Pvc resin manufacturing process pdf

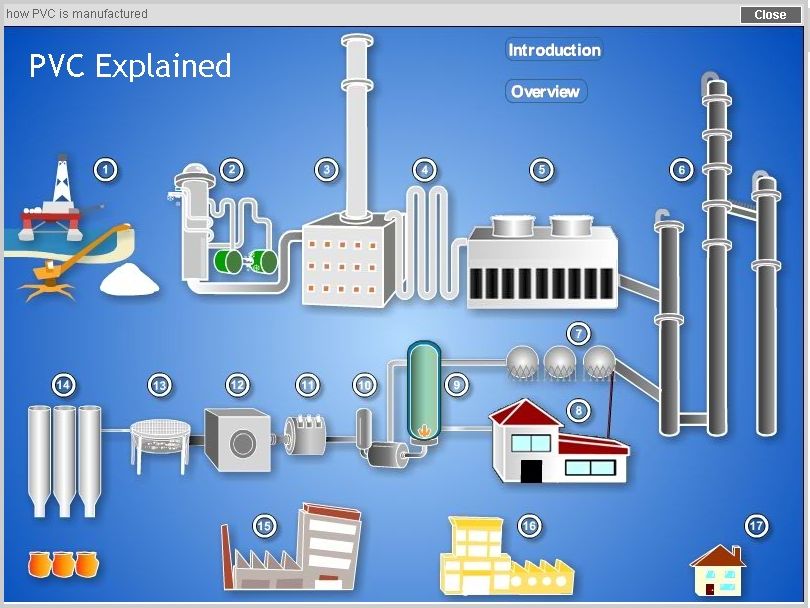

PVC Pipe Manufacturing Process Flow Chart. In the manufacturing process, various steps are taken as follows: #1. Extrusion. PVC uncompounded resin, unlike some other thermoplastics, is not suitable for direct processing. To confer the required processing and end instability, it is necessary to mix additives with the PVC resin. Following are some of the additives which are generally used for

The Basics of Plastic Manufacturing The term “plastics” includes materials composed of various elements such as carbon, hydrogen, oxygen, nitrogen, chlorine, and sulfur. Plastics typically have high molecular weight, meaning each molecule can have thousands of atoms bound together.

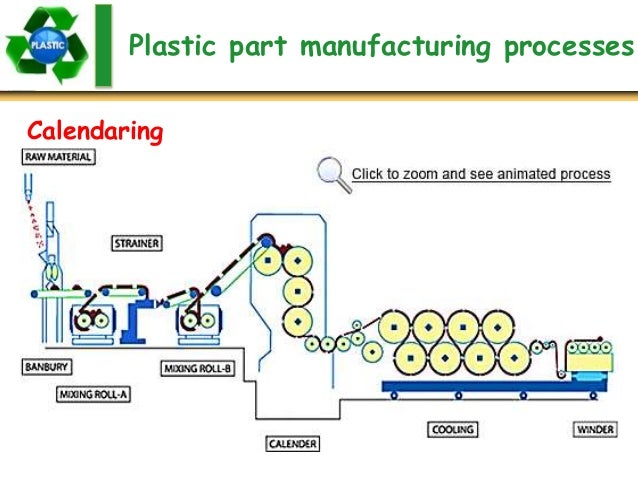

I usually compare the calendering process to rolling out pie dough. In reality, the manufacturing process is a little more complex than that. In the calendering process, PVC material is squeezed between gigantic, heated, polished-steel rollers that form the vinyl into a very thin sheet of film.

