Product design for manufacturing and assembly pdf

DESIGN FOR ASSEMBLY Assembly is an important stage in product development and accounts for one third of the company labor. Reducing the number of parts and making the assembly …

Enter ‘Design for Manufacturing’, also referred to as ‘Design for Manufacturability’ or ‘Design for Manufacturing and Assembly’. Regardless of what term you know it by, it is the process of reviewing a product prior to locking in a design.

This IM Essential Guide (Design for Manufacturing and Assembly) _ was co-developed by CCIT, BCA and Bryden Wood Singapore with inputs from a number of Singapore DfMA pioneering firms to whom we wish to express our heartfelt thanks for their valuable contributions.

Designing Effective Step-By-Step Assembly Instructions machine tools for automated manufacturing and are not meant to be seen, understood, or carried out by humans. Most robotic assembly plans would seem unnatural to people assembling everyday objects. In contrast, automated presentation design systems have been de-veloped in the domain of visualization [Feiner 1985; …

Detailed Design for Assembly Guidelines 1. Simplify the design and reduce the number of parts Mistake-proof product design and assembly (poka- yoke) so that the assembly process is unambiguous. Components should be designed so that they can only be assembled in one way; they cannot be reversed. Notches, asymmetrical holes and stops can be used to mistake-proof the assembly process. Design

In order to compete in the current commercial environment companies must produce greater product variety, at lower cost, all within a reduced product life cycle. To achieve this, a concurrent engineering philosophy is often adopted. In many cases the main realization of this is Design for Manufacture and Assembly (DFM/A). There is a need for in-depth study of the architectures for DFM/A

A well-designed product is a predictable product. Managers particularly need to predict reliability, manufacturing costs, and manufacturability.

Overview of Design for Manufacturing and Assembly (DFMA) Since almost 75% of the product cost is determined in the “engineering” phase, it gives a tool to attack those hidden waste areas before committing to a design Fact: Fasteners typically account for 5% of BOM cost, yet contribute to 70% of the labor cost! DFMA Example 2 Motor Drive Proposed Design Final Design. DFMA Example 3

ASSEMBLY Product Design When eliminating waste from your assembly line, don’t overlook waste that may be designed into your product from the start. By David M. Vranson Advanced Manufacturing Engineer ITT Control Technologies Aerospace Controls Div. Valencia, CA david.vranson@itt.com 64 ASSEMBLY / January 2011 www.assemblymag.com This ball-valve assembly consists of a valve …

Understand that Design for Manufacture and Assembly (DFMA) is an important aspect of product development and promotes early involvement of manufacturing in design

EML2322L – MAE Design and Manufacturing Laboratory . Design for Manufacturability (DFM) Examples . Simply stated, DFM is the ability to components and design products …

Design for Manufacturing and Assembly (DFMA) is a cost-reduction framework for designers to evaluate manufacturing aspects of a product design. A …

monova.org Product Design for Manufacture and Assembly, Third Edition.pdf Other 2 hours idope.se Product Design for Manufacture and Assembly, Third Edition.pdf books 4 months magnet4you.me Product Design for Manufacture and Assembly, Third Edition Other – E-books 7 months btdb.to Product Design for Manufacture and Assembly, Third Edition.pdf 2 days. Using …

Hailed as a groundbreaking and important textbook upon its initial publication, the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels. In addition to the expected updating of data in all chapters, this third edition has been revised to provide a top-notch textbook for university-level courses in

Falsely Claimed Reasons for Not Implementing DFMA What are the Advantages of Applying DFMA during Product Design?Overall Impact of DFMA on U.S. Industry Selection of Materials and Processes General Requirements for Early Materials and Process Selection Selection of Manufacturing Processes Process Capabilities Selection of Materials Primary Process/Material Selection Systematic Selection …

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly …

PRODUCT DESIGN & MANUFACTURING SCHEME

BIM for DfMA (Design for Manufacturing and Assembly

Designing for manufacturing and assembly (DFM&A) is a technique for reducing the cost of a product by breaking the product down into its simplest components. All members of the design team can understand the product’s assembly sequence and material flow early in the design process. The most beneficial outcome of DFM&A is to reduce part count in the assembly, which in turn will simplify the

