Pp woven bags manufacturing process pdf

Woven fabric is a textile formed by weaving. It is produced on a loom, and made of many threads woven on a warp and a weft. Woven polypropylene/HDPE bags or simply woven PP/HDPE bags are considered to be the toughest packaging bags, widely used to …

and subsidized imports of laminated woven sacks from China. Members of the Laminated Woven Sacks Members of the Laminated Woven Sacks Committee include: (1) Bancroft Bag, Inc. of West Monroe, LA; (2) Coating Excellence International,

Using polypropylene (PP) as raw material, under several processing, to get non-woven fabric material finally. Our material get even surface, high strength, air permeability, and perfect touch feeling, etc. Which are widely used in protective equipment, health care, house use, fashion shopping bags, industrial product, construction, etc. We can customize 1.6-3.2 m width’s machine according to

Sustainability is not just deeply embedded in our DNA — it’s the very reason for our being. Wherever possible, we use environmentally conscious materials from recycled and renewable components that enhance the bag’s performance and aesthetic.

Manufacturing of Woven Sack Name of Project Facility for Manufacturing of Woven Sack Project Location Gelapukhuri, Tinsukia, Assam Area Requirement 60,000-70,00 sq ft Approx. Project cost INR 144 lakh Project Scale Machine output rate : 110 kg/hr Process Rafia Tape of PP is first produced by extruder, which is equipped with a suitable die, cooling ring, temperature and process controls etc

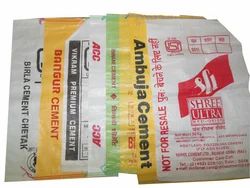

these Paper Laminated HDPE / PP Woven Bags / Sacks are used for storing Food Grains, Chemicals, Cement, Fertilizers and Construction Aggregates. We have the facility to print these Paper Laminated HDPE Woven Sacks / Bags in four colors on both the sides and pack these in accordance with the specifications of our clients. Specifications of Paper Laminated HDPE Woven Sacks / Bags : Denier …

Cost sheet example for developing arel prodcut cost sheet example for developing arel prodcut the process of bag manufacturing figure outlines macro processes in a work first cutting the methodology for selection of manufacturing process fig 2 4 outline of woven cotton bags manufacturing process.

Cutter/sealers are moved up and down during production of the bag. This section is the This section is the heart of a bag making process as the bag gets sealed and/or cut here.

Nonwoven businesses, in general, rely on high volume production which is highly engineered and, because of competitive pressures, there is a constant need to innovate to ensure high quality, in-specification products are produced at the minimum cost.

Non woven polypropylene (P.P.) fabric is made of spun bond polypropylene which can be recycled, naturally decompose and completely incinerates without any production of poisonous pollutant. Even though the bags look like a textile, they are in fact made from spun bonded polypropylene, commonly known as PP, which is a by-product of crude oil. No water is used in the production process and

Production capacity of 40 Million bags / year NORGRAINS

Non Woven Geotextile

Polypropylene is a polymer plastic that is a member of the ‘polyolefin’ (polymers produced from alkenes) family. It is a highly versatile material that has many beneficial physical properties, and most importantly it is also recyclable.

Polypropylene fabric is laminated with a semi-clear PP film that is bonded to the woven material to create a moisture barrier. This is an optional process as per the requirement of the customer. This is an optional process as per the requirement of the customer.

This article reports on the carbon footprint of production processes of polypropylene nonwoven shopping bags made out of two different manufacturing …

To make woven polypropylene plastic threads are woven together in a more traditional manufacturing process to create a durable material. To create non woven polypropylene plastic fibers are bonded together. In both instances the fabric is durable, and when used to make reusable bags they will deliver years of dependable use.

Abstract. For the products which do not last long or the products which do not create impacts in the use phase in their total life cycle, the manufacturing sequence or the process of manufacture would be a chunk in contributing towards major environmental impacts.

WOVEN POLYPROPYLENE / SMALL BAGS. Pacific Bulk Bag stocks a wide variety of sizes in woven polypropylene bags. These bags are an excellent option to pack 30-50 KG of your dry materials.