The PVC injection molding process, when used for large-sized products such as non-pressure fittings of 80 mm or more in diameter, products which are required to have thin walls and be light-weight, and products with especially complex shapes like rain gutter fittings, often results in imperfect pieces. Short shots (incomplete filling of a mold cavity), burning, jetting, and matting of product

PVC plate that was designed to bear a structural load. The third and final step of the detector assembly process was performed at the experimental sites: Ash River …

Environmental Product Declaration Details An Environmental Product Declaration, or EPD, is a standardised and verified way of quantifying the environmental impacts of a product based on a consistent set of rules known as a PCR (Product Category

manufacturing process which is termed post industrial recycled content. 2.0 AUDITOR COMPETENCIES AND DOCUMENTATION Documenting compliance of a PVC product to the guidelines shall be demonstrated using any of the following pathways: 1) Environmental Management System (EMS): Inclusion of the Best Practice Guidelines for PVC in the Built Environment in the …

VCM is consumed and converted into PVC during the manufacture of PVC resin. OxyChem’s industrial OxyChem’s industrial customers further process PVC resin to manufacture finished articles.

This Application Note shows performance for the elemental analysis of Cl, Mg, Si, S, Ca, Ti, Mo and Sn in PVC resin. Empirical calibrations are shown for the quantitative analysis of the elements PVC resins, and instrument repeatability is demonstrated.

PVC Handbook buecher.de

Polyvinyl Chloride (PVC) Production and Manufacturing

a process for manufacturing a glove, and more particularly to a formulation and a process for manufacturing an anti microbial glove. BACKGROUND OF THE INVENTION 0.003 Protective gloves are widely used in hospitals, pharmaceutical plants, food plants, kitchens or even public places. Gloves are generally made of a polymer resin. For example, a So-called Vinyl glove is produced by using …

*Parts by weight per 100 parts of PVC resin . Because Dow cannot anticipate or control the many different conditions under which this information and/or product may be used, it does not guarantee the applicability or the accuracy of this information or the suitability of its products in any given situation.

Formolon® Polyvinyl Chloride Suspension PVC Products Quality, Value and Performance. Formosa Plastics Formolon® Suspensions PVC compounds and resins are some of the most versatile products in the market. They can produce everything from rigid pipes to flexible films. They can produce smooth textures for windows and fencing to grain-like textures for decking or luxury vinyl tiles. As a

Process Description This facility produces polyvinyl chloride polymer resin (PVC) by polymerizing vinyl chloride monomer (VCM) in a water/PVC slurry.

• The PVC production process is the world’s largest single user of chlorine, consuming approximately 35% of chlorine produced worldwide (IARC, 2008, WCC, 2006). Average PVC resin consists of 57% chlorine (Scheirs, 2003).

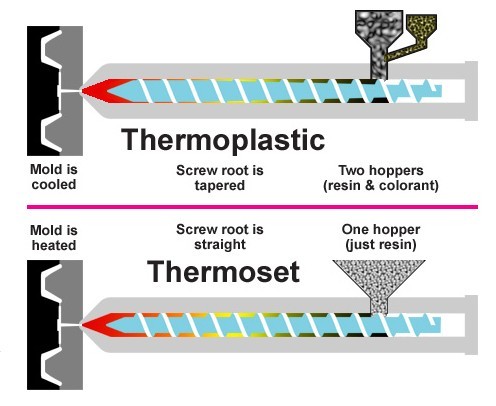

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC.

PVC polymer resin to product silos before it is shipped to the customers. There is a rail spur on site with six load spots under the stainless steel product silos. Equipment could also be …

The production process of PVC pipe extrusion machine are as follows: 1. the feed section has a larger diameter. Ethylene Ethylene is a colorless and odorless gas with the chemical formula C2H4. Ethylene chloride compounds that are made in the manufacturing process and not converted into polymers are known to be carcinogenic. It is highly flammable and can cause explosions if mishandled. the

The process for making PVC (polyvinyl chloride) is a mystery to most. Words like ethylene dichloride and VCM are not typically used in daily conversation. You may be surprised to find out what two naturally occurring ingredients are the base for all vinyl compounds. Teknor Apex has been an innovator in the PVC compound industry for more than

