Manufacturing data systems data flow pdf

manufacturing, Flow Sciences’ units perform. With surrogate powder testing both in our facility as With surrogate powder testing both in our facility as factory acceptance testing and at the customer facility as site acceptance testing, Flow Sciences

A Macro Actor/Token Implementation of Production Systems on a Data-flow Multiprocessor+ Andrew Sohn and Jean-Luc Gaudiot Department of Electrical Engineering – Systems

IN NON-AUTOMATED PRODUCTION SYSTEMS 6.1 INTRODUCTION In a competitive and globalized economy, data acquisition from production systems is becoming a more important issue because it is a means to improve the company’s performance through the integration of the business and manufacturing company layers. The management of the company should obtain updated …

manufacturing information and data systems analysis design and practice franjo cecelja.pdf download at 2shared. Click on document manufacturing information and data systems analysis design and practice franjo cecelja.pdf to start downloading. 2shared – Online file upload – unlimited free web space.

Smart manufacturing and advanced data analytics can help the manufacturing sector unlock energy efficiency from the equipment level to the entire manufacturing facility and the whole supply chain.

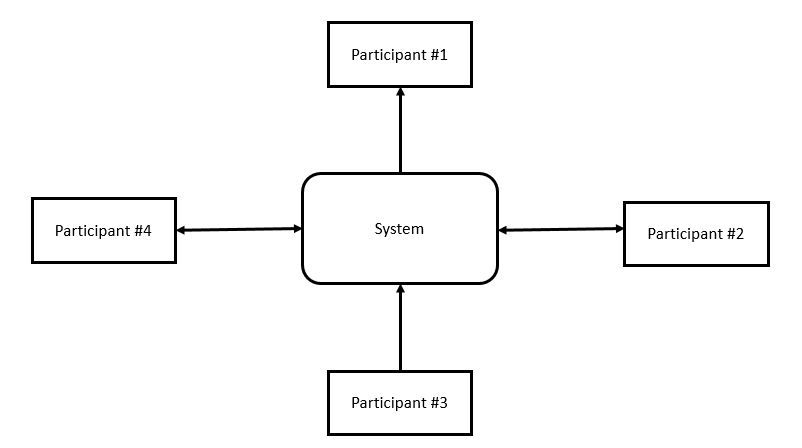

Collaborative manufacturing and real-time data collection and analysis are of great interest in the emerging CPS field. The overall purpose of the data flow system architecture presented below is to enable collaborative analysis and optimization by making manufacturing process data from different machine tools widely available.

FDA Perspective on Continuous Manufacturing IFPAC Annual Meeting Baltimore, January , 2012 . Sharmista Chatterjee, Ph.D. CMC Lead for QbD . ONDQA/CDER/FDA. 2 Pharmaceutical Manufacturing: The Path

The Cybersecurity for Smart Manufacturing Systems (CSMS) Testbed emulates real-world manufacturing processes and their industrial control systems by using software simulators and commercial control hardware in the laboratory environment.

In the Oracle Manufacturing Cloud, engineers can quickly define the necessary data for and process standards, working calendars, work areas, work centers resources, calendars and standard operations.

demonstrated by an example of event data from the simulation model of an automated material handling system (MHS) in a manufacturing company. The purpose of the analysis is the identification of design and operation problems and their causes, prospectively. As a result, the simulation model developer obtains the condensed and ranked information on events. These events describe the internal

consuming and intricate process, especially when multiple data types and data sources such as bills of materials, shop floor photographs, drawings, 3D CAD, health and safety, tooling, and engineering changes are involved.

As the manufacturing industry shifts its focus from process efficiencies to superior customer service, finding new ways to deliver innovative products and services is imperative. But can you support new business models with traditional business systems and processes? Download the new report from Aberdeen to uncover the answer.

Oracle Manufacturing Cloud Data Sheet

MANUFACTURING RESEARCH SOLUTIONS labrepco.com

legacy system to a new information system, or when multiple data sources are to be integrated. As shown in Fig. 2 we roughly distinguish between single-source and multi-source problems and between schema- and instance-related problems.

