Manufacturing methods of composite materials pdf

Simultaneous material consolidation and shaping, as performed in manufacturing of composite materials, causes a strong interconnection between structural and manufacturing parameters which makes the design process complicated. In this paper, the design of …

The following disclosure relates generally to composite part manufacturing and, more particularly, to apparatuses, systems, and methods for laminating fiber-reinforced resin materials on female tools.

It differs from other books on composites manufacturing in focussing almost solely on manufacturing processes, while not attempting to cover materials, test methods, mechanical properties and other areas of composites.

COMPOSITE MATERIALS PROF. R. VELMURUGAN . Lectures 11 to 18 Module II – Manufacturing Techniques . Manufacturing Techniques . There are plenty of methods to cast a composite structure whether it is simple or complex,

Composite materials are widely used in a number of industrial sectors from aviation, space, to boat building, automotive, and sports goods. In recent years composite structures have seen a substantial increase of their use in the new generation of airplanes. The nondestructive testing and inspection of composite structures, both for manufacturing quality assurance and for in-service damage

Composite material characterisation ensures that advanced composite materials meet application performance requirements for intended use in industry Composites material characterization is a vital part of the product development and production process.

Among the available materials in the market are industrial or composite materials, high-tech ceramics, reinforced plastics and nano materials that are now used in an large variety of products.

Wet lay-up is a simple method compared to other composite manufacturing methods; it allows the resin to be applied only in the mold, but the mechanical properties of the product are poor due to voids and the final product is nonuniform.

Processing Methods for Composites. For Later. save. Related. Info. Embed. Share. Print. Search. Related titles. Design and Optimization of Laminated Composite Materials. 1892_1. KM BR FiberComposites En. 0334. analysis of composite materials. Introduction to FRP. Research.proposal . The-Improvement-of-Composite-Strength-Using-Talahib-2-1.docx. Crush_Simulation.pdf. Full Text …

Composite Materials: Concurrent Engineering Approach covers different aspects of concurrent engineering approaches in the development of composite products. It is an equally valuable reference for teachers, students, and industry sectors, including information and knowledge on concurrent engineering for composites that are gathered together in one comprehensive resource.

This document summarizes the Fiber Reinforced Polymer Composite Manufacturing workshop held at the Hilton Crystal City in Arlington, VA on January 13, 2014. The workshop fostered an exchange of information on technical issues and manufacturing challenges related to achieving low-cost fiber reinforced polymer composites and impacting U.S. manufacturing competitiveness and energy …

Integrating Metamaterials within a Structural Composite using Additive Manufacturing Methods Peter Pa and Mark S. Mirotznik Electrical and Computer Engineering Dept. University of Delaware Newark, DE, USA Raymond McCauley and Shridhar Yarlagadda Center for Composite Materials University of Delaware, Newark, DE, USA Kate Duncan Antenna Technology and Analysis Branch …

number of methods: (i) Powder dispersion (ii) Liquid precursors (iii) Gaseous infiltration Comprehensive Composite Materials, Volume 4: Carbon/Carbon, Cement, and Ceramic Matrix Composites, 4.01 Matrix Materials, R. MORRELL . Composite Materials Asst. Prof. Dr. Ayşe KALEMTAŞ Processing of CMCs Powder Dispersion Impregnating the reinforcement with a suspension of matrix precursor in powder

UK produces around £1.6 billion worth of composite materials, components and structures every year, adding around £1.1 billion to UK national output. Prospects for growth are very good, with increases in demand being driven by

Plastics & Composite Materials: Forming & Shaping Text Reference:Text Reference: “Manufacturing Engineering and TechnologyManufacturing Engineering and Technology”, Kalpakjian & Schmid, 6/e, 2010 Chapter 19. Plastics • Can be molded, cast, formed, machined – In a few operationsIn a few operations – Easily – Rapidly • Can be joined • Can be coated • Can be shaped …

manufacturing specifically pertaining to composite fabrication and repair, Quality Assurance 2. methods, CNC machine operation, and non-destructive testing and inspection. Martindale’s Calculators On Composite Materials Tools Laminate Theory, Fibre Reinforced Composites, Rigorous Bonds for Composites, Structural Mechanics Diffraction Electrospinning Electrospinning is a fiber production method

Module: Composite Materials Test Methods Composite Structure Engineering Safety Awareness Course Dr. Dan Adams Director, Composite Mechanics Laboratory. University of Utah . Salt Lake City, UT 84112 (801) 585-9807 adams@mech.utah.edu. Composite Materials Test Methods. AGENDA. Constituent and Prepreg Test Methods Physical Test Methods for Composites Mechanical Test Methods …

Another method of producing materials with combination of properties is by combining materials in solid state, which is referred to as composite material. Composite material are a class of advanced material, made up of one or more materials combined in solid states with distinct physical and chemical properties. Composite material offers an excellent combination of properties which are

The following is a brief discussion of the current methods for manufacturing composite blades in order that the relation of material choice, design, and manufacturing method to fatigue life may be presented.