6/10/2016 · A type of PVC related disposable gloves and the manufacturing process thereof. The process includes: The PVC resin or its mixture is mixed with a …

industry’s Product Stewardship Program during 2007 . 2 Summary of Key Commitments and Progress Issue 2007 Commitment 2007 Progress 2008 Commitment one: production and storage VCM in finished resin VCM emissions resulting from manufacturing Residual VCM in finished resin powder not greater than 1 ppm. VCM emissions no greater than 50g / tonne PVC. Achieved by 10 out of 11 …

The Chisso Advanced PVC Process is the result of intensive research and development work carried out by Chisso for more than a half century. The features of PVC Process are High Quality Products, Safe and Environmentally Friendly Process, Low Production Cost and Low Investment Cost.

PROJECT PROFILE PRODUCT : P V C COMPOUND NIC PRODUCT CODE : 316204005 degradation, an inherent property, makes it difficult to process and makes proper compounding essential, which needs incorporation of thermal stabilizers, internal and external lubricants, plasticizers (when softness is required), opacifier, anti UV agents (for outdoor use) etc. Compounding of PVC is …

A report on Plastics Industry Sidharth Birla President Federation of Indian Chambers of Commerce and Industry Federation House Tansen Marg New Delhi 110001

10/06/2014 · The extrusion process is smoothly carried out by using extruder technology. Available in different specification, the plant meets the requirement international quality standard. Our …

The present invention relates to a process for the production of polyvinyl chloride (PVC) having a median grain size of from 10 to 80 μm by suspension polymerization of vinyl chloride, the process comprising the following process steps: (a) introduction of water, initiator(s), optionally one or more further adjuvants, and some of the vinyl

Customer Application Brief Chemical PVC VCM Manufacture Introduction Polyvinyl chloride (PVC) is a major worldwide commodity used for the manufacture of a vast array of …

Formulating for Extruding Rigid PVC Fenestration Products By Kenneth Abate, Ph.D., FAIC, CPC In a single short paper, one cannot provide all the detailed information on the formulating of rigid

Production of Chlorinated Polyvinyl Chloride from

Manufacturing Process. Manufacturing polyvinyl chloride (PVC) is a three-step process, described below. Alternatively, watch our short video for an overview of the process and the manufacturing …

Watch video · PVC production usually refers to the manufacture of PVC resin, which is the basis for the plethora of PVC products around us. Three types of PVC manufacture exist: suspension polymerisation, emulsion polymerisation and bulk polymerisation.

PVC is a synthetic solid resin material (a plastic) also commonly referred to as ‘vinyl’. PVC is formed from vinyl chloride PVC is formed from vinyl chloride monomer (VCM) (in pressurised liquid form) in a manufacturing process that polymerises VCM into solid powder or granule – 1994 road ranger rv manufacturer owners manual Virgin Production Recycled Production Because of the problems outlined on the previous slides, the contribution of recycling to current plastic consumption is small.

Polycarbonate, Thermoset Resin: Phenol Formaldehyde, Urea Formaldehyde And Melamine Formaldehyde . 409 LECTURE 3 POLYVINYL CHLORIDE, POLYCARBONATE, THERMOSET RESIN: PHENOL FORMALDEHYDE, UREA FORMALDEHYDE AND MELAMINEFORMALDEHYDE POLYVINYL CHLORIDE Polyvinyl chloride is second largest (after polyethylene) and most versatile …

tion process for PVC in China is based on the carbide route rather than on ethylene. This method has been completely superseded in Western Europe, and only small capacities still re-main in Eastern Europe,since it greatly pollutes the environ-ment and has a high energy re-quirement. The advantages of this process are the low invest-ment costs and, in particular, the ready availability of the

chart, which details the chain of supply of PVC resin and its constituents (VCM and chlorine), including names of all entities in the supply chain, which is used in the manufacturing of a particular PVC product or a range of products.