Figure 3.4 Data integration models by the Systems Development Life Cycle Structuring Models on the Reference Architecture Structuring data models to a Systems Development Life Cycle is …

The software also implements Poe’s analysis of production data from fractured wells, converting production data into a constant pressure solution using superposition time for fracture flow regimes from which fracture properties can be inferred (Poe, 1995). Poe’s technique and the analysis of other plots serve to calibrate each other.

flow accounting which improves the data quality of the existing IT-systems and makes quality and value of material flows more transparent. A realtime and A.1 OVERVIEW OF FLOW MANAGEMENT Figure 1: Overview of Flow Management. 5 activity-orientated material reporting focuses on the reduction of material costs as an alterative to one-sided personnel cuts.There is no question about the fact that

Modeling of Traceability Information System for Material Flow Control Data 11M.R. Khabbazi, M.D. Yusof Ismail, 1N. Ismail, 2S.A. Mousavi 1Department mechanical and manufacturing, faculty engineering, UPM, Malaysia; 2Department electrical and electronics, faculty engineering, UPM, Malaysia Abstra ct: This paper focuses on data modeling for traceability of material/work flow in information …

connected to Data Collection System. Many companies, in fact, used a data collection Many companies, in fact, used a data collection system belonging to CIM Model 1 for an integrated manufacturing model.

