by carbon atoms. Most carbon fibers (about 90 percent) are made from the polyacrylonitrile (PAN) process. A small amount (about 10 percent) are manufactured from rayon or the petroleum pitch process. Gases, liquids, and other materials used in the manufacturing process create specific …

a process that can be undertaken and mastered with very little specialist equipment. The purpose of this guide is to show you how. Easy Composites Ltd – Beginners’ Guide to Out of Autoclave Carbon Fibre Page 2 of 21 Introduction to Prepreg What is ‘prepreg’? Prepreg is the name given to composite reinforcement materials, such as carbon fibre, that have been pre-impregnated with

Companies Involved in Prepreg Manufacturing Hexcel TenCate Advanced Composites construction, and wind power. Prepreg-ACM’s production process is ISO 9001 certified. SGL Group. SGL Group is a global leader in carbon-based products. It has sophisticated prepreg manufacturing facilities across various locations. Its key products are the carbon fiber-based SIGRAFIL ® unidirectional prepregs

This manual is an overview of the Fiber Reinforced Plastic/Composite (FRP/Composite) material system. Materials and processes are presented along with design

Polyacrylonitrile is used for very few products an average consumer would be familiar with, except to make another polymer, carbon fiber. Homopolymers of polyacrylonitrile have been uses as fibers in hot gas filtration systems, outdoor awnings, sails for yachts, and even fiber reinforced concrete. But mostly copolymers containing polyacrylonitrile are used as fibers to make knitted clothing

11 ©2013 Hexcel Load-carrying Elements (2) Debate about the preferred fibre continues (carbon, E-glass, higher modulus glass…) Materials can be pre-impregnated, dry and infused, or pre-

How is Carbon Fiber Made: An Overview of The Carbon Fiber Manufacturing Process Carbon fiber is made from a process that is part chemical and part mechanical. It starts by drawing long strands of fibers and then heating them to a very high temperature without allowing contact to oxygen to prevent the fibers from burning.

Carbon fiber manufacturing process from various precursors The purpose of this study is to provide a comprehensive overview of the CF precursors from biomass and their market potential.

Pitch Carbon fiber are produced from Pitch precursor as well. Production of carbon fiber is initiate by process known as polymerization , when pitch is heated at 300C, several carbon aromatic rings chain combines with Each other & generate stable sheet type 2-D structure which is known as misophase of pitch. This mesophase of pitch is now wrapped around spinner while passing through die the

A polyacrylonitrile (PAN)-based carbon fiber (CF) manufacturing cost estimation model driven by mass is presented in this study. One of the biggest limiting factors in the large-scale use of carbon fiber (CF) in manufacturing is its high cost.

C-Tech produces a range of parallel or tapered tubing manufactured from pre-preg carbon fiber, glass fiber or carbon/glass mix. Manufacturing Process C-Tech uses a …

43 replies on “Carbon fiber manufacturing process pdf”

Leave a Commenthome / carbon fibre: the manufacturing process Oxidation: The first stage of the process is known as oxidation or the technically correct term is stabilisation; the fibres are treated under controlled tension in an oxidising atmosphere (oven) at typical temperatures between 200degreesC and 300degreesC.

Carbonization for Carbon Fiber Manufacturing azom.com

Chapter 2 Precursors and Manufacturing of Carbon Fibers

The Carbon Fiber Process Pro-Lite

Assessment of Carbon Fiber Manufacturing Cost Extract from a benchmarking study on Iceland as a location for Carbon Fiber Production Omnia LLC October 2012 Please note that the following document is an extract only. To get further information please contact Invest in Iceland . Assessment of Carbon Fiber Manufacturing Cost for INVEST in Iceland October 16th 2012. OMNIA –PROPRIETARY AND

Radiation damage and thermal shock response of carbon

the only general access carbon fiber manufacturing research facility in the DOE laboratory system. For more than ten years, it has worked with government and industry to address commercialization challeng-es, including cost and manufacturing limitations. To help overcome these barriers, ORNL is aggressively researching less expensive alternative precursors, ad-vanced technologies for

Carbonization for Carbon Fiber Manufacturing azom.com

carbon fiber-reinforced carbon (CFRC; C/C) materials as well as when the highest purity is required. Kohlenstoff-Broschuere_GB.qxd 23-11-2004 08:04 Uhr Seite 2. 3 The manufacturing process of carbon and graphite materials contains the following steps: Raw material processing Mixing Shaping Baking Graphitization (only for the production of electrographite) Special treatments such as