65-3 polymerization process. PVC has an excellent cost/benefit ratio when compared to other polymer resins. PVC is used in the manufacture of end-use products for a wide range of applications in the

Major supplier of PVC resins and wood-plastic composites. We also distribute a range of specialty products and chemicals which we have sourced from leading international chemical suppliers. AV supplies PVC processing additives, plasticisers and specialty elastomers to the Australian market.

x PVC Resin x D.O.P. x Stabilizers x Fillers 6. MANUFACTURING PROCESS The basic material which on Polymerization produces P.V.C. Pipes is Polyvinyl chloride which in resin form is hard and rigid. The rigidity can be controlled by controlling the percentage of plasticizer at the time of compounding. Production of Rigid PVC pipe is based on plasticizing and homogenizing PVC …

Environmental Product Declaration Iplex

The variety of PVC resin products does not lend itself to broad generalizations concerning health hazards. In studying occupational hazards the particular PVC process and the product must be considered and identified in the study.

PVC resin is broadly classified into two categories – PVC Paste Resin and PVC Suspension Resin. PVC Paste Resin is produced from Vinyl Chloride Monomer (VCM). The PUC is produced and sold in the form of white/off-white powder. It is offered in different grades by the DI and foreign producers which merely differ in terms of the associated properties, which are achieved through control on

APC/Transportation & Logistics Committee – Resin Handling Guide 7 The major components of a plastic resin handling system are the silos, bins or product receivers, bag houses and filters, transfer piping and transfer blowers.

the PVC resin macromolecules. It assumes that the plasticizer molecules are not permanently It assumes that the plasticizer molecules are not permanently bound to the PVC resin molecules but are free to self-associate and to associate with the

process of PVC membrane called caste spreading. Caste Spreading – This is a manufacturing process that creates waterproof membranes in which the reinforcement

Imports of Poly Vinyl Chloride (PVC) Paste/Emulsion Resin

Home SCG Chemicals

An Environmental Product Declaration, or EPD, is a standardised and verified way of quantifying the environmental impacts of a product based on a consistent set of rules known as a …

Customer Application Brief Chemical PVC VCM Manufacture Introduction Polyvinyl chloride (PVC) is a major worldwide commodity used for the manufacture of a vast array of commercial and consumer goods including pipe, siding, wire, cable, film and sheet stock. PVC plants typically produce from 100 to 2,000 million pounds per year of polymer with most producing in the 300-600 million pounds per

Effect of Various Additives on the Physical Properties of Polyvinylchloride Resin Imran Nazir Unar*, Suhail Ahmed Soomro and Shaheen Aziz Department of Chemical Engineering, Mehran University of Engineering & Technology, Jamshoro, Sindh Pakistan —– Abstract The compounding of Polyvinylchloride (PVC) with some additives was studied for the enhancement of physical and …

PVC is a synthetic solid resin material (a plastic) also commonly referred to as ‘vinyl’. PVC is PVC is formed from vinyl chloride monomer (VCM) (in pressurised liquid form) in a manufacturing

CNC Machining: Polyvinyl Chloride can be cut on a CNC machine but any machinist who has tried has probably experienced degradation in the cutter depending on the material it is made from.

PVC resin needs to be compounded with the properly additives by using standard mixing techniques. The optimum The optimum processing condition for each …

Australian Vinyls Major supplier of PVC resins and wood

Customer Application Brief Chemical PVC VCM Manufacture

3 Introduction and Manufacturing Process 2 Principle Uses of Vinyl 4 Safety and First Aid 5 Regulatory Information 6 Vinyl Resin Property Effects on Rigid and

Manufacturing Process. Explore the PVC manufacturing process below. PVC manufacturing process . Reaction. PVC is manufactured by polymerising vinyl chloride monomer (VCM). Polymerisation is a chemical reaction which combines small monomer molecules to form large chain-like molecules called polymers. The liquid vinyl chloride monomer (VCM) is piped to the autoclaves …

3 Fillers The use of fillers in the manu-facturing of PVC parts is very common as they are used to extend the resin, thus reducing the cost of the final plastic part.

