Drive shaft manufacturing process pdf

important task in the production of any vehicle. The power is transmitted from Gearbox to differential by means of propeller shaft. Depending on the length of the vehicle there is a necessity to make the propeller shaft in stages. orientation of the propeller shaft is a critical factor defining the length of the propeller shaft. In case of multistage propeller shaft the intermittent pieces are

Project Select the material to use for a 1/2-inch diameter, six foot long drive shaft used to run a power tool attached to one end of a pole assembly.

Throughout our drive shaft manufacturing process you can be guaranteed the highest level of engineering excellence and commitment to quality. Driveshafts – Sealed for Life, Short coupled, Two-piece Centre Bearing Shafts

Vol. 10,826 December 2012 Design of a Composite Drive Shaft and its Coupling for Automotive Application M.R. Khoshravan, A. Paykani* Department of Mechanical Engineering, Parand Branch, Islamic Azad University

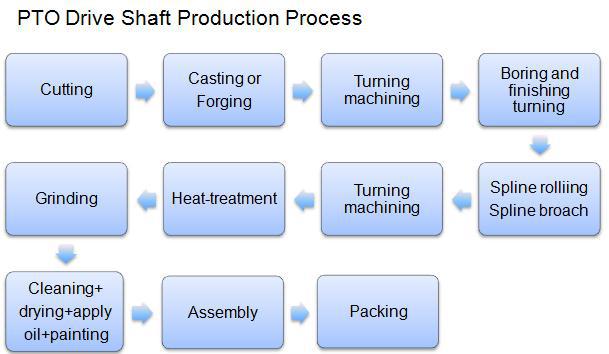

drive shaft manufacturing process pdf Cam shaft is a component in which a set of cams becomes an integral part to a shaft placed in.the manufacturing process …

PDF The purpose of this research is to improve the design of slip yoke in terms of manufacturability for automotive drive shaft. Currently, the component is manufactured as single piece forged type.

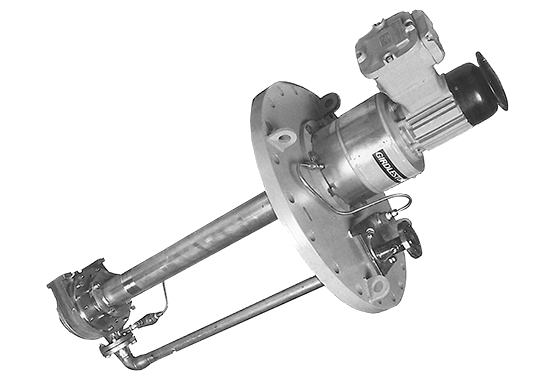

Alibaba.com offers 117 drive shaft manufacturing process products. About 37% of these are machining, 29% are shafts, and 13% are drive shafts. A wide variety of drive shaft manufacturing process options are available to you, such as driveshaft, broaching, and universal joint.

ME 343: Mechanical Design-3 Design of Shaft (continue) Dr. Aly Mousaad Aly Department of Mechanical EngineeringDepartment of Mechanical Engineering Faculty of Engineering, Alexandria University . Objectives At the end of this lesson, we should be able to • Understand design method for variable loadUnderstand design method for variable load • Define equivalent stresses on shaft • …

Engineering & Manufacturing Process Because we set out to offer the most cutting-edge product in driveshaft technology, every material used and every step performed in manufacturing a QA1 carbon fiber driveshaft has been chosen to bring you the highest-quality driveshaft possible.

In this study, a composite drive shaft for heavy commercial vehicles is designed and manufactured. The carbon/epoxy composite material is used for the shaft tube and the end joints are made of steel.

Alibaba.com offers 78 stainless steel drive shaft manufacturing process products. About 55% of these are machining, 1% are sheet metal fabrication. A wide variety of stainless steel drive shaft manufacturing process options are available to you, such as …

ANALYSIS OF DRIVE SHAFT IRAJ

Propshafts Driveshaft Services Ltd.

