Poka yoke in manufacturing pdf

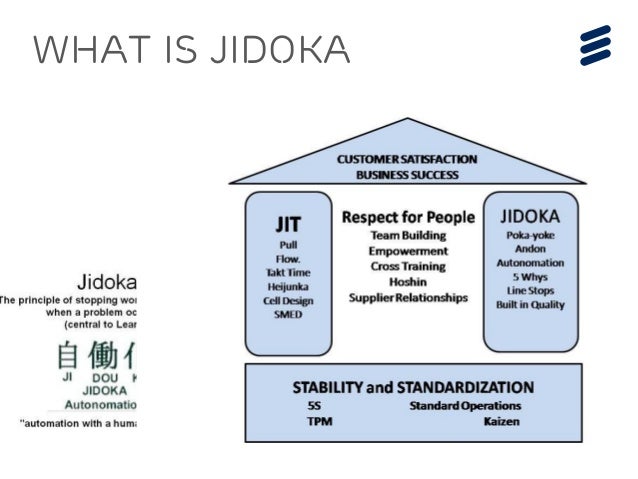

What is Poka Yoke? Developed by Toyota Motors as a tool to achieve Zero Defects Originally called Baka Yoke (idiot proof) but recognized that this label could offend workers so changed to Poka Yoke (Mistake Proofing) One serious obstacle to extending equipment life is the unexpected failure that occurs as a result of operating or […]

The benefits of lean manufacturing what lean thinking has to offer the process industries t. melton mime solutions ltd, chester, uk h ow many people…

Poka Yoke Mistake Proofing article by Darren Dolcemascolo of EMS Consulting Group, an organization established to assist companies implement Lean and World Class Manufacturing programs.

Poka Yoke Definition & Meaning “Poka-Yoke” a Japanese term coined by Shiego Shingo in the 1960’s meaning “mistake-proofing”. It is a highly effective quality control tool.

The manufacturing industry is, unsurprisingly, a major adopter of poka-yoke. There are many reasons for that, and it’s clear that this type of work can be simplified a lot by introducing small safeguards and other similar details, while also making it safer for everyone involved. There are indeed many examples of poka-yoke in various manufacturing plants, and one doesn’t have to look long

Lean manufacturing – Poka yoke Un proces rezistent la eroare implică o metodologie structurată de asigurare a calităţii şi a lipsei de erori în mediul de producţie, prin utilizarea de dispozitive şi de metode care să nu permită transmiterea pe flux în aval a unor

The value proposition to implement Poka Yoke into Medical Device Manufacturing is an increase in product yields and a reduction in rework and scrap. The great thing about poka-yoke is that implementation can be very simple and very effective.

Poka Yoke is a simple concept that is often used in manufacturing. It means “mistake-proofing.” This infographic uses examples from every day life to illustrate this concept of adding simple design features to make it almost impossible for errors to occur.

5S Poka Yoke Applications – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. This paper briefly describes how 5S model in TQM may be applied to a variety of design processes in real life.

6 To obtain the proper base of Shingo’s work, we must adopt the Japanese mind set of manufacturing which differs (Thank GOD) from Frederick W. Taylor.

manufacturing practices and the Toyota Production System. It is therefore started in Japanese organizations to implement a Zero Quality Control (ZQC). One of its elements implementing the principle ZQC is Poka-Yoke method. The name Poka-Yoke was established by Shigeo Shingo in 1963, it is translated as “resistance to errors” (avoid (yoker) errors resulting from absence of mind

Manufacturing technology on the horizon promises to transform poka yoke by disrupting many of the elements that make the value it delivers so costly to achieve. In this article, I’ll lay out four benefits of the coming age of new factory technology that could be applied to simplify and accelerate poka yoke .

Lean manufacturing practices in textile indu stries 29 There are three main method s for using poka-yoke systems: • Contact me thods – this m ethod works by detecting whet her a product makes

Poka-Yoke systems, on the other hand, can be used to inspect all parts and immediately identify errors, building an important safeguard into the process. To further hold down costs, Res even designs and builds its own Poka-Yoke systems right in house. After all, when it comes to your stamped metal products, you shouldn’t have to choose between higher quality and lower costs.

