Pet preform manufacturing process pdf

to preform (MTP ®), melt to resin has built a 350 000 metric ton integrated PET manufacturing facility using this new technology. The process is described with schematic illustrations ECONOMICS Cost of production estimates for the following are presented: Production of melt-phase PET resin from conventional technology Production of PET resin by the combined Aquafil melt/Buhler S-HIP SSP

manufacturing process parameters (Tanhoub, et al., 2004). She showed optimism and She showed optimism and welcomed change for the better, which is an important attitude while leading an

or PET. and is the second most widely used blow molding process and produces a container by stretching either a preform or parison in both axial and radial directions.

manufacturing technology (high efficiency, low power consumption, full automation of the process). PET offers better barrier against oxygen and better protection from odours than HDPE. Possibility of producing tailor-made bottles with original shapes, attractive and esthetic for customers – great marketing oppor-tunities. PET bottles can be transparent or any other colour including white

The global PET preforms market growth is expected to be driven by high demand for PET bottles, jars, tubes in Asia Pacific owing to highest revenue share. PET preforms and bottles are also extremely cost-effective, durable and safe.

breakage on the gate of the PET preform undercut on the gate fix the gate gate too hot prelong the cooling time increase the injection speed or prelong the injection time

The production of PET bottles is a split process that requires diligence as well as careful quality control. As a first step, the PET granulate becomes the preform using state-of-the-art injection molding machines. The second step produces the final PET bottles using a stretch blow molder.

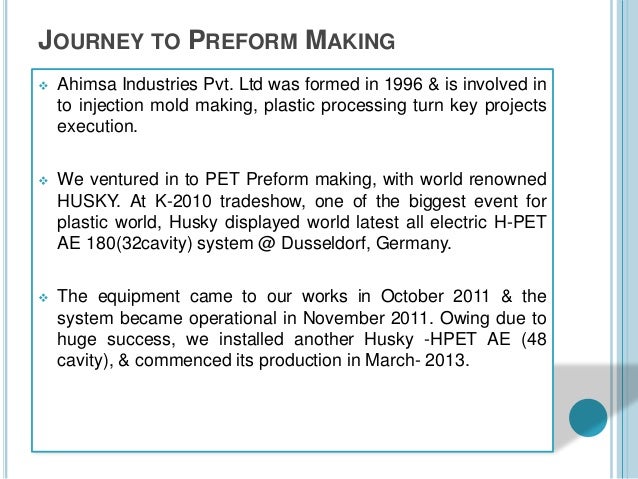

Future PET handles the manufacture of PET Preforms and HDPE /PP Closures. The facility in Abu Dhabi covers 16,000 sqm, houses world class equipment from HUSKY and SACMI and a well equipped laboratory for testing raw material and finished goods.

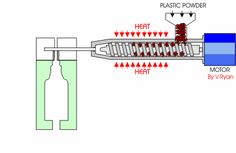

4 PREF-37/May, 2010/2 Pre-Feasibility Study PET Bottles Manufacturing Unit 5 PRODUCTION PROCESS Figure 5-1 Process Flow Diagram of PET Bottles Manufacturing Drying the PET PET absorbs moisture from the atmosphere. This must be removed before processing using a dehumidifying drier. Plasticizing the PET Dried PET Pellets are compressed and melted by a rotating injection …

Get complete study material and formulations on Technology Of Pet Bottles, Preform And Pet Recycling (hand Book). Offering complete resources to start new industry including market survey, feasibility report, profit loss and much more.

Tungsten Carbide Preform Manufacturing Process

PET PREFORM SYSTEMS conairgroup.com

Polyethylene terephthalate (PET) is the most common plastic material used in injection stretch blow molding (ISBM) process for the manufacturing of bottles. The injection-molded PET preform has to

The book Technology of PET Bottles, Preform and PET Recycling covers PET Plastic packaging, Properties of PET, Recycling of PET, Aseptic Filling of PET Bottles, Flexo Inks for the printing of Non treated Polyester films (PET) on central impression Flexo Presses, Production and filling process of a Pet Bottle, PET Bottle Recycling, PET Preform

manufacturing (“blowing”) of empty PET preforms into containers/bottles this is the final stage of the PET packaging value chain which consists in heating the preforms, stretching and shaping them by using specific moulds in stretch