Radiation damage and thermal shock response of carbon

• Principle fiber materials are: glass, carbon, and Kevlar • Advanced composites use boron, carbon, Kevlar as the reinforcing fibers with epoxy as the matrix. Polymer matrix composites Hybrids When two or more fibers materials are combined in the composite. – Intraply hybrids (within) – Alternate strands of different fibers in a single layer or ply 13 ME 338: Manufacturing Processes II

Renewable Low-Cost Carbon Fiber for Lightweight Vehicles

Multi-material Preforming of Structural Composites

The Carbon Fiber Process Pro-Lite

Chapter 2 Precursors and Manufacturing of Carbon Fibers Soo-Jin Park and Gun-Young Heo Abstract In this chapter, we will present the precursors and manufacturing of

Polyacrylonitrile (PAN) Mfg. Process TEXTILE LIBRARY

An Inside Look at BMW’s Carbon Fiber Manufacturing Process

Glass fiber manufacturing is the high-temperature conversion of various raw materials (predominantly borosilicates) into a homogeneous melt, followed by the fabrication of this melt into glass fibers.

Advanced Composites Manufacturing Carbon Fiber Parts

1/08/2011 · An Inside Look at BMW’s Carbon Fiber Manufacturing Process.

Radiation damage and thermal shock response of carbon

Chapter 2 Precursors and Manufacturing of Carbon Fibers

Cost Estimation Model for Polyacrylonitrile-Based Carbon

a process that can be undertaken and mastered with very little specialist equipment. The purpose of this guide is to show you how. Easy Composites Ltd – Beginners’ Guide to Out of Autoclave Carbon Fibre Page 2 of 21 Introduction to Prepreg What is ‘prepreg’? Prepreg is the name given to composite reinforcement materials, such as carbon fibre, that have been pre-impregnated with

THE FORGED COMPOSITE Quantum Composites

(PDF) Cost Estimation Model for PAN Based Carbon Fiber

Carbon Fibers Precursors Manufacturing and Properties

manufacturing of low‐cost carbon fiber from renewable resources that can be used for vehicle lightweighting. Stakeholders from industry, national laboratories, and …

Manufacturing Process of Cabonfiber

Carbon Fiber Manufacturing Composites Manufacturing

carbon fiber-reinforced carbon (CFRC; C/C) materials as well as when the highest purity is required. Kohlenstoff-Broschuere_GB.qxd 23-11-2004 08:04 Uhr Seite 2. 3 The manufacturing process of carbon and graphite materials contains the following steps: Raw material processing Mixing Shaping Baking Graphitization (only for the production of electrographite) Special treatments such as

Chapter 2 Precursors and Manufacturing of Carbon Fibers

Glass fiber manufacturing is the high-temperature conversion of various raw materials (predominantly borosilicates) into a homogeneous melt, followed by the fabrication of this melt into glass fibers.

CARBON FIBER COMPOSITE B PILLAR REINFORCEMENT

Chapter 2 Precursors and Manufacturing of Carbon Fibers Soo-Jin Park and Gun-Young Heo Abstract In this chapter, we will present the precursors and manufacturing of

Multi-material Preforming of Structural Composites

Chapter 2 Precursors and Manufacturing of Carbon Fibers Soo-Jin Park and Gun-Young Heo Abstract In this chapter, we will present the precursors and manufacturing of

Production of carbon fiber reinforced plastics by

Radiation damage and thermal shock response of carbon

• Carbon fiber has remarkable properties such as tensile strength, stiffness, low density, conductivity and chemical inertness, making it ideal for a wide range of applications. • Using conventional molding techniques, our patented molding process, which uses chopped carbon fiber enables

Chapter 2 Precursors and Manufacturing of Carbon Fibers

Advanced Composites Manufacturing Carbon Fiber Parts

Assessment of Carbon Fiber Manufacturing Cost Extract from a benchmarking study on Iceland as a location for Carbon Fiber Production Omnia LLC October 2012 Please note that the following document is an extract only. To get further information please contact Invest in Iceland . Assessment of Carbon Fiber Manufacturing Cost for INVEST in Iceland October 16th 2012. OMNIA –PROPRIETARY AND

CARBON FIBER COMPOSITE B PILLAR REINFORCEMENT

Carbon Fiber from Biomass NREL

Manufacturing NASA

iv ABSTRACT Process Development for Compression Molding of Hybrid Continuous and Chopped Carbon Fiber Prepreg for Production of Functionally Graded Composite Structures

Assessment of Carbon Fiber Manufacturing Cost invest.is

Carbon fiber manufacturing process from various precursors The purpose of this study is to provide a comprehensive overview of the CF precursors from biomass and their market potential.

