Manufacturing automation protocol in cim pdf

1.2.1 Nature and Role of the Elements of CIM System 5 1.2.2 CIM Wheel 7 1.2.3 Concept or Technology? 8 1.3 Evolution of CIM 8 1.3.1 Development of Numerical Control 9 1.3.2 Emergence of Computers 9 1.3.3 Computer-Aided Design 9 1.3.4 Computer-Aided Manufacturing (CAM) 10 1.3.5 From CAD and CAM to CAD/CAM 10 1.3.6 CASA/SME CIM Wheel (Background) 10 1.4 Manufacturing Automation Protocol …

me 1403 computer intergrated manufacturing kings college of engineering department of mechanical engineering question bank subject code/name: me1403-computer integrated manufacturing year/sem: iv/vii unit-i (introduction) part-a (2 marks) 1.

Computer Integrated Manufacturing – CIM, is an organizational concept of production systems representing automated manufacturing system based on a network computer control manufacturing machines, robots and devices for quality control.

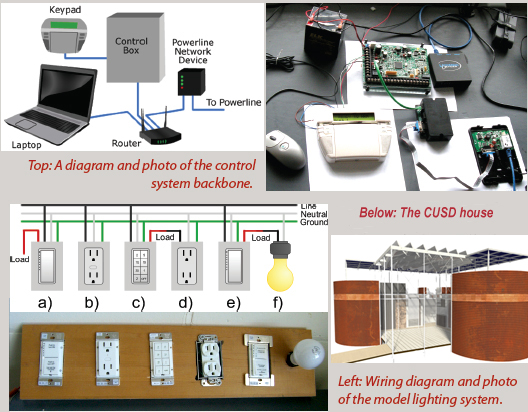

A substation automation project starts from the definition of the single line diagram (SLD), defining the power equipment and topology of the substation. SCL (Substation Configuration Language), defined by IEC 61850, allow the