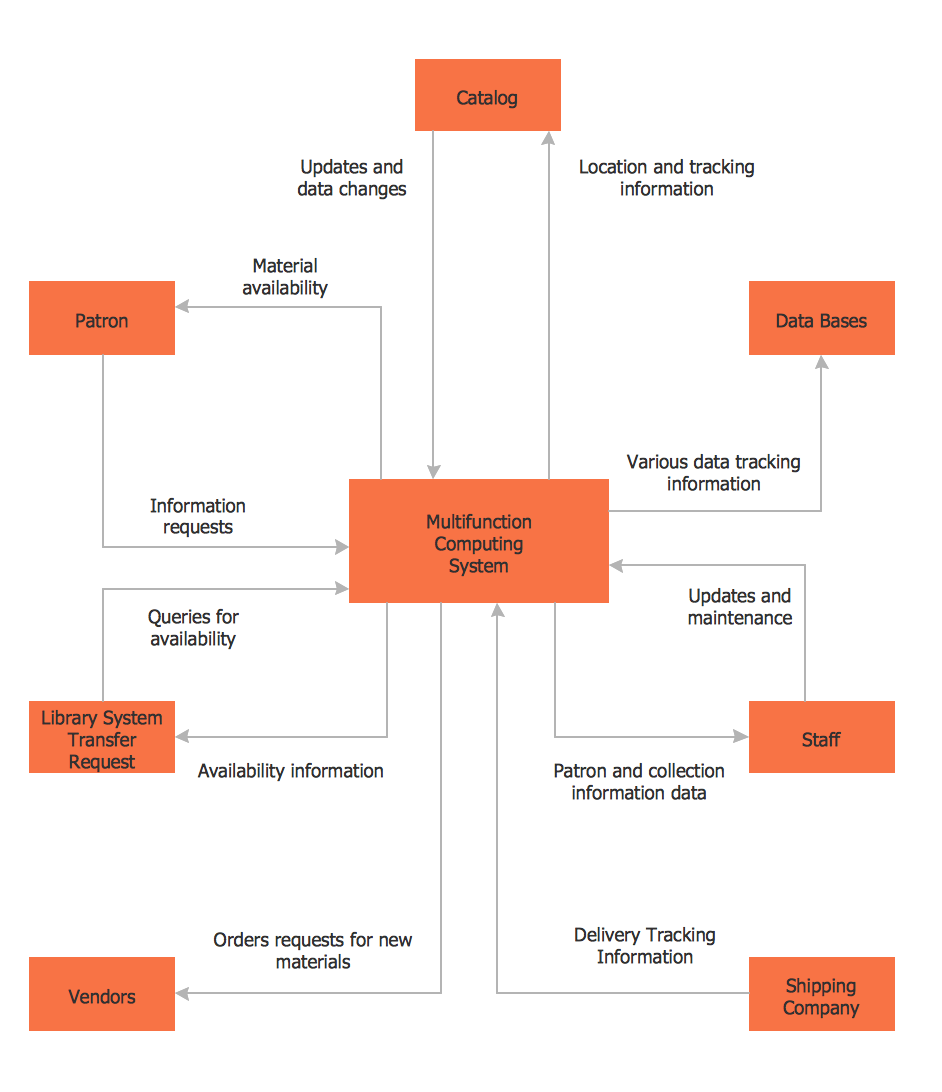

Data flow maps are a recognized method of tracing the flow of data through a process or physically through a network. For instance, beginning with version 3.0, Payment Card Industry Digital

Data Flow Diagram for Inventory Management System PDF. Find Information and Other Software to Define Your Requirements, In Relation To Data Flow Diagram for Inventory Management System PDF. The Five Sure-fire Strategies for Gaining Management Approval for WMS Projects Despite the consensus that warehouse management systems (WMS) offer many benefits, getting approval for a new system …

These flowcharts help to understand the flow of data thru and ERP system for small to mid size manufacturing and distribution companies.

IoT can share this data with systems and with people. (For more information on the definition of IoT read Part 1 of the series “The IoT Primer”). In the case of manufacturing, high value production equipment has been heavily instrumented for some time in a closed, hard-wired network environment. Industrial standard sensors, controllers and networks are expensive and upgrade projects in

ever more sophisticated data-gathering and analytics capabilities enabled by the Internet of Things (IoT) have led to a shift toward an information-based economy. With the IoT, data, in addition to physical objects, are a source of value—and connectivity makes it possible to build smarter supply chains, manufacturing processes, and even end-to-end ecosystems.3 As these waves of change

Software Design Methodologies data flow model As complex computer systems influence every facet of our lives – the cars we drive, the airplane and trains we rely on others to drive for us, and even everyday machinery such as domestic washing machines, the need for reliable and dependable software systems has become apparent. Developing a complex computer system follows a development

database systems or global web-based information systems, the need for data cleaning increases significantly. This is because the sources often contain redundant data in different representations.