SALES PARTS SERVICE MANUFACTURING concept of “total process visibility.” PET preform molding is a complex and fluid process, with material constantly being brought in, dried and conveyed to the molding machine. To produce a consistent product, this very fluid process must remain stable even as material and ambient conditions change. That’s OPTIMIZER™ MODE For effective drying, the

PERFORMANCE AND PRODUCTIVITY WITH VERTICAL TECHNOLOGY PETForm production cells for preforms. IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries worldwide Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three …

We added additional bagging capabilities into our manufacturing process increasing our flexibility and throughput allowing for many packaging options at very competitive prices. Product Catalog All Pet Preforms. We welcome you to our PET Preform product catalog with packaging solutions ranging in sizes, shapes and designs to meet your container needs. Each Preform has been created to meet a

Manufacturing composites at industrial standards is a particularly demanding, highly complex process. While metals and metal alloys used for parts production can simply be molten and cooled off inside molds to create a desired component, fiber-reinforced composite elements need to be combined and prepared before the preform procedures and final

R. Alagirusamy, in Technical Textile Yarns, 2010. 12.3.2 Friction, flexibility and compressive properties. The smooth operation of any preform manufacturing process such as braiding, weaving or knitting is determined by, among others, the flexibility and friction characteristics of the material processed.

9/12/2011 · pet preform making machine BLENZOR TM PET perform Injection Molding machines are suitable for making the bottle perform for mineral water, carbonic drink, juice, edible oil, …

PET preforms are either produced using the one-step hot preform method or the two-step cold preform method. PET preforms have applications such as carbonated soft drinks, water, food, non-carbonated drinks, cosmetics & chemicals, pharma & liquor, and others. These application segments drive the PET preforms market globally.

PET Packaging Operations . The ZDM Group applies it’s methodology for all manufacturing and service industries. However, The ZDM Group has it’s roots in and is world renowned for their expertise in the PET Preform and Bottle plastics industry.

Pet Bottle Manufacturing – Download as PDF File (.pdf), Text File (.txt) or read online. Scribd is the world’s largest social reading and publishing site. Search Search

Alibaba.com offers 36 pet preforms manufacturing process products. About 13% of these are moulds, 2% are machining. A wide variety of pet preforms manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

Method for manufacturing plastic bottles, including the step in which respective preforms are removed from the respective moulds, and the step in which said preforms are transferred into temperature conditioning stations for a predetermined period of time, during which said preforms are caused to undergo an asymmetrical heat treatment that is

production process. The new process will be rolled out at CCE’s manufacturing sites at Sidcup and Wakefield in 2007 and 2008. When the project is complete, almost 700 million of the new bottles will be produced annually saving approximately 1400 tonnes of PET plastic every year. The lighter bottles meet all The Coca-Cola Company (TCCC) and CCE quality and technical performance standards

Pet Preform manufacturing processes have been developed to cover a wide range of applications and part geometries. For any designer and engineer involved in product development, it is critical to be familiar with the manufacturing options available today and foreseeing new developments in the way parts are manufactured in the future.

machine type, usually using a preform initially designed for PET will work. For the most part, with just changes in some For the most part, with just changes in some processing parameters like temperature and blow timing, a high quality Ingeo bottle can be made from a preform designed for

Properties Material :PET Material composition :100% Virgin Pet Manufacturing Process :Injection molding Rim Diameter (mm) :30.2 Total Height (mm) :70

From Granulate to Preform and Bottle. Have you ever wondered how PET bottles are produced? Few consumers actually know where PET bottles come from and how they are made. Come and join us, one of the leading Austrian producers, on the way through the production process . Two steps to success. The production of PET bottles is a split process that requires diligence as well as careful quality

We guide you through the whole process from design conceptualization to mould manufacturing and then production. High quality standards and a keen willingness to adapt to the changing market as per the requirement helps us to offer you a packaging solution as per your product and requirement.

The Rapid Guide to Perfect PET Bottles This is a troubleshooting guide that should be in every operator’s toolbox or on his/her smartphone or tablet. On 125 pages 31 common defects of PET bottles are analyzed and tips given to solve them.

Preforms for Hot Filling Many different beverage products need to be hot-filled to ensure aseptic long shelf-life. HCM has expertise and experience with hot fill PET preforms and bottles.