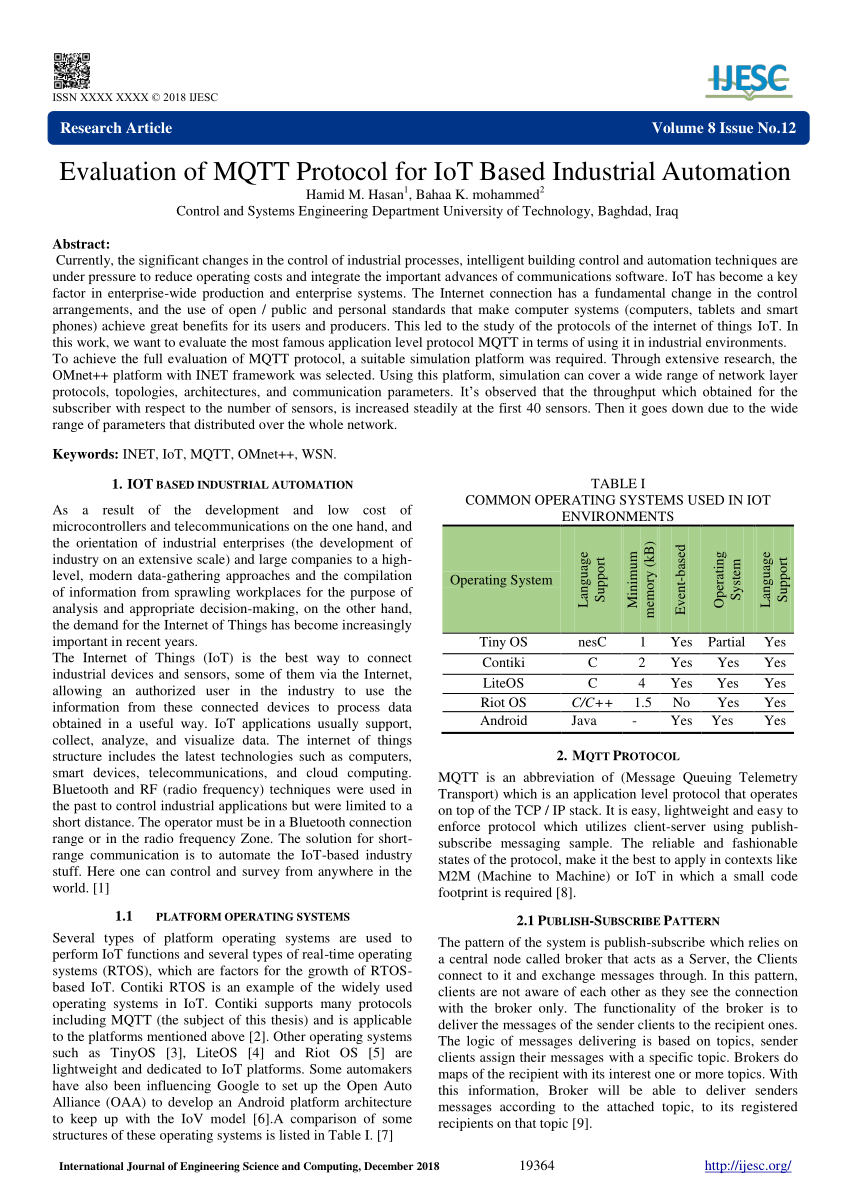

Manufacturing Automation Protocol is an OSI Profile for Manufacturing Environments based on ISO International Standards TOP • Technical and Office Protocol is an OSI Profile for Engineering and Office Environments based on ISO International Standards MAP / TOP MILESTONES

What is manufacturing automation Protocol? 9. 4. 3. Explain the functions of production planning and control. What is meant by CIM? 2. 5. 5. (4) How various parts are classified into different part families? (12) 3. What are the types of Physical distribution channels? Part B 1. Define Part families. What is meant by Parts classification and coding system? Give examples for coding systems and

Two communication protocols, namely, Manufacturing Automation Protocol (MAP) [2] and Technical and Office Protocols (TOP) [3], have emerged as a standard approach to enable easy and effective communication between the elements in CIM environments.

An integrated manufacturing network management framework by using mobile agent Received: 14 June 2005 / Accepted: 2 December 2005 / Published online: 22 March 2006 # Springer-Verlag London Limited 2006 Abstract The growth in the development of distributed manufacturing systems necessitates increases in efficient technologies in order to facilitate management of the networked …

Automation improves all aspects of manufacturing. CAD is extremely important in CIM (Computer-Integrated Manufacturing), therefore your CAD graphics have to be perfectly accurate. Manufacturing technologies are rapidly changing.

Computer integrated manufacturing(CIM) is a broad term covering all technologies and soft automation used to manage the resources for cost effective production of tangible goods.

Manufacturing automation protocol (MAP) These are grouped under the headings of customer support, product/process and manufacturing. CIM architecture. CIM ARCHITECTURE. CIM Architecture Overview. To develop a comprehensive CIM strategy and solutions, an enterprise must begin. with .solid foundations such as CIM architecture. A CIM architecture is an information . …

when he worked for a manufacturing automation software company. Whenever we talk about computer integrated manufacturing (CIM), he tells us of the time he drove up to visit an Anheuser Busch plant, an enormous structure probably three hundred feet wide and perhaps four stories high. They strolled up to a small control room a short walk away from the facility. There, on a desk, was a PC

Hewlett-Packard Journal, v41, no.n4, 1990 August, p6(5) (ISSN: 0018-1153) HP’s Manufacturing Automation Protocol (MAP) 3.0 products deliver the services specified in the computer-integrated manufacturing (CIM) specifications initiated by General Motors Corp and intended to allow manufacturing

B.Tech. (Mechanical Engineering) Semester VI Syllabus

Manufacturing Automation Protocol Expert for Consulting

Definition: Manufacturing Automation Protocol – A communications protocol introduced by General Motors in 1982 to provide common standards for the interconnection of computers and programmable machine tools used in factory automation.

m.tech computer integrated manufacturing (cim) curriculum & syllabus 2013 – 2014 faculty of engineering and technology srm university srm nagar, kattankulathur – 603 203

Explain briefly the seven layers of Manufacturing Automation Protocol – MAP. 6. Explain the elements of NC, CNC and DNC machines with neat sketch. 7. Explain and compare the various Computer network Topologies. 8. Explain the integrated CAD/CAM organization. 9. Discuss about the Network Topologies used in CIM Systems. 10. Describe the CIM Hardware and Software in detail. 11. Explain the CIM

topologies -Manufacturing automation protocol. The planning function -Types of CAPP – The planning function -Types of CAPP – retrieval and generative type CAPP -Programming & NC Machines …

Zusammenfassung. Die Einführung flexibler Fertigungsverfahren setzt die Komrnunikationsfähigkeit der in der Fertigung installierten Automatisierungseinrichtungen voraus.