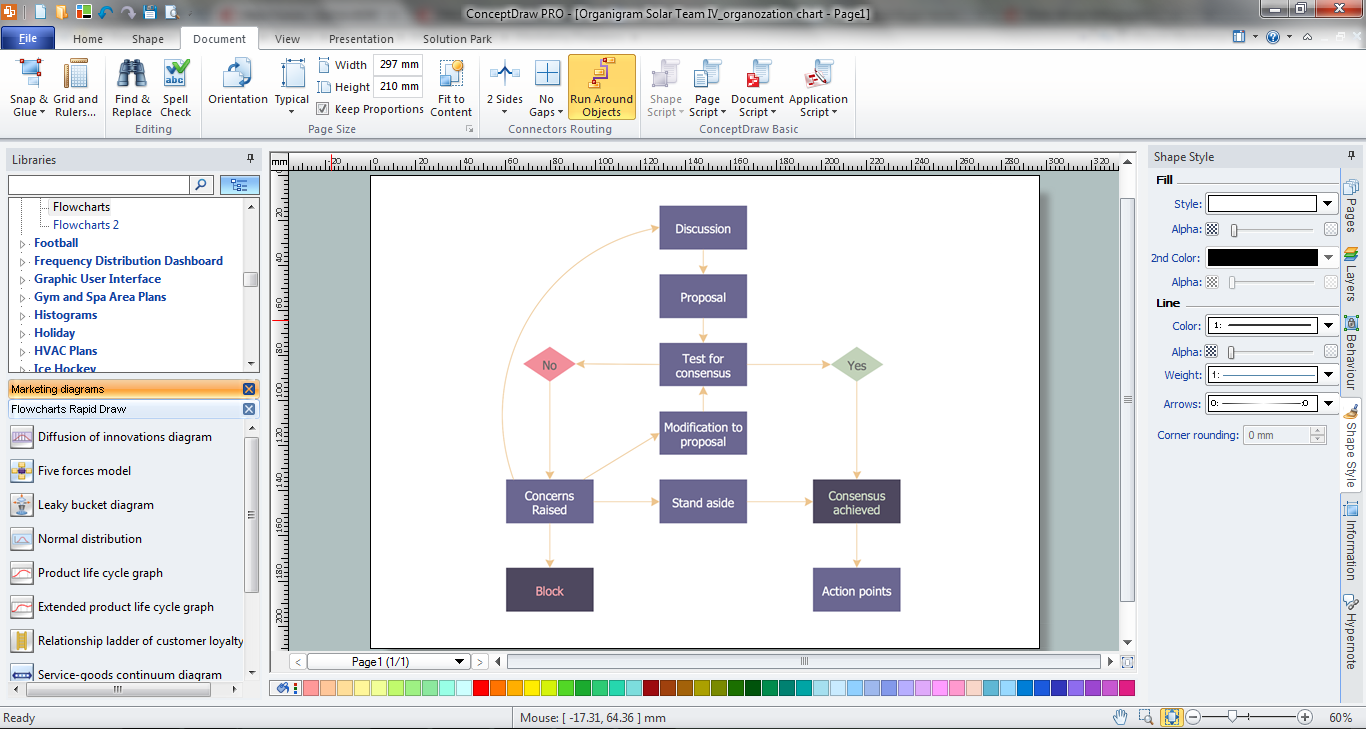

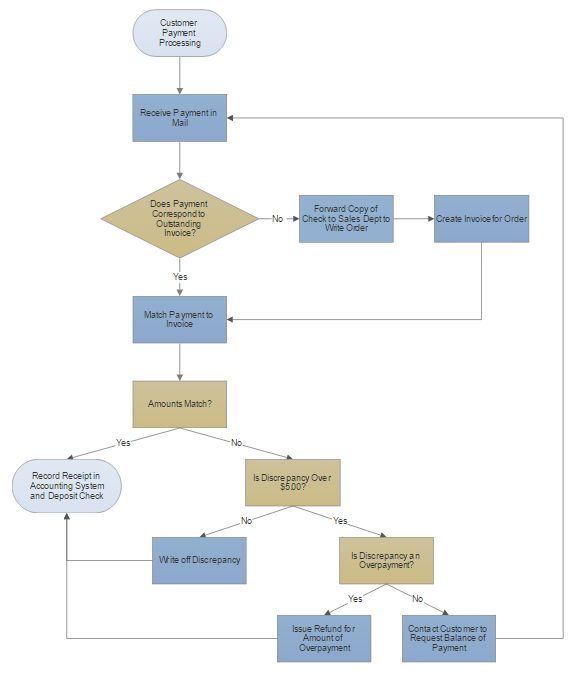

Data Flowcharts – shows controls over data-flow in a system System Flowcharts – displays controls involved at the resource or physical level. A flow chart of a …

The new Program Smart Manufacturing Systems Design and Analysis • Objective: The objective is to deliver measurement science, standards and protocols, and tools needed to predict, assess,

This enables critical information to flow throughout the organization—including the once-forgotten areas of manufacturing. Collecting data from the shop floor and transacting in real time to other enterprise systems thereby replacing unnecessary and error-prone manual data entry systems. Having information about events as they occur allows planning departments to identify and prevent

Manufacturing System that maximizes the flow and re-use of data throughout the enterpriseThe ability of . disparate systems, however, to exchange, understand, and exploit product, production, and business data rests

Data flow is a flow of information from one data holder to another. A data holder is a register, memory location, or even a A data holder is a register, memory location, or even a signal and therefore a variable, file, paper, and so on.

manufacturing system using real-world industrial hardware devices, while the chemical manufacturing process is simulated in software. This system employs a modular design which allows a greater flexibility for re-configuration and