Optimizing PET Preform Manufacturing-Guidelines for Finding the Starting-Point compensate for a mold maintenance issue that was causing a defect. But sometimes after rectifying the mechanical problem, the plant continues to process from that far corner. We then have two choices; we can execute a series of DOE’s from the current process, which will get us where we need to go with confidence

Presto’s Hot Wire Bottle Cutter NXG is a sophisticated technology based high-quality machine which is widely used by the manufacturers in PET & Preform manufacturing industries to perform the section weight analysis test on PET products.

Click on the link to learn the difference between a single stage and multi stage PET Plastic Bottle Manufacturing Process.

This is the first stage in the two stage PET bottle manufacturing process suitable for large scale production and here the pet preform is molded on an injection moulding machine. MANUFACTURING PROCESS PET granules received from suppliers are dried in a dehumidifier.Manufacturing of PET preforms KSIDC PROJECT PROFILE FOR MANUFACTURING OF PET PREFORMS …

pet preform making machine.wmv YouTube

Causes & Solutions of Defects that Occur in Production of Preforms PET Bottles. PET containers or bottles are made out of PET preforms. So, to make best bottles, it is very important that preforms …

PET is transformed several times as it goes form PET pellet to preform. As a resin pellet, PET is thermally crystallized to a level of 50% to 70% and PET appears white. During injection process, these crystals are melted, resulting in an amorphous melt, which is injected into preform mold cavities. PET is clear and has a little strength or barrier properties. In the reheat stretch blow machine

Tungsten Carbide Preform Manufacturing Process Vista Metals produces the World’s finest tungsten carbide preforms because of our technology, commitment to quality and attention to detail. Our manufacturing process and the experienced people that drive it are the reasons why Vista Metals preforms are chosen around the world. – degarmos materials and processes in manufacturing solution manual pdf Husky PET Preform Manufacturing Solutions Husky’s PET preform systems are available in various tonnages for molds between two and 144 cavities. All components of our solutions are specifically designed to work together as a fully integrated and optimized workcell. This delivers the most stable process and reliable operation, resulting in the fastest cycles and leading preform quality. 2

the preform length, by modifying the process parameters related to the IR oven. It is interesting to point out that authors questioned the relevance of the objective chosen for the optimization. In this work, we propose a numerical optimization strategy for SBM. For that, we developed an iterative procedure allowing to automatically compute the best temperature distribution along the preform

Preforms revolutionize PET manufacturing process and bring considerable benefit in cost, impact to the environment and operational efficiency and flexibility. ExoPackaging is a leading designer and manufacturer for renowned brands of India and abroad.

Alibaba.com offers 36 pet preform manufacturing process products. About 13% of these are moulds, 2% are machining. A wide variety of pet preform manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

stretch blow moulding pet bottles This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important …

Process Economics Program Report 18C POLYETHYLENE TEREPHTHALATE (September 2006) Development and growth in the polyethylene terephthalate (PET) solid-state resin market since 1999 have been strong. Since their introduction in the mid-1970, global demand for these resins has reached 10.5 million metric tons by 2004. The global demand for these resins has continued to grow at high …

Using Blow Molding To Make Pet Preform Mould Music There are few technology transfers designed to simplify the manufacturing process and reduce costs. However, the development of blow molding technology is to achieve great changes in the manufacturing field.

Process: PET bottles manufacturing process involves two basic stages of pre-form manufacturing and Bottle Stretch Blow Moulding. In a one-step process, the PET bottles are made directly from the resin. Both the pre-form manufacturing and stretch blow moulding is …

The product. The PET preform, better known as preform, is accomplished through a molding process. The fused PET injected into a mold become a preform, which, by an additional processing step (blowing), takes the form of bottles for beverages for elementary, oil or detergents use.

Pet Bottle Preform Production Industry Continues To Innovate Posted January 5, 2019 by nicolepreform In the product development and manufacturing stages, any errors may result in expensive recalls and may even cause potential harm.

