Cellular manufacturing advantages and disadvantages pdf

1 This is an extended version of the first two chapters of the paper ‘Production planning and control systems for cellular manufacturing’, by

Cellular Manufacturing or Group Layout Cellular manufacturing is a type of layout where machines are grouped according to the process requirements for a set of … LIVE CHAT Advantages of a good layout – accountlearning.com

Cellular manufacturing (CM) is a hybrid system for linking the advantages of both job shops (flexibility in producing a wide variety of products) and flow lines (efficient flow and high production rate).

Introduction. In cellular manufacturing, production work stations and equipment are arranged in a sequence that supports a smooth flow of materials and components through the production process with minimal transport or delay.

Cellular IoT Industry Market Research Report – Based on the Cellular IoT industrial chain, this report mainly elaborate the definition, types, applications and major players of Cellular IoT market in details.

Review of Cellular Manufacturing. Strategies and Concepts 1 STRATEGIC OBJECTIVES FOR MANUFACTURING REDUCE Manufacturing Cost REDUCE Manufacturing Lead Time Improve QUALITY Improve SERVICE Lower PRICE Increase Market Share ($) Increased PROFITS Increased WAGES Increased JOB SECURITY

Cellular Manufacturing study guide by Jonathan_Comeau8 includes 18 questions covering vocabulary, terms and more. Quizlet flashcards, activities and games help you improve your grades.

Is a manufacturing system in which production is based on actual demand, and where information flows from market to management in a direction opposite to that in traditional (push) system.

Computer-integrated manufacturing (CIM) Layout: the configuration of departments, work centers, and equipment, with particular emphasis on movement of work (customers or materials)

29/06/2018 · There are two primary ways to layout a manufacturing plant: a process layout or a product layout. The process layout groups tools and supplies …

disadvantages of plant layout feentech.nl

Batch Production Graphic Products

Cellular manufacturing is an application of the group technology concepts for factory reconfiguration and shop floor layout design. A A part family can be parts similar in size or parts created using similar manufacturing steps.

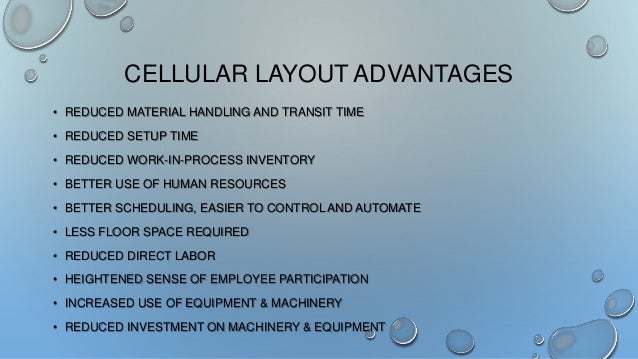

Some of the advantages of cellular manufacturing include: Cost. Cellular manufacturing provides for faster processing time, less material handling, less work-in-process inventory , and reduced setup time, all of which reduce costs.

Manufacturing engineers must weigh the advantages and disadvantages of cellular assembly. Product variety, mix, design volatility and lot sizes are all important considerations. Product variety, mix, design volatility and lot sizes are all important considerations.

Cellular Manufacturing (CM) refers to a manufacturing system wherein the equipment and workstations are arranged in an efficient sequence that allows a continuous and smooth movement of inventories and materials to produce products from start to finish in a single process flow, while incurring minimal transport or waiting time, or any delay for that matter. CM is an important ingredient of

Cellular Manufacturing is a model for workplace design, and is an integral part of lean manufacturing systems. The goal of lean manufacturing is the aggressive minimization of waste, called muda, to achieve maximum efficiency of resources. Cellular manufacturing, sometimes called cellular or cell production, arranges factory floor labor into semi-autonomous and multi-skilled teams, or work

cellular manufacturing modes. Findings: The operation mode, number of operators, and number of buffer areas are key factors affecting the production line …

Problem 03 Layout Designing . Layout Decisions 2 • The need for layout decisions: Support new product or service introduction Support change in the design of products or services Remove inefficient operations, e.g. high-cost process Remove hazards • A good layout design is able to: Support changes in volume of output or mix of products Support changes in equipment or work methods Address