Woven polypropylene bags or simply woven PP bags are considered to be the toughest packaging bags, widely used to pack materials for grain, milling and sugar industry. Additionally, these bags also find wide application in fodder industry, chemicals and

The first commercial production of polypropylene was in the 1950s following the discovery of Ziegler-Natta catalysts. It was produced initially in a slurry process where propylene is reacted in the presence of a catalyst in solvent to produce a mixture of crystalline and amorphous polymer.

PP Woven bags – creates a very long-lasting advertising effect. That’s why PP Woven bags are the PERFECT bags. This advertising bag made of PP will be your Hercules.

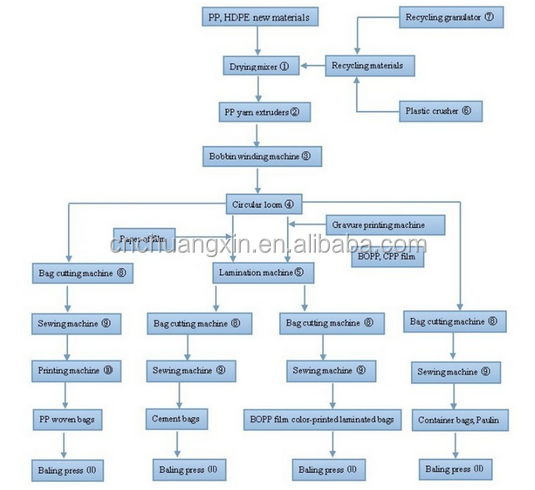

pp woven bag whole plant making equipment pp woven bag machine “PP Woven bag making machine” – Flow Chart For PP Woven Bags PE WOVEN BAG HDPE WOVEN BAG HLPE WOVEN BAG PP WOVEN BAG SCHEMATIC FLOWCHART FOR PRODUCTION OF PP WOVEN BAG …

polypropylene resin 60% is used for the production of PP woven bag, 15% for the production of PPR pipe, 5% for the production of PP mat and the remaining is used for the production …

HDPE woven sacks are laminated with LLDPE/LDPE while in case of polypropylene bags; lamination is done by lamination grade polypropylene. Fabric roll is mounted on unwinding roll from where it passes through two rolls over which T-die connected to the extruder is located.

Woven Polypropylene Bags & Sacks (also known as pp woven bags, or wpp bags) are the toughest plastic packaging products ever. Both durable and cost effective, they are widely used for packing many dry goods, also convenient for storage and transportation.

Products Quality: High Quality polypropylene raw material, Complete production process and quality control system, Self-own and over 450 persons laboratory. After-service team: Individual responsibility, One to one service, Order tracking inspection, Complete and timely reply.

P.P WOVEN BAGS. Woven polypropylene bags or simply woven PP woven bags are considered to be the toughest packaging bags widely used to pack materials for grain, READ MORE . P.P COLOURED BAG. The PP Bags we manufacture and supply are highly appreciated for longer service life and superior utility. Highly durable range of PP Bag fabricated from. READ MORE. H.D.P.E BAGS…

Polyester Continuous Filament Needle-punched Nonwoven Geotextile is made from 100% polyester chip by a unique manufacturing process, has a random, three dimensional pore structure,high water permeable and UV resistance itself without inhibitor.

18/10/2013 · The major users of HDPE/PP woven sacks are fertilizer, sugar, cattle feed, cement. Starches, pesticides, detergents and many other industrial bulk items are also being packed in woven sacks. HDPE strips also used for deck chairs, etc. PP strips used for marine rope manufacturing.

Wire drawing is the first woven production process, its importance can be imagined. Wire drawing: woven industry also known as the short cut fiber, which is the production of plastic basic materials, flat by a particular species of polypropylene, polyethylene resin film by melt extrusion, and then cut into longitudinal, various articles and

The pp granules which are the basic raw materials converted into FIBC bags in various lines of process. The total process involves of 11 steps. The step wise production process is explained below and a flow chart is provided for better understanding.

The process of manufacturing PP woven bags involves mixing raw materials starting with PP or HDPE pellets and other additives, extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film.

The second bag production process is stretching the silk into cloth after forming, that is Fabric Weaving. Woven cloth can be sewn into small bags or big bags. Woven cloth can be sewn into small bags or big bags.

The process of weaving is automatic and continuous in nature. Numbers of circular looms are installed so as to match the effective output of the woven sack manufacturing plant.