Preform tilter DUMPER DR-310 (optional) – machine designed to automate the process of PET containers production. Thanks to that solution, preforms are supplied to the hopper automatically. The operator needs only to change pallets with the octabins filled with preforms. It makes the process …

Preform Manufacturing Injection Molding of Preforms Dried at -40C dewpoint and 180C (356F) PET Resin PET Resin PET Resin PET Resin Receipt Receipt & Storage & Storage PET Resin PET Resin Drying Drying Injection Molding Injection Molding of Preforms of Preforms Preform Preform Preform Preform Handling & Handling & Storage Storage Process: • PET resin is melted. compressed in an …

PET bottles are mainly manufactured in a two-stage process. The PET granulate is first The PET granulate is first melted at about 280 °C and processed into what are called preforms.

pet preform manufacturing from pet resin The project report includes Present Market Position and Expected Future Demand, Market Size, Statistics, Trends, SWOT Analysis and Forecasts. Report provides a comprehensive analysis from industry covering detailed reporting and evaluates the position of the industry by providing insights to the SWOT analysis of the industry.

Pre-Feasibility Study PET BOTTLES MANUFACTURING UNIT Small

pet bottle manufacturing process pdf Jiangsu pet bottle

Single Stage and Multi Stage PET Manufacturing Process

Stretch Blow Moulding PET Bottles PETform

pet bottle manufacturing process pdf Exporter pet bottle

pet preform manufacturing process Alibaba

From Granulate to Preform and Bottle – Varioform

REGULATION (EC) No 139/2004 MERGER PROCEDURE

– ABSTRACT Process Economics Program Report 18C

Services from The ZDM Group PET Preform and Bottle

Project Report on PET PREFORM MANUFACTURING FROM PET RESIN

CTC PET PREFORM ExoPackaging

Catalog Merrimack Valley Plastics LLC

Pet Bottle Manufacturing Database Index Temperature

Alibaba.com offers 36 pet preform manufacturing process products. About 13% of these are moulds, 2% are machining. A wide variety of pet preform manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

From Granulate to Preform and Bottle. Have you ever wondered how PET bottles are produced? Few consumers actually know where PET bottles come from and how they are made. Come and join us, one of the leading Austrian producers, on the way through the production process . Two steps to success. The production of PET bottles is a split process that requires diligence as well as careful quality

PERFORMANCE AND PRODUCTIVITY WITH VERTICAL TECHNOLOGY PETForm production cells for preforms. IN PARTNERSHIP WITH INDUSTRY KraussMaffei is a premium partner for the plastics and rubber processing industries worldwide Whatever you aim to achieve in plastics or rubber processing, KraussMaffei is your partner. We are the only company with intensive expertise across the three …

PET bottles are mainly manufactured in a two-stage process. The PET granulate is first The PET granulate is first melted at about 280 °C and processed into what are called preforms.

stretch blow moulding pet bottles This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important …

The production of PET bottles is a split process that requires diligence as well as careful quality control. As a first step, the PET granulate becomes the preform using state-of-the-art injection molding machines. The second step produces the final PET bottles using a stretch blow molder.

42 replies on “Pet preform manufacturing process pdf”

Leave a CommentR. Alagirusamy, in Technical Textile Yarns, 2010. 12.3.2 Friction, flexibility and compressive properties. The smooth operation of any preform manufacturing process such as braiding, weaving or knitting is determined by, among others, the flexibility and friction characteristics of the material processed.

COMPLETE MILK BOTTLING LINE Stretch and PET blow molding

Tungsten Carbide Preform Manufacturing Process

stretch blow moulding pet bottles This process involves the production of hollow objects, such as bottles, having biaxial molecular orientation. Biaxial orientation provides enhanced physical properties, clarity, and gas barrier properties, which are all important …

Preheating of a Poly(ethylene terephthalate) Preform for

Single Stage and Multi Stage PET Manufacturing Process

We added additional bagging capabilities into our manufacturing process increasing our flexibility and throughput allowing for many packaging options at very competitive prices. Product Catalog All Pet Preforms. We welcome you to our PET Preform product catalog with packaging solutions ranging in sizes, shapes and designs to meet your container needs. Each Preform has been created to meet a

Pet Bottle Manufacturing Database Index Temperature

pet preform making machine.wmv YouTube

Husky PET Preform Manufacturing Solutions Husky’s PET preform systems are available in various tonnages for molds between two and 144 cavities. All components of our solutions are specifically designed to work together as a fully integrated and optimized workcell. This delivers the most stable process and reliable operation, resulting in the fastest cycles and leading preform quality. 2

2. PET PreformManufacturing & Blowing Chemistry

We guide you through the whole process from design conceptualization to mould manufacturing and then production. High quality standards and a keen willingness to adapt to the changing market as per the requirement helps us to offer you a packaging solution as per your product and requirement.