A plastic extrusion is a high volume manufacturing process in which raw PVC material is melted and formed into a continuous profile [7]. Fundamentally, the process of extrusion consists of converting a suitable raw material into a

PVC Pipe Manufacturing Plant YouTube

for Formolon® suspension PVC resins do not contain any of the materials listed below. Based upon our Based upon our knowledge of the manufacturing process and …

Page 3/9 PVC Products for the Production of Semi-Rigid and Flexible Films Examples for semi-rigid and flexible films: Roofing sheets, label films, insulating tapes, tarpaulins, artificial leather etc.

DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT QUALITY Manufacturing of polyvinyl chloride (PVC) in India started 60 years ago with the country’s first PVC plant set up in Mumbai in 1951. The plant operated by Calico had a capacity of 6000 metric tonne/year. At present, the Indian PVC industry boasts of a production capacity of 1.3 million mt/year. In India, …

PVC Pipes Manufacturing Project. Production of Polyvinyl Chloride (PVC) Pipes. www.entrepreneurindia.co Introduction Polyvinyl Chloride (PVC) piping is the most widely used plastic piping material. PVC pipe is manufactured by extrusion in a variety of sizes and dimensions and generally sold in 10′ and 20′ lengths. PVC pipe is available in both solid wall and cellular core …

PVC is a thermoplastic that contains mainly PVC resin with the addition of compounds such as stabilisers, lubricants, plasticisers, pigments and other products that aid in the manufacturing process. PVC compound produced without plasticisers increases the strength attributes of the material.

Bangkok, 21 December 2018 : Chemicals Business, SCG, and Bangchak have signed a Memorandum of Understanding (MoU) for Greenovative Lube Packaging to develop a lubricant packaging recycling scheme with the aim of minimizing the use of new raw materials in the production process and reducing plastic wastes based on Circular Economy concept.

A process for the recycling of PVC has been developed by Solvay. A 10,000 tonnes/year demonstration plant at Ferrara, Italy, was brought on-stream in early 2002. The Vinyloop process involves using a solvent to dissolve the polymer, separating it completely from other materials in a mixture or composite structure. The PVC is then recovered by precipitation and dried to give PVC resin granules.

Project report on PVC Pipe Manufacturing Plant – Free download as PDF File (.pdf), Text File (.txt) or read online for free.

A case study of S-PVC resin manufacturing process located in Map Ta Phut Industrial Estate, Rayong province, Thailand, is presented. The studying results indicate that the amount of water used to produce 1 Kg of S-PVC resin is 14.72 liters, of which 6.22 liters are withdrawn from local water resources. Additionally, the direct and indirect water use along the production supply chain is

About 80% of production involves suspension polymerization. First, the raw material VCM is pressurized and liquefied, and then fed into the polymerization reactor, which contains water and suspending agents in advance. Next, the initiator is fed into the reactor, and PVC is produced under a few bars at 40 – 60°C.

Coperion is a specialist in the design of complete plants for PVC processing – from the raw material handling and feeding, dryblend production in the heat-cool mixer to the cooling and filling of the pellets.

Production of Chlorinated Polyvinyl Chloride from Polyvinyl Chloride Molecular structure: “PVC”: PVC chlorination Reaction Chemistry: CPVC is produced by reacting suspension PVC resin with chlorine. The reaction is initiated by decomposing diatomic chlorine dissolved in water into highly unstable and reactive chlorine atoms, With either high heat or ultraviolet radiation. Once this

Project report on PVC Pipe Manufacturing Plant Polyvinyl

Everything You Need To Know About PVC Plastic

– Verification Guidance for Best Environmental Practice PVC

PROFILE ON PVC RESIN PRODUCTION

PVC CONDUIT PIPES AND FITTINGS standupmitra.in

VCM/PVC Process pall.fr

Environmental Product Declaration Iplex

Home SCG Chemicals

VCM is consumed and converted into PVC during the manufacture of PVC resin. OxyChem’s industrial OxyChem’s industrial customers further process PVC resin to manufacture finished articles.