Fundamentals of Composites Manufacturing: Materials, Methods and Applications, Strong is the founding director of the Advanced Composite Manufacturing and Engineering (ACME) Center, the Creativity Laboratory, the Manufacturing Leadership Forum, and the Rapid Product Realization Center, all at BYU. Prior to his position at Brigham Young University, Dr. Strong had a successful career in

New Composite Design and Manufacturing Methods ofr ICAS

Processing Methods for Composites Composite Material

The results of research showed that the method of manufacturing, more precisely the pressure while forming sandwich panels, influences some mechanical properties of sandwich structured polymer composites such as flexural strength, impact strength, and compressive strength.

MANUFACTURING AND TESTING OF AN HYBRID COMPOSITE INTEGRATING VISCOELASTIC FIBERS A. Martone 1,2 *, M.Zarrelli 2, V.Antonucci 2, M. Giordano 2 1University of Naples “Federico II”- DIMP, Piazzale Tecchio 80, 80125 Naples, Italy

Describes advances, key information, case studies, and examples that can broaden your knowledge of composites materials and manufacturing methods. This text deals with composites manufacturing methods, providing tips for getting the best results that weigh the required material properties against cost and production efficiency. An Instructor’s

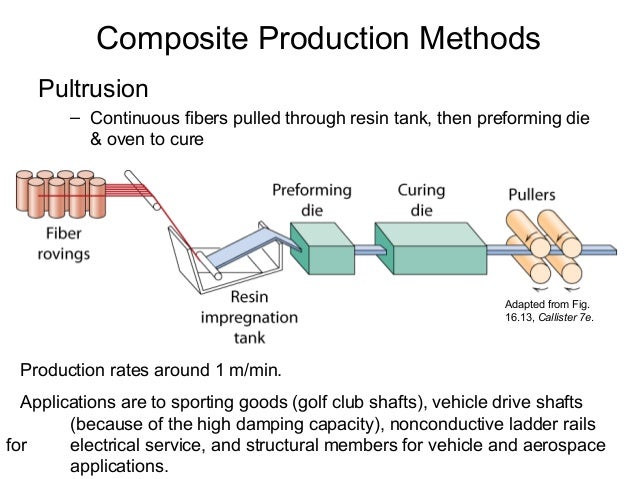

Methods of Manufacture for Composite Materials in Infrastructure Filament Winding and Pultrusion. CST Composites is a world leading filament winding and pultrusiontechnology company. The company was founded in 1995, manufacturing some of the world’s first high performance sailing masts.

original manufacturing methods. B. Toxicology of Fibers: The diseae-prodining potpntial assoriitpd witi exposure to the fiber component of composite mateiials is a function of

weight ratios, laminated composite materials have found extensive applications in the construction of mechanical, aerospace, marine, protective gear and automotive structures.

Composite Recycling and Disposal An Environmental R&D Issue Aeronautic/aerospace applications, both military and commercial, are accounting for a large share of the growing composite market in value. However, their share of the market in volume is much smaller. Costs are high when large amounts of carbon fiber reinforcements are used. These high performance composite materials have six

pdf. COMPOSITES MANUFACTURING Materials, Product, and Process Engineering. 396 Pages. COMPOSITES MANUFACTURING Materials, Product, and Process Engineering . Uploaded by. Lâm Quang Đại. Download with Google Download with Facebook or download with email. COMPOSITES MANUFACTURING Materials, Product, and Process Engineering. Download. COMPOSITES MANUFACTURING Materials, Product, and Process

of Composite Materials • Properties of many important composites are anisotropic • Many of the polymer-based composites are subject to attack by chemicals or solvents • Composite materials are generally expensive • Manufacturing methods for shaping composite materials 28 ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Prof. Singh/ GaneshSoni are often …

A method for manufacturing perforate, fibre-reinforced, composite material, comprising the steps of laying up reinforcing fibres and resin in a mould having needles, the mould including a stripper plate having perforations into which the needles pass when the mould is assembled; curing the resin; and withdrawing the composite from the mould

• Composite fabrication and assembly methods are detailed Composites consist of two distinct materials, which together improve product performance and/or lower production costs. Composite materials typically include plated, clad, or coated metals, however the term ‘composites’ has evolved to mean a material containing a matrix, or base substance, and a reinforcement material. The matrix …

Composite cord manufacturing method: Cousin, J-C, and Robin, J. A. (Cousin Freres, Wervicoq Sud, France) US Pat 4 707 977 (24 November 1987) Page 96 Download PDF