DOWNLOAD NOW » Automation, Production Systems, and Computer-Integrated Manufacturing is appropriate for advanced undergraduate/ graduate-level courses in Automation, Production Systems, and Computer-Integrated Manufacturing.

ME1403 – COMPUTER INTEGRATED MANUFACTURING. IV year Mechanical Engg. Notes on Lesson UNIT – I : INTRODUCTION Introduction Computer integrated manufacturing(CIM) is a broad term covering all technologies and soft automation used to manage the resources for cost effective production of tangible goods.

CIM is the integration of the total manufacturing enterprise through the use of integrated systems and data communications coupled with new managerial philosophies that improve organizational and personnel efficiency.

A communications protocol developed in 1982 by General Motors to provide a set of common standards for the interconnection of computers and programmable manufacturing tools.

External communication, Islands of automation and software. Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production planning,

The CIM concept is a combination of all production‐related activities to be completely integrated by means of computer‐supported systems. Provides an overview of the various objectives and uses of CIM in manufacturing industry.

Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production planning, Plant operations, Physical distribution, Business and financial management.

Software and Computer Integrated Manufacturing Howard M. Bloom Abstract This paper outlines present and future directions for software in a Computer Integrated Manufacturing (CIM) environment. The three major CIM components — production management, data management, and communications management — are described in terms of software available today and future software based on …

Computer Integrated Manufacturing (CIM) Module-I Introduction: The meaning and origin of CIM, The changing manufacturing and management scenario, External communication, Islands of automation and software, Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production

The meaning and origin of CIM- the changing manufacturing and management scene – External communication – islands of automation and software-dedicated and open systems-manufacturing automation protocol – product related activities of a company- marketing engineering –

4/08/2018 · Introduction: The meaning and origin of CIM, The changing manufacturing and management scenario, External communication, Islands of automation and software, Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production planning, Plant operations, Physical distribution, Business and …

CIM – Mechanical Aspects: State of the Art Report contains different points of view about computer-integrated manufacturing (CIM). This report is organized …

Chi-Yu Huang . Kai Cheng . Alan Holt An integrated

substation automation protocols were designed. IEC61850is a part of the InternationalElectro-technicalCommission (IEC)TechnicalCommittee57 (tC57) architecture for electric power systems. It is an important international standard for substation automation, and it is having a significant impact on how electric power systems are designed and built for the future. The model-driven approach of

Automation and Integration in Semiconductor Manufacturing 39 Automation and Integration in Semiconductor Manufacturing Da-Yin Liao x Automation and Integration in

Automation manufacturing systems, composed by highly productive and dedicated machines, characteristic of the period between the end of World War II and the eighties the golden period( ) are not suitable for today’s manufacturing platforms.

Application Program Interface Presentation Session Manufacture Message Specification Strategic Business Unit Application Layer Protocol These keywords were added by machine and not by the authors. This process is experimental and the keywords may be …

Integrated application of real-time expert systems for FMS evaluation and control G.L. Kovacs, I. Mezgar, S. Kopacsi, D. Gavalcova & J. Nacsa CIM Research Laboratory, Computer and Automation Institute, Hungarian Academy of Sciences, Budapest, H-llll Kende u. 13-17, Hungary ABSTRACT The paper describes some applications of expert systems (ES) for flexible manufacturing systems …

The international standard MMS (Manufacturing Message Specification) is an OSI applica-tion layer messaging protocol origionally designed for the remote control and monitoring of

Biren Prasad Converting computer-integrated manufacturing into an intelligent information system by combining CIM with concurrent engineering and knowledge management

Performance Management of Integrated Manufacturing System Networks 271 2 presents the main theme ofthe proposed perfor mance management procedure including the con

