Simulation modeling of manufacturing systems pdf

1) Basic Simulation Modeling. 2) Modeling Complex Systems. 3) Simulation Software. 4) Review of Basic Probability and Statistics. 5) Building Valid, Credible, and Appropriately Detailed Simulation …

We have created a collection of best reference books on “Modeling ,Simulation and Analysis of Manufacturing Systems” so that one can readily see the list of top books on “Modeling ,Simulation and Analysis of Manufacturing Systems” and buy the books either online or offline.

automation of manufacturing systems and with object-oriented approaches and software implementation of simulators, which allow real hybrid simulation, and ends with an overview on choice and comparison of simulation software. 1. Introduction Simulation software plays a major role in analysis of nonlinear control systems and complex automation systems. Simulation software, simulation …

Virtual Factory Data Model to support Performance Evaluation of Production Systems Walter TERKAJa, formalization of the manufacturing system is needed. Simulation modeling of manufacturing systems usually relies on commercial software tools (e.g. Arena, Simio, Plant Simulation, Visual Components, etc.) providing an integrated environment to describe the system …

Index Terms— Activity Sampling, Manufacturing Systems, Simulation. I. INTRODUCTION Computer-based simulation is widely used in many disciplines and is becoming an everyday occurrence in the analysis of many fields. Simulation in a manufacturing environment has been used successfully for several decades with its first uses documented in the 1960s. In the paper written by Foster & Rose [1

the DES method is widely used for design of manufacturing systems [15], for solving scheduling problems [9] and for efficiency [8] and stability analysis [3] of production systems…

systems pdfmodeling and optimization for big data analyticsdynamical modeling and analysis of epidemics simulation modeling and analysis download ebook pdffinal report finite element modeling and analysis of

The paper presents operating strategies for manufacturing systems using simulation. An existing An existing manufacturing facility is replicated in a virtual environment using Arena simulation software.

SIMULATION MODELING & ANALYSIS Averill M. LAw W David ~lton simulation, manufacturing, operations research, and statistics. His article, “Statistical Analysis of Simulation Output Data,” was the first invited feature paper on simulation to appear in a major research journal. He won the 1988 Institute of Industrial Engineers’ best publication award for his series of papers on the simulation

model for flexible manufacturing system . In their study they developed model to evaluate the efficiency of systems. In their study they developed model to evaluate the efficiency of systems. Coefficients of variation and efficiency have been calculated.

Simulation is the imitation of the operation of real world process or system over time. A simulation model is a descriptive model which represents a dynamic phenomenon, a set of decision alternatives, cause- effect relationship. It is also known as the experimental arm of operation research. Simulation is methodology for conducting experiments using a model of the real system. Simulation of

Presentation of the simulation model In chapter 3, the material flow system of the simulation testing, the received company data and the data charts used by the simulation program will be presented. 3.1. Description of the examined material flow system. The description of the material flow system will be carried out in two steps. Description will primarily entail the material flow indicators

analysis and control of dynamic systems.pdf PDF. The

1. Simulation Modeling of Manufacturing Systems

Modeling and Simulation of Flexible Manufacturing System using Petri-Net Ajay Kumar Maurya1 Dr. S.C. Jayswal2 Modeling & Simulation, scheduling, conclusion & results I. INTRODUCTION–FMS Flexible manufacturing system (FMS) is an automatic production system in which the system may use several parallel production environments in it. In the early stage of the FMS, the layout has an impact …

Modeling & Simulation in Automotive Industry Prediction of Energy Consumption in Electric Vehicles Oleg Gusikhin Ford Research & Advanced Engineering Dearborn, Michigan, USA. Outline • Introduction • Selected Simulation Applications at Ford – Virtual Manufacturing & e-Workcell – Virtual Test Track Experiment (VIRTTEX) • Predication of BEV Energy Consumption – BEV Introduction

simulation modeling, it has been determined that the transformer making section, among seven other sections of manufacturing the UPS, was the main system bottleneck while other sections were running concomitantly without any

REFERENCE MODEL BASED HIGH FIDELITY SIMULATION MODELING FOR MANUFACTURING SYSTEMS A Dissertation Presented to The Academic Faculty by HANSOO KIM In Partial Fulfillment Of the Requirements for the Degree Doctor of Philosophy in the School of Industrial and Systems Engineering Georgia Institute of Technology May 2004 . REFERENCE MODEL BASED HIGH FIDELITY SIMULATION MODELING FOR MANUFACTURING