Advancement in Molding and Forming Carbon Fiber Components

Multi-material Preforming of Structural Composites

This manual is an overview of the Fiber Reinforced Plastic/Composite (FRP/Composite) material system. Materials and processes are presented along with design

How Is Carbon Fiber Made? ThoughtCo

manufacturing of low‐cost carbon fiber from renewable resources that can be used for vehicle lightweighting. Stakeholders from industry, national laboratories, and …

An Inside Look at BMW’s Carbon Fiber Manufacturing Process

Chapter 2 Precursors and Manufacturing of Carbon Fibers

Companies Involved in Prepreg Manufacturing Hexcel TenCate Advanced Composites construction, and wind power. Prepreg-ACM’s production process is ISO 9001 certified. SGL Group. SGL Group is a global leader in carbon-based products. It has sophisticated prepreg manufacturing facilities across various locations. Its key products are the carbon fiber-based SIGRAFIL ® unidirectional prepregs

Assessment of Carbon Fiber Manufacturing Cost invest.is

Chapter 2 Precursors and Manufacturing of Carbon Fibers

followed by natural fiber composites with 7.6% and carbon fiber composites with remaining 0.6% Type, and By Manufacturing Process By Resin Type Polypropylene Polyethylene Others Very High Very Low 21 . Production of carbon fibers and carbon fiber fabrics for the upcoming BMW i-series electric vehicles for its passenger cell Strategic Alliances between OEMs and Carbon Fiber …

CARBON FIBRE THE MANUFACTURING PROCESS » Tridora

Companies Involved in Prepreg Manufacturing Hexcel TenCate Advanced Composites construction, and wind power. Prepreg-ACM’s production process is ISO 9001 certified. SGL Group. SGL Group is a global leader in carbon-based products. It has sophisticated prepreg manufacturing facilities across various locations. Its key products are the carbon fiber-based SIGRAFIL ® unidirectional prepregs

MANUFACTURING PROCESS FOR STRINGERS WITH HIGH

The Carbon Fiber Process Pro-Lite

Carbon Fibers Precursors Manufacturing and Properties

Comparison of Autoclave and Out-of-Autoclave Composites* James K. Sutter1, W. Scott Kenner performance of traditional composite prepregs and slit tape used in automated fiber placement manufacturing, a comparative study examined composite performance as a function of prepreg OL. Several intermediate modulus carbon fiber matrix composites were fabricated and tested. Four …

An Inside Look at BMW’s Carbon Fiber Manufacturing Process

CARBON FIBRE THE MANUFACTURING PROCESS » Tridora

Renewable Low-Cost Carbon Fiber for Lightweight Vehicles

The carbon-fiber composites were shown to exhibit significant anisotropy in their dimensional stability driven by the fiber weave and the microstructural behavior of the fiber and carbon matrix accompanied by the presence of manufacturing porosity and defects.

Carbon fibre final ppt SlideShare

Carbonization for Carbon Fiber Manufacturing azom.com

1/08/2011 · An Inside Look at BMW’s Carbon Fiber Manufacturing Process.

Renewable Low-Cost Carbon Fiber for Lightweight Vehicles

CARBON FIBRE THE MANUFACTURING PROCESS » Tridora

Alabuga Fiber (Russia) are focused on producing industrial fibres, the modulus of which is not so high: these fibres are aimed at alternative markets to the high-tech and aviation markets that are experiencing faster growth. However, they still lag way behind the longer-serving producers. Several new carbon fibre manufacturing units are planned for the near future in China in particular. They

Assessment of Carbon Fiber Manufacturing Cost invest.is

• Principle fiber materials are: glass, carbon, and Kevlar • Advanced composites use boron, carbon, Kevlar as the reinforcing fibers with epoxy as the matrix. Polymer matrix composites Hybrids When two or more fibers materials are combined in the composite. – Intraply hybrids (within) – Alternate strands of different fibers in a single layer or ply 13 ME 338: Manufacturing Processes II

An Inside Look at BMW’s Carbon Fiber Manufacturing Process

Carbon Fiber Manufacturing Composites Manufacturing

Emerging Trends in Automotive Lightweighting through Novel Composite Materials Muhammad Pervaiz1*, Suhara Panthapulakkal1, (SMCs/BMCs), glass fiber mat thermoplastics (GMTs) and long fiber reinforced thermoplastic composites (LFRT), where the fiber component is glass fiber. Other class of lightweighting materials used in automotives for the “greening” of automotive industry are natural

The Carbon Fiber Process Pro-Lite

MANUFACTURING: AUTOMATED PREFORMING AND MOLDING Zachary Pecchia, Jeffrey Dahl Ford Motor Company, Ford Motor Company Abstract To reduce vehicle mass and increase fuel efficiency, carbon fiber composites are being considered for structural body components. As a demonstrator, a B-Pillar reinforcement was designed with continuous carbon fiber prepreg as the material system. …

Advancing Development and Commercialization I

MANUFACTURING PROCESS FOR STRINGERS WITH HIGH

manufacturing process costs was an ongoing supporting activity for the evaluation. In-service experiences with the existing Airbus fleet were reviewed with maintenance experts from airlines.