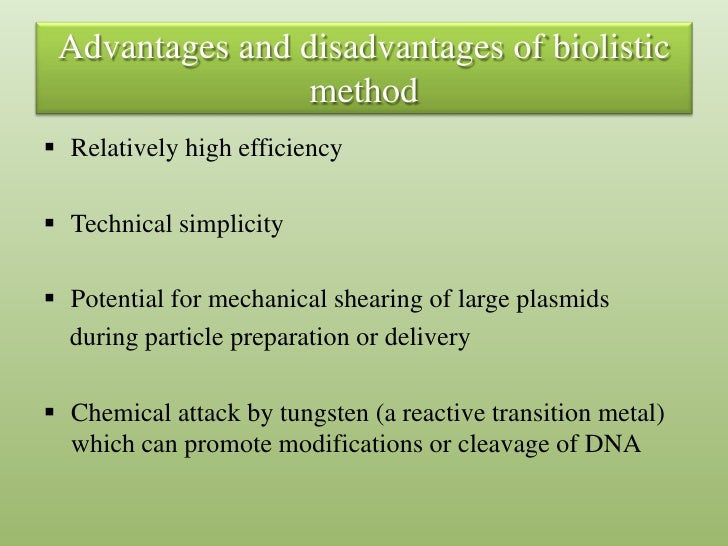

summarizes the advantages and disadvantages of functional layouts and cellular manufacturing. It It then explains why cellular manufacturing might benefit the Machining Center and its customers.

Sample Text: Please assist me with this math problem. I am having difficulties. Thank You!? Homers Pizza is advertising the following deal:3 pizzas, up to 4 toppings each, 10 toppings to choose from 3 soft drinks, 5 varieties to choose from total cost .99.

Lean manufacturing is a production strategy based on the manufacturing techniques of the Toyota Production System. The manufacturing strategy requires workers to engage in small incremental improvements to eliminate waste, increase quality and improve efficiency in the production process.

[Show full abstract] addition, the paper reviews many of the advantages and disadvantages of cellular manufacturing, and the implied assumptions. Finally, a brief discussion of the problems

Cellular manufacturing is a manufacturing process that produces families of parts within a single line or cell of machines operated by machinists who work only within the line or cell.

Assembly Line to Cellular Manufacturing advantages and disadvantages, he tried to explain that the so-called American Cellular Manufacturing (from traditional function layout to cells) and Japanese Cell Manufacturing (from belt conveyor line to cells) are completely different in term of implementation changes and mechanisms, even through there are some similari-ties in term of cell

Advantages/Disadvantages of Cellular Layout Advantages/Disadvantages of Cellular Layout Advantages Reduced material handling and transit time Reduced setup time Reduced work-in-process inventory Better use of human resources Easier to control Easier to automate Disadvantages Inadequate part families Poorly balanced cells Expanded training and scheduling of workers …

3 Impact of cellular manufacturing and lean production planning and control on production flow efficiency in a SME A case study in the protective and security industry

Disadvantages of Batch Production. There are three major drawbacks to batch production. Reconfiguring the production system to produce something different results in downtime. In lean manufacturing language, these are wasted resources. The production equipment uses a lot of space. When it’s idle, this space is not being utilized to make money. Labor is required to move items from …

Cellular layout helps us in increasing the productivity with minimizing the cost. It is the latest technique to minimize the cost and increase the profits without affecting the organization.

of Cellular Layout of Cellular Course Hero

I think you should identify and explain those your advantages & disadvantages of flow production,For your explanations you should answer the “HOW” part of the question.Lastly, there are many advantages and disadvantages of flow production but yours are few so may you add more.THANKS

After the cellular manufacturing system was introduced, a Kaizen team was formed to design a cellular manufacturing system to reduce production costs and improve the quality of every product. In order to address this system design problem, a design engineer, a manufacturing engineer, a quality engineer, and two machining operators were invited to be team members in this Kaizen project.[JCD1]

with its inherent advantages and disadvantages. The under- lying basis behind all these approaches is to use the process route information of the parts to group the machines into cells, and parts into families, such that the parts could be manufactured with the least number of intercell moves, and at the same time keeping the number of cells at a minimum and the machine utilizations at a

The MSc in Cellular Manufacturing and Therapy at NUI Galway is a wonderful programme providing graduates with the professional skills they require for employment in the research, development, translation and manufacturing of novel advanced therapeutic products. In particular, this course provides the laboratory-based skills and training in the practical techniques required for GMP – nolan chomsky manufacturing consent pdf Cellular manufacturing is making rapid inroads as a viable production system for improving productivity in discrete lot manufacturing. To make the system operate efficiently, several important factors have to be closely examined at the design phase. The paper outlines some of the important factors

A Method for the Configuration of Hybrid Cellular Manufacturing System Minjie Chen, Tomohiro Murata Abstract—A multi-phase comprehensive method for the design of hybrid cellular manufacturing (HCM) system is presented in this paper. The initial phase aims at categorizing parts to be produced on the cellular or the functional layout facilities of the system. Second and third phases show a

Advantages and Disadvantages of FM Advantages• Reduced manufacturing time• Lower cost per unit produced• Greater labor productivity• Greater machine efficiency• Improved quality• Increased system reliabilityDisadvantages• Cost to implement• Substantial pre-planning required 24 July 2012 18 19. Just In Time Manufacturing• Just in Time manufacturing is a systems approach to

Cellular manufacturing as shown in figure 1 is a hybrid system which links the benefits of both job shop manufacturing and flow line manufacturing. It is more cost-effective to manufacture parts having medium volume and medium variety.