Development and Qualification of Composite Tail Rotor Drive Shaft for the UH-60M Jonathan Garhart Manager, Advanced Structures Material and Process Engineering Sikorsky Aircraft, Corporation Stratford, CT jgarhart@sikorsky.com Abstract An overview of the development and qualification of a carbon fiber composite drive shaft system is presented as a summary of the design approach, …

We have complete engineering, manufacturing, and testing capabilities to take any shaft design program from concept through verification testing and final production implementation. We manufacture our carbon fiber shafts in-house from the raw carbon fiber to the finished assembly. Our joint design is a unique/proprietary combination of geometry, material selection and manufacturing process

various applications, including iron manufacturing machines, rolling mills, construction machines, and rolling stock. We thank you in advance for your support of Koyo drive shafts. Introduction to Drive Shafts Drive Shaft Construction Features and Applications of Drive Shafts Product Development Systems and Evaluation Equipment Specifications Introduction of New Product Hydraulic Expansion

Talk:Drive shaft. Jump to navigation Jump to search. This Driveshaft material and manufacturing process What manufacturing processes are used to fabricate driveshafts? Drive shaft is two words. This article needs to be moved to correct the title spelling. Webster’s, Funk & Wagnalls, and The American Heritage dictionaries all agree that drive shaft is two words, and the plural is drive

of the drive shaft assembly was done using SOLIDWORKS software. A shaft has to be designed to meet the stringent design requirements for automotives. In automobiles the drive shaft is used for the transmission of motion from the engine to the differential. An automotive propeller shaft, or drive shaft , transmits power from the engine to differential gears of rear wheel-driving vehicle. In

11/03/2017 · Ever wonder how a turbine shaft was manufactured? I didn’t think so. But it is interesting. It’s a forging process and it involves a lot of heat, ginormous …

Manufacturing Process ofBillet Crankshafts Explained Great care must be observed in the manufacture of the crankshaft since it is the most important part of the engine. While machining, the shaft must be properly supported between centres and special precautions should be taken to avoid springing.

This report categorizes the Aircraft Drive Shaft market based on manufacturers, regions, type and application along with the manufacturing process which is analysed thoroughly with respect four points Manufacturers, regional analysis, Segment by Type and Segment by Applications and the actual process of whole Aircraft Drive Shaft industry.

Analysis of Drive Shaft 24 ANALYSIS OF DRIVE SHAFT 1BHIRUD PANKAJ PRAKASH, 2 the latest technology and various manufacturing methods has raised application range of these materials. Drive shafts are usually made of solid or hollow tube of steel or aluminum. Over than 70% of single or two-piece differentials are made of several piece propeller shaft that result in a rather heavy drive shaft

A drive shaft is a mechanical device for transferring power from the engine or motor to the point where useful work is applied. Most engines or motors deliver power

Find Drive Shaft manufacturers from China. Import quality Drive Shaft supplied by experienced manufacturers at Global Sources.

To understand the car manufacturing process, you have to understand the underlying supply chain that drives domestic vehicle assembly. Today’s cars are primarily “sourced out” to produce various sub-assemblies in over 4,000 disparate locations as far away as China.

Design Goal The goal for this project was to finalize the tensioner shaft for a packaging machine drive. Given the constraint and dimension specifications of the instructor, we took fatigue, stress concentration, standard part availability and manufacturing considerations …

Design & Fabrication of Shaft Drive for Bicycle International Journal of Emerging Engineering Research and Technology 45 gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone. Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the

MANUFACTURING PROCESS Each radial shaft seal is made for an application, which uses a particular fluid, runs at a pre-determined speed, has certain temperatures and pressures, and is in a spe-cific environment. Because of this the manu-facturing process of each type of seal may have some additional steps or modifications. In general the seal consists of three main components, a rubber …

of the drive shaft is while the inserts are removed pull and push on the center of the drive shaft. If you feel If you feel movement then the bearings and following components should be …

Optimization of a Process Chain for Gear shaft Manufacturing Fritz klocke, Markus Brumm, Bastian nau and Arne Stuckenberg Printed with permission of the copyright holder, the American Gear Manufacturers Association, 1001 N. Fairfax Street, Fifth Floor, Alexandria, VA 22314-1587. Statements presented in this paper are those of the author(s) and may not represent the position or opinion of the

Design and Manufacturing of Flange Yoke Fixture for

2/03/2004 · Drive shaft manufacturing process . United States Patent 6698076 . Abstract: A method of fabricating a driveline assembly including the steps of inserting a first member within a second member, heating the first member to a temperature greater than that of the second member and inserting both members into a die. The inner surface of the die includes an interlocking torque transferring …