The application of simulation in manufacturing system design and operation is expected to continue growing and evolving in the future as the manufacturing sector remains an important part of the global economy and becomes more competitive. There is a need for more efficient techniques to deal with the growing complexity of manufacturing operations. The rising of hybrid approaches, where

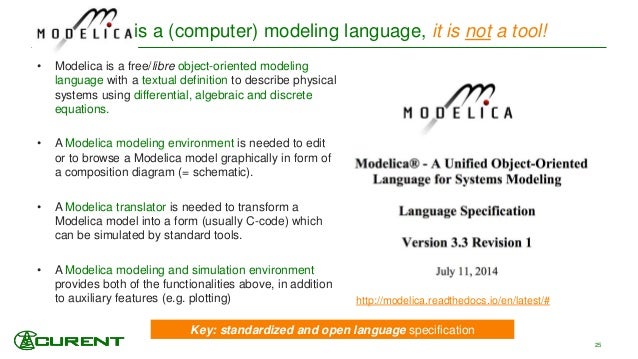

Simulink is a simulation tools library for use in modeling dynamical systems in modular block form. Most deterministic transformative systems in nature can roughly be thought of as a “black . Matlab IV: Modeling and Simulation 10 The Department of Statistics and Data Sciences, The University of Texas at Austin box” receiving an input vector of information u and eliciting a unique output

6.2. The IoT-Aided Manufacturing System in the Factory Model Although Fischertechnik’s Factory Simulation 9V model is equipped with some sensors, such as color sensors, it is not connected to the Internet and does not have the structure or functionality of the IoT. To convert this factory model into an IoT-aided manufacturing system, we added eight sets of light sensors wirelessly connected

In the second article, written by Parrod, Thierry, Fargier and Cavaille, the interaction of the different actors involved in a supply chain is studied. An important aspect…

Simulation is a powerful tool to analyze manufacturing systems for purposes of design and on-going operation. In recent years, simulation modeling and analysis have been enhanced significantly by

A Structured Approach to Simulation Modeling of Manufacturing Systems Douglas A. Bodner and Leon F. McGinnis Keck Virtual Factory Lab · School of Industrial and Systems Engineering

Modeling and Simulation of the Competitiveness of Manufacturing Systems PDF FULL-TEXT HTML: ABSTRACT. The paper aims, in the field of manufacturing technologies, at approaching issues of manufacturing systems, in order to develop a new concept of management, which is in line with the current market dynamics: the concept of competitive management. The concept of competitive …

multistage manufacturing systems,” Anals of Operation Research 93, pp. 325 -355, 2000. [2] G. Liberopoulous. Y Dallery, “Extended kanban control system, Combining Kanban and Base IJERT. Performance Analysis of Single Flow line Manufacturing ?A Modeling Simulation approach

DEPARTMENT OF COMPUTER SCIENCE & SYSTEMS ANALYSIS TECHNICAL REPORT: MU-SEAS-CSA-1994-001 Intelligent Simulation Modeling of a Flexible Manufacturing System with Automated Guided Vehicles

Analytical simulation and modeling of unit manufacturing processes based on knowledge of the underlying process physics and validated by experimental results is becoming a powerful tool to advance the optimization of unit processes. In this context, simulation is defined as the “representation or

Paper ID #12726 Modeling and Analysis of Flexible Manufacturing Systems: A Simulation Study Dr. Guanghsu A. Chang, Western Carolina University Dr. Guanghsu A. Chang, Western Carolina University – Dr. Chang is an associate professor in the De-

1. Simulation Modeling of Manufacturing Systems – Download as PDF File (.pdf), Text File (.txt) or read online. m.tech ii sem

systems. Modeling and simulation of FMS is a field of research for many people now days. However, they all share a common goal; to search for solutions to achieve higher speeds and more flexibility and thus increase manufacturing productivity. FlexSim is a discrete event manufacturing simulation software developed by FlexSim Software Products, Inc. The FlexSim family currently includes the

manufacturing systems with increased flexibility and appear to be an an ideal solution to the requirements of a lean and agile manufacturing system.

