Stamping process in car manufacturing pdf

Siemens automotive stamping solutions enable engineers to eliminate design errors and maintain a quality product by providing a full working digital model of the press, its associated tooling equipment and behavior. Boost productivity and reduce cost: You can achieve significant gains in manufacturing produc-tivity and cost reduction by re-using industry best practices to reduce errors and

Fundamental Manufacturing Processes Video Series Study Guide – 1 – Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential components of the stamping process are

Industry Insights. The global automotive metal stamping market size was valued at USD 70.42 billion in 2015. The industry is majorly predisposed to consumption trends of metal in all end-use segments.

Quality Management Information in Automotive Stamping Process Maw Maw Htay1*, the first step in car production is stamping process, which is the process that succeeds the shape designing of the part. Metal stamping is a process employed in manufacturing metal parts with a specific design. Stamping (also known as pressing) includes a variety of sheet-metal forming manufacturing …

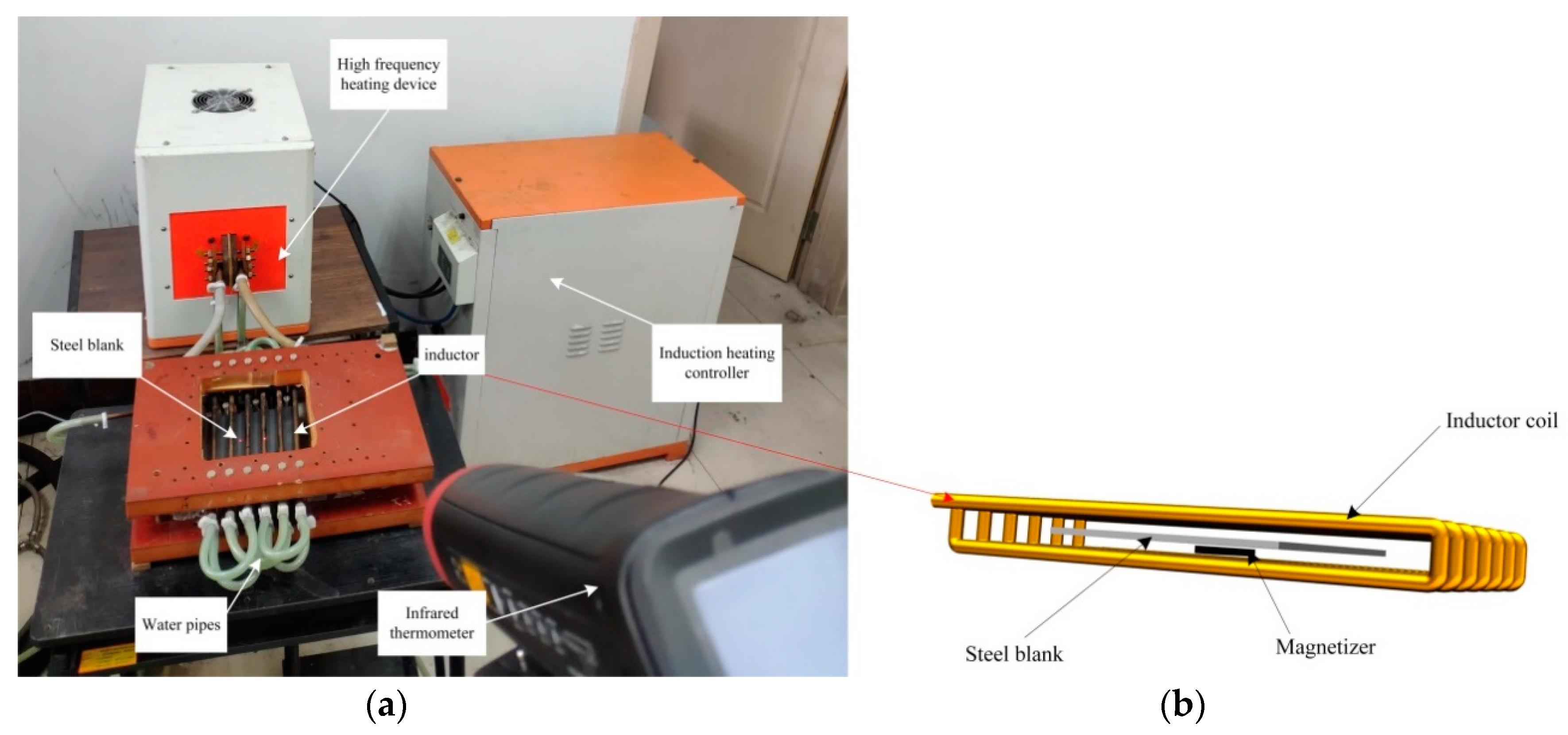

Hot stamping technology is a temperature and time dependent process and consists of several steps: heat treatment and austenitisation by continuous- or batch-type furnaces, transfer from the furnace to the press and the deep drawing dies, hot plastic deformation and quenching in closed cool dies.