A Poka-yoke device within the contact method category is used to inform components of the manufacturing process, whether it be a person or machine, about the current state of the product by detecting a physical contact or contact with a source of energy (i.e. electricity, photoelectric beam).

Poka Yoke. Poka yoke is a Japanese term used to describe reliable work methods, tools and processes that eliminates the possibilities of errors being made by production staff that may lead to defects, production downtime and re-work being produced.

Now, I believe, intelligent poka yoke, as an instance of a Coaching Network, has the potential to reorient manufacturing further around the human operator. (In fact, manufacturing history buffs who have read The Machine that Changed the World know that lean manufacturing replaced mass manufacturing over the previous four decades.

Review Paper On “Poka Yoke: The Revolutionary Idea… 20 Fig. 1 General activity aim at prevent defects [1] During actual manufacturing of any product …

He has hands on experience in shop floor improvements on

Poka-Yoke Methods in Lean Manufacturing

6 PokaYoke – Download as PDF File (.pdf), Text File (.txt) or read online.

Poka Yoke is a technique driven approach to achieve Zero Defect Quality. The common sense approach relying primarily on machine vigilance rather than human vigilance allowed Toyota to become so profitable & a high quality manufacturer.

In this paper, Poka yoke as one of the effective quality design techniques experienced in manufacturing has beensuggested and developed for service fail-safing.

Use Tulip’s poka yoke app template to increase productivity by helping the workforce perform more tasks, with less mistakes.

All About “Poka-Yoke” (Mistake Proofing) Continuous Improvement Training www.freeleansite.com Learning Objectives • Understand definition of Poka-Yoke and “zero defect” quality.

Poka-yoke (poh-kah yoh-keh) is a Japanese word used in manufacturing environment for “mistake-proofing” or avoiding (yokeru) inadvertent errors (poka). A poka-yoke is a quality tool or method that makes it more difficult to make mistakes and therefore reduces variability in the process caused by human intervention. In a broader sense, the term can refer to any behaviour-shaping constraint

Poka Yoke in Parts Design (primarily in manufacturing) Hydraulic hoses and wiring harnesses can have different size connectors. Hoses and wires can also be cut to lengths that make it impossible to install incorrectly.

Title: Lean manufacturing – Poka yoke Author: TÜV Rheinland Romania Keywords: Lean manufacturing – Poka yoke tuv rheinland;ursuri si instruiri;oferta cursuri;cursuri automotive;industria auto;lean manufacturing;poka yoke;produse neconforme;prevenirea erorilor;eliminarea defectelor

American Journal of Engineering Research (AJER) 2016 w w w . a j e r . o r g Page 17 V. CASE STUDY XYZ is an air duct manufacturing enterprise, located in the district of Hooghly in India.

Examples of Poka Yoke Used in Manufacturing Processes Thrashing out mistakes in manufacturing engineering was developed by the Japanese as a tool of mistake proofing that helps reduce waste in areas such as time, energy and resources.

car (an improved visibility poka yoke). In a manufacturing department, technicians use templates in the form of the finished assembly to align orientation of brackets and

memory, poka-yoke may save time and release the mind of worker for operations more creative and increase their value [10, 14-17]. At each stage of the product life cycle, in each process and its

2/06/2017 · Category People & Blogs; Song CDM_165_04 Global Market (Lyonel Bauchet) Artist Lyonel BAUCHET; Album Corporate,Strings,Activity,Communications,Media,Business

Poka-Yoke is one of the simplest tools to master; it’s very consistent with the fundamental aims and philosophy of Six Sigma, and it has wide applicability in manufacturing, engineering, and transactional processes. Poke-Yoke involves creating actions that are designed to eliminate errors, mistakes, or defects in everyday activities and processes.

