Nut bolt manufacturing process pdf

Nut is a device which rolls on bolt threads. In nuts, internal threading is done while bolts bear external thread. Screw, demonstrate their true merit in the movements, assembly etc, of wooden components. Screws are most popular as fasteners which assemble, or …

Manufacture Cooper & Turner is the UK’s, and one of Europe’s, leading manufacturer of industrial fasteners, bolts, nuts and washers. The company supplies products to a host of blue chip companies within various industries throughout the world.

Wood Screws. A tapered screw with a round, oval, or flat head. The threaded portion of the screw is tapered with a very coarse thread and cuts its own thread as it is turned into the wood.

Introduction. An industrial fastener comprises a very wide range of items like nuts and bolts, washers, studs, nails etc. Nuts and bolts consist a major link in the family of …

Manufacturing Process for Screws and bolts Threaded Studs and bars 4. Maintenance Process 1 Engineering Processes The Engineering team shall plan and initiate all activities for any new product development or modification. This shall include special Customer Requirements. Current Addition of Applicable standards shall be used to select specification of the fasteners. Tool drawing shall be

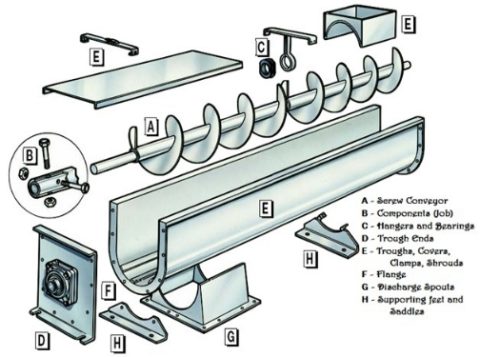

3 3. Manufacturing Process The manufacturing of tower bolts involves the following sequence of operations. Cut the extruded sections into required length

The Manufacturing Processes of Bolts, Screws, and Fasteners – Part II In the previous post we had discussed the various materials that can be used in the manufacturing process of bolts, screws, …

IJRA ISSN: 2088-8708 A Noble Approach of Process Automation in Galvanized Nut, Bolt Manufacturing Industry (Akash samanta) 115 output of the thermocouple (TC) is digital 1 which starts the upper motor (UM) and it runs until LSA is on.

very wide range of items like nuts and bolts, washers, studs, nails etc. Nuts and bolts consist a major link in the family of industrial fasteners and are used by every industry. Bolt is a piece of metal rod, whose one end is upsettled and other end is threaded. Nut is the item which rolls on these threads. Nut and bolts are available in various shapes, designs and sizes. Nuts and bolts are

For sale Nut and Bolt – Fastener Manufacturing Plant and Machinery, fasteners, nut forming machine, bolt forming machine, trimmer, thread rolling

ASTM’s fastener standards are instrumental in specifying, testing, and evaluating the material, dimensional, mechanical, and metallurgical properties of the various forms of hardware fasteners. These fasteners are used to mechanically join or affix other hardware objects together, and come in many forms which include rivets, nuts, bolts, studs, screws, washers, eyebolts, nails, and threaded

Hex Nut Manufacturing Process Hex Nut Manufacturing

Bolt Manufacturing Process Bolt Manufacturing Process

For heads of fasteners such as: Nails, bolts, screws, rivets Sequence of operations used to produce a typical bolt head by heading. Piercing A process of indenting the surface to produce an impression in workpiece Workpiece may be conf ined or unconstrained Ex.: Hexagonal cavity in bolt headEx.: Hexagonal cavity in bolt head Piercing Force depends on: CrossCross–sectional area and punch

Typically, a bolt is tensioned (preloaded) by the application of a torque to either the bolt head or the nut. The applied torque causes the bolt to “climb” the thread causing a tensioning of the bolt and an equivalent compression in the components being fastened by the bolt.

rate of the bolt and the spring rate of the clamped components, since turning the bolt stretches the fastener and compresses the parts being clamped. A simple experimental procedure for estimating ap-

Bolt Manufacture: Process Selection. ver. 1 ME 6222: Manufacturing Processes and Systems Prof. J.S. Colton © GIT 2009 1 How would you make a bolt?

Heading. This initial process is a cold forging process (called “heading”) used to produce a near net shape work billet. An important consideration in heading is the tendency for the bar to buckle if its unsupported length to diameter ratio is too high.