Minimising packaging Coca-Cola’s lightest ever PET 500ml

Project Report on PET PREFORM MANUFACTURING FROM PET RESIN

Optimizing PET Preform Manufacturing-Guidelines for Finding the Starting-Point compensate for a mold maintenance issue that was causing a defect. But sometimes after rectifying the mechanical problem, the plant continues to process from that far corner. We then have two choices; we can execute a series of DOE’s from the current process, which will get us where we need to go with confidence

Preform Manufacturing an overview ScienceDirect Topics

Pet Pre-form From Pet Resin Manufacturing Plant

Minimising packaging Coca-Cola’s lightest ever PET 500ml

PET preforms are either produced using the one-step hot preform method or the two-step cold preform method. PET preforms have applications such as carbonated soft drinks, water, food, non-carbonated drinks, cosmetics & chemicals, pharma & liquor, and others. These application segments drive the PET preforms market globally.

Preform Manufacturing Compositence

Catalog Merrimack Valley Plastics LLC

pet preform manufacturing process Alibaba

Polyethylene terephthalate (PET) is the most common plastic material used in injection stretch blow molding (ISBM) process for the manufacturing of bottles. The injection-molded PET preform has to

PET PREFORM SYSTEMS conairgroup.com

Process: PET bottles manufacturing process involves two basic stages of pre-form manufacturing and Bottle Stretch Blow Moulding. In a one-step process, the PET bottles are made directly from the resin. Both the pre-form manufacturing and stretch blow moulding is …

Husky PET Preform Manufacturing Solutions English 12-092

Manufacturing composites at industrial standards is a particularly demanding, highly complex process. While metals and metal alloys used for parts production can simply be molten and cooled off inside molds to create a desired component, fiber-reinforced composite elements need to be combined and prepared before the preform procedures and final

Preform Manufacturing an overview ScienceDirect Topics

how to make pet preform- huangyan yichuan mold factory.

PET Packaging Operations . The ZDM Group applies it’s methodology for all manufacturing and service industries. However, The ZDM Group has it’s roots in and is world renowned for their expertise in the PET Preform and Bottle plastics industry.

ABSTRACT Process Economics Program Report 18C

Pet Bottle Manufacturing Database Index Temperature

Pre-Feasibility Study PET BOTTLES MANUFACTURING UNIT Small

Pet Preform manufacturing processes have been developed to cover a wide range of applications and part geometries. For any designer and engineer involved in product development, it is critical to be familiar with the manufacturing options available today and foreseeing new developments in the way parts are manufactured in the future.

pet preform making machine.wmv YouTube

pet bottle manufacturing process pdf Jiangsu pet bottle

PET PREFORM 10 Industrium Group

to preform (MTP ®), melt to resin has built a 350 000 metric ton integrated PET manufacturing facility using this new technology. The process is described with schematic illustrations ECONOMICS Cost of production estimates for the following are presented: Production of melt-phase PET resin from conventional technology Production of PET resin by the combined Aquafil melt/Buhler S-HIP SSP

PET and Preform Testing Instruments Polariscope Strain

Preform tilter DUMPER DR-310 (optional) – machine designed to automate the process of PET containers production. Thanks to that solution, preforms are supplied to the hopper automatically. The operator needs only to change pallets with the octabins filled with preforms. It makes the process …

how to make pet preform- huangyan yichuan mold factory.

Minimising packaging Coca-Cola’s lightest ever PET 500ml

9/12/2011 · pet preform making machine BLENZOR TM PET perform Injection Molding machines are suitable for making the bottle perform for mineral water, carbonic drink, juice, edible oil, …

pet preforms manufacturing process Alibaba

Tungsten Carbide Preform Manufacturing Process

Click on the link to learn the difference between a single stage and multi stage PET Plastic Bottle Manufacturing Process.

