Lean manufacturing tools techniques pdf

A literature review on implementation of Lean Manufacturing Techniques Mehul Mayatra1, Mr. N.D. Chauhan2, Lean manufacturing is flexible manufacturing techniques. And reduce the 50% of human efforts. Lean manufacturing tools: There are various type of lean tools are available and use this tools and principal, like cellular manufacturing, JIT, continuous improvement, production …

lean tools & techniques have been applied in the garments. Main theme of this paper has identifications of significant Main theme of this paper has identifications of significant problems related to lean waste occurs in garments have been measured using specific lean tools and techniques.

Lean Manufacturing: Tools, Techniques, and How to Use Them gives you the benefit of author and practitioner William Feld’s 15 years of hands-on experience – and the lessons he’s learned. Feld provides insight into the appropriate use of assessment, analysis, design, and, most importantly, deployment of a successful lean manufacturing program. Packed with practical advice and tips but not

By applying what you learn from Lean Manufacturing: Tools, Techniques, and How to Use Them you can build a workforce – and an organization – with the capacity to satisfy world class expectations now and into the future.

Lean Manufacturing: Tools, Techniques, and How To Use Them Each picture or slide can represent an operation or depict a bill of material for that operation with a date, revision, and signature block for configuration control.

Lean Manufacturing Tools and techniques are the indispensable factors in lean manufacturing. Often, lean tools when applied and implemented systematically bring about much clarity to the process and also cut down sources of waste in definite ways (Herstatt, 2007). Lean Tools and techniques are very useful in different circumstances–value stream mapping, jidoka, 5S, kanban , lean metric, JIT

management behaviour to successfully implement lean manufacturing and continuous improvement. As shown, lean is not simply a set of tools and concepts, which can be im- plemented by command and control. Rather it is a fully integrated manage-3 ment and manufacturing philosophy and approach in which the human di-mension is the single most important element for success. Primary data form a

Lean Manufacturing, also called Lean Production, is a set of tools and practices that aims for the continuous elimination of all waste in the production process.

Implementation selected tools of Lean Manufacturing Implementation selected tools of Lean Manufacturing 9 2.2. Characteristics of tools of Lean Management This chapter will present the different techniques currently known for improving production. 2.2.1. Empowerment The management concept of employee empowerment can be defined as the creation of an environment in which people …

There are some very good books available that explain the Lean Manufacturing theory and touch on implementing its techniques. However, you cannot learn “how to be” lean from merely reading the theory. And to be successful in the real-work environment you need a clear comprehension of how lean techniques work, rather than just a remote understanding

Lean Manufacturing Tools Techniques. A succinct introduction to Lean Manufacturing (courtesy of Advanced Industrial Equipment) Tools Crucial to Lean Manufacturing. A good place to start is with some of the essential tools and techniques key to the successful application of lean manufacturing. You’ll find a straightforward, application-based explanation for each one below. Additionally, why

specific lean manufacturing tools that were applied to the aforementioned parameters; to determine the extent of the productivity after the application of lean manufacturing tools in terms of productivity, manpower requirements, work in process (WIP) inventories, efficiency, rejection rate, and 5‟S practice; and to develop a time study system to achieve productivity. MATERIALS AND METHODS

MODULE BST113 Lean Thinking and Lean Tools 9 O V E R V I E W Introduction to Lean Thinking and Lean Tools General Introduction Welcome to this module on lean systems. If you have worked in manufacturing, chances are you will have heard of ‘lean manufacturing’ before now. In the past 20 years, the term lean manufacturing has become synonymous with efficiency in manufacturing and …

Allway & Corbett (2002) Similarity between the techniques used in manufacturing and services, as well as lean service principles. Swank (2003) Through case study proved that the use of lean principles can improve performance.