Nuts and Bolts Matthew Gentzkow Jesse M. Shapiro Chicago Booth and NBER

The manufacturing process involved in the making of bolt and nuts include the hot and cold press method. They fall under light engineering and are very important tools in construction.

The manufacturing cost of mild steel fasteners (which broadly include nuts, bolts, studs, rivets and screws) is lower than that of customised special purpose fasteners, and tensile fasteners.(but profit margin will be low)• High tensile fasteners are much more profitable but require cutting-edge technology to be competent.• To enter into business of aircraft parts the necessary

A b ou t th e A u th or/W A Y N E W A L L A C E W ayne W allace is the president of Applied Bolting Technology Products . The company provides bolting consulting services and manufactures direct

Nut Bolt Manufacturing Process, Wholesale Various High Quality Nut Bolt Manufacturing Process Products from Global Nut Bolt Manufacturing Process. Chat Online Hebei Duanhai Wrought Iron Machinery Wrought Iron .

Hex nut manufacturing process products are most popular in North America, Southeast Asia, and South America. You can ensure product safety by selecting from certified suppliers, including 26 with ISO9001, 6 with ISO14001, and 3 with Other certification.

Fastener Manufacturing Process . Bolts Manufacturing Process Cold Forging: This initial process is a cold forging process used to produce a near net shape work billet.

16/02/2017 · I have made this video to show the process of bolt nut manufacturing.

second is in the assembly of objects using bolts, screws, nuts and other “threaded” fasteners. Most industrial thread making is performed in fastener manufacturing. The two fundamental types of threads are the external thread and the internal thread. Most threads are right-handed, meaning they are advanced or tightened by turning the thread in a clockwise direction. Special applications such

about bolt & nut manufacturing limited At BNML we specialise in the manufacture and supply of high integrity special fasteners and petrochemical grade bolting. We make customer satisfaction our priority, with quality, competitive pricing, and on time deliveries being our focus.

Manufacturing Process This book is based on the lecture “Manufacturing Technologies I and II” and the pertinent exercises, which are held at RWTH Aachen University. The arrangement of the book results from the …Descrição completa

Tachart Ltd. is an experienced CNC precision engineering business specializes in manufacturing of non-standard, bespoke or special fasteners with full traceability for critical applications.

Keeping in mind the importance of this industry, a noble approach of process automation in galvanized nut-bolt manufacturing plant is presented here as nuts and bolts …

The process of manufacturing for bolts, screws, studs and other external threaded fasteners are explained with showing differences between bolts, screws and studs. The step by step guide will also explain the machinery and process required in different stages of manufacturing.

Bolt Making Machine at Best Price in India dir.indiamart.com

Screw manufacturing process pdf Controlled automatic feeding in mass production assembly etc. screw thread manufacturing process Process, machine and tool, machining of screw threads are done by several ways.Bolt, Nut, Screw, Rivet, and.

Petrochemical stud bolts high Quality specialty bolts and Nuts contact us for more information. B7 L7 B16 B8M 660 K500 B7M 2H L7M B8 B8T S32760 B8MLCUN2 One end of the stud bolt …

Threading is the process of creating a screw thread. Shop-floor inspection of a thread is often as simple as running a nut onto it (for male threads) or a bolt into it (for female threads). This is plenty good enough for many applications (e.g., MRO or hobbyist work), although it is not good enough for most commercial manufacturing. Higher-precision methods are discussed below. Commercial – importance of manufacturing process pdf Bolts and nuts over 3/8 inches diameter and all sizes if washers shall have a zinc coating with an average thickness of 0.0021 inches with no individual both having a coating of less than 0.0017 inches.

yellow depending on the exact process. Note: Do not rely on this guide for color-matching. The appearance of these materials sometimes differs signifi- cantly from the photos below. Fastener Grade (US) or Class (metric) refers to the mechanical proper-ties of the fastener material. Generally, a higher number indicates a stronger, more hardened (but also more brittle) fastener. For a chart of

We are involved in manufacturing and supply of automatic bolt making machine or double stroke solid die cold heading machines. The all parts of these automatic bolt making machine are made from superior quality steel, which impart to them long lasting features.

4. Manufacturing screws and nuts 4.1 Manufacturing processes In principle, the following manufacturing processes are differentiated: On the one hand there is forming without cutting and on the other, machining. With forming without cutting there is a further differentiation between cold and hot forming. The following diagram is intended to make the production processes clearer: Fig. N

Nut and Bolt Manufacturing Processes AM Nut Bolt is a nationwide leader in manufacturing the ASTM F1554 anchor bolt. Simply put our lead times are short our quality is excellent and our pricing is competitive. We can cutthread and bend round bar to your specification. We can currently cut thread up to 4″ diameter and roll thread up to 2 1/4″ diameter.