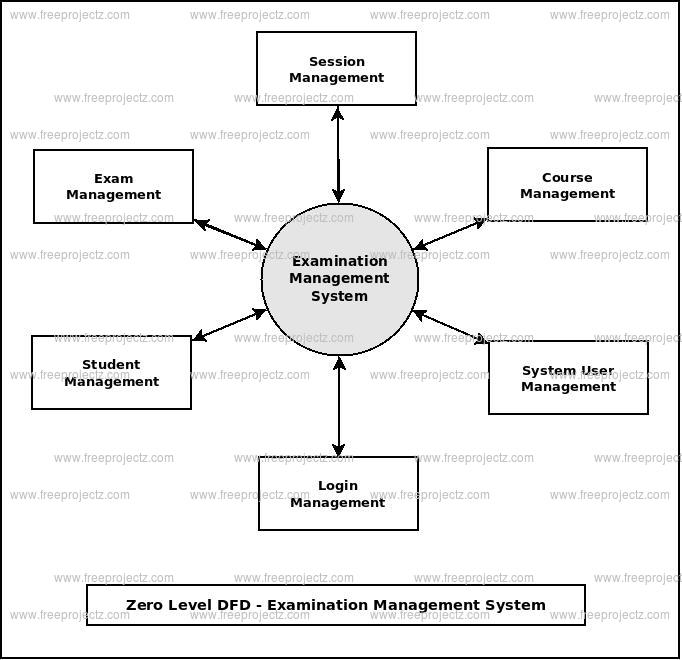

through systems (and how that data is transformed in the process), data flow diagrams (DFDs) are the method of choice over technical descriptions for three principal reasons. 1. DFDs are easier to understand by technical and nontechnical audiences 2. DFDs can provide a high level system overview, complete with boundaries and connections to other systems 3. DFDs can provide a detailed

tags coupled with readers and information systems architecture can increase visibility of operations by associating unique product identification with its current location, and by synchronising the physical flow of components/products and the related information flow

this facet provides all data related to production to the hands of management in formats that provide valuable metrics and insight into the characteristics of the production.

The applications that make up the system share data across various departments (manufacturing, purchasing, sales, accounting, etc.) that provide the data. ERP facilitates information flow between all business functions and manages connections to outside stakeholders .

Production Flow Analysis (PFA) method of grouping part into families used to analyze the operation steps and machine routes for the parts produced groups parts with similar or identical routings together these groups can be used to form logical machine cells in a GT layout uses manufacturing data rather than design data to make groups, so takes care of the problem of: parts whose basic

Get a head start on creating your data flow diagrams with these DFD examples and templates. Use Lucidchart for all your DFD needs! GDPR compliant. Lucidchart is dedicated to keeping your data private and secure. Learn more x. Enterprise. Solutions Back. Solutions. Engineering

Smart Manufacturing Technologies and Data Analytics for

Material and Information Flow Chart (MIFC) Mapping for Lean Manufacturing Implementation in the D55D Assembly Line 1) Nurul Hayati Binti Abdul Halim

the data collection process and streamlining the data flow to the other systems. Analyzing the Current Processes The company conducted an analysis of the entire process for tracking the time

Manufacturing Execution Systems, are coined by major short-comings considerably limiting continuous process improvement. In particular, they do not make use of data mining to identify hidden patterns in manufacturing-related data. In this article, we present indication-based and pattern-based manufacturing process optimization as novel data mining approaches provided by the Advanced

must flow freely and not cake. To ensure accuracy of the content of the product, monitoring and analysis of the manufacturing processes was required. Key Requirements Easy data retrieval Modem connectivity Fire in the hole!: Explosives being used in an open-pit mine. dataTaker dataTaker Data Logging ProductsData Logging ProductsData Logging Products 1 Cost effective data logging …

data-driven modeling (DDM) and is based on analyzing the data within a system. One of the focal points inherent in DDM is to discover connections between the system state variables (input and output) without explicit knowledge of the

tracking requirements flow through the design effort, and • Life cycle integration that involves customers in the design process and ensures that the system developed is viable throughout its life. Each one of these activities is necessary to achieve proper management of a development effort. Phas-ing has two major purposes: it controls the design effort and is the major connection between

Manufacturing Information and Data Systems Acknowledgements I am grateful to and wish to acknowledge Dr Jean-Noel Ezi…

In current cyber-physical systems, data are collected from pieces of manufacturing equipment and used to drive useful change and affect production output. The data gathered typically describe the – list of manufacturing companies in singapore pdf With the increase in data availability and sensor fusion in the manufacturing industry, the role of data analytics in the development of smart manufacturing systems has grown

flow-charting are therefore seen at the level of operations and management, in both Spatial Data Handling and Cartographic context and includes an education component. In the paper principles and symbolisation of flow chart items for digital mapping are explained and displayed.