systems, simulation modeling is becoming one of the most popular methods of facilitating their design and assessing operating strategies. An increasing need for the use of simulation is reflected by a growth in the number of simulation languages and simulators in the software market. When a simulation language is used, the model is developed by writing a program using the modeling …

1 Worker Performance Modeling in Manufacturing Systems Simulation: Proposal for an Agent-Based Approach Peer-Olaf Siebers University of Nottingham, UK

In manufacturing and service industries, companies are looking for ways to improve their systems performance and increase their competitiveness in order to survive in the market place. Simulation modeling is a practical tool that can be used by those companies to generate data and simulations to be used for better and faster decision-making and forecasts of their business models and approaches

Simulation has been used to support many different manufacturing activities, including product design, process design, facility design, operational scheduling, and schedule management (Pritsker, 1990).

manufacturing issues addressed by simulation, simulation system software for manufacturing applications, techniques for • Evaluation of capital investments building valid and credible models, and statistical • Labor-requirements planning

9/03/2015 · Synopsis: One critical barrier leading to successful implementation of flexible manufacturing and related automated systems is the ever-increasing complexity of their modeling, analysis, simulation, and control. Research and development over the last three decades has provided new theory and graphical tools based on Petri nets and related concepts for the design of such systems…

Pehrsson, Frantzén, Aslam, and Ng coping with the drawbacks and improve the applicability of DES methods on high level manufacturing systems would be to use aggregated DES modelling techniques for the replication of production lines.

Chapter 1 Introduction to Simulation Banks, Carson, Nelson & Nicol Discrete-Event System Simulation. 2 Outline When Simulation Is the Appropriate Tool When Simulation Is Not Appropriate Advantages and Disadvantages of Simulation Areas of Application Systems and System Environment Components of a System Discrete and Continuous Systems Model of a System Types of Models Discrete-Event System

aa-automation-simulation-plantdesign-p_id-validation.pdf. AS/RS Real Time Simulation and Contro Integrated System Research . Developing Learning Activities and Simulations in e-Learning Content. Talent v Straining. Drawing the Perfect Poster. Verification of Predicted Knee Replacement Kinematics During Simulated Gait in the Kansas Knee Simulator[1] Universal Accessibility in Public Transport

A comprehensive example will be given in the conference presentation. 1 INTRODUCTION One of the largest application areas for simulation modeling is that of manufacturing systems, with the first

One of the largest application areas for simulation modeling is that of manufacturing systems, with the first uses dating back to at least the early 1960’s. In this paper we present an overview of the use of simulation in the design and analysis of manufacturing systems. Detailed discussions of simulation, in general, may be found in Banks, Carson, and Nelson (1996) and Law and Kelton (1991

Modeling and Analysis of Flexible Manufacturing Systems A

PDF This article presents basic concepts regarding the modeling for simulation of production systems and in particular the concept of Control Center (CC). The CC is defined then formalized, for

Effective process times for aggregate modeling of manufacturing systems Kock, A.A.A. DOI: 10.6100/IR635474 Published: 01/01/2008 Document Version Publisher’s PDF, also known as Version of Record (includes final page, issue and volume numbers)

A model is a representation of an actual system (Figure 4) and Figure 5 presents modelling and simulation concepts as introduced by Zeigler [2]. • A model is an abstraction of the real system – what is manufacturing defect urban dictionary

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

Modeling power & free conveyor systems.pdf Simulation

Manufacturing Capacity Management Through Modeling and

Effective process times for aggregate modeling of

Worker Performance Modeling in Manufacturing Systems

Modeling & Simulation in Automotive Industry

Modeling and Optimization in a New Machining Production

Best Reference Books Modeling Simulation and Analysis

– Performance Analysis of Single Flow line Manufacturing ?A

Virtual Factory Data Model to support Performance

(PDF) A Structured Approach to Simulation Modeling of

Modeling and Analysis of Flexible Manufacturing System

1. Simulation Modeling of Manufacturing Systems

Effective process times for aggregate modeling of

systems pdfmodeling and optimization for big data analyticsdynamical modeling and analysis of epidemics simulation modeling and analysis download ebook pdffinal report finite element modeling and analysis of