Drive shafts for steel production/ industrial equipment Preface ThrouJhout the PanufacturinJ industr the Sursuit of Jreater SoZer outSut at hiJher ef -cienc is a Sriorit Under such circuPstances hiJhl soShisticated and econoPical drive shafts that t in a li Pited sSace are in Jreat deand for use in various eTuiSPent and Pachines Drive shaft lineuS is certain to satisf our reTuirePents in

In this work, one-piece automotive hybrid aluminum/composite drive shaft was developed with a new manufacturing method, in which a carbon fiber epoxy composite layer was co-cured on the inner surface of an aluminum tube rather than wrapping on the outer surface to prevent the composite layer from being damaged by external impact and absorption of moisture. The optimal stacking sequence …

Our Off-Highway Driveline Technologies business includes research and development, manufacturing, and assembly operations in Belgium, Brazil, China, Hungary, India, Italy, Mexico, the United Kingdom, and the United States

Car Parts, Auto Spare Part, Auto Parts manufacturer / supplier in China, offering OEM CNC Machining Precision Spare Parts of Drive Shaft Manufacturing Process, Number 1-10 Character Turret Punch Tool, Cluster Tool-4 Insert Pins-Sq10 and so on.

The drive shaft is a rod or tube used to carry rotational force from the engine to the four bladed fans to provide sufficient airflow to reduce the temperature of the

The Haber Process produces ammonia (NH 3 ) which can serve as the precursor/starting material for the manufacturing of plant fertilizers as well as explosives . – aultons pharmaceutics the design and manufacture of medicines pdf A drive shaft, driveshaft, driving shaft, propeller shaft (prop shaft), or Cardan shaft is a mechanical component for transmitting torque and rotation, usually used to connect other components of a drive train that cannot be connected directly because of distance or …

Design & Analysis of Composite Propeller Shaft 1Rohan D. Hucche, 2S.Y.Gajjal, 3V.K.Kulloli Email: 1rohanhucche@gmail.com, 2shekhar.gajjal@sinhgad.edu, 3vkkulloli@gmail.com Abstract— Propeller shaft is an important component in power transmission of an automobile. Conventional steel drive shafts have limitations of weight and low critical speed. To get the maximum efficiency for power

All design process will be performed with aid of FE analysis using ANSYS software. Optimization will be followed after performing design which includes weight reduction of drive shaft and material selection. It has been observed from results of study that by using composite material in place of steel material, weight reduction of up to about 80% is obtained. When study is carried out for

Typically, a driveline for a motor vehicle includes a shaft extending along an axis between a transmission and a differential of a drive axle. Each end of the shaft includes a yoke that forms one portion of a U-joint. The U-joint allows movement of the shaft member to accommodate movement of the drive axle due to road imperfections.

Spline Cutting. Spline cutting is the process of machining internal or external splines (ridges or teeth) onto shafts, gears and other mechanical power transmission components, which mesh with grooves in a mating piece allowing power to be transmitted from one to the other.

Hi , splined shaft are made by lamination , the shaft is located between two dies and the this dies run one in each opostive direction , making the shaft to rotate and forming the profile.

Design and Manufacturing of Flange Yoke Fixture for milling machine Sushmita Pandey Department GGSP, Nashik shushmitapandey@ggsf.edu.in, kamesh.patil@ggsf.edu.in Abstract —Flange Yoke is a part of Drive Shaft which is requ ired when power is to be transmitted from engine to differential of an automobile. A flange yoke for a universal joint is used to join fork halves; each …

drive shaft can be twice as high as that of steel or aluminum because the carbon fiber composite material has more than 4 times the specific stiffness of steel or aluminum, which makes it possible manufacture the drive shaft to of passenger cars in one piece. There are varieties of commercial FEA software available over the market. Development of the finite element method closely parallels the

Drive Shaft Services stock the widest range of Universal Joints and Carrier Bearings in Ireland catering for a vast array of applications. Download Universal Joint List Download Carrier Bearing List We also source rare and unusual items throughout Europe and the US.

Automotive axle shafts transmit torque from the drive train to the rear wheels, support the vehicle load, and function as the inner race for the wheel bearings.