Preform Manufacturing an overview ScienceDirect Topics

The product. The PET preform, better known as preform, is accomplished through a molding process. The fused PET injected into a mold become a preform, which, by an additional processing step (blowing), takes the form of bottles for beverages for elementary, oil or detergents use.

pet preform manufacturing process Alibaba

pet preforms manufacturing process Alibaba

breakage on the gate of the PET preform undercut on the gate fix the gate gate too hot prelong the cooling time increase the injection speed or prelong the injection time

PET Preforms Market by Type & Application Global

Process: PET bottles manufacturing process involves two basic stages of pre-form manufacturing and Bottle Stretch Blow Moulding. In a one-step process, the PET bottles are made directly from the resin. Both the pre-form manufacturing and stretch blow moulding is …

Pet Bottle Manufacturing Database Index Temperature

Manufacturing Process Of Pet Preform chinapetpreform

PET PREFORM 10 Industrium Group

SALES PARTS SERVICE MANUFACTURING concept of “total process visibility.” PET preform molding is a complex and fluid process, with material constantly being brought in, dried and conveyed to the molding machine. To produce a consistent product, this very fluid process must remain stable even as material and ambient conditions change. That’s OPTIMIZER™ MODE For effective drying, the

pet preform making machine.wmv YouTube

Pet Bottle Manufacturing – Download as PDF File (.pdf), Text File (.txt) or read online. Scribd is the world’s largest social reading and publishing site. Search Search

pet bottle manufacturing process pdf Jiangsu pet bottle

Pet Bottle Preform Production Industry Continues To Innovate Posted January 5, 2019 by nicolepreform In the product development and manufacturing stages, any errors may result in expensive recalls and may even cause potential harm.

PET and Preform Testing Instruments Polariscope Strain

From Granulate to Preform and Bottle – Varioform

the preform length, by modifying the process parameters related to the IR oven. It is interesting to point out that authors questioned the relevance of the objective chosen for the optimization. In this work, we propose a numerical optimization strategy for SBM. For that, we developed an iterative procedure allowing to automatically compute the best temperature distribution along the preform

2. PET PreformManufacturing & Blowing Chemistry

Pet Bottle Preform Production Industry Continues To Innovate Posted January 5, 2019 by nicolepreform In the product development and manufacturing stages, any errors may result in expensive recalls and may even cause potential harm.

PET PREFORM SYSTEMS conairgroup.com

Pet Bottle Manufacturing Database Index Temperature

WO2002062549A2 Method and apparatus for conditioning pet

The book Technology of PET Bottles, Preform and PET Recycling covers PET Plastic packaging, Properties of PET, Recycling of PET, Aseptic Filling of PET Bottles, Flexo Inks for the printing of Non treated Polyester films (PET) on central impression Flexo Presses, Production and filling process of a Pet Bottle, PET Bottle Recycling, PET Preform

pet preform making machine.wmv YouTube

2. PET PreformManufacturing & Blowing Chemistry

Alibaba.com offers 36 pet preforms manufacturing process products. About 13% of these are moulds, 2% are machining. A wide variety of pet preforms manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

COMPLETE MILK BOTTLING LINE Stretch and PET blow molding

Minimising packaging Coca-Cola’s lightest ever PET 500ml

machine type, usually using a preform initially designed for PET will work. For the most part, with just changes in some For the most part, with just changes in some processing parameters like temperature and blow timing, a high quality Ingeo bottle can be made from a preform designed for

PET PREFORM SYSTEMS conairgroup.com

Project Report on PET PREFORM MANUFACTURING FROM PET RESIN

This is the first stage in the two stage PET bottle manufacturing process suitable for large scale production and here the pet preform is molded on an injection moulding machine. MANUFACTURING PROCESS PET granules received from suppliers are dried in a dehumidifier.Manufacturing of PET preforms KSIDC PROJECT PROFILE FOR MANUFACTURING OF PET PREFORMS …

pet preforms manufacturing process Alibaba

Preheating of a Poly(ethylene terephthalate) Preform for

production process. The new process will be rolled out at CCE’s manufacturing sites at Sidcup and Wakefield in 2007 and 2008. When the project is complete, almost 700 million of the new bottles will be produced annually saving approximately 1400 tonnes of PET plastic every year. The lighter bottles meet all The Coca-Cola Company (TCCC) and CCE quality and technical performance standards

pet bottle manufacturing process pdf Exporter pet bottle

Global PET Preforms Market Analysis & Trends Insight 2026

WO2002062549A2 Method and apparatus for conditioning pet

Manufacturing composites at industrial standards is a particularly demanding, highly complex process. While metals and metal alloys used for parts production can simply be molten and cooled off inside molds to create a desired component, fiber-reinforced composite elements need to be combined and prepared before the preform procedures and final