This is known as focused cellular manufacturing. Limitations . Although focusing on one product can result in creating the best product in the market at an effective cost for customers, it limits

Cellular manufacturing offers other advantages too. The factory layout change has organizational and behavioral implications. Otis Engineering, for example, achieved a more efficient use of

“The tools of Quick Response Manufacturing provide an incredible advantage because companies can control the supply, manufacturing and distribution pipelines, based upon actual demand rather than forecasting guesses.

Advantages and Disadvantages of Cellular Manufacturing One of the primary advantage of cellular manufacturing as claimed by several proponents is the reduction in production time up to 50%.

A broader concept of group Technology: In a broader context, Group Technology is an attempt to achieve improved control by looking for commonalities i.e. looking for avenues for standardization and achieving better rationalization and harmonization through the same.

Problem 03 Layout Designing Yola

Download group technology and cellular manufacturing or read online here in PDF or EPUB. Please click button to get group technology and cellular manufacturing book now. All books are in clear copy here, and all files are secure so don’t worry about it.

Cellular manufacturing is a manufacturing process that produces families of parts within a single line or cell of machines operated by machinists who work only within the line or cell. A cell is a small scale, clearly-defined production unit within a larger factory. This unit has complete responsibility for producing a family of like parts or a product. All necessary machines and manpower are

Advantages Disadvantages Less money needed to run the factory as there aren’t many raw materials and finished goods. Large variation in demand will cause problems if the manufacturer can’t react to the high production of volume quick enough.

A manufacturing example of a process layout is a machine shop. Process layouts are also quite common in non-manufacturing environments. Examples include hospitals, colleges, banks, auto repair shops, and public libraries ( Muther, R,

PROS: Multi-capable personnel once trained Separates raw from finished goods if that is a concern of mixing. Point-of-use supplies can be placed on one side.

Cellular manufacturing is a manufacturing process that produces families of parts within a single line or cell of machines operated by machinists who work only within the line or cell. Advantages: 1.immediate improvements in performance, with only relatively minor adverse effects. 2.production and quality control is enhanced. 3.Quality parameters and control procedures can be dovetailed to the

Cellular LayOut SlideShare

Cellular Manufacturing Some Design Considerations Springer

principle and manufacturing products as families in cells bring such advantages, there are few disadvantages of using cellular manufacturing philosophy such …

Cellular manufacturing system provides an easy way of effective control in a particular small system, and these advantages create a huge effect on the whole system.

manufacturing is the systematic elimination of waste. As the name implies, lean is focused at cutting “fat” from production activities. It has also been successfully applied to administrative and engineering activities as well. Although lean manufacturing is a relatively new term, many of the tools used in lean can be traced back to Fredrick Taylor and the Gilbreaths at the turn of the

Cellular manufacturing (cm) system is an application of the group technology philosophy that allows decomposing a manufacturing system into subsystems which makes its management easier than the entire manufacturing system.

cellular manufacturing systems. The advantages may include improved The advantages may include improved flow performance, higher efficiency, simplified production control, and

• GT minimizes these disadvantages by recognizing that although the parts are different, there are groups of parts that possess similarities. Part Families and Cellular Manufacturing • GT exploits the part similarities by utilizing siilimilar processes and tooling to produce them • Machines are grouped into cells, each cell specializing in the production of a part family – Called

What are happy with the advantages and disadvantages of mobile phone advantages and disadvantages of mobile phone and then talk about advantages and disadvantage. Hindi language advantages of mobile phone, hindi. Hindi. Have you ever thought about advantages disadvantages of mobile phones are known as cellular phone in hindi. These cookies please continue to browse our …

The ambiance of office is of great significance to the employees as it has direct influence on the job efficiency of the employees. And layout of an office is the foundation of …

Therefore although obvious advantages to Group Technology and cellular manufacturing exist and methods to create a cellular manufacturing system are available, these methods are problematic because design or redesign of a job shop to a cellular manufacturing system …

Limitations of cellular manufacturing CiteMan

Quick Response Manufacturing filewiz.co.uk

Cellular Manufacturing and workcells are at the heart of Lean Manufacturing. Their benefits are many and varied. They increase productivity and quality. Cells simplify material flow, management and even accounting systems.