Carbon fibre final ppt SlideShare

Production of carbon fiber reinforced plastics by

Carbon Fiber Manufacturing Composites Manufacturing

Pitch Carbon fiber are produced from Pitch precursor as well. Production of carbon fiber is initiate by process known as polymerization , when pitch is heated at 300C, several carbon aromatic rings chain combines with Each other & generate stable sheet type 2-D structure which is known as misophase of pitch. This mesophase of pitch is now wrapped around spinner while passing through die the

Polyacrylonitrile (PAN) Mfg. Process TEXTILE LIBRARY

Manufacturing NASA

MANUFACTURING PROCESS FOR STRINGERS WITH HIGH

11 ©2013 Hexcel Load-carrying Elements (2) Debate about the preferred fibre continues (carbon, E-glass, higher modulus glass…) Materials can be pre-impregnated, dry and infused, or pre-

Carbon fibre (fiber) tube C-Tech

Production of carbon fiber reinforced plastics by

Chapter 2 Precursors and Manufacturing of Carbon Fibers Soo-Jin Park and Gun-Young Heo Abstract In this chapter, we will present the precursors and manufacturing of

Carbon Fiber from Biomass NREL

carbon fiber-reinforced carbon (CFRC; C/C) materials as well as when the highest purity is required. Kohlenstoff-Broschuere_GB.qxd 23-11-2004 08:04 Uhr Seite 2. 3 The manufacturing process of carbon and graphite materials contains the following steps: Raw material processing Mixing Shaping Baking Graphitization (only for the production of electrographite) Special treatments such as

HIGH-PRESSURE RTM PROCESS VARIANTS FOR

Manufacturing Process of Cabonfiber

The high quality polyacrylonitrile (PAN) fibers, which were used to manufacture the high performance carbon fibers, were prepared by the dry‐jet wet spinning process.

Manufacturing Process of Cabonfiber

the only general access carbon fiber manufacturing research facility in the DOE laboratory system. For more than ten years, it has worked with government and industry to address commercialization challeng-es, including cost and manufacturing limitations. To help overcome these barriers, ORNL is aggressively researching less expensive alternative precursors, ad-vanced technologies for

Advancement in Molding and Forming Carbon Fiber Components

Carbon Fibers Precursors Manufacturing and Properties

CARBON FIBER COMPOSITE B PILLAR REINFORCEMENT

Carbon fiber manufacturing process from various precursors The purpose of this study is to provide a comprehensive overview of the CF precursors from biomass and their market potential.

Polyacrylonitrile (PAN) Mfg. Process TEXTILE LIBRARY

Carbon fibre final ppt SlideShare

manufacturing of low‐cost carbon fiber from renewable resources that can be used for vehicle lightweighting. Stakeholders from industry, national laboratories, and …

Multi-material Preforming of Structural Composites

Manufacturing NASA

manufacturing of low‐cost carbon fiber from renewable resources that can be used for vehicle lightweighting. Stakeholders from industry, national laboratories, and …

(PDF) Cost Estimation Model for PAN Based Carbon Fiber

Advanced Composites Manufacturing Carbon Fiber Parts

Glass fiber manufacturing is the high-temperature conversion of various raw materials (predominantly borosilicates) into a homogeneous melt, followed by the fabrication of this melt into glass fibers.

Renewable Low-Cost Carbon Fiber for Lightweight Vehicles

Carbon fibre final ppt SlideShare

Chapter 2 Precursors and Manufacturing of Carbon Fibers

This manual is an overview of the Fiber Reinforced Plastic/Composite (FRP/Composite) material system. Materials and processes are presented along with design

Carbon Fibers Precursors Manufacturing and Properties

The carbon-fiber composites were shown to exhibit significant anisotropy in their dimensional stability driven by the fiber weave and the microstructural behavior of the fiber and carbon matrix accompanied by the presence of manufacturing porosity and defects.

THE FORGED COMPOSITE Quantum Composites

Assessment of Carbon Fiber Manufacturing Cost invest.is

Production of carbon fiber reinforced plastics by

Comments are closed.