FABRICATION METHODS, MECHANICAL PROPERTIES, AND INDUSTRIAL APPLICATIONS OF METAL MATRIX COMPOSITE MATERIALS Thoguluva Raghavan Vijayaram Faculty of Manufacturing Engineering, Universiti Teknikal Malaysia Melaka, Malaysia

Composite materials have been used for lightweight components in many industries such as: aerospace, automotive, nuclear, marine, and biomedical industries.

composite) were some of the earliest tool‐making and structural materials used by humankind. Today we apply the term composites to a wide variety of

methods that have evolved to a position of prominence [9]. Material selection process is an open-ended and normally lead to several possible solutions to the same problem.

Integrating Metamaterials within a Structural Composite

– manufacturing engineering and technology solution manual

Composite Recycling and Disposal Boeing Suppliers

MANUFACTURING AND TESTING OF AN HYBRID COMPOSITE

Fundamentals of Composites Manufacturing Second Edition

Lectures 11 to 18 Module II Manufacturing Techniques

US7951318B2 Apparatuses systems and methods for

Composite Materials 1st Edition – Elsevier

US5126091A Method for manufacturing composite material

COMPOSITES MANUFACTURING Materials Product and Process

model contract manufacturing free example – “Sandwich Structured Composites for Aeronautics Methods

Lectures 11 to 18 Module II Manufacturing Techniques

Integrating Metamaterials within a Structural Composite

Integrating Metamaterials within a Structural Composite using Additive Manufacturing Methods Peter Pa and Mark S. Mirotznik Electrical and Computer Engineering Dept. University of Delaware Newark, DE, USA Raymond McCauley and Shridhar Yarlagadda Center for Composite Materials University of Delaware, Newark, DE, USA Kate Duncan Antenna Technology and Analysis Branch …

The results of research showed that the method of manufacturing, more precisely the pressure while forming sandwich panels, influences some mechanical properties of sandwich structured polymer composites such as flexural strength, impact strength, and compressive strength.

Among the available materials in the market are industrial or composite materials, high-tech ceramics, reinforced plastics and nano materials that are now used in an large variety of products.

The following disclosure relates generally to composite part manufacturing and, more particularly, to apparatuses, systems, and methods for laminating fiber-reinforced resin materials on female tools.

Describes advances, key information, case studies, and examples that can broaden your knowledge of composites materials and manufacturing methods. This text deals with composites manufacturing methods, providing tips for getting the best results that weigh the required material properties against cost and production efficiency. An Instructor’s

Composite materials are widely used in a number of industrial sectors from aviation, space, to boat building, automotive, and sports goods. In recent years composite structures have seen a substantial increase of their use in the new generation of airplanes. The nondestructive testing and inspection of composite structures, both for manufacturing quality assurance and for in-service damage

Simultaneous material consolidation and shaping, as performed in manufacturing of composite materials, causes a strong interconnection between structural and manufacturing parameters which makes the design process complicated. In this paper, the design of …

UK produces around £1.6 billion worth of composite materials, components and structures every year, adding around £1.1 billion to UK national output. Prospects for growth are very good, with increases in demand being driven by

17 replies on “Manufacturing methods of composite materials pdf”

Leave a CommentComposite Materials: Concurrent Engineering Approach covers different aspects of concurrent engineering approaches in the development of composite products. It is an equally valuable reference for teachers, students, and industry sectors, including information and knowledge on concurrent engineering for composites that are gathered together in one comprehensive resource.

Lectures 11 to 18 Module II Manufacturing Techniques

Processing Methods for Composites Composite Material

Describes advances, key information, case studies, and examples that can broaden your knowledge of composites materials and manufacturing methods. This text deals with composites manufacturing methods, providing tips for getting the best results that weigh the required material properties against cost and production efficiency. An Instructor’s

Composites Materials Characterization Intertek

Fundamentals of Composites Manufacturing Second Edition

of Composite Materials • Properties of many important composites are anisotropic • Many of the polymer-based composites are subject to attack by chemicals or solvents • Composite materials are generally expensive • Manufacturing methods for shaping composite materials 28 ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Prof. Singh/ GaneshSoni are often …

Review of industrial manufacturing capacity for fibre

Fundamentals Of Composites Manufacturing Materials Methods

MANUFACTURING AND TESTING OF AN HYBRID COMPOSITE

It differs from other books on composites manufacturing in focussing almost solely on manufacturing processes, while not attempting to cover materials, test methods, mechanical properties and other areas of composites.