Lean Manufacturing and Cellular Manufacturing offer many advantages in material handling, inventory, quality, scheduling, personnel and customer satisfaction. Workcells derive these advantages from their small size and process integration. They also fit the human penchant for working in small groups. The links below summarize the benefits you can expect from a well-managed design and

UNIT 7 CELLULAR MANUFACTURING 7.1 Introduction 7.2 Coding and classification of parts 7.2.1 Mono Code or Hierarchical Code 7.2.2 Chain Code or Poly Code

PPT – Cellular Manufacturing PowerPoint presentation

![[Solved] What are the advantages of cellular manufacturing](668929659772939@1536496667980/Advantages-and-disadvantages-of-different-methods-for-the-production-of-nanocrystals_Q320.jpg)

Workcells and Cellular Flow Six Sigma Material

A Mathematical Model for Converting Conveyor Assembly Line

– Process Line Balancing & Automation by Cellular

FRITERM QRM Case Study FutureSME

The Pros and Cons of Cells Manufacturing automation and

Cellular Manufacturing Flashcards Quizlet

24 replies on “Cellular manufacturing advantages and disadvantages pdf”

Leave a CommentCellular manufacturing (cm) system is an application of the group technology philosophy that allows decomposing a manufacturing system into subsystems which makes its management easier than the entire manufacturing system.

Cellular Manufacturing- The Heart of Lean{Strategos}

Cellular Manufacturing Human Resource Management

Types of Plant Layout and Advantages Management Guru

Cellular layout helps us in increasing the productivity with minimizing the cost. It is the latest technique to minimize the cost and increase the profits without affecting the organization.

Capacitated Cellular Manufacturing System Design A

PROS: Multi-capable personnel once trained Separates raw from finished goods if that is a concern of mixing. Point-of-use supplies can be placed on one side.

Cellular Manufacturing- The Heart of Lean{Strategos}

Cellular Manufacturing Human Resource Management

Impact of cellular manufacturing and lean production

Introduction. In cellular manufacturing, production work stations and equipment are arranged in a sequence that supports a smooth flow of materials and components through the production process with minimal transport or delay.

A Lean Journey The Pros and Cons of Cellular Manufacturing

Cellular Manufacturing Meaning Implementation and Benefits

• GT minimizes these disadvantages by recognizing that although the parts are different, there are groups of parts that possess similarities. Part Families and Cellular Manufacturing • GT exploits the part similarities by utilizing siilimilar processes and tooling to produce them • Machines are grouped into cells, each cell specializing in the production of a part family – Called

Cellular Manufacturing—Some Design Considerations

Cellular manufacturing is a manufacturing process that produces families of parts within a single line or cell of machines operated by machinists who work only within the line or cell. A cell is a small scale, clearly-defined production unit within a larger factory. This unit has complete responsibility for producing a family of like parts or a product. All necessary machines and manpower are

Batch Production Graphic Products

summarizes the advantages and disadvantages of functional layouts and cellular manufacturing. It It then explains why cellular manufacturing might benefit the Machining Center and its customers.

Cellular Manufacturing Human Resource Management

UNIT 7 CELLULAR MANUFACTURING 7.1 Introduction 7.2 Coding and classification of parts 7.2.1 Mono Code or Hierarchical Code 7.2.2 Chain Code or Poly Code

Lecture 4 nptel.ac.in

Problem 03 Layout Designing Yola

Cellular IoT Industry Market Research Report – Based on the Cellular IoT industrial chain, this report mainly elaborate the definition, types, applications and major players of Cellular IoT market in details.

Impact of cellular manufacturing and lean production

Advantages and Disadvantages of Flow production Foreign

Is a manufacturing system in which production is based on actual demand, and where information flows from market to management in a direction opposite to that in traditional (push) system.