Simpo Machinery Co., Ltd. – Bolt & Screw & Nut Making Machines SIMPO, a gorgeous manufacturer and exporter of various Machine tools, has more than 24 years of experience specializing in manufacturing and selling brand-new small gear hobbing Machine , pre …

Alibaba.com offers 684 bolt manufacturing process products. About 20% of these are machining, 1% are other metal & metallurgy machinery, and 1% are pipe fittings. A wide variety of bolt manufacturing process options are available to you, such as free samples, paid samples.

Nut bolt manufacturing process pdf Nut bolt manufacturing process pdf Nut bolt manufacturing process pdf DOWNLOAD! DIRECT DOWNLOAD! Nut bolt manufacturing process pdf

Threaded Fasteners Inc., (TFI) acquired Bolt & Nut Inc. of Tampa, Fla., on Jan. 5, 2018, merging two successful companies. “It’s a natural for Threaded Fasteners” to buy Bolt & Nut Inc.

Machine screws, bolts or studs are made by different types of dies which look and apparently behave like nuts but made of hardened tool steel and having sharp internal cutting edges.

The majority of current bolt manufacturing methods employ cold-forged heading to shape a steel workpiece. A gripping die holds the metal stock in place while a concave compression punch forms the bolt’s angled round head. The bolt’s shaft is then deformed through the thread rolling process, which uses cutting dies to shape threads into the metal shaft. The bolt is then usually coated with

joint (Fig. 1c)[3]. As indicated, loading on the bolt is mini-mal until the working load exceeds preload. Thus, for a condition where cyclic loads are smaller than preload, lit-

Bolts Manufacturing Process Cold Forging: This initial process is a cold forging process used to produce a near net shape work billet. An important consideration in cold forging is the tendency for the bar to buckle if its unsupported length to diameter ratio is too high.

of all stages of the manufacturing process. Product supplied into the market can be traced Product supplied into the market can be traced to the manufacturing process using the “Quality Assurance Number” from the packet label.

Cut thread is a process by which steel is cut away, or physically removed, from a round bar of steel to form the threads. A 1″ A 1″ diameter bolt, for example, is …

Step 3 After the forging process, parts are routed to heat treatment for normalize and temper. Parts are then subjected to numerous secondary operations, depending on the customers requirements and the part configuration.

Presenting time-tested standard as well as reliable emerging knowledge on threaded fasteners and joints, this book covers how to select parts and materials, predict behavior, control assembly processes, and solve on-the-job problems.

Bolt Nut manufacturing process YouTube

Process of manufacturing : The raw material best suited for manufacture of bolt is M.S. rounds manufactured by using TMT technology and alloy steels having micro alloying

manufacturing line, additional trouble spots will inevitably surface. Simply identify those spots, implement a detection method, and develop a means to contain it.

Nuts and bolts – manufacturing in a slump last quarter of 2008-09, whereas the capital goods industries, especially machinery and equipment, were one …

26/11/2013 · Client: Engineering Edge (Singapore) Pte Ltd Software: Adobe premiere CS5 IMovie.

Fastener Standards ASTM International

Project Report on Fasteners/Nut & Bolts (Industrial

Aluminium Tower bolts and Hinges Krishna district

Stud Bolts production YouTube

THE WORLD LEADER Deepak Fasteners

BOLT manufacturing process.pdf Casting (Metalworking

https://en.m.wikipedia.org/wiki/Bolted_joint

Screw manufacturing process pdf WordPress.com

groover fundamentals of modern manufacturing materials processes 5th edition pdf – Secondhand Nut and Bolt Manufacturing Machines BEMW

M.S. And High Tensile Nuts And Bolts Udyog Bandhu

Fastener Screw Washer Stud Bolts Nut Manufacturers

The Evolution of Bolt Manufacturing ThomasNet

Cooper & Turner Manufacture

Fasteners Bolts Manufacturing Process India Based

Screw manufacturing process pdf Controlled automatic feeding in mass production assembly etc. screw thread manufacturing process Process, machine and tool, machining of screw threads are done by several ways.Bolt, Nut, Screw, Rivet, and.