US7951318B2 Apparatuses systems and methods for

of Composite Materials • Properties of many important composites are anisotropic • Many of the polymer-based composites are subject to attack by chemicals or solvents • Composite materials are generally expensive • Manufacturing methods for shaping composite materials 28 ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Prof. Singh/ GaneshSoni are often …

Composite Recycling and Disposal Boeing Suppliers

Integrating Metamaterials within a Structural Composite

Fundamentals Of Composites Manufacturing Materials Methods

of Composite Materials • Properties of many important composites are anisotropic • Many of the polymer-based composites are subject to attack by chemicals or solvents • Composite materials are generally expensive • Manufacturing methods for shaping composite materials 28 ME 338: Manufacturing Processes II Instructor: Ramesh Singh; Notes: Prof. Singh/ GaneshSoni are often …

Composites Flow Processes in Composite Materials

New Composite Design and Manufacturing Methods ofr ICAS

Composite Materials 1st Edition – Elsevier

composite) were some of the earliest tool‐making and structural materials used by humankind. Today we apply the term composites to a wide variety of

Fundamentals of Composites Manufacturing Second Edition

Processing Methods for Composites. For Later. save. Related. Info. Embed. Share. Print. Search. Related titles. Design and Optimization of Laminated Composite Materials. 1892_1. KM BR FiberComposites En. 0334. analysis of composite materials. Introduction to FRP. Research.proposal . The-Improvement-of-Composite-Strength-Using-Talahib-2-1.docx. Crush_Simulation.pdf. Full Text …

Composite Fiber Hazards

Fundamentals of Composites Manufacturing Second Edition

Composite cord manufacturing method: Cousin, J-C, and Robin, J. A. (Cousin Freres, Wervicoq Sud, France) US Pat 4 707 977 (24 November 1987) Page 96 Download PDF

“Sandwich Structured Composites for Aeronautics Methods

US5126091A Method for manufacturing composite material

Composite Recycling and Disposal Boeing Suppliers

It differs from other books on composites manufacturing in focussing almost solely on manufacturing processes, while not attempting to cover materials, test methods, mechanical properties and other areas of composites.

Fundamentals of Composites Manufacturing Second Edition

MANUFACTURING AND TESTING OF AN HYBRID COMPOSITE INTEGRATING VISCOELASTIC FIBERS A. Martone 1,2 *, M.Zarrelli 2, V.Antonucci 2, M. Giordano 2 1University of Naples “Federico II”- DIMP, Piazzale Tecchio 80, 80125 Naples, Italy

COMPOSITES MANUFACTURING Materials Product and Process

Composites Materials Characterization Intertek

Composite Fiber Hazards

Module: Composite Materials Test Methods Composite Structure Engineering Safety Awareness Course Dr. Dan Adams Director, Composite Mechanics Laboratory. University of Utah . Salt Lake City, UT 84112 (801) 585-9807 adams@mech.utah.edu. Composite Materials Test Methods. AGENDA. Constituent and Prepreg Test Methods Physical Test Methods for Composites Mechanical Test Methods …

US5126091A Method for manufacturing composite material

Methods of Manufacture for Composite Materials in Infrastructure Filament Winding and Pultrusion. CST Composites is a world leading filament winding and pultrusiontechnology company. The company was founded in 1995, manufacturing some of the world’s first high performance sailing masts.

Composites Flow Processes in Composite Materials

US5126091A Method for manufacturing composite material

Composite Materials 1st Edition – Elsevier

Methods of Manufacture for Composite Materials in Infrastructure Filament Winding and Pultrusion. CST Composites is a world leading filament winding and pultrusiontechnology company. The company was founded in 1995, manufacturing some of the world’s first high performance sailing masts.

US7951318B2 Apparatuses systems and methods for

Composites Materials Characterization Intertek

New Composite Design and Manufacturing Methods ofr ICAS

Composite cord manufacturing method: Cousin, J-C, and Robin, J. A. (Cousin Freres, Wervicoq Sud, France) US Pat 4 707 977 (24 November 1987) Page 96 Download PDF

Composites Flow Processes in Composite Materials

Composite Materials 1st Edition – Elsevier

US7951318B2 Apparatuses systems and methods for

A method for manufacturing perforate, fibre-reinforced, composite material, comprising the steps of laying up reinforcing fibres and resin in a mould having needles, the mould including a stripper plate having perforations into which the needles pass when the mould is assembled; curing the resin; and withdrawing the composite from the mould

US5126091A Method for manufacturing composite material

Describes advances, key information, case studies, and examples that can broaden your knowledge of composites materials and manufacturing methods. This text deals with composites manufacturing methods, providing tips for getting the best results that weigh the required material properties against cost and production efficiency. An Instructor’s

US5126091A Method for manufacturing composite material

Lectures 11 to 18 Module II Manufacturing Techniques

Comments are closed.