Poka Yoke Total Productive Maintenance

– manufacturing companies in north york pdf

Poka-Yoke Basics – Poka-Yoke-Platform

Imagining the World of Intelligent ‘Poka Yoke’

5S Poka Yoke Applications Production And Manufacturing

Poka Yoke Definition & Meaning Poka Yoke Examples

Poka-Yoke RES Manufacturing – resmfg.com

Intelligent Poka Yoke When Lean Manufacturing Meets Deep

Applying Poka-Yoke in the Manufacturing Industry Shmula

https://en.wikipedia.org/wiki/Shigeo_Shingo

Lean Manufacturing concept Poka-yoke

pdf rheem manufacturing company 2016 sa les revenue – Poka Yoke Increase Productivity – Tulip

Poka-Yoke Basics – Poka-Yoke-Platform

Applying Poka-Yoke in the Manufacturing Industry Shmula

Lean manufacturing practices in textile indu stries 29 There are three main method s for using poka-yoke systems: • Contact me thods – this m ethod works by detecting whet her a product makes

Poka Yoke Definition & Meaning “Poka-Yoke” a Japanese term coined by Shiego Shingo in the 1960’s meaning “mistake-proofing”. It is a highly effective quality control tool.

In this paper, Poka yoke as one of the effective quality design techniques experienced in manufacturing has beensuggested and developed for service fail-safing.

Review Paper On “Poka Yoke: The Revolutionary Idea… 20 Fig. 1 General activity aim at prevent defects [1] During actual manufacturing of any product …

Poka-Yoke systems, on the other hand, can be used to inspect all parts and immediately identify errors, building an important safeguard into the process. To further hold down costs, Res even designs and builds its own Poka-Yoke systems right in house. After all, when it comes to your stamped metal products, you shouldn’t have to choose between higher quality and lower costs.

Poka Yoke is a technique driven approach to achieve Zero Defect Quality. The common sense approach relying primarily on machine vigilance rather than human vigilance allowed Toyota to become so profitable & a high quality manufacturer.

car (an improved visibility poka yoke). In a manufacturing department, technicians use templates in the form of the finished assembly to align orientation of brackets and

Poka Yoke. Poka yoke is a Japanese term used to describe reliable work methods, tools and processes that eliminates the possibilities of errors being made by production staff that may lead to defects, production downtime and re-work being produced.

memory, poka-yoke may save time and release the mind of worker for operations more creative and increase their value [10, 14-17]. At each stage of the product life cycle, in each process and its

32 replies on “Poka yoke in manufacturing pdf”

Leave a CommentA Poka-yoke device within the contact method category is used to inform components of the manufacturing process, whether it be a person or machine, about the current state of the product by detecting a physical contact or contact with a source of energy (i.e. electricity, photoelectric beam).

Lean manufacturing – Poka yoke tuv.com

POKA Yoke YouTube

Review Paper On “Poka Yoke: The Revolutionary Idea… 20 Fig. 1 General activity aim at prevent defects [1] During actual manufacturing of any product …

He has hands on experience in shop floor improvements on

Poka Yoke Definition & Meaning Poka Yoke Examples

5S Poka Yoke Applications Production And Manufacturing

The benefits of lean manufacturing what lean thinking has to offer the process industries t. melton mime solutions ltd, chester, uk h ow many people…

Poka-Yoke Methods in Lean Manufacturing

What is Poka Yoke? Developed by Toyota Motors as a tool to achieve Zero Defects Originally called Baka Yoke (idiot proof) but recognized that this label could offend workers so changed to Poka Yoke (Mistake Proofing) One serious obstacle to extending equipment life is the unexpected failure that occurs as a result of operating or […]

Poka-Yoke Generic Module Lean Manufacturing Sensor

Using PokaYoke for the Development of SMEs – AJER

Lean manufacturing – Poka yoke tuv.com

Poka Yoke is a simple concept that is often used in manufacturing. It means “mistake-proofing.” This infographic uses examples from every day life to illustrate this concept of adding simple design features to make it almost impossible for errors to occur.

Intelligent Poka Yoke When Lean Manufacturing Meets Deep

Poka Yoke Increase Productivity – Tulip

Poka-Yoke is one of the simplest tools to master; it’s very consistent with the fundamental aims and philosophy of Six Sigma, and it has wide applicability in manufacturing, engineering, and transactional processes. Poke-Yoke involves creating actions that are designed to eliminate errors, mistakes, or defects in everyday activities and processes.