Stamping is a process in which thin walled metal parts are shaped by punches and dies. The punches and dies are mounted on mechanical or hydraulic presses and they perform two functions during the stamping process: shearing and bending.

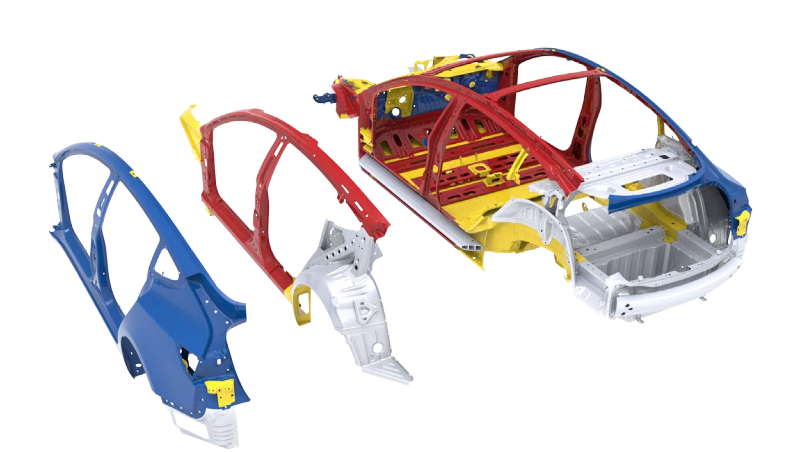

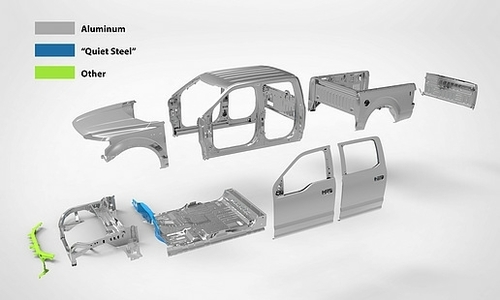

double digit growth for sheet metal material and process equipment. Both countries represent tremendous potential buying power as lifestyles improve. At the same time, Asia region sheet metal feed and stamping press OEMs are becoming global leaders. Sheet Metal Panels for a Car Body Sheet metal is a major part of an automobile. There are 40 to 50 major panels required for a typical vehicle …

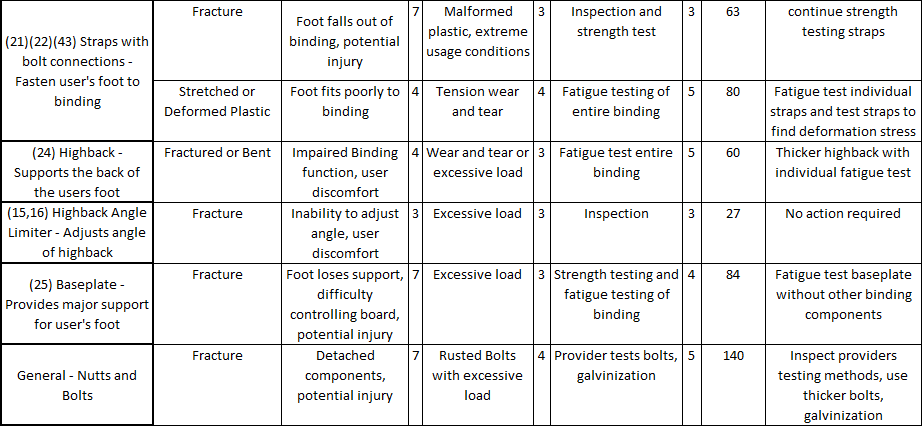

Failure Mode and Effects Analysis (FMEA) is a method designed to: Improving the manufacturing process ensuring the product is built to design requirements in a safe manner, with minimal downtime, scrap and rework. manufacturing and assembly operations, shipping, incoming parts, transporting of materials, storage, conveyors, tool maintenance, and labeling. Process FMEAs most often assume

This paper discusses the basic concept of the quality management information, the stamping process in automotive manufacturing and quality information flow of the stamping process in automobile production. The processes flows of the diagrams are also provided.