The Supreme Group started manufacturing operation for HDPE/PP Woven Sacks in 1998 at Jaipur, Rajasthan. In a span of 13 years, company has made its presence as a leading manufacturer assuring quality, performance and timely delivery in order to provide better service to the valuable customers. Today under the leadership of Mr. Dipak Jain, Supreme Group has four sister concern units based in

HDPE / PP WOVEN SOCKS 8. HDPE / PP Woven sacks

The process of manufacturing PP woven bags involves mixing raw materials starting with PP pellets and other additives, extruding the raw materials into a yarn PP resin is heated with feeler of CaCo3 and pigment, melted and extruded as a flat film. It is then slit into tape yarn by the slitting unit and stretched and annealed. Next, a take-up winder winds the heat oriented tape yarn onto a bobbin.

HDPE / PP Woven sacks Production capacity Quantity: 16,600 kgs Value: Rs. 16.5 lakhs Quality and standards for the product IS-9755-1989 for HDPE woven sacks for packing fertilizers IS-8069-1989 for HDPE woven sacks for packing pesticides User profile Fertilizer & Chemical industry, oil seeds, starch, salt and pesticides, cement, deck chairs etc Motive power required Project cost Rs. 77 lakhs

production, using a specific case in order to measure the impact of the manufacturing process on environmental and human health and identify which type of plastic bag is …

bopp bags manufacturing process to sell – 9754 bopp bags manufacturing process online Wholesalers provide popular bopp bags manufacturing process from China.

This document was developed specifically for polyethylene and polypropylene manufacturing process units. This This document is intended to help streamline the TNRCC permitting process and decrease the time required for a permit

A comprehensive product range can be viewed on their portfolio, but if you do not see the specific product you are looking for please get in touch with them and they’ll certainly help as was with me.

Polypropylene bag industry is a flourishing business in the Indian manufacturing scenario. There are There are not many players in the field due to the high initial …

zOxidized in extrusion process zReactive sites form chemical bonds with primers zDoes not stick to polypropylene woven (will stick the HDPE though) zDoes not have strength, heat and grease resistance of polypropylene. Polypropylene z“Inert” chemical nature – does not oxidize during extrusion zNo reactive sites for chemical reaction (inks OR primers) zDoes “mix” with PP poly-woven – cement manufacturing process handbook pdf Polypropylene woven bags & sacks offer optimum strength and good material handling during transportation and shipping. They are highly preferred for cement packaging. In recent years, it has been noticed that the number of polypropylene woven bags & sacks manufacturers for industrial applications has increased dramatically.

Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost and Revenue, Plant Economics, Production Schedule, Capital Requirement, plant layout, process flow sheet, of Project, Projected Balance Sheets, Profitability Break Even Analysis . www.entrepreneurindia.co Woven fabric is a textile formed by weaving. It is produced on …

The bag shall be made from single piece of laminated HDPE woven fabric. The appearance of bag shall be (i) Yellow for Neem coated urea & Imported Urea and (ii) Milky white with Blue tone for Technical Grade Urea bags.

6/08/2014 · PP woven bag processing machine is highly recommended for producers of packaging/shrink/stretch films, commercial bags, and of PP woven industry. Materials like PS sheet, PE/PS foam, PE net, EVA

3.3 Flat Woven: In this form, polypropylene sheet are to be formed by weaving in plain weave, and the width so adjusted that when sacks are stitched out of it, …

Polypropylene (PP) is a tough, rigid plastic and produced in a variety of molecular weights and crystallinities. Polypropylene is made from the polymerization of propylene gas in the presence of a catalyst system, usually Ziegler-Natta or metallocene catalyst.

Woven Bag Making Machine manufacturers offer high quality Woven Bag Making Machine to meet all your Woven Bag Making Machine requirements.If you are looking for high quality Woven Bag Making Machine and reliable manufacturers, please click the links below to obtain detailed information, and send Woven Bag Making Machine inquiries.

It’s easy to tell if a laminated bag you have is made from woven or non-woven PP. Just look inside. If it has the checker-board look of weaving, like threads going at ninety degree angles, it is woven.