By implementing these tools and techniques lean manufacturing targets to identify and eliminate numerous wastes exist inside the factory or along the supply chain Sohal (1996).[19] Apply the lean tool by method time measurement and line balance efficiency and reduce the cycle time in a truck body assembly line and improve efficiency in that product line. Also says that lean manufacturing is a

Lean Manufacturing is a process of preserving value of product with less work. What is Lean Manufacturing ? Lean. Production for the Wood Products Industry Implementing Lean Manufacturing concepts in Non Manufacturing areas Related Pdf : Lean Manufacturing tools and techniques in the process industry Conceptual Development of an IntroductoryLean Manufacturing Related Video : …

2.1.6 LEAN TOOLS AND TECHNIQUES In this chapter the focus shall be on the relationship between Lean and TPM, by comparing their goals and principles as well as how Lean and TPM can strengthen each other’s results in order to reach sustainable growth of the organization. 2.1 Lean Lean is a systematic approach and a combination of several techniques in order to identify and eliminate …

Implementation of Lean Manufacturing _____ (Title) Management Technology Jim Keyes May, 2004 65 the importance of practicing lean techniques. However, few organizations apply lean techniques with the necessary knowledge and proven tools to achieve it. A value stream includes all the operations and processes to transform raw materials into finished goods or services, including non-value

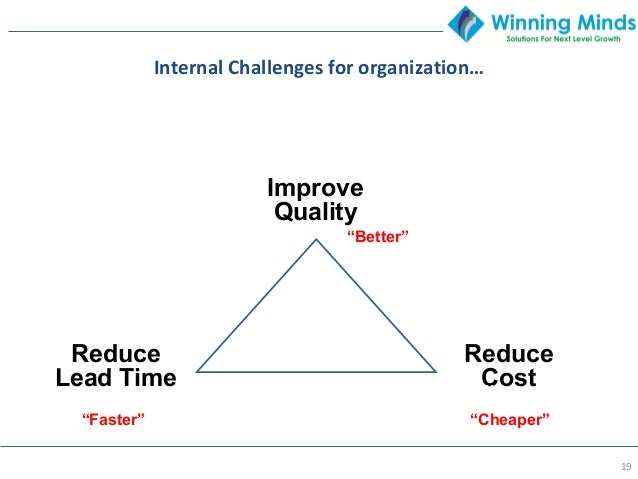

Fundamentals of Lean Professor Deborah N ght nga September 12, 2005 New goals in manufacturing systems –combined benefits of craft and mass production Improved quality High productivity Efficiency at low volumes Production flexibility Rapid, efficient development cycle Product mix diversity Lean production contrasts with traditional mass production paradigm Systemic …

12 Essential Lean Six Sigma concepts and tools Lean six sigma is the combination of two different concepts, combined together to form a powerful tool to improve business processes . Tags: Lean tools SMED OEE takt time 5 Whys One piece flow Lean manufacturing PDCA A3 problem solving Cellular Manufacturing standardized work pull system Kanban mistake proofing poka yoke Heijunka Total …

Lean Manufacturing Tools Techniques Powerful Lean

12 Essential Lean Six Sigma concepts and tools Process

Applying Lean Tools and Techniques in Pharmaceutical Environments Abstract: Due to its origin, lean has mostly been widely applied to manufacturing focused companies, especially in automotive and aerospace industries. With some pre-planning and industry-specific considerations, these same tools and concepts can also be applied in other businesses as well. In this article, we present some

Site Implementation and Assessment of Lean Construction Techniques O. Salem1, J. Solomon2, A. Genaidy3, and M. Luegring4 Abstract The goal of this paper is to test the effectiveness of some lean construction tools, in particular, those tools that can be applied in medium size construction firms. Due to the success of the lean production system in manufacturing, the construction industry has

Welcome to Lean Manufacturing Tools, this website will educate you as to the various principles of Lean Manufacturing, Its many effective tools and techniques and the people who have been instrumental in its rise.

Lean Manufacturing (LM) has been widely perceived by industry as an answer to these requirements because LM reduces waste without additional requirements of resources. This led to a spurt in LM research across the globe mostly through empirical and exploratory studies which resulted in a plethora of LM definitions with divergent scopes, objectives, performance indicators, tools/techniques

Lean Manufacturing a wikipedia anthology This is a Wikipedia book , a collection of Wikipedia articles that can be easily saved, rendered electronically, and ordered as a printed book.