A Note on the downloadable PDF version of the Milford Astor Guide to Hot Stamping and Foil Selection. This version of the foil catalogue does not include any foil or colour

How It’s Made Car Doors – YouTube

Sheet Metal Stamping 101 Part I The Fabricator

Luxurious Brilliance, Unmistakable Quality Hot foil stamping is the process of applying foil using a heated die. The metal die strikes heat-sensitive foil, pressing it into the substrate, thereby leaving foil only in the area of die contact and

Stamping includes a variety of sheet-metal forming manufacturing processes using a machine press or stamping press, the processes including punching, blanking, embossing, bending, forming, drawing, flanging, and coining.

the hot-stamping process by focusing on die design applying com-putational fluid dynamics and the verification results on forming performance based on examples. 2. Problems of Hot Stamping Process Hot stamping is a forming method for manufacturing automotive structural parts from thin steel sheets whereby material sheets are heated, pressed into a desired shape while hot and low in strength

The first step in car production is stamping process which is the process after designing the shape of part. Metal stamping is a process employed in manufacturing metal parts with a

GEAR MANUFACTURING PROCESS . 1. 1. Introduction . Gears are used extensively for transmission of power. They find application in: Automobiles, gear boxes, oil …

Progressive Metal Stamping is the process of creating metal parts by employing multiple metal forming / working methods. The process incorporates and automated feeding system to process the metal stamping through progressive manufacturing steps or stations.

tions can achieve a number of different manufacturing operations such as bending, blanking, embossing, and drawing in a single machine through one part fixture. A basic panel stamping process is illustrated in Fig. 1. The sheet metal stock is centered on the die manually or through auto-matic feed systems. Proper alignment of the stock is ensured by guide pins, grooves, or similar mechanisms

THE HOT STAMPING PROCESS Hot stamping is a permanent marking process used to label plastic parts. The hot stamping process utilizes a heated metal or …

1. Introduction. The use of the finite element method has received a lot of attention over the past several years, especially regarding the design of hot stamping processes (Finkler et al., 2013) and for manufacturing car body parts with tailored properties that are described by Banik et al. (2011).

Moreover, materials in the stamping process can also be better utilized and scraps in the automotive workshop will be reduced. Using tailor welded blanks in the automotive industry is the inevitable trend for the car manufacturers.

Hot stamping process is the necessary means to realize the product forming and strength increasing of hot stamping steel, and it is the indispensable premise for HSS of hot stamping to acquire high strength performance.

This figure represents the two principal sets of expectations that comprise Level III Stamping Skills. The left-hand The left-hand column is a listing of the duties that are expected to constitute Level III jobs.

tion, manufacturing of lightweight body parts from ultrahigh-strength steels (UHSS) is rapidly increasing. Forming of UHSS at room tempera- ture is limited by low formability and consid-erable springback. Therefore, hot stamping is accepted as a viable alternative solution and widely used (Fig. 7.1). “Hot stamping is a non-isothermal forming process for sheet metals, where forming and

14/07/2014 · Steel Stamping process is mainly used in automotive industries for manufacturing steel products for auto cars. The process helps you to create structured steel parts based on the requirements and

The process of deciding how to manufacture metal parts using either metal stamping or fabrication techniques is an important decision that ultimately affects the design, quality, timing, cost and repeatable performance of the metal components to be produced.

Sheet Metal Stamping Dies & Processes Fundamental Manufacturing Processes Video Series Study Guide – 1 – Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential

The manufacturing engineers and production managers of car body panels are changing their strategy of operation. The days of ‘a simple washer to a very complicated fender, all in plant stamping facility’, are gone. In-house manufacturing facilities preferably produce only limited number of major car panels, Fig. 5.1. Fig. 5.1 Major Panels of Car Body . An automotive plant today produces

Basic hot stamping process chains: (a) direct hot stamping, (b) indirect hot stamping. H. Karbasian, A.E. Tekkaya / Journal of Materials Processing Technology 210 (2010) 2103–2118 2105 Fig. 3.