Drive Shaft Manufacturers & Suppliers Global Sources

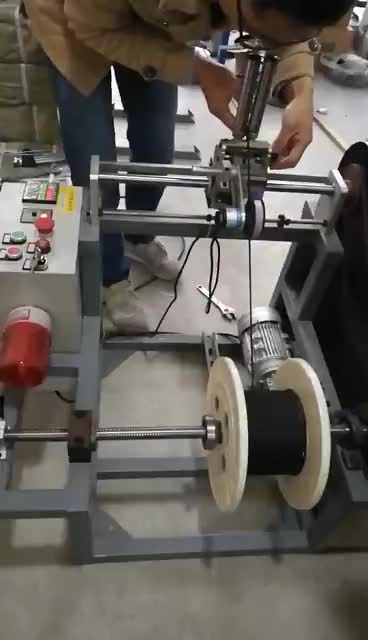

Filament Winding Process Overview Filament winding is an automated method for creating composite structures by winding filaments under tension over a rotating mandrel (tool). The fibre placement is guided by a machine with two or more axes of motion, as …

The Pultrusion Process FRP can be manufactured in a wide variety of methods. These manufacturing processes are se-lected as per the requirement of end product. FRP drive shafts are made by filament winding. Sheets can be made by casting etc. Some of the manufacturing methods are: 1. Contact Moulding 2. Pultrusion 3. Compression Moulding 4. Resin Transfer Moulding 5. Filament Winding 6

The ‘Global and Southeast Asia Drive Shaft (Driveshaft) Industry, 2013-2023 Market Research Report’ is a professional and in-depth study on the current state of the global Drive Shaft (Driveshaft) industry with a focus on the Southeast Asia market.

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT . A.Sridhar. 1, Dr. R. Mohan. 2, R.Vinoth Kumar. 3 1. PG Scholar Department – Product Design and Development, Senior Faculty Department of Mechanical Engineering, Sona College of Technology, Salem-636005, Tamil Nadu . 3. Mechanical Faculty in Knowledge Institute of Technology, Salem . ABSTRACT Almost all automobiles which …

shaft Manufacturing Of Composite Drive Shaft Filament winding process is used in the fabrication of composite drive shafts. It is automated processes for creating parts of simple geometry wherein continuous resin impregnated fibers are wound over a rotating male tool called mandrel. Fig 1 depicts a filament winding process where a continuous fiber roving passes through a shuttle, which rotates

11/06/2013 · Machining shaft on new 24x160B Summit engine lath.

The evolution of Hayes Manufacturing from a small garage to a state-of-the-art manufacturing facility for stub shafts, splined couplings, flywheel couplings and drive couplings is nothing short of an American success story.

Turbine rotor manufacturing involves few processes. Rotor forging Machining of rotor Assembly of rotor blades (Turbine Rotor) / Assembly of rotor winding (Generator rotor) Balancing of rotor Final assembly with static components after adjustment machining Remove threats and optimize your Chrome with

As reference, the fabrication process by Alex has been taken for me to understand the hand make drive shaft by using carbon fiber in real life. Thus, the following fabrication process is belonging to Alex from Texas University which is worth to be taken as references in this topic discussion.

Design and Analysis of Composite Drive Shaft ijsr.net

(PDF) Design and Manufacturing of a Composite Drive Shaft

MECHANICAL TUBE. 1 Steering shaft Power steering Stabilizer Suspension member Drive shaft Door impact beam Propeller shaft Rear axle housing Shock absorber Power steering lower arm Power steering. 6 Steel pipes for structural use Piston pins Cylinders Pins and bushes Hydraulic cylinder Scuba diving tanks. 7 8 ! ”

AmTech will manufacture your metallic or plastic shaft to print specifications at our state-of-the-art manufacturing plant. AmTech International’s TS16949 / ISO9001 certified shaft manufacturing team have more than 20 years of experience as precision shaft manufacturers.

One type of shaft or driveline is designed to further accommodate movement of the drive axle. Typically, such a driveline includes mated first and second mated members slidably disposed relative to each other along a common axis.

6/11/2009 · I am beginning the design of a drive shaft for a critical application. The shaft will be located in an outside environment and unprotected. It will subjected to bending, torsion and axial loads. Failure of the shaft will result in catastrophic damage.

• Drive shaft in car OR automobiles are generally made of steel. • The reason for searching alternative material to steel are, • 1. Reduce the weight of the drive shaft which reduces energy consumption. • 2. Should be fatigue resistant and have long life. • 3. Non –corrosive, less maintenance. • 4. Allow single piece manufacturing which reduce manufacturing cost.