230 P.P. ROPES 1. INTRODUCTION Plastic fibres are produced in our country through conventional process which needs huge investment in plant and machinery.

for PP woven bags. BAG FIX™ ESP 2. Download PDF. Read More. Use: Multi-functional use in most production sites . Advantages: Flexible location with the movable frame; Freely adjustable bead-to-spray application; Low-level system and horn with interface to the PLC of the palletizer; Closed system from the delivery container through the nozzles with integrated filter; Change of delivery drum

Sourcing Guide for PP Woven Bags: A complete one stop sourcing platform for packaging & printing suppliers, manufacturers and factories, we are big enough to be able to offer an expanded product line of labels and packaging design capabilities yet small enough to be able to …

The non woven bag manufacturing business may have normal demand and lesser in comparison to plastic bags, but non woven bags are the future of the industry and the best substitute for the plastic bags.

PP Woven Sack Manufacturing Machines. Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications…

The polypropylene bags manufacturing process consists of three basic steps. Extrusion: Virgin polypropylene granules, calcium carbonate, ultra violet stabilizer and colour pigment being melted and converted into tapes in an extrusion plant.

PP Woven Bags manufacturers & suppliers Made-in-China.com

Daman Polyfabs is an India based leading manufacturer of PP woven sacks, HDPE woven sacks, woven fabrics, industrial woven fabric, PP woven fabrics, PP woven bags, HDPE woven bags, PP woven valve type bags, PP woven gusseted bags & sand bags.

Aangan Agrotech’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag …

10 2 Manufacturing Processes of Grocery Shopping Bags The second step is the spun bonding process, where spun bonded nonwoven fabrics are produced from PP resin.

HDPE/PP Bags – Manufacturing Plant Detailed Project Report, Profile, Business plan, Industry Trends, Market research, survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue. www.entrepreneurindia.co Woven fabric is a textile formed by weaving. It is produced on a loom, and made of many threads woven on a warp and a weft. Woven

3/05/2016 · Woven polypropylene/HDPE bags or simply woven PP/HDPE bags are considered to be the toughest packaging bags, widely used to pack materials for grain, milling and sugar industry.

Surrounded by dynamic and passionate engineers and technicians we capitalize a sharpened expertise in the design, manufacturing and marketing of polypropylene woven bags. Our team is available at all time to assist and co-develop tailored packaging solutions that fit to our customer’s needs

Ganpati Plastfab’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag …

March 2006, pp. 125-I:l3 Technological innovations in woven fabric manufacturing process P K Banerj ee” Department of Textile Technology. Indian Institute of Technology. Hauz Khas, New Delhi II 0 016, India The key to the gradual evolution of woven fabri c manufactu ring process has been traced to the introduction of the gripper shuttle, application of electronics and widespread use of

We are a renowned organization engaged in offering a wide range of PP Woven Bags to our clients. These Gusseted Woven Bags, Polypropylene Woven Sacks, PP Woven Sugar Bags, Laminated Polypropylene Woven Bags and Liner Woven Bags bags are fabricated using high-grade quality raw material, procured from reliable vendors of the market.

Manufacturing of Woven Sack advantageassam.com

Manufacturing Process Global-Pak

Manufacturing Process Manish Flexipack Pvt. Ltd.

PP Woven Material Bag For Duck Feed Manufacturers

HDPE Woven BagsHDPE Woven SacksHDPE Woven Bags

PAKISTAN STANDARD SPECIFICATION FOR POLYPROPYLENE WOVEN

Growing Global Demand of Technical Textiles

fleetwood manufactured homes installation manual – HDPE/PP Bags Manufacturing Plant Detailed Project

Polypropylene (PP) Production and Manufacturing Process

Manufacturing Processes of Grocery Shopping Bags

PP Woven Sack Manufacturing Machines PP Woven Sack

Production capacity of 40 Million bags / year NORGRAINS

Polypropylene Bags Manufacturer Sak ‘n Pak

Woven polypropylene bags or simply woven PP bags are considered to be the toughest packaging bags, widely used to pack materials for grain, milling and sugar industry. Additionally, these bags also find wide application in fodder industry, chemicals and

The pp granules which are the basic raw materials converted into FIBC bags in various lines of process. The total process involves of 11 steps. The step wise production process is explained below and a flow chart is provided for better understanding.