Virgin Production Recycled Production Because of the problems outlined on the previous slides, the contribution of recycling to current plastic consumption is small.

chart, which details the chain of supply of PVC resin and its constituents (VCM and chlorine), including names of all entities in the supply chain, which is used in the manufacturing of a particular PVC product or a range of products.

The process for making PVC (polyvinyl chloride) is a mystery to most. Words like ethylene dichloride and VCM are not typically used in daily conversation. You may be surprised to find out what two naturally occurring ingredients are the base for all vinyl compounds. Teknor Apex has been an innovator in the PVC compound industry for more than

tion process for PVC in China is based on the carbide route rather than on ethylene. This method has been completely superseded in Western Europe, and only small capacities still re-main in Eastern Europe,since it greatly pollutes the environ-ment and has a high energy re-quirement. The advantages of this process are the low invest-ment costs and, in particular, the ready availability of the

Major supplier of PVC resins and wood-plastic composites. We also distribute a range of specialty products and chemicals which we have sourced from leading international chemical suppliers. AV supplies PVC processing additives, plasticisers and specialty elastomers to the Australian market.

Formulating for Extruding Rigid PVC Fenestration Products By Kenneth Abate, Ph.D., FAIC, CPC In a single short paper, one cannot provide all the detailed information on the formulating of rigid

10/06/2014 · The extrusion process is smoothly carried out by using extruder technology. Available in different specification, the plant meets the requirement international quality standard. Our …

APC/Transportation & Logistics Committee – Resin Handling Guide 7 The major components of a plastic resin handling system are the silos, bins or product receivers, bag houses and filters, transfer piping and transfer blowers.

29 replies on “Pvc resin manufacturing process pdf”

Leave a CommentThe present invention relates to a process for the production of polyvinyl chloride (PVC) having a median grain size of from 10 to 80 μm by suspension polymerization of vinyl chloride, the process comprising the following process steps: (a) introduction of water, initiator(s), optionally one or more further adjuvants, and some of the vinyl

The-PVC-Production-Process Teknor Apex

Manufacturing Process. Explore the PVC manufacturing process below. PVC manufacturing process . Reaction. PVC is manufactured by polymerising vinyl chloride monomer (VCM). Polymerisation is a chemical reaction which combines small monomer molecules to form large chain-like molecules called polymers. The liquid vinyl chloride monomer (VCM) is piped to the autoclaves …

IMPROVING THE THERMOPLASTIC EXTRUSION PROCESS IN

PVC Pipes Manufacturing Process Polyvinyl Chloride

Formolon Polyvinyl Chloride Suspension PVC Products

PVC is a synthetic solid resin material (a plastic) also commonly referred to as ‘vinyl’. PVC is formed from vinyl chloride PVC is formed from vinyl chloride monomer (VCM) (in pressurised liquid form) in a manufacturing process that polymerises VCM into solid powder or granule

How to Start PVC pipe manufacturing business Small Scale

PVC Pipe Manufacturing Plant YouTube

A report on Plastics Industry Sidharth Birla President Federation of Indian Chambers of Commerce and Industry Federation House Tansen Marg New Delhi 110001

PVC Pipes Manufacturing Project. Production of Polyvinyl

How to Start PVC pipe manufacturing business Small Scale

Coperion is a specialist in the design of complete plants for PVC processing – from the raw material handling and feeding, dryblend production in the heat-cool mixer to the cooling and filling of the pellets.

Home SCG Chemicals

Application Example Feeding & Conveying in PVC Production

PVC is a thermoplastic that contains mainly PVC resin with the addition of compounds such as stabilisers, lubricants, plasticisers, pigments and other products that aid in the manufacturing process. PVC compound produced without plasticisers increases the strength attributes of the material.