Get a head start on creating your data flow diagrams with these DFD examples and templates. Use Lucidchart for all your DFD needs!

smart manufacturing, the Internet of Things, cyber-physical systems and digital transformation. The Industry 4.0 concept encompasses the digitalization of the horizontal and vertical value chain, innovation in products and services and the creation of new business models.

PROCESS ANALYSIS FOR MATERIAL FLOW SYSTEMS Thorsten Schmidt, David Wustmann, Robert Schmaler Technische Universität Dresden Institute of Material Handling and Industrial Engineering

Data sources. This is a list of primary data sources that are helpful for power system modeling of Europe. For other open data projects that collect or vizualize data see data projects.

Data Flow Diagram (DFD) provides a visual representation of the flow of information (i.e. data) within a system. By creating a Data Flow Diagram, you can tell the information provided by and delivered to someone who takes part in system processes, the information needed in order to complete the processes and the information needed to be stored and accessed. Data Flow Diagram is widely …

MANAGEMENT: PRODUCTION FLOW ANALYSIS I I II on functional organisation. Primary flow is based on the Pareto principle, in which 20 % of the PRCs covers 80 % of

MES & MOM Data Flow & Business Process Modeling 3 A fully integrated MOM system may also include other systems which need to be functionality and physically integrated.

PROCESS ANALYSIS FOR MATERIAL FLOW SYSTEMS

ERP flow charts ERP123 A Better Approach to ERP

Production Flow Analysis (PFA)

About Manufacturing Execution Systems uni-ruse.bg

Data Flow Diagram for Inventory Management System PDF

16 Data Flow Diagrams – I – YouTube

MANUFACTURING DATA ACQUISITION IN NON-AUTOMATED PRODUCTION

Modeling of Traceability Information System for Material

handbook of sulphuric acid manufacturing pdf – FDA Perspective on Continuous Manufacturing

MES & MOM Data Flow & Business Process Modeling I&E Systems

Material Flow Analysis MIT OpenCourseWare

manufacturing information and data systems.pdf download

MANUFACTURING DATA ACQUISITION IN NON-AUTOMATED PRODUCTION

Focus Group Big Data Analytics for Smart Manufacturing

database systems or global web-based information systems, the need for data cleaning increases significantly. This is because the sources often contain redundant data in different representations.

flow accounting which improves the data quality of the existing IT-systems and makes quality and value of material flows more transparent. A realtime and A.1 OVERVIEW OF FLOW MANAGEMENT Figure 1: Overview of Flow Management. 5 activity-orientated material reporting focuses on the reduction of material costs as an alterative to one-sided personnel cuts.There is no question about the fact that

flow-charting are therefore seen at the level of operations and management, in both Spatial Data Handling and Cartographic context and includes an education component. In the paper principles and symbolisation of flow chart items for digital mapping are explained and displayed.

Production Flow Analysis (PFA) method of grouping part into families used to analyze the operation steps and machine routes for the parts produced groups parts with similar or identical routings together these groups can be used to form logical machine cells in a GT layout uses manufacturing data rather than design data to make groups, so takes care of the problem of: parts whose basic

data-driven modeling (DDM) and is based on analyzing the data within a system. One of the focal points inherent in DDM is to discover connections between the system state variables (input and output) without explicit knowledge of the

consuming and intricate process, especially when multiple data types and data sources such as bills of materials, shop floor photographs, drawings, 3D CAD, health and safety, tooling, and engineering changes are involved.

tags coupled with readers and information systems architecture can increase visibility of operations by associating unique product identification with its current location, and by synchronising the physical flow of components/products and the related information flow

Data flow maps are a recognized method of tracing the flow of data through a process or physically through a network. For instance, beginning with version 3.0, Payment Card Industry Digital

Data flow is a flow of information from one data holder to another. A data holder is a register, memory location, or even a A data holder is a register, memory location, or even a signal and therefore a variable, file, paper, and so on.

manufacturing information and data systems analysis design and practice franjo cecelja.pdf download at 2shared. Click on document manufacturing information and data systems analysis design and practice franjo cecelja.pdf to start downloading. 2shared – Online file upload – unlimited free web space.