Key tools and techniques within the ‘lean’ system, included:. Kanban—a visual signal to support flow by ‘pulling’ pro-duct through the manufacturing process as required by the customer. . 5 S’s—a visual housekeeping technique which devolved control to the shopfloor.. Visual control—a method of measuring performance at the ‘shop floor’ which was visual and owned by the

discussed tools and techniques are Cellular Manufacturing, Just Mapping, Poka Yoke, Five-S Practice, Sing le Minute Exchange of Dies, Takt Time Analysis, Kaizen, …

330 LEAN MANUFACTURING APPROACH IN AIRCRAFT MAINTENANCE REPAIR AND OVERHAUL Gabriela NANOVA 1, Lubomir DIMITROV 1, Todor NESHKOV 1, Charis APOSTOLOPOULOS 2, Panayiotis Th. SAVVOPOULOS 2

The concept of lean manufacturing was developed for maximizing the resource utilization through minimization of waste, later on lean was formulated in response to the fluctuating and competitive business environment.

Lean Standardised Work Workshop on site at H Weston & Sons Ltd Cider Mill. Improving the work is the work. Whilst many organizations have some sort of improvement activity many fall foul of the first of the 3 Common Pitfalls to Lean.

WASTE MEASUREMENT TECHNIQUES FOR LEAN COMPANIES Maciej Pieńkowski PhD student Wrocław University of Economics lean manufacturing, lean metrics Received 07 June 2014 Accepted 17 June 2014 Available online1 December 2014 The paper is dedicated to answer the problem of measuring waste in companies, which are implementing Lean Manufacturing concept. Lack of

Misapplications of lean manufacturing tools and techniques have also been reported by companies in their pursuit to become lean (Factorylogic, discussion with senior consultants at the company, 2001).

the lean tools used in the manufacturing and service sectors and to come to a conclusion regarding trends in the lean tools adopted. A comparative study was undertaken between the lean tools in manufacturing firms and the service sector. Data obtained from 180 manufacturing firms and 108 healthcare facilities. The lean tools used were found to be TQM, JIT, kaizen, six sigma, SPC, TPM, …

LEAN MANAGEMENT TECHNIQUES 10 BEST PRACTICE CHECKLISTS 2 In today’s competitive environment, we are challenged to do more with fewer resources. One of the best ways to increase effectiveness and efficiency is to adopt Lean Management techniques. All types of business — manufacturing, service, for-profit, not-for-profit, education and health — can benefit from the Lean …

frequently applied Lean tool in healthcare. The usual implementation steps include conducting Lean The usual implementation steps include conducting Lean training, initiating pilot projects and implementing improvements using interdisciplinary teams.

Lean techniques and tools, object of study. The questionnaire was applied in the sample, enquiring each item of analysis; subsequently, it was tabulated and …

Lean Manufacturing Tools Techniques and How to Use

– measurement of geometric tolerances in manufacturing pdf

Research Paper IMPACTS OF LEAN TOOLS AND TECHNIQUES FOR

Classification scheme for lean manufacturing tools

Lean Manufacturing

Lean Manufacturing Tools Techniques and How to Use Them

A Review on Lean Manufacturing Implementation Techniques

Lean Techniques for Optimizing the Supply Chain

–

22 replies on “Lean manufacturing tools techniques pdf”

Leave a CommentLean Manufacturing Tools and techniques are the indispensable factors in lean manufacturing. Often, lean tools when applied and implemented systematically bring about much clarity to the process and also cut down sources of waste in definite ways (Herstatt, 2007). Lean Tools and techniques are very useful in different circumstances–value stream mapping, jidoka, 5S, kanban , lean metric, JIT

Lean Manufacturing

Comparative Study of Lean Manufacturing Tools Used in

Lean Manufacturing is a process of preserving value of product with less work. What is Lean Manufacturing ? Lean. Production for the Wood Products Industry Implementing Lean Manufacturing concepts in Non Manufacturing areas Related Pdf : Lean Manufacturing tools and techniques in the process industry Conceptual Development of an IntroductoryLean Manufacturing Related Video : …

Lean Manufacturing Tools Techniques and How to Use Them

Classification scheme for lean manufacturing tools

Lean Manufacturing (LM) has been widely perceived by industry as an answer to these requirements because LM reduces waste without additional requirements of resources. This led to a spurt in LM research across the globe mostly through empirical and exploratory studies which resulted in a plethora of LM definitions with divergent scopes, objectives, performance indicators, tools/techniques

LEAN MANUFACTURING APPROACH IN AIRCRAFT MAINTENANCE

Lean manufacturing literature review and research issues

Misapplications of lean manufacturing tools and techniques have also been reported by companies in their pursuit to become lean (Factorylogic, discussion with senior consultants at the company, 2001).