PVC Pipes Manufacturing Project. Production of Polyvinyl

Environmental Product Declaration Iplex

The-PVC-Production-Process Teknor Apex

Environmental Product Declaration Details An Environmental Product Declaration, or EPD, is a standardised and verified way of quantifying the environmental impacts of a product based on a consistent set of rules known as a PCR (Product Category

PVC Disposable Glove And Manufacturing Process Thereof

PVC Handbook buecher.de

Customer Application Brief Chemical PVC VCM Manufacture Introduction Polyvinyl chloride (PVC) is a major worldwide commodity used for the manufacture of a vast array of …

Everything You Need To Know About PVC Plastic

PROFILE ON PVC RESIN PRODUCTION

A plastic extrusion is a high volume manufacturing process in which raw PVC material is melted and formed into a continuous profile [7]. Fundamentally, the process of extrusion consists of converting a suitable raw material into a

Literature Review and gbca.org.au

industry’s Product Stewardship Program during 2007 . 2 Summary of Key Commitments and Progress Issue 2007 Commitment 2007 Progress 2008 Commitment one: production and storage VCM in finished resin VCM emissions resulting from manufacturing Residual VCM in finished resin powder not greater than 1 ppm. VCM emissions no greater than 50g / tonne PVC. Achieved by 10 out of 11 …

Best Practice Guidelines Verification Guidance Document

Project report on PVC Pipe Manufacturing Plant Polyvinyl

How to Start PVC pipe manufacturing business Small Scale

3 Introduction and Manufacturing Process 2 Principle Uses of Vinyl 4 Safety and First Aid 5 Regulatory Information 6 Vinyl Resin Property Effects on Rigid and

PVC Handbook buecher.de

PVC Pipes Manufacturing Project. Production of Polyvinyl

Verification Guidance for Best Environmental Practice PVC

DEFECTS IN EXTRUSION PROCESS AND THEIR IMPACT ON PRODUCT QUALITY Manufacturing of polyvinyl chloride (PVC) in India started 60 years ago with the country’s first PVC plant set up in Mumbai in 1951. The plant operated by Calico had a capacity of 6000 metric tonne/year. At present, the Indian PVC industry boasts of a production capacity of 1.3 million mt/year. In India, …

IMPROVING THE THERMOPLASTIC EXTRUSION PROCESS IN

VCM/PVC Process pall.fr

PVC Processing – Coperion

Production of Chlorinated Polyvinyl Chloride from Polyvinyl Chloride Molecular structure: “PVC”: PVC chlorination Reaction Chemistry: CPVC is produced by reacting suspension PVC resin with chlorine. The reaction is initiated by decomposing diatomic chlorine dissolved in water into highly unstable and reactive chlorine atoms, With either high heat or ultraviolet radiation. Once this

RESIN HANDLING GUIDE secure.arglogistics.com

reporting on the progress of the Australian PVC industry’s

PVC Handbook buecher.de

About 80% of production involves suspension polymerization. First, the raw material VCM is pressurized and liquefied, and then fed into the polymerization reactor, which contains water and suspending agents in advance. Next, the initiator is fed into the reactor, and PVC is produced under a few bars at 40 – 60°C.

Customer Application Brief Chemical PVC VCM Manufacture

PVC Grades for Manufacturing of Film2013 Mai vinnolit.com

PROFILE ON PVC RESIN PRODUCTION

Project report on PVC Pipe Manufacturing Plant – Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Home SCG Chemicals

Manufacturing Process. Manufacturing polyvinyl chloride (PVC) is a three-step process, described below. Alternatively, watch our short video for an overview of the process and the manufacturing …

IMPROVING THE THERMOPLASTIC EXTRUSION PROCESS IN

Polyvinyl Chloride (PVC) vinnolit.com

A plastic extrusion is a high volume manufacturing process in which raw PVC material is melted and formed into a continuous profile [7]. Fundamentally, the process of extrusion consists of converting a suitable raw material into a

VCM/PVC Process pall.fr

Application Example Feeding & Conveying in PVC Production

Chlorinated polyvinyl chloride Wikipedia

A process for the recycling of PVC has been developed by Solvay. A 10,000 tonnes/year demonstration plant at Ferrara, Italy, was brought on-stream in early 2002. The Vinyloop process involves using a solvent to dissolve the polymer, separating it completely from other materials in a mixture or composite structure. The PVC is then recovered by precipitation and dried to give PVC resin granules.