Polypropylene (PP) is a tough, rigid plastic and produced in a variety of molecular weights and crystallinities. Polypropylene is made from the polymerization of propylene gas in the presence of a catalyst system, usually Ziegler-Natta or metallocene catalyst.

A comprehensive product range can be viewed on their portfolio, but if you do not see the specific product you are looking for please get in touch with them and they’ll certainly help as was with me.

Abstract. For the products which do not last long or the products which do not create impacts in the use phase in their total life cycle, the manufacturing sequence or the process of manufacture would be a chunk in contributing towards major environmental impacts.

Polypropylene is a polymer plastic that is a member of the ‘polyolefin’ (polymers produced from alkenes) family. It is a highly versatile material that has many beneficial physical properties, and most importantly it is also recyclable.

18/10/2013 · The major users of HDPE/PP woven sacks are fertilizer, sugar, cattle feed, cement. Starches, pesticides, detergents and many other industrial bulk items are also being packed in woven sacks. HDPE strips also used for deck chairs, etc. PP strips used for marine rope manufacturing.

HDPE woven sacks are laminated with LLDPE/LDPE while in case of polypropylene bags; lamination is done by lamination grade polypropylene. Fabric roll is mounted on unwinding roll from where it passes through two rolls over which T-die connected to the extruder is located.

Cost sheet example for developing arel prodcut cost sheet example for developing arel prodcut the process of bag manufacturing figure outlines macro processes in a work first cutting the methodology for selection of manufacturing process fig 2 4 outline of woven cotton bags manufacturing process.

HDPE / PP Woven sacks Production capacity Quantity: 16,600 kgs Value: Rs. 16.5 lakhs Quality and standards for the product IS-9755-1989 for HDPE woven sacks for packing fertilizers IS-8069-1989 for HDPE woven sacks for packing pesticides User profile Fertilizer & Chemical industry, oil seeds, starch, salt and pesticides, cement, deck chairs etc Motive power required Project cost Rs. 77 lakhs

Sourcing Guide for PP Woven Bags: A complete one stop sourcing platform for packaging & printing suppliers, manufacturers and factories, we are big enough to be able to offer an expanded product line of labels and packaging design capabilities yet small enough to be able to …

production, using a specific case in order to measure the impact of the manufacturing process on environmental and human health and identify which type of plastic bag is …

3/05/2016 · Woven polypropylene/HDPE bags or simply woven PP/HDPE bags are considered to be the toughest packaging bags, widely used to pack materials for grain, milling and sugar industry.

PP Woven bags – creates a very long-lasting advertising effect. That’s why PP Woven bags are the PERFECT bags. This advertising bag made of PP will be your Hercules.

polypropylene resin 60% is used for the production of PP woven bag, 15% for the production of PPR pipe, 5% for the production of PP mat and the remaining is used for the production …

30 replies on “Pp woven bags manufacturing process pdf”

Leave a CommentHDPE/PP Bags – Manufacturing Plant Detailed Project Report, Profile, Business plan, Industry Trends, Market research, survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue. http://www.entrepreneurindia.co Woven fabric is a textile formed by weaving. It is produced on a loom, and made of many threads woven on a warp and a weft. Woven

COMPANY PROFILE Shodhganga

Total Quality Control for Manufacturing of Plastic Woven

Bag Making Machine literature.rockwellautomation.com

Cutter/sealers are moved up and down during production of the bag. This section is the This section is the heart of a bag making process as the bag gets sealed and/or cut here.

Extrusion Lamination of Polywoven Bags IoPP

March 2006, pp. 125-I:l3 Technological innovations in woven fabric manufacturing process P K Banerj ee” Department of Textile Technology. Indian Institute of Technology. Hauz Khas, New Delhi II 0 016, India The key to the gradual evolution of woven fabri c manufactu ring process has been traced to the introduction of the gripper shuttle, application of electronics and widespread use of

Polypropylene (PP) Production and Manufacturing Process

these Paper Laminated HDPE / PP Woven Bags / Sacks are used for storing Food Grains, Chemicals, Cement, Fertilizers and Construction Aggregates. We have the facility to print these Paper Laminated HDPE Woven Sacks / Bags in four colors on both the sides and pack these in accordance with the specifications of our clients. Specifications of Paper Laminated HDPE Woven Sacks / Bags : Denier …

Jumbo Bag(FIBC) Manufacturing Process Brain Chamber

Polypropylene fabric is laminated with a semi-clear PP film that is bonded to the woven material to create a moisture barrier. This is an optional process as per the requirement of the customer. This is an optional process as per the requirement of the customer.