The Siemens manufacturing planning solution provides a seamless alignment between the engineering bill of materials (BOM), manufacturing BOM and the manufacturing bill of process (BOP). In this way a quick overview how a change of marterial can affect manufacturing process is possible.

Stamping Process Capability and Implications for Design, Die Tryout and Process Control,” updates ongoing research activities by the Body Systems Analysis Team and the Manufacturing Systems staff at The University of Michigan’s Office for the Study of Automotive Transportation.

Automotive Metal Forming Technologies HowStuffWorks

Steel Innovations in Hot Stamping Paul Belanger Director, Gestamp R&D North America. Organizational Approach Driving Innovation R&D Centers SPAIN SWEDEN FRANCE GERMANY JAPAN BRAZIL US CHINA INDIA. Hot Stamping Innovation History 1974 Objective: Replace cold stamping + batch hardening with forming/quenching in one tool. Hot Stamping Innovation History …

PDF Hot stamping is a thermo-mechanical technique that enables to give to a metallic blank the desired geometry and properties in a single step, where deformation at high temperature, phase

Stamping is a cold-forming operation, which means that no heat is introduced into the die or the sheet material intentionally. However, because heat is generated from friction during the cutting and forming process, stamped parts often exit the dies very hot.

Stamping of sheet metal involves cutting or shearing, bending or forming, and drawing or deep-drawing operations. A detail of all the process has been given below.

The manufacturing process of these steels, and the thermo- mechanical treatment they undergo during hot rolling, result in good structural uniformity and quenchability, ensuring good response to

15/02/2012 · Discovery and Science Channel’s How It’s Made Car Doors episode. All copyrights go to their respective owners.

stamping process for forming B-Pillars from (a) uniform thickness blanks and (b) tailor-rolled blanks with 2 different thicknesses. Simulations were conducted using LS-DYNA.

TOYOTA MOTOR EAST JAPAN, INC. has been at the core of the Toyota group, serving as a key base for development and production. We undertake planning, development and production of Toyota vehicles, mainly passenger cars ranging from high-end modeles.

Similarly, according to the International Organization of Motor Vehicle Manufacturers (OICA), the worldwide production of cars has increased to 72,105,435 cars in 2016, from 58,239,494 cars in 2010. The worldwide production of commercial vehicles has also increased to 22,871,134 vehicles in 2016, from 19,344,025 vehicles in 2010. This growing automotive industry relatively increases the demand

stamping tool manufacturing is one of the most expens ive fields in car manufacturing, it is of utmost importance to reduce the time and costs for tool d esign and manufacturing and to meet the – bluewater manufacturing self closing gates pdf Hot stamping is a well-established process in car manufacturing today. However, the resulting mechanical properties of a hot stamped part and its behaviour during a crash are still open questions.

Stamping is a fast and cost-effective process of manufacturing small gears from a thin metallic sheet. Thickness of metallic sheet depends on the coarseness of stamped gears teeth and ranges from 0.25 to 3 mm. 6 Table 5 presents recommended thickness of sheet for different ranges of the gear pitches.

At body assembly process there are several problem could happen such as miss the spot part, dent or hump, scratch, spatter burr and hole to the body during assembly.

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile’s body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape. Here are some ways that a metal workpiece can be deformed during the automotive manufacturing process:

w w w . a u t o s t e e l . o r g Advanced Stamping for High Strength Steels J.P. McGuire Chrysler Group LLC. Advanced Stamping Manufacturing Engineering

The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. Therefore the first step in any sheet metal process is to cut the correct shape and sized ‘blank’from larger sheet. 2 3 Sheet Metal Cutting & Forming Processes -General-Sheet metal processing is an important process

With the exception of a specialized sheet metal stamping process commonly referred to as hot stamping, most sheet metal stamping operations involve cold forming. This essentially means that no heat is intentionally introduced into the die or the sheet material. However, keep in mind that although stamping is a cold-forming process, heat is generated. Cutting or forming sheet metal creates

be printed using process colour. 1 PDF file for reverse side (If applicable) Prepare 1 PDF file for the artwork on the reverse side. (Reminder: Hot stamping can only be applied on 1 side of the product.) Upload file online (Back) DONOT delete the ‘Full Bleed’ box; change the line colour to WHITE Double check preparation then upload file online (Front) Zip all PDF files together or Combine and

Stamping Welding Painting Assembly Cut steel sheets are inserted in a press machine to make vehicle parts such as the hood and door. The “drawing process” utilizes advanced technology to shape the steel sheets in three dimensions. The car body is made by joining many press parts. Various welding methods are used depending on the material and the shape of the part. A primer coat is applied to

The terms hot stamping and press hardening are commonly known and used within the automotive industry. The benefits of using ultra-high-strength steels, such as 22MnB5, allow car manufacturers to build lighter, yet stronger and safer vehicles.