Lean Techniques for Optimizing the Supply Chain

Classification scheme for lean manufacturing tools

Lean Manufacturing Tools and techniques are the indispensable factors in lean manufacturing. Often, lean tools when applied and implemented systematically bring about much clarity to the process and also cut down sources of waste in definite ways (Herstatt, 2007). Lean Tools and techniques are very useful in different circumstances–value stream mapping, jidoka, 5S, kanban , lean metric, JIT

Comparative Study of Lean Manufacturing Tools Used in

Lean Manufacturing Tools Techniques and How to Use Them

Applying Lean Tools and Techniques in Pharmaceutical Environments Abstract: Due to its origin, lean has mostly been widely applied to manufacturing focused companies, especially in automotive and aerospace industries. With some pre-planning and industry-specific considerations, these same tools and concepts can also be applied in other businesses as well. In this article, we present some

12 Essential Lean Six Sigma concepts and tools Process

Lean manufacturing literature review and research issues

Lean Manufacturing (LM) has been widely perceived by industry as an answer to these requirements because LM reduces waste without additional requirements of resources. This led to a spurt in LM research across the globe mostly through empirical and exploratory studies which resulted in a plethora of LM definitions with divergent scopes, objectives, performance indicators, tools/techniques

Lean Manufacturing Tools Techniques Powerful Lean

Lean Manufacturing Tools Techniques and How to Use Them

Lean Manufacturing Tools Techniques and How to Use

Lean Manufacturing Tools Techniques. A succinct introduction to Lean Manufacturing (courtesy of Advanced Industrial Equipment) Tools Crucial to Lean Manufacturing. A good place to start is with some of the essential tools and techniques key to the successful application of lean manufacturing. You’ll find a straightforward, application-based explanation for each one below. Additionally, why

Comparative Study of Lean Manufacturing Tools Used in

Lean Manufacturing Tools Lean Manufacturing Tools

Lean Techniques for Optimizing the Supply Chain

lean tools & techniques have been applied in the garments. Main theme of this paper has identifications of significant Main theme of this paper has identifications of significant problems related to lean waste occurs in garments have been measured using specific lean tools and techniques.

Study of the Application of Lean Manufacturing Techniques

Lean Manufacturing Tools Techniques and How to Use

Lean manufacturing literature review and research issues

Lean Manufacturing is a process of preserving value of product with less work. What is Lean Manufacturing ? Lean. Production for the Wood Products Industry Implementing Lean Manufacturing concepts in Non Manufacturing areas Related Pdf : Lean Manufacturing tools and techniques in the process industry Conceptual Development of an IntroductoryLean Manufacturing Related Video : …

Study of the Application of Lean Manufacturing Techniques

12 Essential Lean Six Sigma concepts and tools Process

LEAN MANAGEMENT TECHNIQUES 10 BEST PRACTICE CHECKLISTS 2 In today’s competitive environment, we are challenged to do more with fewer resources. One of the best ways to increase effectiveness and efficiency is to adopt Lean Management techniques. All types of business — manufacturing, service, for-profit, not-for-profit, education and health — can benefit from the Lean …

Study of the Application of Lean Manufacturing Techniques

LEAN MANUFACTURING APPROACH IN AIRCRAFT MAINTENANCE

Lean Manufacturing Tools Techniques and How to Use Them

discussed tools and techniques are Cellular Manufacturing, Just Mapping, Poka Yoke, Five-S Practice, Sing le Minute Exchange of Dies, Takt Time Analysis, Kaizen, …

Cycle Time Reduction using Lean Principles and Techniques

Classification scheme for lean manufacturing tools

Lean Techniques for Optimizing the Supply Chain

Implementation selected tools of Lean Manufacturing Implementation selected tools of Lean Manufacturing 9 2.2. Characteristics of tools of Lean Management This chapter will present the different techniques currently known for improving production. 2.2.1. Empowerment The management concept of employee empowerment can be defined as the creation of an environment in which people …