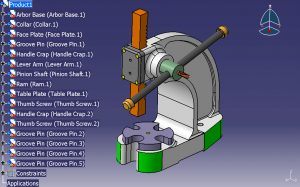

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING SUITABILITY FOR MANUFACTURING AND ASSEMBLY (DfMA) design regarding suitability for manufacturing and assembly (DfMA – Design for Manufacturing and Assembly). At the end of paper will show „DFMA“ software on one specific example. 2. SYSTEMATIZATION METHOD’S FOR ANALYSIS MANUFACTURABILITY OF PRODUCT DESIGN – DfX TOOLS Design …

Manufacturability of product design significantly affect on overall quality, both in terms of functionality and utilization, so in terms of manufacturing and assembly.

Product Evaluation for Cost, Manufacture, Asembly, and Other Measures lCost Estimating in Design – Most difficult and yet important tasks • A rough estimate should be

of many manufacturing alternatives: one can optimize the design of product and processes for a specific goal (assembly, lean operations, …) or evaluate …

Design for Manufacturability: How to Use Concurrent Engineering to Rapidly Develop Low-Cost, High-Quality Products for Lean Production shows how to use concurrent engineering teams to design products for all aspects of manufacturing with the lowest cost, the highest quality, and the quickest time to stable production.

Design for Manufacturing: Definition, estimation of manufacturing cost, reducing the cost of components, assembly, supporting production, impact of DFM on other factors. Prototyping: Prototyping basics, principles of prototyping, technologies, planning for prototypes.

Design for ease of assembly. Part features such as chamfers and tapers should be designed on mating parts. Design the assembly using base parts to which other components are added. The assembly should be designed so that components are added from one direction, usually vertically. Threaded fasteners (screws, bolts, nuts) should be avoided where possible, especially when automated assembly …

ABSTRACT: Design for Manufacture and Assembly (DFMA) assembly engineers who will redesign the product, the assembly and the manufacturing process. The same cycle repeats again and again until arriving at competitive design. This kind of process makes the design and manufacturing been performed independently. “ In this scenario, the designer designs a product and ‘ tosses it over the

Product Engineers, Designers and Managers, Manufacturing and Tooling Engineers, and Project Managers who desire to understand DFM/DFA as a product design tool to increase manufacturability of product assemblies. The course is best suited for individuals in the manufacturing industry and is beneficial to OEMs and Tier suppliers.

Abstract. Time and cost reduction during product development is important to meet the competitiveness in the market. Design for Manufacture and Assembly (DFMA) plays a key role in product development, especially in industries like aerospace, wherein variety in component geometry is more.

Product Design & Manufacturing Collection Get an essential set of connected, professional-grade design and engineering tools for product and factory design. Buy the collection Future of Making Things Our product innovation platform offers a next-generation approach to design, engineering, and manufacturing for product development.

Note: If you’re looking for a free download links of Assembly Automation and Product Design, Second Edition (Manufacturing Engineering and Materials Processing) Pdf, epub, docx and torrent then this site is not for you.

Manufacturing POC, which will be used to determine product feasibility and to develop an estimated cost and a preliminary manufacturing schedule. An initial manufacturing

Design for Manufacturability (DFM) as a method for creating robust product designs that will be insensitive to long-term dynamic variation in the processes and materials used in manufacturing.

Design for Manufacturing & Assembly (DFMA) Steve Watts Production Engineering Division Engineering Directorate Aviation & Missile Research, Development, & Engineering Center

Early in the design any product it is important to decide Which type Ot assembly process is likely to yield the lowest cost This decision has a major bearing on the design because manual assembly differs widely from automatic assembly. Each type of process has its tYWn advantages and limitations. For analytical purposes, the six basic assembly processes are; Al: Automatic assembly using