Software Design Methodologies data flow model As complex computer systems influence every facet of our lives – the cars we drive, the airplane and trains we rely on others to drive for us, and even everyday machinery such as domestic washing machines, the need for reliable and dependable software systems has become apparent. Developing a complex computer system follows a development

Manufacturing Execution Systems, are coined by major short-comings considerably limiting continuous process improvement. In particular, they do not make use of data mining to identify hidden patterns in manufacturing-related data. In this article, we present indication-based and pattern-based manufacturing process optimization as novel data mining approaches provided by the Advanced

connected to Data Collection System. Many companies, in fact, used a data collection Many companies, in fact, used a data collection system belonging to CIM Model 1 for an integrated manufacturing model.

24 replies on “Manufacturing data systems data flow pdf”

Leave a CommentIoT can share this data with systems and with people. (For more information on the definition of IoT read Part 1 of the series “The IoT Primer”). In the case of manufacturing, high value production equipment has been heavily instrumented for some time in a closed, hard-wired network environment. Industrial standard sensors, controllers and networks are expensive and upgrade projects in

ERP flow charts ERP123 A Better Approach to ERP

PRODUCTION FLOW ANALYSIS Lean Manufacturing

Manufacturing System that maximizes the flow and re-use of data throughout the enterpriseThe ability of . disparate systems, however, to exchange, understand, and exploit product, production, and business data rests

Are You Using Word Excel PowerPoint or PDF’s to Create

In the Oracle Manufacturing Cloud, engineers can quickly define the necessary data for and process standards, working calendars, work areas, work centers resources, calendars and standard operations.

ERP flow charts ERP123 A Better Approach to ERP

Get a head start on creating your data flow diagrams with these DFD examples and templates. Use Lucidchart for all your DFD needs!

How to Better Monitor Work Floor Performance Streamline

Data Flow Diagram for Inventory Management System PDF

flow accounting which improves the data quality of the existing IT-systems and makes quality and value of material flows more transparent. A realtime and A.1 OVERVIEW OF FLOW MANAGEMENT Figure 1: Overview of Flow Management. 5 activity-orientated material reporting focuses on the reduction of material costs as an alterative to one-sided personnel cuts.There is no question about the fact that

PRODUCTION FLOW ANALYSIS Lean Manufacturing

Data Analysis Schlumberger

consuming and intricate process, especially when multiple data types and data sources such as bills of materials, shop floor photographs, drawings, 3D CAD, health and safety, tooling, and engineering changes are involved.

PRODUCTION FLOW ANALYSIS Lean Manufacturing

With the increase in data availability and sensor fusion in the manufacturing industry, the role of data analytics in the development of smart manufacturing systems has grown

Data Flow Diagram with Examples Customer Service System

database systems or global web-based information systems, the need for data cleaning increases significantly. This is because the sources often contain redundant data in different representations.

Modeling of Traceability Information System for Material

A Macro Actor/Token Implementation of Production Systems

Are You Using Word Excel PowerPoint or PDF’s to Create

The software also implements Poe’s analysis of production data from fractured wells, converting production data into a constant pressure solution using superposition time for fracture flow regimes from which fracture properties can be inferred (Poe, 1995). Poe’s technique and the analysis of other plots serve to calibrate each other.

MANUFACTURING RESEARCH SOLUTIONS labrepco.com

consuming and intricate process, especially when multiple data types and data sources such as bills of materials, shop floor photographs, drawings, 3D CAD, health and safety, tooling, and engineering changes are involved.