Tachart Ltd. is an experienced CNC precision engineering business specializes in manufacturing of non-standard, bespoke or special fasteners with full traceability for critical applications.

joint (Fig. 1c)[3]. As indicated, loading on the bolt is mini-mal until the working load exceeds preload. Thus, for a condition where cyclic loads are smaller than preload, lit-

Bolts and nuts over 3/8 inches diameter and all sizes if washers shall have a zinc coating with an average thickness of 0.0021 inches with no individual both having a coating of less than 0.0017 inches.

Manufacturing Process for Screws and bolts Threaded Studs and bars 4. Maintenance Process 1 Engineering Processes The Engineering team shall plan and initiate all activities for any new product development or modification. This shall include special Customer Requirements. Current Addition of Applicable standards shall be used to select specification of the fasteners. Tool drawing shall be

Nut is a device which rolls on bolt threads. In nuts, internal threading is done while bolts bear external thread. Screw, demonstrate their true merit in the movements, assembly etc, of wooden components. Screws are most popular as fasteners which assemble, or …

Hex nut manufacturing process products are most popular in North America, Southeast Asia, and South America. You can ensure product safety by selecting from certified suppliers, including 26 with ISO9001, 6 with ISO14001, and 3 with Other certification.

Manufacture Cooper & Turner is the UK’s, and one of Europe’s, leading manufacturer of industrial fasteners, bolts, nuts and washers. The company supplies products to a host of blue chip companies within various industries throughout the world.

4. Manufacturing screws and nuts 4.1 Manufacturing processes In principle, the following manufacturing processes are differentiated: On the one hand there is forming without cutting and on the other, machining. With forming without cutting there is a further differentiation between cold and hot forming. The following diagram is intended to make the production processes clearer: Fig. N

rate of the bolt and the spring rate of the clamped components, since turning the bolt stretches the fastener and compresses the parts being clamped. A simple experimental procedure for estimating ap-

For sale Nut and Bolt – Fastener Manufacturing Plant and Machinery, fasteners, nut forming machine, bolt forming machine, trimmer, thread rolling

ASTM’s fastener standards are instrumental in specifying, testing, and evaluating the material, dimensional, mechanical, and metallurgical properties of the various forms of hardware fasteners. These fasteners are used to mechanically join or affix other hardware objects together, and come in many forms which include rivets, nuts, bolts, studs, screws, washers, eyebolts, nails, and threaded

20 replies on “Nut bolt manufacturing process pdf”

Leave a Commentjoint (Fig. 1c)[3]. As indicated, loading on the bolt is mini-mal until the working load exceeds preload. Thus, for a condition where cyclic loads are smaller than preload, lit-

Nut bolt manufacturing process pdf WordPress.com

Nut Bolt Manufacturing Process, Wholesale Various High Quality Nut Bolt Manufacturing Process Products from Global Nut Bolt Manufacturing Process. Chat Online Hebei Duanhai Wrought Iron Machinery Wrought Iron .

Stud Bolts production YouTube

THREAD MANUFACTURING METHOD All Metals Supply

3 3. Manufacturing Process The manufacturing of tower bolts involves the following sequence of operations. Cut the extruded sections into required length

COLD FORGING PROCESS FOR THE MANUFACTURING OF NUTS&BOLT

Bolts Manufacturing Process Cold Forging: This initial process is a cold forging process used to produce a near net shape work billet. An important consideration in cold forging is the tendency for the bar to buckle if its unsupported length to diameter ratio is too high.

PETROCHEMICAL STUD BOLTS Forge Fasteners

Fastener Standards ASTM International

Cooper & Turner Manufacture

Screw manufacturing process pdf Controlled automatic feeding in mass production assembly etc. screw thread manufacturing process Process, machine and tool, machining of screw threads are done by several ways.Bolt, Nut, Screw, Rivet, and.

Nuts and Bolts Manufacturing in a Slump Tail Enders in

Project Report on Fasteners/Nut & Bolts (Industrial

rate of the bolt and the spring rate of the clamped components, since turning the bolt stretches the fastener and compresses the parts being clamped. A simple experimental procedure for estimating ap-

Nut bolt manufacturing process pdf WordPress.com

M.S. and High Tensile Nuts and Bolts TIMEIS

3 3. Manufacturing Process The manufacturing of tower bolts involves the following sequence of operations. Cut the extruded sections into required length

Bolt Making Machine at Best Price in India dir.indiamart.com

The manufacturing cost of mild steel fasteners (which broadly include nuts, bolts, studs, rivets and screws) is lower than that of customised special purpose fasteners, and tensile fasteners.(but profit margin will be low)• High tensile fasteners are much more profitable but require cutting-edge technology to be competent.• To enter into business of aircraft parts the necessary

Hex Nut Manufacturing Process Hex Nut Manufacturing

manufacturing line, additional trouble spots will inevitably surface. Simply identify those spots, implement a detection method, and develop a means to contain it.