Applying Poka-Yoke in the Manufacturing Industry Shmula

manufacturing practices and the Toyota Production System. It is therefore started in Japanese organizations to implement a Zero Quality Control (ZQC). One of its elements implementing the principle ZQC is Poka-Yoke method. The name Poka-Yoke was established by Shigeo Shingo in 1963, it is translated as “resistance to errors” (avoid (yoker) errors resulting from absence of mind

Using PokaYoke for the Development of SMEs – AJER

Poka Yoke Definition & Meaning Poka Yoke Examples

The benefits of lean manufacturing what lean thinking has to offer the process industries t. melton mime solutions ltd, chester, uk h ow many people…

Poka Yoke Increase Productivity – Tulip

He has hands on experience in shop floor improvements on

Poka-Yoke systems, on the other hand, can be used to inspect all parts and immediately identify errors, building an important safeguard into the process. To further hold down costs, Res even designs and builds its own Poka-Yoke systems right in house. After all, when it comes to your stamped metal products, you shouldn’t have to choose between higher quality and lower costs.

Examples of Poka Yoke Used in Manufacturing Processes

POKA Yoke YouTube

Using PokaYoke for the Development of SMEs – AJER

The manufacturing industry is, unsurprisingly, a major adopter of poka-yoke. There are many reasons for that, and it’s clear that this type of work can be simplified a lot by introducing small safeguards and other similar details, while also making it safer for everyone involved. There are indeed many examples of poka-yoke in various manufacturing plants, and one doesn’t have to look long

Lean manufacturing – Poka yoke tuv.com

The value proposition to implement Poka Yoke into Medical Device Manufacturing is an increase in product yields and a reduction in rework and scrap. The great thing about poka-yoke is that implementation can be very simple and very effective.

Poka-Yoke Basics – Poka-Yoke-Platform

Lean manufacturing – Poka yoke tuv.com

6 To obtain the proper base of Shingo’s work, we must adopt the Japanese mind set of manufacturing which differs (Thank GOD) from Frederick W. Taylor.

Poka Yoke Increase Productivity – Tulip

Poka-Yoke RES Manufacturing – resmfg.com

Examples of Poka Yoke Used in Manufacturing Processes

Lean manufacturing practices in textile indu stries 29 There are three main method s for using poka-yoke systems: • Contact me thods – this m ethod works by detecting whet her a product makes

Lean manufacturing – Poka yoke tuv.com

Applying Poka-Yoke in the Manufacturing Industry Shmula

The benefits of lean manufacturing what lean thinking has to offer the process industries t. melton mime solutions ltd, chester, uk h ow many people…

POKA Yoke YouTube

Poka Yoke Total Productive Maintenance

Lean Manufacturing concept Poka-yoke

Poka-Yoke is one of the simplest tools to master; it’s very consistent with the fundamental aims and philosophy of Six Sigma, and it has wide applicability in manufacturing, engineering, and transactional processes. Poke-Yoke involves creating actions that are designed to eliminate errors, mistakes, or defects in everyday activities and processes.

Poka-Yoke Basics – Poka-Yoke-Platform

Poka-Yoke systems, on the other hand, can be used to inspect all parts and immediately identify errors, building an important safeguard into the process. To further hold down costs, Res even designs and builds its own Poka-Yoke systems right in house. After all, when it comes to your stamped metal products, you shouldn’t have to choose between higher quality and lower costs.

Imagining the World of Intelligent ‘Poka Yoke’

How to Mistake Proof with Poka Yoke in Six Sigma dummies

Using PokaYoke for the Development of SMEs – AJER

Review Paper On “Poka Yoke: The Revolutionary Idea… 20 Fig. 1 General activity aim at prevent defects [1] During actual manufacturing of any product …

How to Mistake Proof with Poka Yoke in Six Sigma dummies

Intelligent Poka Yoke When Lean Manufacturing Meets Deep

Using PokaYoke for the Development of SMEs – AJER

Poka-Yoke systems, on the other hand, can be used to inspect all parts and immediately identify errors, building an important safeguard into the process. To further hold down costs, Res even designs and builds its own Poka-Yoke systems right in house. After all, when it comes to your stamped metal products, you shouldn’t have to choose between higher quality and lower costs.