Key Performance Indicators for Process Control System

manufacturing information and data systems.pdf download

Data Flowcharts – shows controls over data-flow in a system System Flowcharts – displays controls involved at the resource or physical level. A flow chart of a …

Production Flow Analysis (PFA)

manufacturing information and data systems.pdf download

Smart Manufacturing Technologies and Data Analytics for

through systems (and how that data is transformed in the process), data flow diagrams (DFDs) are the method of choice over technical descriptions for three principal reasons. 1. DFDs are easier to understand by technical and nontechnical audiences 2. DFDs can provide a high level system overview, complete with boundaries and connections to other systems 3. DFDs can provide a detailed

MANUFACTURING DATA ACQUISITION IN NON-AUTOMATED PRODUCTION

PRODUCTION FLOW ANALYSIS Lean Manufacturing

BRIDGE WP08 methodology process analysis

flow accounting which improves the data quality of the existing IT-systems and makes quality and value of material flows more transparent. A realtime and A.1 OVERVIEW OF FLOW MANAGEMENT Figure 1: Overview of Flow Management. 5 activity-orientated material reporting focuses on the reduction of material costs as an alterative to one-sided personnel cuts.There is no question about the fact that

PRODUCTION FLOW ANALYSIS Lean Manufacturing

manufacturing information and data systems.pdf download

manufacturing information and data systems analysis design and practice franjo cecelja.pdf download at 2shared. Click on document manufacturing information and data systems analysis design and practice franjo cecelja.pdf to start downloading. 2shared – Online file upload – unlimited free web space.

Smart Manufacturing Technologies and Data Analytics for

Manufacturing Execution Systems, are coined by major short-comings considerably limiting continuous process improvement. In particular, they do not make use of data mining to identify hidden patterns in manufacturing-related data. In this article, we present indication-based and pattern-based manufacturing process optimization as novel data mining approaches provided by the Advanced

Data Analysis Schlumberger

MANAGEMENT: PRODUCTION FLOW ANALYSIS I I II on functional organisation. Primary flow is based on the Pareto principle, in which 20 % of the PRCs covers 80 % of

Focus Group Big Data Analytics for Smart Manufacturing

Data Flowcharts – shows controls over data-flow in a system System Flowcharts – displays controls involved at the resource or physical level. A flow chart of a …

FDA Perspective on Continuous Manufacturing

16 Data Flow Diagrams – I – YouTube

IN NON-AUTOMATED PRODUCTION SYSTEMS 6.1 INTRODUCTION In a competitive and globalized economy, data acquisition from production systems is becoming a more important issue because it is a means to improve the company’s performance through the integration of the business and manufacturing company layers. The management of the company should obtain updated …

Modeling of Traceability Information System for Material

PROCESS ANALYSIS FOR MATERIAL FLOW SYSTEMS

MES & MOM Data Flow & Business Process Modeling I&E Systems

Figure 3.4 Data integration models by the Systems Development Life Cycle Structuring Models on the Reference Architecture Structuring data models to a Systems Development Life Cycle is …

How to keep track of sensitive data with a data flow map

Data Sources – Open Power System Data

The applications that make up the system share data across various departments (manufacturing, purchasing, sales, accounting, etc.) that provide the data. ERP facilitates information flow between all business functions and manages connections to outside stakeholders .

Production Flow Analysis (PFA)

Focus Group Big Data Analytics for Smart Manufacturing

manufacturing information and data systems.pdf download

tags coupled with readers and information systems architecture can increase visibility of operations by associating unique product identification with its current location, and by synchronising the physical flow of components/products and the related information flow

manufacturing information and data systems.pdf download

Industry 4.0 and manufacturing ecosystems Deloitte US

Data Flow Diagram with Examples Customer Service System

MES & MOM Data Flow & Business Process Modeling 3 A fully integrated MOM system may also include other systems which need to be functionality and physically integrated.

BRIDGE WP08 methodology process analysis

Key Performance Indicators for Process Control System

Data Flow Diagram for Inventory Management System PDF

As the manufacturing industry shifts its focus from process efficiencies to superior customer service, finding new ways to deliver innovative products and services is imperative. But can you support new business models with traditional business systems and processes? Download the new report from Aberdeen to uncover the answer.

Are You Using Word Excel PowerPoint or PDF’s to Create

The new Program Smart Manufacturing Systems Design and Analysis • Objective: The objective is to deliver measurement science, standards and protocols, and tools needed to predict, assess,

Material Flow Analysis MIT OpenCourseWare

Comments are closed.