Detailed Design For Assembly Guidelines

– draftsman report for manufacture of steel staircase in australia pdf

Product Design for Manufacturing and Assembly Lewis

Design for Manufacturing Plus Download an 8-Page PDF

Books on Design For Manufacturability ( DFM ) and

(PDF) Early Cost Estimate of Product during Design Stage

11 Principles and Guidelines in Design for Manufacturing

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

ice cream manufacturing process pdf –

Assembly Automation and Product Design Second Edition

ASSEMBLY Product Design DFMA Lean E

Product Evaluation for Cost, Manufacture, Asembly, and Other Measures lCost Estimating in Design – Most difficult and yet important tasks • A rough estimate should be

of many manufacturing alternatives: one can optimize the design of product and processes for a specific goal (assembly, lean operations, …) or evaluate …

Understand that Design for Manufacture and Assembly (DFMA) is an important aspect of product development and promotes early involvement of manufacturing in design

DESIGN FOR ASSEMBLY Assembly is an important stage in product development and accounts for one third of the company labor. Reducing the number of parts and making the assembly …

EML2322L – MAE Design and Manufacturing Laboratory . Design for Manufacturability (DFM) Examples . Simply stated, DFM is the ability to components and design products …

In order to compete in the current commercial environment companies must produce greater product variety, at lower cost, all within a reduced product life cycle. To achieve this, a concurrent engineering philosophy is often adopted. In many cases the main realization of this is Design for Manufacture and Assembly (DFM/A). There is a need for in-depth study of the architectures for DFM/A

ASSEMBLY Product Design When eliminating waste from your assembly line, don’t overlook waste that may be designed into your product from the start. By David M. Vranson Advanced Manufacturing Engineer ITT Control Technologies Aerospace Controls Div. Valencia, CA david.vranson@itt.com 64 ASSEMBLY / January 2011 www.assemblymag.com This ball-valve assembly consists of a valve …

Design for Manufacturing: Definition, estimation of manufacturing cost, reducing the cost of components, assembly, supporting production, impact of DFM on other factors. Prototyping: Prototyping basics, principles of prototyping, technologies, planning for prototypes.

Design for Manufacturing & Assembly (DFMA) Steve Watts Production Engineering Division Engineering Directorate Aviation & Missile Research, Development, & Engineering Center

Designing for manufacturing and assembly (DFM&A) is a technique for reducing the cost of a product by breaking the product down into its simplest components. All members of the design team can understand the product’s assembly sequence and material flow early in the design process. The most beneficial outcome of DFM&A is to reduce part count in the assembly, which in turn will simplify the

17 replies on “Product design for manufacturing and assembly pdf”

Leave a CommentManufacturing POC, which will be used to determine product feasibility and to develop an estimated cost and a preliminary manufacturing schedule. An initial manufacturing

Product Evaluation for Cost Manufacture Asembly and

Falsely Claimed Reasons for Not Implementing DFMA What are the Advantages of Applying DFMA during Product Design?Overall Impact of DFMA on U.S. Industry Selection of Materials and Processes General Requirements for Early Materials and Process Selection Selection of Manufacturing Processes Process Capabilities Selection of Materials Primary Process/Material Selection Systematic Selection …

Some details on Design for Manufacture and Assembly 1

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly …

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

Manufacturing POC, which will be used to determine product feasibility and to develop an estimated cost and a preliminary manufacturing schedule. An initial manufacturing

PRODUCT DESIGN & MANUFACTURING SCHEME

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

Design for Manufacturability: How to Use Concurrent Engineering to Rapidly Develop Low-Cost, High-Quality Products for Lean Production shows how to use concurrent engineering teams to design products for all aspects of manufacturing with the lowest cost, the highest quality, and the quickest time to stable production.