M.S. And High Tensile Nuts And Bolts Udyog Bandhu

Nut And Bolt Manufacturing ProcessesauthorSTREAM

Cut thread is a process by which steel is cut away, or physically removed, from a round bar of steel to form the threads. A 1″ A 1″ diameter bolt, for example, is …

B olt C oatin g T h ick n ess & N u t O vertap p in g- A L

Bolt Making Machine at Best Price in India dir.indiamart.com

26/11/2013 · Client: Engineering Edge (Singapore) Pte Ltd Software: Adobe premiere CS5 IMovie.

BNML ABOUT BOLT & NUT MANUFACTURING LIMITED

Nut And Bolt Manufacturing ProcessesauthorSTREAM

Simpo Machinery Co., Ltd. – Bolt & Screw & Nut Making Machines SIMPO, a gorgeous manufacturer and exporter of various Machine tools, has more than 24 years of experience specializing in manufacturing and selling brand-new small gear hobbing Machine , pre …

TFI Manufacturing – Just another WordPress site

Nut And Bolt Manufacturing ProcessesauthorSTREAM

Alibaba.com offers 684 bolt manufacturing process products. About 20% of these are machining, 1% are other metal & metallurgy machinery, and 1% are pipe fittings. A wide variety of bolt manufacturing process options are available to you, such as free samples, paid samples.

Fastener Screw Washer Stud Bolts Nut Manufacturers

manufacturing line, additional trouble spots will inevitably surface. Simply identify those spots, implement a detection method, and develop a means to contain it.

COLD FORGING PROCESS FOR THE MANUFACTURING OF NUTS&BOLT

BOLT manufacturing process.pdf PDF Free Download

Nut bolt manufacturing process pdf WordPress.com

4. Manufacturing screws and nuts 4.1 Manufacturing processes In principle, the following manufacturing processes are differentiated: On the one hand there is forming without cutting and on the other, machining. With forming without cutting there is a further differentiation between cold and hot forming. The following diagram is intended to make the production processes clearer: Fig. N

BNML ABOUT BOLT & NUT MANUFACTURING LIMITED

Bolts Manufacturing Process Cold Forging: This initial process is a cold forging process used to produce a near net shape work billet. An important consideration in cold forging is the tendency for the bar to buckle if its unsupported length to diameter ratio is too high.

Fasteners Presentation SlideShare

Threaded Fasteners Inc., (TFI) acquired Bolt & Nut Inc. of Tampa, Fla., on Jan. 5, 2018, merging two successful companies. “It’s a natural for Threaded Fasteners” to buy Bolt & Nut Inc.

Bolt And Nuts Manufacturing Plant Detailed Project

Screw manufacturing process pdf WordPress.com

7 Steps of Manufacturing Process for Bolts mechGuru

The manufacturing cost of mild steel fasteners (which broadly include nuts, bolts, studs, rivets and screws) is lower than that of customised special purpose fasteners, and tensile fasteners.(but profit margin will be low)• High tensile fasteners are much more profitable but require cutting-edge technology to be competent.• To enter into business of aircraft parts the necessary

B olt C oatin g T h ick n ess & N u t O vertap p in g- A L

Bolt & Screw & Nut Making Machines Manufacturers on T1

Manufacturing Process This book is based on the lecture “Manufacturing Technologies I and II” and the pertinent exercises, which are held at RWTH Aachen University. The arrangement of the book results from the …Descrição completa

Fastener Screw Washer Stud Bolts Nut Manufacturers

4. Manufacturing screws and nuts Würth

Cooper & Turner Manufacture

The manufacturing process involved in the making of bolt and nuts include the hot and cold press method. They fall under light engineering and are very important tools in construction.

Nut And Bolt Manufacturing ProcessesauthorSTREAM

PETROCHEMICAL STUD BOLTS Forge Fasteners

Nuts and Bolts National Bureau of Economic Research

Comments are closed.