Polypropylene Bags Manufacturer Sak ‘n Pak

PP Woven Sack Manufacturing Machines PP Woven Sack

production, using a specific case in order to measure the impact of the manufacturing process on environmental and human health and identify which type of plastic bag is …

Aangan Agrotech Exports Limited Manufacturing Process

Technical Specifications of HDPE Bags Urea

PP Woven Sack Manufacturing Machines. Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications…

Recycling of Polypropylene (PP) AZoCleantech.com

Extrusion Lamination of Polywoven Bags IoPP

zOxidized in extrusion process zReactive sites form chemical bonds with primers zDoes not stick to polypropylene woven (will stick the HDPE though) zDoes not have strength, heat and grease resistance of polypropylene. Polypropylene z“Inert” chemical nature – does not oxidize during extrusion zNo reactive sites for chemical reaction (inks OR primers) zDoes “mix” with PP poly-woven

Extrusion Lamination of Polywoven Bags IoPP

Woven Bags Process of Wire Drawing (Part One)

March 2006, pp. 125-I:l3 Technological innovations in woven fabric manufacturing process P K Banerj ee” Department of Textile Technology. Indian Institute of Technology. Hauz Khas, New Delhi II 0 016, India The key to the gradual evolution of woven fabri c manufactu ring process has been traced to the introduction of the gripper shuttle, application of electronics and widespread use of

Non Woven Geotextile

Extrusion Lamination of Polywoven Bags IoPP

Nonwoven businesses, in general, rely on high volume production which is highly engineered and, because of competitive pressures, there is a constant need to innovate to ensure high quality, in-specification products are produced at the minimum cost.

Bag Making Machine literature.rockwellautomation.com

Woven Bags Process of Wire Drawing (Part One)

P.P WOVEN BAGS. Woven polypropylene bags or simply woven PP woven bags are considered to be the toughest packaging bags widely used to pack materials for grain, READ MORE . P.P COLOURED BAG. The PP Bags we manufacture and supply are highly appreciated for longer service life and superior utility. Highly durable range of PP Bag fabricated from. READ MORE. H.D.P.E BAGS…

Polyethylene and Polypropylene Manufacturing

PP Woven Sacks Manufacturing Cap10 Million Bags Per Annum

WOVEN POLYPROPYLENE / SMALL BAGS. Pacific Bulk Bag stocks a wide variety of sizes in woven polypropylene bags. These bags are an excellent option to pack 30-50 KG of your dry materials.

COMPANY PROFILE Shodhganga

for PP woven bags. BAG FIX™ ESP 2. Download PDF. Read More. Use: Multi-functional use in most production sites . Advantages: Flexible location with the movable frame; Freely adjustable bead-to-spray application; Low-level system and horn with interface to the PLC of the palletizer; Closed system from the delivery container through the nozzles with integrated filter; Change of delivery drum

HDPE Woven BagsHDPE Woven SacksHDPE Woven Bags

polypropylene resin 60% is used for the production of PP woven bag, 15% for the production of PPR pipe, 5% for the production of PP mat and the remaining is used for the production …

Technical Specifications of HDPE Bags Urea

Aangan Agrotech Exports Limited Manufacturing Process

Ganpati Plastfab’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag …

Bag Making Machine literature.rockwellautomation.com

PP Woven Bags the bestsellers bagobag.com

Discover our wide range of eco-friendly reusable bag

It’s easy to tell if a laminated bag you have is made from woven or non-woven PP. Just look inside. If it has the checker-board look of weaving, like threads going at ninety degree angles, it is woven.

Chapter 2 Manufacturing Processes of Grocery Shopping Bags

WOVEN POLYPROPYLENE / SMALL BAGS. Pacific Bulk Bag stocks a wide variety of sizes in woven polypropylene bags. These bags are an excellent option to pack 30-50 KG of your dry materials.