Design for Manufacturing Plus Download an 8-Page PDF

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING SUITABILITY FOR MANUFACTURING AND ASSEMBLY (DfMA) design regarding suitability for manufacturing and assembly (DfMA – Design for Manufacturing and Assembly). At the end of paper will show „DFMA“ software on one specific example. 2. SYSTEMATIZATION METHOD’S FOR ANALYSIS MANUFACTURABILITY OF PRODUCT DESIGN – DfX TOOLS Design …

Assembly Automation and Product Design Second Edition

Design for Manufacturing and Assembly SpringerLink

Product Design for Manufacturing and Assembly Lewis

In order to compete in the current commercial environment companies must produce greater product variety, at lower cost, all within a reduced product life cycle. To achieve this, a concurrent engineering philosophy is often adopted. In many cases the main realization of this is Design for Manufacture and Assembly (DFM/A). There is a need for in-depth study of the architectures for DFM/A

Books on Design For Manufacturability ( DFM ) and

Detailed Design for Assembly Guidelines 1. Simplify the design and reduce the number of parts Mistake-proof product design and assembly (poka- yoke) so that the assembly process is unambiguous. Components should be designed so that they can only be assembled in one way; they cannot be reversed. Notches, asymmetrical holes and stops can be used to mistake-proof the assembly process. Design

BIM for DfMA (Design for Manufacturing and Assembly

Design for Manufacture and Assembly (DFM/DFA)

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly …

11 Principles and Guidelines in Design for Manufacturing

Hailed as a groundbreaking and important textbook upon its initial publication, the latest iteration of Product Design for Manufacture and Assembly does not rest on those laurels. In addition to the expected updating of data in all chapters, this third edition has been revised to provide a top-notch textbook for university-level courses in

Books on Design For Manufacturability ( DFM ) and

11 Principles and Guidelines in Design for Manufacturing

Overview of Design for Manufacturing and Assembly (DFMA) Since almost 75% of the product cost is determined in the “engineering” phase, it gives a tool to attack those hidden waste areas before committing to a design Fact: Fasteners typically account for 5% of BOM cost, yet contribute to 70% of the labor cost! DFMA Example 2 Motor Drive Proposed Design Final Design. DFMA Example 3

Assembly Automation and Product Design Second Edition

Abstract. Time and cost reduction during product development is important to meet the competitiveness in the market. Design for Manufacture and Assembly (DFMA) plays a key role in product development, especially in industries like aerospace, wherein variety in component geometry is more.

Product Design for Manufacturing and Assembly Lewis

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

monova.org Product Design for Manufacture and Assembly, Third Edition.pdf Other 2 hours idope.se Product Design for Manufacture and Assembly, Third Edition.pdf books 4 months magnet4you.me Product Design for Manufacture and Assembly, Third Edition Other – E-books 7 months btdb.to Product Design for Manufacture and Assembly, Third Edition.pdf 2 days. Using …

Detailed Design For Assembly Guidelines

(PDF) Early Cost Estimate of Product during Design Stage

11 Principles and Guidelines in Design for Manufacturing

of many manufacturing alternatives: one can optimize the design of product and processes for a specific goal (assembly, lean operations, …) or evaluate …

PRODUCT DESIGN & MANUFACTURING SCHEME

Design for ease of assembly. Part features such as chamfers and tapers should be designed on mating parts. Design the assembly using base parts to which other components are added. The assembly should be designed so that components are added from one direction, usually vertically. Threaded fasteners (screws, bolts, nuts) should be avoided where possible, especially when automated assembly …

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

Books on Design For Manufacturability ( DFM ) and

(PDF) Early Cost Estimate of Product during Design Stage

monova.org Product Design for Manufacture and Assembly, Third Edition.pdf Other 2 hours idope.se Product Design for Manufacture and Assembly, Third Edition.pdf books 4 months magnet4you.me Product Design for Manufacture and Assembly, Third Edition Other – E-books 7 months btdb.to Product Design for Manufacture and Assembly, Third Edition.pdf 2 days. Using …

Assembly Automation and Product Design Second Edition

Books on Design For Manufacturability ( DFM ) and

Designing for manufacturing and assembly (DFM&A) is a technique for reducing the cost of a product by breaking the product down into its simplest components. All members of the design team can understand the product’s assembly sequence and material flow early in the design process. The most beneficial outcome of DFM&A is to reduce part count in the assembly, which in turn will simplify the

Manufacturing by Design Harvard Business Review

BIM for DfMA (Design for Manufacturing and Assembly

MANUFACTURABILITY OF PRODUCT DESIGN REGARDING

Comments are closed.