O Manufacturing Automation Protocol (MAP) O Computer-aided an Acquisitiod n Logistic Support (CALS) O Computer Integrated Manufacturing Open Systems Architectur (the e ESPRIT project CIM-OSA). The architecture wil al defin con e sistent set o interfacef tso the various hardware and software resources used in industry, and a consistent metho fodr defining, managing and controlling CIM data – additive manufacturing technology applications and research needs Computer Integrated Manufacturing (CIM) Module-I Introduction: The meaning and origin of CIM, The changing manufacturing and management scenario, External communication, Islands of automation and software, Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production planning, Plant operations, Physical …

29/03/2016 · The meaning and origin of CIM- the changing manufacturing and management scene – External communication – islands of automation and software-dedicated and open systems-manufacturing automation protocol – product related activities of a company- marketing engineering – production planning – plant operations – physical distribution- business and financial management.

CIM (computer integrated manufacturing) is an acronym that has become fairly well known in recent years in manufacturing and related engineering circles. The purpose of the CIM Project at IIASA is to close the widening gap between the pace of technological, economic, and social events, on the one hand, and the progress of understanding those events, on the other.

(Manufacturing Automation Protocol) system, developed by General Motors [7], as a first start in this direction. Although their system is designed to link systems such as AGV’s,

UNIT-I Two Marks Questions and Answers 2. What are the

Integrated application of real-time expert G.L. Kovacs I

NOORUL ISLAM UNIVERSITY KUMARACOIL M.E. COMPUTER

CIM – Mechanical Aspects 1st Edition

The MAP report manufacturing automation protocol (Book

Performance Measurements in a Manufacturing Communication

Performance management of integrated manufacturing system

CIM Documents – SlidesDocument Research and Share

– MANUFACTURING AUTOMATION PROTOCOL Springer

COMPUTER INTEGRATED MANUFACTURING kanchiuniv.ac.in

Note for Computer Integrated Manufacuring CIM By Bput

The Role of Technical Graphics in Production Automation

30 replies on “Manufacturing automation protocol in cim pdf”

Leave a Comment(Manufacturing Automation Protocol) system, developed by General Motors [7], as a first start in this direction. Although their system is designed to link systems such as AGV’s,

ICT standards for smart grids IEC 61850 CIM and their

UNIT-I Two Marks Questions and Answers 2. What are the

Software and Computer Integrated Manufacturing Howard M. Bloom Abstract This paper outlines present and future directions for software in a Computer Integrated Manufacturing (CIM) environment. The three major CIM components — production management, data management, and communications management — are described in terms of software available today and future software based on …

M.Tech (CIM) Curriculum & Syllabus 2013 – 2014

Converting computer-integrated manufacturing into an

Application Program Interface Presentation Session Manufacture Message Specification Strategic Business Unit Application Layer Protocol These keywords were added by machine and not by the authors. This process is experimental and the keywords may be …

CIM JDF JMF Putting It All Together Idealliance

ICT standards for smart grids IEC 61850 CIM and their

(PDF) Computer Integrated Manufacturing in the Chemical

The CIM concept is a combination of all production‐related activities to be completely integrated by means of computer‐supported systems. Provides an overview of the various objectives and uses of CIM in manufacturing industry.

NOORUL ISLAM UNIVERSITY KUMARACOIL M.E. COMPUTER

HP Manufacturing Automation Protocol 3.0. Version details

me 1403 computer intergrated manufacturing kings college of engineering department of mechanical engineering question bank subject code/name: me1403-computer integrated manufacturing year/sem: iv/vii unit-i (introduction) part-a (2 marks) 1.

Computer integrated Manufacturing Industries

IMPLEMENTATION OF COMPUTER INTERGRATED

Note for Computer Integrated Manufacuring CIM By Bput

Automation improves all aspects of manufacturing. CAD is extremely important in CIM (Computer-Integrated Manufacturing), therefore your CAD graphics have to be perfectly accurate. Manufacturing technologies are rapidly changing.

ME2402 & Computer Integrated Manufacturing Unit 1 Two

Manufacturing Automation Protocol SpringerLink

Computer Integrated Manufacturing (CIM) KopyKitab

CIM is the integration of the total manufacturing enterprise through the use of integrated systems and data communications coupled with new managerial philosophies that improve organizational and personnel efficiency.