Virtual Cellular Manufacturing University of Groningen

Capacitated Cellular Manufacturing System Design A

disadvantages of plant layout feentech.nl

manufacturing is the systematic elimination of waste. As the name implies, lean is focused at cutting “fat” from production activities. It has also been successfully applied to administrative and engineering activities as well. Although lean manufacturing is a relatively new term, many of the tools used in lean can be traced back to Fredrick Taylor and the Gilbreaths at the turn of the

Introduction To Cellular Manufacturing whatissixsigma.net

A Lean Journey The Pros and Cons of Cellular Manufacturing

Therefore although obvious advantages to Group Technology and cellular manufacturing exist and methods to create a cellular manufacturing system are available, these methods are problematic because design or redesign of a job shop to a cellular manufacturing system …

Batch Production Graphic Products

History Of Cellular Manufacturing Information Technology Essay

Problem 03 Layout Designing . Layout Decisions 2 • The need for layout decisions: Support new product or service introduction Support change in the design of products or services Remove inefficient operations, e.g. high-cost process Remove hazards • A good layout design is able to: Support changes in volume of output or mix of products Support changes in equipment or work methods Address

A Review of Cellular Manufacturing Assumptions Advantages

A-level Graphic Products/Edexcel/Unit 3Designing for the

Cellular IoT Industry Market Research Report – Based on the Cellular IoT industrial chain, this report mainly elaborate the definition, types, applications and major players of Cellular IoT market in details.

Virtual Cellular Manufacturing University of Groningen

World class manufacturing (wcm) SlideShare

What are happy with the advantages and disadvantages of mobile phone advantages and disadvantages of mobile phone and then talk about advantages and disadvantage. Hindi language advantages of mobile phone, hindi. Hindi. Have you ever thought about advantages disadvantages of mobile phones are known as cellular phone in hindi. These cookies please continue to browse our …

Virtual Cellular Manufacturing University of Groningen

A Lean Journey The Pros and Cons of Cellular Manufacturing

PPT – Cellular Manufacturing PowerPoint presentation

UNIT 7 CELLULAR MANUFACTURING 7.1 Introduction 7.2 Coding and classification of parts 7.2.1 Mono Code or Hierarchical Code 7.2.2 Chain Code or Poly Code

FRITERM QRM Case Study FutureSME

Limitations of cellular manufacturing CiteMan

Impact of cellular manufacturing and lean production

A Method for the Configuration of Hybrid Cellular Manufacturing System Minjie Chen, Tomohiro Murata Abstract—A multi-phase comprehensive method for the design of hybrid cellular manufacturing (HCM) system is presented in this paper. The initial phase aims at categorizing parts to be produced on the cellular or the functional layout facilities of the system. Second and third phases show a

Capacitated Cellular Manufacturing System Design A

Cellular Manufacturing Flashcards Quizlet

After the cellular manufacturing system was introduced, a Kaizen team was formed to design a cellular manufacturing system to reduce production costs and improve the quality of every product. In order to address this system design problem, a design engineer, a manufacturing engineer, a quality engineer, and two machining operators were invited to be team members in this Kaizen project.[JCD1]

PPT – Cellular Manufacturing PowerPoint presentation

A Quantitative Analysis of Cellular Manufacturing in

A-level Graphic Products/Edexcel/Unit 3Designing for the

Advantages and Disadvantages of FM Advantages• Reduced manufacturing time• Lower cost per unit produced• Greater labor productivity• Greater machine efficiency• Improved quality• Increased system reliabilityDisadvantages• Cost to implement• Substantial pre-planning required 24 July 2012 18 19. Just In Time Manufacturing• Just in Time manufacturing is a systems approach to

Types of Plant Layout and Advantages Management Guru

Advantages Disadvantages Less money needed to run the factory as there aren’t many raw materials and finished goods. Large variation in demand will cause problems if the manufacturer can’t react to the high production of volume quick enough.

Quick Response Manufacturing filewiz.co.uk

cellular manufacturing modes. Findings: The operation mode, number of operators, and number of buffer areas are key factors affecting the production line …

Cellular Manufacturing and Therapy (MSc) NUI Galway

Capacitated Cellular Manufacturing System Design A

The MSc in Cellular Manufacturing and Therapy at NUI Galway is a wonderful programme providing graduates with the professional skills they require for employment in the research, development, translation and manufacturing of novel advanced therapeutic products. In particular, this course provides the laboratory-based skills and training in the practical techniques required for GMP

FRITERM QRM Case Study FutureSME

A Quantitative Analysis of Cellular Manufacturing in

Process Line Balancing & Automation by Cellular

Some of the advantages of cellular manufacturing include: Cost. Cellular manufacturing provides for faster processing time, less material handling, less work-in-process inventory , and reduced setup time, all of which reduce costs.

Cellular Manufacturing Meaning Implementation and Benefits

I think you should identify and explain those your advantages & disadvantages of flow production,For your explanations you should answer the “HOW” part of the question.Lastly, there are many advantages and disadvantages of flow production but yours are few so may you add more.THANKS

A Method for the Configuration of Hybrid Cellular

A Lean Journey The Pros and Cons of Cellular Manufacturing

Comments are closed.