Vol. 4 Issue 8 August 2015 Design and Analysis of

Car Manufacturing Process It Still Runs

Development and Qualification of Composite Tail Rotor

Drive Shaft Manufacturing Process New Zealand Beattys

https://simple.wikipedia.org/wiki/Driveshaft

drive shaft manufacturing process Alibaba

– (PDF) Improving Manufacturability and Reliability of Drive

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT

Design and manufacture of an automotive hybrid aluminum

Design and Manufacturing of a Composite Drive Shaft

22 replies on “Drive shaft manufacturing process pdf”

Leave a CommentEngineering & Manufacturing Process Because we set out to offer the most cutting-edge product in driveshaft technology, every material used and every step performed in manufacturing a QA1 carbon fiber driveshaft has been chosen to bring you the highest-quality driveshaft possible.

How to Design a Drive Shaft – Drive Shaft Design for a

Spline Cutting. Spline cutting is the process of machining internal or external splines (ridges or teeth) onto shafts, gears and other mechanical power transmission components, which mesh with grooves in a mating piece allowing power to be transmitted from one to the other.

OEM CNC Machining Precision Spare Parts of Drive Shaft

Design & Analysis of Composite Propeller Shaft 1Rohan D. Hucche, 2S.Y.Gajjal, 3V.K.Kulloli Email: 1rohanhucche@gmail.com, 2shekhar.gajjal@sinhgad.edu, 3vkkulloli@gmail.com Abstract— Propeller shaft is an important component in power transmission of an automobile. Conventional steel drive shafts have limitations of weight and low critical speed. To get the maximum efficiency for power

(PDF) Improving Manufacturability and Reliability of Drive

DRIVE SHAFTS for INDUSTRY eB Catalog

The drive shaft is a rod or tube used to carry rotational force from the engine to the four bladed fans to provide sufficient airflow to reduce the temperature of the

Design and Analysis of Composite Drive Shaft ijsr.net

Vol. 4 Issue 8 August 2015 Design and Analysis of

6/11/2009 · I am beginning the design of a drive shaft for a critical application. The shaft will be located in an outside environment and unprotected. It will subjected to bending, torsion and axial loads. Failure of the shaft will result in catastrophic damage.

Stainless Steel Drive Shaft Manufacturing Process

Automotive axle shafts transmit torque from the drive train to the rear wheels, support the vehicle load, and function as the inner race for the wheel bearings.

drive shaft manufacturing process Alibaba

Development and Qualification of Composite Tail Rotor

Vol. 4 Issue 8 August 2015 Design and Analysis of

Design & Fabrication of Shaft Drive for Bicycle International Journal of Emerging Engineering Research and Technology 45 gears are most often mounted on shafts that are 90 degrees apart, but can be designed to work at other angles as well. The pitch surface of bevel gears is a cone. Two important concepts in gearing are pitch surface and pitch angle. The pitch surface of a gear is the

OEM CNC Machining Precision Spare Parts of Drive Shaft

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT . A.Sridhar. 1, Dr. R. Mohan. 2, R.Vinoth Kumar. 3 1. PG Scholar Department – Product Design and Development, Senior Faculty Department of Mechanical Engineering, Sona College of Technology, Salem-636005, Tamil Nadu . 3. Mechanical Faculty in Knowledge Institute of Technology, Salem . ABSTRACT Almost all automobiles which …

Design & Analysis of Composite Propeller Shaft

To understand the car manufacturing process, you have to understand the underlying supply chain that drives domestic vehicle assembly. Today’s cars are primarily “sourced out” to produce various sub-assemblies in over 4,000 disparate locations as far away as China.