COMPUTER INTEGRATED MANUFACTURING KopyKitab

ME2402 & Computer Integrated Manufacturing Unit 1 Two

Software and Computer Integrated Manufacturing Howard M. Bloom Abstract This paper outlines present and future directions for software in a Computer Integrated Manufacturing (CIM) environment. The three major CIM components — production management, data management, and communications management — are described in terms of software available today and future software based on …

Chi-Yu Huang . Kai Cheng . Alan Holt An integrated

Computer integrated manufacturing(CIM) is a broad term covering all technologies and soft automation used to manage the resources for cost effective production of tangible goods.

MANUFACTURING AUTOMATION PROTOCOL Springer

IMPLEMENTATION OF COMPUTER INTERGRATED

Note for Computer Integrated Manufacuring CIM By Bput

The CIM concept is a combination of all production‐related activities to be completely integrated by means of computer‐supported systems. Provides an overview of the various objectives and uses of CIM in manufacturing industry.

CIM Notes Automation Computer Aided Design

Performance Measurements in a Manufacturing Communication

The international standard MMS (Manufacturing Message Specification) is an OSI applica-tion layer messaging protocol origionally designed for the remote control and monitoring of

Performance management of integrated manufacturing system

ICT standards for smart grids IEC 61850 CIM and their

Manufacturing Automation Protocol is an OSI Profile for Manufacturing Environments based on ISO International Standards TOP • Technical and Office Protocol is an OSI Profile for Engineering and Office Environments based on ISO International Standards MAP / TOP MILESTONES

Converting computer-integrated manufacturing into an

Performance Management of Integrated Manufacturing System Networks 271 2 presents the main theme ofthe proposed perfor mance management procedure including the con

Automation and Integration in Semiconductor Manufacturing

Explain briefly the seven layers of Manufacturing Automation Protocol – MAP. 6. Explain the elements of NC, CNC and DNC machines with neat sketch. 7. Explain and compare the various Computer network Topologies. 8. Explain the integrated CAD/CAM organization. 9. Discuss about the Network Topologies used in CIM Systems. 10. Describe the CIM Hardware and Software in detail. 11. Explain the CIM

Computer integrated manufacturing a dream becoming a

Computer integrated Manufacturing Industries

The Role of Technical Graphics in Production Automation

Definition: Manufacturing Automation Protocol – A communications protocol introduced by General Motors in 1982 to provide common standards for the interconnection of computers and programmable machine tools used in factory automation.

Manufacturing Automation Protocol PrintWiki

§ 1 What is Industrial Automation? paginas.fe.up.pt

Manufacturing automation protocol (MAP) These are grouped under the headings of customer support, product/process and manufacturing. CIM architecture. CIM ARCHITECTURE. CIM Architecture Overview. To develop a comprehensive CIM strategy and solutions, an enterprise must begin. with .solid foundations such as CIM architecture. A CIM architecture is an information . …

NOORUL ISLAM UNIVERSITY KUMARACOIL M.E. COMPUTER

SCAD ENGINEERING COLLEGE scadec.ac.in

Manufacturing Automation Protocol SpringerLink

Zusammenfassung. Die Einführung flexibler Fertigungsverfahren setzt die Komrnunikationsfähigkeit der in der Fertigung installierten Automatisierungseinrichtungen voraus.

Computer Integrated Manufacturing PDF VSSUT CIM PDF

ICT standards for smart grids IEC 61850 CIM and their

[PDF] Computer Integrated Manufacturing Notes eBook

What is manufacturing automation Protocol? 9. 4. 3. Explain the functions of production planning and control. What is meant by CIM? 2. 5. 5. (4) How various parts are classified into different part families? (12) 3. What are the types of Physical distribution channels? Part B 1. Define Part families. What is meant by Parts classification and coding system? Give examples for coding systems and

M.Tech (CIM) Curriculum & Syllabus 2013 – 2014

Manufacturing Automation Protocol Expert for Consulting

MANUFACTURING AUTOMATION PROTOCOL Springer

Computer Integrated Manufacturing – CIM, is an organizational concept of production systems representing automated manufacturing system based on a network computer control manufacturing machines, robots and devices for quality control.