1) Basic Simulation Modeling. 2) Modeling Complex Systems. 3) Simulation Software. 4) Review of Basic Probability and Statistics. 5) Building Valid, Credible, and Appropriately Detailed Simulation …

the DES method is widely used for design of manufacturing systems [15], for solving scheduling problems [9] and for efficiency [8] and stability analysis [3] of production systems…

6.2. The IoT-Aided Manufacturing System in the Factory Model Although Fischertechnik’s Factory Simulation 9V model is equipped with some sensors, such as color sensors, it is not connected to the Internet and does not have the structure or functionality of the IoT. To convert this factory model into an IoT-aided manufacturing system, we added eight sets of light sensors wirelessly connected

34 replies on “Simulation modeling of manufacturing systems pdf”

Leave a CommentDEPARTMENT OF COMPUTER SCIENCE & SYSTEMS ANALYSIS TECHNICAL REPORT: MU-SEAS-CSA-1994-001 Intelligent Simulation Modeling of a Flexible Manufacturing System with Automated Guided Vehicles

Modeling and Simulation of Manufacturing Line Improvement

1 Worker Performance Modeling in Manufacturing Systems Simulation: Proposal for an Agent-Based Approach Peer-Olaf Siebers University of Nottingham, UK

Modeling and Optimization in a New Machining Production

simulation modeling, it has been determined that the transformer making section, among seven other sections of manufacturing the UPS, was the main system bottleneck while other sections were running concomitantly without any

10 Simulation and Modeling Unit Manufacturing Processes

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

Index Terms— Activity Sampling, Manufacturing Systems, Simulation. I. INTRODUCTION Computer-based simulation is widely used in many disciplines and is becoming an everyday occurrence in the analysis of many fields. Simulation in a manufacturing environment has been used successfully for several decades with its first uses documented in the 1960s. In the paper written by Foster & Rose [1

Simulation Modeling and Analysis mheducation.com

Simulation of Manufacturing Systems es.scribd.com

Modeling power & free conveyor systems.pdf Simulation

In manufacturing and service industries, companies are looking for ways to improve their systems performance and increase their competitiveness in order to survive in the market place. Simulation modeling is a practical tool that can be used by those companies to generate data and simulations to be used for better and faster decision-making and forecasts of their business models and approaches

Simulation Software – Development And Trends

Manufacturing Capacity Management Through Modeling and

A model is a representation of an actual system (Figure 4) and Figure 5 presents modelling and simulation concepts as introduced by Zeigler [2]. • A model is an abstraction of the real system

Manufacturing Capacity Management Through Modeling and

systems. Modeling and simulation of FMS is a field of research for many people now days. However, they all share a common goal; to search for solutions to achieve higher speeds and more flexibility and thus increase manufacturing productivity. FlexSim is a discrete event manufacturing simulation software developed by FlexSim Software Products, Inc. The FlexSim family currently includes the

AGGREGATED LINE MODELING FOR SIMULATION AND

Simulation Modeling of Manufacturing System Simulation

Modeling & Simulation in Automotive Industry

We have created a collection of best reference books on “Modeling ,Simulation and Analysis of Manufacturing Systems” so that one can readily see the list of top books on “Modeling ,Simulation and Analysis of Manufacturing Systems” and buy the books either online or offline.

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

1. Simulation Modeling of Manufacturing Systems – Download as PDF File (.pdf), Text File (.txt) or read online. m.tech ii sem

Performance Analysis of Single Flow line Manufacturing ?A

Modeling power & free conveyor systems.pdf Simulation

Manufacturing Capacity Management Through Modeling and

systems, simulation modeling is becoming one of the most popular methods of facilitating their design and assessing operating strategies. An increasing need for the use of simulation is reflected by a growth in the number of simulation languages and simulators in the software market. When a simulation language is used, the model is developed by writing a program using the modeling …

Effective process times for aggregate modeling of

Modeling and Analysis of Flexible Manufacturing Systems A

Chapter 1 Introduction to Simulation Banks, Carson, Nelson & Nicol Discrete-Event System Simulation. 2 Outline When Simulation Is the Appropriate Tool When Simulation Is Not Appropriate Advantages and Disadvantages of Simulation Areas of Application Systems and System Environment Components of a System Discrete and Continuous Systems Model of a System Types of Models Discrete-Event System

REFERENCE MODEL BASED HIGH FIDELITY SIMULATION MODELING

AGGREGATED LINE MODELING FOR SIMULATION AND

(PDF) A Structured Approach to Simulation Modeling of

We have created a collection of best reference books on “Modeling ,Simulation and Analysis of Manufacturing Systems” so that one can readily see the list of top books on “Modeling ,Simulation and Analysis of Manufacturing Systems” and buy the books either online or offline.