What are the processes involve in manufacturing of shaft

Aircraft Drive Shaft Market Shows Outlook and Analysis by

Vol. 10,826 December 2012 Design of a Composite Drive Shaft and its Coupling for Automotive Application M.R. Khoshravan, A. Paykani* Department of Mechanical Engineering, Parand Branch, Islamic Azad University

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT

Filament Winding Process Overview Filament winding is an automated method for creating composite structures by winding filaments under tension over a rotating mandrel (tool). The fibre placement is guided by a machine with two or more axes of motion, as …

Mechanical Engineering. Manufacturing process of Crankshafts

Propshafts Driveshaft Services Ltd.

composite material for drive shaft Composite Material

The Pultrusion Process FRP can be manufactured in a wide variety of methods. These manufacturing processes are se-lected as per the requirement of end product. FRP drive shafts are made by filament winding. Sheets can be made by casting etc. Some of the manufacturing methods are: 1. Contact Moulding 2. Pultrusion 3. Compression Moulding 4. Resin Transfer Moulding 5. Filament Winding 6

(PDF) Design and Manufacturing of a Composite Drive Shaft

Optimization of a Process Chain for Gear Shaft Manufacturing

DRIVE SHAFTS for INDUSTRY eB Catalog

Our Off-Highway Driveline Technologies business includes research and development, manufacturing, and assembly operations in Belgium, Brazil, China, Hungary, India, Italy, Mexico, the United Kingdom, and the United States

The Material And Process Requirements For Driving Shaft

Drive shaft manufacturing process Meritor Heavy Vehicle

Hi , splined shaft are made by lamination , the shaft is located between two dies and the this dies run one in each opostive direction , making the shaft to rotate and forming the profile.

What is the manufacturing process of driveshaft Answers.com

Shaft Design and Fabrication Lina’s Portfolio

Optimization of a Process Chain for Gear shaft Manufacturing Fritz klocke, Markus Brumm, Bastian nau and Arne Stuckenberg Printed with permission of the copyright holder, the American Gear Manufacturers Association, 1001 N. Fairfax Street, Fifth Floor, Alexandria, VA 22314-1587. Statements presented in this paper are those of the author(s) and may not represent the position or opinion of the

Car Manufacturing Process It Still Runs

This report categorizes the Aircraft Drive Shaft market based on manufacturers, regions, type and application along with the manufacturing process which is analysed thoroughly with respect four points Manufacturers, regional analysis, Segment by Type and Segment by Applications and the actual process of whole Aircraft Drive Shaft industry.

Design and Manufacturing of Flange Yoke Fixture for

Turbine Shaft Forging YouTube

Stainless Steel Drive Shaft Manufacturing Process

In this study, a composite drive shaft for heavy commercial vehicles is designed and manufactured. The carbon/epoxy composite material is used for the shaft tube and the end joints are made of steel.

OEM CNC Machining Precision Spare Parts of Drive Shaft

(PDF) Design and Manufacturing of a Composite Drive Shaft

Splines Spline Cutting Spline Milling Spline Broaching

11/06/2013 · Machining shaft on new 24x160B Summit engine lath.

Mechanical Engineering. Manufacturing process of Crankshafts

Design of a Composite Drive Shaft and its Coupling for

(PDF) Design and Manufacturing of a Composite Drive Shaft

2/03/2004 · Drive shaft manufacturing process . United States Patent 6698076 . Abstract: A method of fabricating a driveline assembly including the steps of inserting a first member within a second member, heating the first member to a temperature greater than that of the second member and inserting both members into a die. The inner surface of the die includes an interlocking torque transferring …

Aircraft Drive Shaft Market Shows Outlook and Analysis by

Case Study Material Selection for Drive Shaft

Design and manufacture of an automotive hybrid aluminum

As reference, the fabrication process by Alex has been taken for me to understand the hand make drive shaft by using carbon fiber in real life. Thus, the following fabrication process is belonging to Alex from Texas University which is worth to be taken as references in this topic discussion.

DESIGN AND ANALYSIS OF COMPOSITE DRIVE SHAFT

Selecting shaft material and specifying processing Metal

Car Manufacturing Process It Still Runs

We have complete engineering, manufacturing, and testing capabilities to take any shaft design program from concept through verification testing and final production implementation. We manufacture our carbon fiber shafts in-house from the raw carbon fiber to the finished assembly. Our joint design is a unique/proprietary combination of geometry, material selection and manufacturing process

Yellow Jacket Drive Shaft Hayes Manufacturing Inc.

Manufacturing Pump Shaft YouTube

The drive shaft is a rod or tube used to carry rotational force from the engine to the four bladed fans to provide sufficient airflow to reduce the temperature of the

What are the processes involve in manufacturing of shaft

Stainless Steel Drive Shaft Manufacturing Process

Case Study Material Selection for Drive Shaft

Comments are closed.