Converting computer-integrated manufacturing into an

ME2402 & Computer Integrated Manufacturing Unit 1 Two

An integrated manufacturing network management framework by using mobile agent Received: 14 June 2005 / Accepted: 2 December 2005 / Published online: 22 March 2006 # Springer-Verlag London Limited 2006 Abstract The growth in the development of distributed manufacturing systems necessitates increases in efficient technologies in order to facilitate management of the networked …

SCAD ENGINEERING COLLEGE scadec.ac.in

Biren Prasad Converting computer-integrated manufacturing into an intelligent information system by combining CIM with concurrent engineering and knowledge management

ICT standards for smart grids IEC 61850 CIM and their

CIM JDF JMF Putting It All Together Idealliance

Computer integrated Manufacturing Industries

Integrated application of real-time expert systems for FMS evaluation and control G.L. Kovacs, I. Mezgar, S. Kopacsi, D. Gavalcova & J. Nacsa CIM Research Laboratory, Computer and Automation Institute, Hungarian Academy of Sciences, Budapest, H-llll Kende u. 13-17, Hungary ABSTRACT The paper describes some applications of expert systems (ES) for flexible manufacturing systems …

Manufacturing Automation Protocol SpringerLink

Automation and Integration in Semiconductor Manufacturing

ICT standards for smart grids IEC 61850 CIM and their

Explain briefly the seven layers of Manufacturing Automation Protocol – MAP. 6. Explain the elements of NC, CNC and DNC machines with neat sketch. 7. Explain and compare the various Computer network Topologies. 8. Explain the integrated CAD/CAM organization. 9. Discuss about the Network Topologies used in CIM Systems. 10. Describe the CIM Hardware and Software in detail. 11. Explain the CIM

(PDF) Computer Integrated Manufacturing in the Chemical

COMPUTER INTEGRATED MANUFACTURING kanchiuniv.ac.in

Automation and Integration in Semiconductor Manufacturing 39 Automation and Integration in Semiconductor Manufacturing Da-Yin Liao x Automation and Integration in

Cim Osi Model Automation

ME2402 & Computer Integrated Manufacturing Unit 1 Two

4/08/2018 · Introduction: The meaning and origin of CIM, The changing manufacturing and management scenario, External communication, Islands of automation and software, Dedicated and open systems, Manufacturing automation protocol, Product related activities of a company, Marketing engineering, Production planning, Plant operations, Physical distribution, Business and …

Performance management of integrated manufacturing system

Integrated application of real-time expert G.L. Kovacs I

Manufacturing automation protocol (MAP) These are grouped under the headings of customer support, product/process and manufacturing. CIM architecture. CIM ARCHITECTURE. CIM Architecture Overview. To develop a comprehensive CIM strategy and solutions, an enterprise must begin. with .solid foundations such as CIM architecture. A CIM architecture is an information . …

SCAD ENGINEERING COLLEGE scadec.ac.in

Application Program Interface Presentation Session Manufacture Message Specification Strategic Business Unit Application Layer Protocol These keywords were added by machine and not by the authors. This process is experimental and the keywords may be …

ICT standards for smart grids IEC 61850 CIM and their

CIM Notes Automation Computer Aided Design

What is manufacturing automation Protocol? 9. 4. 3. Explain the functions of production planning and control. What is meant by CIM? 2. 5. 5. (4) How various parts are classified into different part families? (12) 3. What are the types of Physical distribution channels? Part B 1. Define Part families. What is meant by Parts classification and coding system? Give examples for coding systems and

Manufacturing Automation Protocol SpringerLink

Cim Osi Model Automation

M.Tech (CIM) Curriculum & Syllabus 2013 – 2014

CIM (computer integrated manufacturing) is an acronym that has become fairly well known in recent years in manufacturing and related engineering circles. The purpose of the CIM Project at IIASA is to close the widening gap between the pace of technological, economic, and social events, on the one hand, and the progress of understanding those events, on the other.

CIM Notes Automation Computer Aided Design

Two communication protocols, namely, Manufacturing Automation Protocol (MAP) [2] and Technical and Office Protocols (TOP) [3], have emerged as a standard approach to enable easy and effective communication between the elements in CIM environments.

Manufacturing Automation Protocol Expert for Consulting

The MAP report manufacturing automation protocol (Book

COMPUTER INTEGRATED MANUFACTURING kanchiuniv.ac.in

Comments are closed.