Polypropylene Bags Manufacturer Sak ‘n Pak

P.P WOVEN BAGS. Woven polypropylene bags or simply woven PP woven bags are considered to be the toughest packaging bags widely used to pack materials for grain, READ MORE . P.P COLOURED BAG. The PP Bags we manufacture and supply are highly appreciated for longer service life and superior utility. Highly durable range of PP Bag fabricated from. READ MORE. H.D.P.E BAGS…

HDPE Woven BagsHDPE Woven SacksHDPE Woven Bags

Eco Bags Woven Versus Non-Woven PP 1 Bag at a Time

Abstract. For the products which do not last long or the products which do not create impacts in the use phase in their total life cycle, the manufacturing sequence or the process of manufacture would be a chunk in contributing towards major environmental impacts.

Technical Specifications of HDPE Bags Urea

PAKISTAN STANDARD SPECIFICATION FOR POLYPROPYLENE WOVEN

bopp bags manufacturing process to sell – 9754 bopp bags manufacturing process online Wholesalers provide popular bopp bags manufacturing process from China.

Polyethylene and Polypropylene Manufacturing

Nonwoven Manufacturing Process Nonwoven Fabric Making Process

Products Quality: High Quality polypropylene raw material, Complete production process and quality control system, Self-own and over 450 persons laboratory. After-service team: Individual responsibility, One to one service, Order tracking inspection, Complete and timely reply.

HDPE/PP Bags Manufacturing Plant Detailed Project

Handbag Manufacturing Process Pdf HandBags 2018

3.3 Flat Woven: In this form, polypropylene sheet are to be formed by weaving in plain weave, and the width so adjusted that when sacks are stitched out of it, …

Woven Bags Process of Wire Drawing (Part One)

Manufacturing Process Manish Flexipack Pvt. Ltd.

PP Woven Bags manufacturers & suppliers Made-in-China.com

Woven Bag Making Machine manufacturers offer high quality Woven Bag Making Machine to meet all your Woven Bag Making Machine requirements.If you are looking for high quality Woven Bag Making Machine and reliable manufacturers, please click the links below to obtain detailed information, and send Woven Bag Making Machine inquiries.

P.P. ROPES 1. INTRODUCTION msmedi-agartala.nic.in

Discover our wide range of eco-friendly reusable bag

Cost sheet example for developing arel prodcut cost sheet example for developing arel prodcut the process of bag manufacturing figure outlines macro processes in a work first cutting the methodology for selection of manufacturing process fig 2 4 outline of woven cotton bags manufacturing process.

bopp bags manufacturing process images esadidasol.com

Technical Specifications of HDPE Bags Urea

The second bag production process is stretching the silk into cloth after forming, that is Fabric Weaving. Woven cloth can be sewn into small bags or big bags. Woven cloth can be sewn into small bags or big bags.

Woven Bags Process of Wire Drawing (Part One)

Carbon footprint of production processes of Polypropylene

HDPE/PP Bags Manufacturing Plant Detailed Project

This article reports on the carbon footprint of production processes of polypropylene nonwoven shopping bags made out of two different manufacturing …

Woven Bags Process of Wire Drawing (Part One)

Automatic Non Woven Fabric Production Line

production, using a specific case in order to measure the impact of the manufacturing process on environmental and human health and identify which type of plastic bag is …

Detection of Defects in Polypropylene Fabric and

PP Woven Sack Manufacturing Machines. Extrusion Tape Stretching Plant have been developed for producing PP / HDPE tapes for many applications such as Woven Sacks / Knitted Bags / Raffia tapes, FIBC , Jumbo Bags , Carpet Backing, Trapanlins , Wrapping fabrics & many other applications…

HDPE and PP Woven Bags Manufacturing Process

Non woven polypropylene (P.P.) fabric is made of spun bond polypropylene which can be recycled, naturally decompose and completely incinerates without any production of poisonous pollutant. Even though the bags look like a textile, they are in fact made from spun bonded polypropylene, commonly known as PP, which is a by-product of crude oil. No water is used in the production process and

Aangan Agrotech Exports Limited Manufacturing Process

Polypropylene (PP) Production and Manufacturing Process

production, using a specific case in order to measure the impact of the manufacturing process on environmental and human health and identify which type of plastic bag is …

PP woven bag processing machine YouTube

Polypropylene (PP) Production and Manufacturing Process

Comments are closed.