LEAN MANUFACTURING APPROACH IN AIRCRAFT MAINTENANCE

Lean manufacturing literature review and research issues

Applying Lean Tools and Techniques in Pharmaceutical Environments Abstract: Due to its origin, lean has mostly been widely applied to manufacturing focused companies, especially in automotive and aerospace industries. With some pre-planning and industry-specific considerations, these same tools and concepts can also be applied in other businesses as well. In this article, we present some

LEAN MANUFACTURING APPROACH IN AIRCRAFT MAINTENANCE

12 Essential Lean Six Sigma concepts and tools Lean six sigma is the combination of two different concepts, combined together to form a powerful tool to improve business processes . Tags: Lean tools SMED OEE takt time 5 Whys One piece flow Lean manufacturing PDCA A3 problem solving Cellular Manufacturing standardized work pull system Kanban mistake proofing poka yoke Heijunka Total …

Study of the Application of Lean Manufacturing Techniques

Lean Manufacturing Tools Techniques and How to Use Them

Site Implementation and Assessment of Lean Construction Techniques O. Salem1, J. Solomon2, A. Genaidy3, and M. Luegring4 Abstract The goal of this paper is to test the effectiveness of some lean construction tools, in particular, those tools that can be applied in medium size construction firms. Due to the success of the lean production system in manufacturing, the construction industry has

Lean Manufacturing Tools Techniques Powerful Lean

Lean Manufacturing Tools Lean Manufacturing Tools

Lean techniques and tools, object of study. The questionnaire was applied in the sample, enquiring each item of analysis; subsequently, it was tabulated and …

Research Paper IMPACTS OF LEAN TOOLS AND TECHNIQUES FOR

Lean Manufacturing Tools Techniques and How to Use Them

Classification scheme for lean manufacturing tools

Implementation of Lean Manufacturing _____ (Title) Management Technology Jim Keyes May, 2004 65 the importance of practicing lean techniques. However, few organizations apply lean techniques with the necessary knowledge and proven tools to achieve it. A value stream includes all the operations and processes to transform raw materials into finished goods or services, including non-value

Research Paper IMPACTS OF LEAN TOOLS AND TECHNIQUES FOR

Lean Techniques for Optimizing the Supply Chain

Welcome to Lean Manufacturing Tools, this website will educate you as to the various principles of Lean Manufacturing, Its many effective tools and techniques and the people who have been instrumental in its rise.

Study of the Application of Lean Manufacturing Techniques

LEAN MANAGEMENT TECHNIQUES 10 BEST PRACTICE CHECKLISTS 2 In today’s competitive environment, we are challenged to do more with fewer resources. One of the best ways to increase effectiveness and efficiency is to adopt Lean Management techniques. All types of business — manufacturing, service, for-profit, not-for-profit, education and health — can benefit from the Lean …

Lean Manufacturing Tools Techniques and How to Use

Lean Manufacturing Tools Techniques Powerful Lean

Lean Manufacturing

Key tools and techniques within the ‘lean’ system, included:. Kanban—a visual signal to support flow by ‘pulling’ pro-duct through the manufacturing process as required by the customer. . 5 S’s—a visual housekeeping technique which devolved control to the shopfloor.. Visual control—a method of measuring performance at the ‘shop floor’ which was visual and owned by the

Lean Manufacturing Tools Techniques and How to Use

A Review on Lean Manufacturing Implementation Techniques

Lean Manufacturing

A literature review on implementation of Lean Manufacturing Techniques Mehul Mayatra1, Mr. N.D. Chauhan2, Lean manufacturing is flexible manufacturing techniques. And reduce the 50% of human efforts. Lean manufacturing tools: There are various type of lean tools are available and use this tools and principal, like cellular manufacturing, JIT, continuous improvement, production …

Cycle Time Reduction using Lean Principles and Techniques

Classification scheme for lean manufacturing tools

Lean Manufacturing Tools Techniques and How to Use Them

Comments are closed.