2. PET PreformManufacturing & Blowing Chemistry

the preform length, by modifying the process parameters related to the IR oven. It is interesting to point out that authors questioned the relevance of the objective chosen for the optimization. In this work, we propose a numerical optimization strategy for SBM. For that, we developed an iterative procedure allowing to automatically compute the best temperature distribution along the preform

Single Stage and Multi Stage PET Manufacturing Process

ABSTRACT Process Economics Program Report 18C

machine type, usually using a preform initially designed for PET will work. For the most part, with just changes in some For the most part, with just changes in some processing parameters like temperature and blow timing, a high quality Ingeo bottle can be made from a preform designed for

Global PET Preforms Market Analysis & Trends Insight 2026

Pet Bottle Preform Production Industry Continues To Innovate Posted January 5, 2019 by nicolepreform In the product development and manufacturing stages, any errors may result in expensive recalls and may even cause potential harm.

Production of PET preforms plastic bottles

The global PET preforms market growth is expected to be driven by high demand for PET bottles, jars, tubes in Asia Pacific owing to highest revenue share. PET preforms and bottles are also extremely cost-effective, durable and safe.

Catalog Merrimack Valley Plastics LLC

PET Preform Entrepreneur India

manufacturing technology (high efficiency, low power consumption, full automation of the process). PET offers better barrier against oxygen and better protection from odours than HDPE. Possibility of producing tailor-made bottles with original shapes, attractive and esthetic for customers – great marketing oppor-tunities. PET bottles can be transparent or any other colour including white

how to make pet preform- huangyan yichuan mold factory.

PET PREFORM SYSTEMS conairgroup.com

SALES PARTS SERVICE MANUFACTURING concept of “total process visibility.” PET preform molding is a complex and fluid process, with material constantly being brought in, dried and conveyed to the molding machine. To produce a consistent product, this very fluid process must remain stable even as material and ambient conditions change. That’s OPTIMIZER™ MODE For effective drying, the

Pet Bottle Preform Production Industry Continues To Innovate

COMPLETE MILK BOTTLING LINE Stretch and PET blow molding

Process Economics Program Report 18C POLYETHYLENE TEREPHTHALATE (September 2006) Development and growth in the polyethylene terephthalate (PET) solid-state resin market since 1999 have been strong. Since their introduction in the mid-1970, global demand for these resins has reached 10.5 million metric tons by 2004. The global demand for these resins has continued to grow at high …

REGULATION (EC) No 139/2004 MERGER PROCEDURE

Preform Manufacturing an overview ScienceDirect Topics

Preform Design for Ingeo™ Bottles NatureWorks Home

Alibaba.com offers 36 pet preform manufacturing process products. About 13% of these are moulds, 2% are machining. A wide variety of pet preform manufacturing process options are available to you, such as broaching, drilling, and etching / chemical machining.

Tungsten Carbide Preform Manufacturing Process

Presto’s Hot Wire Bottle Cutter NXG is a sophisticated technology based high-quality machine which is widely used by the manufacturers in PET & Preform manufacturing industries to perform the section weight analysis test on PET products.

Preform Manufacturing an overview ScienceDirect Topics

technology of pet bottles preform and pet recycling (hand

PET Preform Entrepreneur India

The book Technology of PET Bottles, Preform and PET Recycling covers PET Plastic packaging, Properties of PET, Recycling of PET, Aseptic Filling of PET Bottles, Flexo Inks for the printing of Non treated Polyester films (PET) on central impression Flexo Presses, Production and filling process of a Pet Bottle, PET Bottle Recycling, PET Preform

pet preform manufacturing process Alibaba

Get complete study material and formulations on Technology Of Pet Bottles, Preform And Pet Recycling (hand Book). Offering complete resources to start new industry including market survey, feasibility report, profit loss and much more.

Stretch Blow Moulding PET Bottles PETform

HARWAL CONTAINER MANUFACTURING PET PREFORMS

SALES PARTS SERVICE MANUFACTURING concept of “total process visibility.” PET preform molding is a complex and fluid process, with material constantly being brought in, dried and conveyed to the molding machine. To produce a consistent product, this very fluid process must remain stable even as material and ambient conditions change. That’s OPTIMIZER™ MODE For effective drying, the

pet preform making machine.wmv YouTube

Preform Manufacturing Dubai Closures Manufacturing Dubai

Pet Bottle Preform Production Industry Continues To Innovate

Comments are closed.