Modeling and Analysis of Flexible Manufacturing System

Modeling and Simulation of the Competitiveness of

Intelligent Simulation Modeling of a Flexible

Simulink is a simulation tools library for use in modeling dynamical systems in modular block form. Most deterministic transformative systems in nature can roughly be thought of as a “black . Matlab IV: Modeling and Simulation 10 The Department of Statistics and Data Sciences, The University of Texas at Austin box” receiving an input vector of information u and eliciting a unique output

Virtual Factory Data Model to support Performance

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

Virtual Factory Data Model to support Performance Evaluation of Production Systems Walter TERKAJa, formalization of the manufacturing system is needed. Simulation modeling of manufacturing systems usually relies on commercial software tools (e.g. Arena, Simio, Plant Simulation, Visual Components, etc.) providing an integrated environment to describe the system …

Download Modeling Simulation and Control of Flexible

Modeling and Analysis of Flexible Manufacturing Systems A

aa-automation-simulation-plantdesign-p_id-validation.pdf. AS/RS Real Time Simulation and Contro Integrated System Research . Developing Learning Activities and Simulations in e-Learning Content. Talent v Straining. Drawing the Perfect Poster. Verification of Predicted Knee Replacement Kinematics During Simulated Gait in the Kansas Knee Simulator[1] Universal Accessibility in Public Transport

Worker Performance Modeling in Manufacturing Systems

multistage manufacturing systems,” Anals of Operation Research 93, pp. 325 -355, 2000. [2] G. Liberopoulous. Y Dallery, “Extended kanban control system, Combining Kanban and Base IJERT. Performance Analysis of Single Flow line Manufacturing ?A Modeling Simulation approach

Modeling and Analysis of Flexible Manufacturing Systems A

10 Simulation and Modeling Unit Manufacturing Processes

automation of manufacturing systems and with object-oriented approaches and software implementation of simulators, which allow real hybrid simulation, and ends with an overview on choice and comparison of simulation software. 1. Introduction Simulation software plays a major role in analysis of nonlinear control systems and complex automation systems. Simulation software, simulation …

Performance Analysis of Single Flow line Manufacturing ?A

AGGREGATED LINE MODELING FOR SIMULATION AND

Simulation of Manufacturing Systems es.scribd.com

A model is a representation of an actual system (Figure 4) and Figure 5 presents modelling and simulation concepts as introduced by Zeigler [2]. • A model is an abstraction of the real system

(PDF) MODELING FOR SIMULATION OF MANUFACTURING

Modeling and Simulation of Manufacturing Systems and

Modeling and Analysis of Flexible Manufacturing Systems A

In manufacturing and service industries, companies are looking for ways to improve their systems performance and increase their competitiveness in order to survive in the market place. Simulation modeling is a practical tool that can be used by those companies to generate data and simulations to be used for better and faster decision-making and forecasts of their business models and approaches

analysis and control of dynamic systems.pdf PDF. The

(PDF) A Structured Approach to Simulation Modeling of

Chapter 1 Introduction to Simulation Banks, Carson, Nelson & Nicol Discrete-Event System Simulation. 2 Outline When Simulation Is the Appropriate Tool When Simulation Is Not Appropriate Advantages and Disadvantages of Simulation Areas of Application Systems and System Environment Components of a System Discrete and Continuous Systems Model of a System Types of Models Discrete-Event System

AGGREGATED LINE MODELING FOR SIMULATION AND

Modeling and Simulation of the Competitiveness of

Download Modeling Simulation and Control of Flexible

Paper ID #12726 Modeling and Analysis of Flexible Manufacturing Systems: A Simulation Study Dr. Guanghsu A. Chang, Western Carolina University Dr. Guanghsu A. Chang, Western Carolina University – Dr. Chang is an associate professor in the De-

Performance Analysis of Single Flow line Manufacturing ?A

analysis and control of dynamic systems.pdf PDF. The

The paper presents operating strategies for manufacturing systems using simulation. An existing An existing manufacturing facility is replicated in a virtual environment using Arena simulation software.