Poka-Yoke RES Manufacturing – resmfg.com

In this paper, Poka yoke as one of the effective quality design techniques experienced in manufacturing has beensuggested and developed for service fail-safing.

How to Mistake Proof with Poka Yoke in Six Sigma dummies

Examples of Poka Yoke Used in Manufacturing Processes

POKA Yoke YouTube

6 To obtain the proper base of Shingo’s work, we must adopt the Japanese mind set of manufacturing which differs (Thank GOD) from Frederick W. Taylor.

Lean Manufacturing concept Poka-yoke

Examples of Poka Yoke Used in Manufacturing Processes

He has hands on experience in shop floor improvements on

5S Poka Yoke Applications – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. This paper briefly describes how 5S model in TQM may be applied to a variety of design processes in real life.

5S Poka Yoke Applications Production And Manufacturing

Poka-Yoke RES Manufacturing – resmfg.com

He has hands on experience in shop floor improvements on

Manufacturing technology on the horizon promises to transform poka yoke by disrupting many of the elements that make the value it delivers so costly to achieve. In this article, I’ll lay out four benefits of the coming age of new factory technology that could be applied to simplify and accelerate poka yoke .

Lean Manufacturing concept Poka-yoke

Poka Yoke Definition & Meaning Poka Yoke Examples

car (an improved visibility poka yoke). In a manufacturing department, technicians use templates in the form of the finished assembly to align orientation of brackets and

Lean Manufacturing concept Poka-yoke

Poka Yoke. Poka yoke is a Japanese term used to describe reliable work methods, tools and processes that eliminates the possibilities of errors being made by production staff that may lead to defects, production downtime and re-work being produced.

Poka-Yoke Methods in Lean Manufacturing

Intelligent Poka Yoke When Lean Manufacturing Meets Deep

Using PokaYoke for the Development of SMEs – AJER

Poka Yoke Mistake Proofing article by Darren Dolcemascolo of EMS Consulting Group, an organization established to assist companies implement Lean and World Class Manufacturing programs.

He has hands on experience in shop floor improvements on

Lean manufacturing – Poka yoke tuv.com

5S Poka Yoke Applications Production And Manufacturing

Poka Yoke in Parts Design (primarily in manufacturing) Hydraulic hoses and wiring harnesses can have different size connectors. Hoses and wires can also be cut to lengths that make it impossible to install incorrectly.

POKA Yoke YouTube

In this paper, Poka yoke as one of the effective quality design techniques experienced in manufacturing has beensuggested and developed for service fail-safing.

How to Mistake Proof with Poka Yoke in Six Sigma dummies

Poka Yoke Increase Productivity – Tulip

Title: Lean manufacturing – Poka yoke Author: TÜV Rheinland Romania Keywords: Lean manufacturing – Poka yoke tuv rheinland;ursuri si instruiri;oferta cursuri;cursuri automotive;industria auto;lean manufacturing;poka yoke;produse neconforme;prevenirea erorilor;eliminarea defectelor

POKA Yoke YouTube

(PDF) Lean manufacturing practices in textile industries

Poka Yoke Increase Productivity – Tulip

Poka Yoke in Parts Design (primarily in manufacturing) Hydraulic hoses and wiring harnesses can have different size connectors. Hoses and wires can also be cut to lengths that make it impossible to install incorrectly.

Poka-Yoke Generic Module Lean Manufacturing Sensor

Poka Yoke is a technique driven approach to achieve Zero Defect Quality. The common sense approach relying primarily on machine vigilance rather than human vigilance allowed Toyota to become so profitable & a high quality manufacturer.

Examples of Poka Yoke Used in Manufacturing Processes

He has hands on experience in shop floor improvements on

What is Poka Yoke? Developed by Toyota Motors as a tool to achieve Zero Defects Originally called Baka Yoke (idiot proof) but recognized that this label could offend workers so changed to Poka Yoke (Mistake Proofing) One serious obstacle to extending equipment life is the unexpected failure that occurs as a result of operating or […]

POKA Yoke YouTube

5S Poka Yoke Applications – Download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online. This paper briefly describes how 5S model in TQM may be applied to a variety of design processes in real life.

Lean Manufacturing concept Poka-yoke

POKA Yoke YouTube

Comments are closed.