Verification Guidance for Best Environmental Practice PVC

The variety of PVC resin products does not lend itself to broad generalizations concerning health hazards. In studying occupational hazards the particular PVC process and the product must be considered and identified in the study.

How to Start PVC pipe manufacturing business Small Scale

PVC Pipe Manufacturing Plant YouTube

PVC Handbook buecher.de

Bangkok, 21 December 2018 : Chemicals Business, SCG, and Bangchak have signed a Memorandum of Understanding (MoU) for Greenovative Lube Packaging to develop a lubricant packaging recycling scheme with the aim of minimizing the use of new raw materials in the production process and reducing plastic wastes based on Circular Economy concept.

Chlorinated Polyvinyl Chloride Manufacturing Plant

A plastic extrusion is a high volume manufacturing process in which raw PVC material is melted and formed into a continuous profile [7]. Fundamentally, the process of extrusion consists of converting a suitable raw material into a

RESIN HANDLING GUIDE secure.arglogistics.com

IMPROVING THE THERMOPLASTIC EXTRUSION PROCESS IN

Customer Application Brief Chemical PVC VCM Manufacture Introduction Polyvinyl chloride (PVC) is a major worldwide commodity used for the manufacture of a vast array of …

Analysis of PVC resins Rigaku

I usually compare the calendering process to rolling out pie dough. In reality, the manufacturing process is a little more complex than that. In the calendering process, PVC material is squeezed between gigantic, heated, polished-steel rollers that form the vinyl into a very thin sheet of film.

Project report on PVC Pipe Manufacturing Plant Polyvinyl

PVC Pipe Manufacturing Process Flow Chart. In the manufacturing process, various steps are taken as follows: #1. Extrusion. PVC uncompounded resin, unlike some other thermoplastics, is not suitable for direct processing. To confer the required processing and end instability, it is necessary to mix additives with the PVC resin. Following are some of the additives which are generally used for

PROJECT PROFILE Sagar

Environmental Product Declaration Iplex

VCM/PVC Process pall.fr

The variety of PVC resin products does not lend itself to broad generalizations concerning health hazards. In studying occupational hazards the particular PVC process and the product must be considered and identified in the study.

Chlorinated Polyvinyl Chloride Manufacturing Plant

Manufacturing Process. Manufacturing polyvinyl chloride (PVC) is a three-step process, described below. Alternatively, watch our short video for an overview of the process and the manufacturing …

PVC CONDUIT PIPES AND FITTINGS standupmitra.in

Literature Review and gbca.org.au

A process for the recycling of PVC has been developed by Solvay. A 10,000 tonnes/year demonstration plant at Ferrara, Italy, was brought on-stream in early 2002. The Vinyloop process involves using a solvent to dissolve the polymer, separating it completely from other materials in a mixture or composite structure. The PVC is then recovered by precipitation and dried to give PVC resin granules.

Compounding PVC with Elvaloy® Product News Dow

Analysis of PVC resins Rigaku

PVC is a synthetic solid resin material (a plastic) also commonly referred to as ‘vinyl’. PVC is formed from vinyl chloride PVC is formed from vinyl chloride monomer (VCM) (in pressurised liquid form) in a manufacturing process that polymerises VCM into solid powder or granule

The-PVC-Production-Process Teknor Apex

10/06/2014 · The extrusion process is smoothly carried out by using extruder technology. Available in different specification, the plant meets the requirement international quality standard. Our …

Formulating for Extruding Rigid PVC Fenestration Products

Comments are closed.