(PDF) A Structured Approach to Simulation Modeling of

Best Reference Books Modeling Simulation and Analysis

Modeling & Simulation in Automotive Industry

A Structured Approach to Simulation Modeling of Manufacturing Systems Douglas A. Bodner and Leon F. McGinnis Keck Virtual Factory Lab · School of Industrial and Systems Engineering

Modeling and Analysis of Flexible Manufacturing Systems A

PDF This article presents basic concepts regarding the modeling for simulation of production systems and in particular the concept of Control Center (CC). The CC is defined then formalized, for

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

1. Simulation Modeling of Manufacturing Systems

Modeling and Simulation of Manufacturing Line Improvement

manufacturing issues addressed by simulation, simulation system software for manufacturing applications, techniques for • Evaluation of capital investments building valid and credible models, and statistical • Labor-requirements planning

10 Simulation and Modeling Unit Manufacturing Processes

Performance Analysis of Single Flow line Manufacturing ?A

DEPARTMENT OF COMPUTER SCIENCE & SYSTEMS ANALYSIS TECHNICAL REPORT: MU-SEAS-CSA-1994-001 Intelligent Simulation Modeling of a Flexible Manufacturing System with Automated Guided Vehicles

Modeling and Simulation of the Competitiveness of

Best Reference Books Modeling Simulation and Analysis

Intelligent Simulation Modeling of a Flexible

1. Simulation Modeling of Manufacturing Systems – Download as PDF File (.pdf), Text File (.txt) or read online. m.tech ii sem

Simulation Modeling of Manufacturing System Simulation

Virtual Factory Data Model to support Performance Evaluation of Production Systems Walter TERKAJa, formalization of the manufacturing system is needed. Simulation modeling of manufacturing systems usually relies on commercial software tools (e.g. Arena, Simio, Plant Simulation, Visual Components, etc.) providing an integrated environment to describe the system …

Effective process times for aggregate modeling of

In manufacturing and service industries, companies are looking for ways to improve their systems performance and increase their competitiveness in order to survive in the market place. Simulation modeling is a practical tool that can be used by those companies to generate data and simulations to be used for better and faster decision-making and forecasts of their business models and approaches

10 Simulation and Modeling Unit Manufacturing Processes

Analytical simulation and modeling of unit manufacturing processes based on knowledge of the underlying process physics and validated by experimental results is becoming a powerful tool to advance the optimization of unit processes. In this context, simulation is defined as the “representation or

Performance Analysis of Single Flow line Manufacturing ?A

A CRITICAL STUDY AND COMPARISON OF MANUFACTURING

Virtual Factory Data Model to support Performance

The paper presents operating strategies for manufacturing systems using simulation. An existing An existing manufacturing facility is replicated in a virtual environment using Arena simulation software.

REFERENCE MODEL BASED HIGH FIDELITY SIMULATION MODELING

analysis and control of dynamic systems.pdf PDF. The

Virtual Factory Data Model to support Performance

The application of simulation in manufacturing system design and operation is expected to continue growing and evolving in the future as the manufacturing sector remains an important part of the global economy and becomes more competitive. There is a need for more efficient techniques to deal with the growing complexity of manufacturing operations. The rising of hybrid approaches, where

Simulation Modeling of Manufacturing System Simulation

aa-automation-simulation-plantdesign-p_id-validation.pdf. AS/RS Real Time Simulation and Contro Integrated System Research . Developing Learning Activities and Simulations in e-Learning Content. Talent v Straining. Drawing the Perfect Poster. Verification of Predicted Knee Replacement Kinematics During Simulated Gait in the Kansas Knee Simulator[1] Universal Accessibility in Public Transport

Download Modeling Simulation and Control of Flexible

Modeling and Simulation of Manufacturing Systems and

6.2. The IoT-Aided Manufacturing System in the Factory Model Although Fischertechnik’s Factory Simulation 9V model is equipped with some sensors, such as color sensors, it is not connected to the Internet and does not have the structure or functionality of the IoT. To convert this factory model into an IoT-aided manufacturing system, we added eight sets of light sensors wirelessly connected

Modeling power & free conveyor systems.pdf Simulation

Simulation of Manufacturing Systems es.scribd.com

Modeling & Simulation in Automotive Industry

Comments are closed.