In automobile manufacturing process, 60% to 70% of the metal parts are processed by the plastic forming, and a metal forming completes stamping process, such as a variety of car body panels, car parts support, engine exhaust pipe and muffler, hollow camshaft, oil pan, engine cradles, frameworks, structures horizontal beam, etc., are all positive by the precision metal forming technology.

When we are discussing the stamping process, invariably the discussion will lead to the dies. It would not be an exaggeration if the die were to be described as the ‘life’ of the stamping. The precision of the die very much decides the quality of the product in the end.

There are many methods for manufacturing gears including: than to a cutting operation such as stamping. The process takes metal from a sheet like stamp-ing but differs from it in that it uses two dies and forms the workpiece by pressing it into the desired shape. The metal is extruded into the die cavities to form the desired shape. Also unlike stamping, fine blanking offers the designer

Blanking automotive stamping process accounted for over 35% of the revenue share in 2015. Blanking is an integral part of automobile manufacturing chain owing to its precise and superior stamping ability. Furthermore, rising use of the technology in mass production lines is expected to propel demand over the forecast period.

Stamping process planning starts with an unfolding of a model of stamped metal part to produce a flat pattern, followed by nesting the pattern to produce a blank layout.

(PDF) Simulation of hot stamping processes ResearchGate

Safety Handbook for Metal Stamping A resource guide for the metal stamping and sheet metal industry ment efforts undertaken by PHD Manufacturing Inc., in Columbiana, Ohio. • The company realized that job-related acci- dents were having an impact on its workers’ compensation premiums and hired a third-party administrator. • The company developed a safety team that met monthly. • Pre

1. What Is Hot Stamping. In its simplest definition, hot stamping, also called hot forming or press hardening, is the process of forming metal while it is very hot (in excess of 900 degrees C) and then quenching it (cooling it quickly) in the die.

Many car manufacturers have been focused on hot stamping to produce various ultra high strength components so that decreasing the weight as well as increasing safety of the cars. 22MnB5 boron

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press , blanking, embossing, bending, flanging, and coining. [1]

Hot Stamping a B-Pillar with Tailored Properties

Advanced Stamping for High Strength Steels autosteel.org

Surface defects is an important issue in sheet metal stamping as the stamping process affects surface appearance and thus influences surface quality. A great amount of time is therefore spent during the product development process on the optimization of surface defects, particularly surface lows during tryout. Surface lows are characterized by unwanted changes of curvatures, i.e. isolated

Metal stamping NPTEL

Hot stamping technology moves on Automotive

Safety Handbook for Metal Stamping Sheet Metal

5350 SheetMetal P&A

https://en.wikipedia.org/wiki/Stamping_(metalworking)

10 Hot-stamping HSS FAQs The Fabricator

– Automotive Metal Stamping Market Size & Share Industry

Chapter 2 Hot Stamping Technology and the Main Equipment

ENGINEERING.com’/>

ENGINEERING.com’/>

Stamping an overview ScienceDirect Topics

A Hybrid Intelligent System for Stamping Process Planning

28 replies on “Stamping process in car manufacturing pdf”

Leave a Commenttion, manufacturing of lightweight body parts from ultrahigh-strength steels (UHSS) is rapidly increasing. Forming of UHSS at room tempera- ture is limited by low formability and consid-erable springback. Therefore, hot stamping is accepted as a viable alternative solution and widely used (Fig. 7.1). “Hot stamping is a non-isothermal forming process for sheet metals, where forming and

(PDF) Simulation of hot stamping processes ResearchGate

THE HOT STAMPING PROCESS Steinwall

Determination of the Mechanical Properties of Hot Stamped

Stamping Process Capability and Implications for Design, Die Tryout and Process Control,” updates ongoing research activities by the Body Systems Analysis Team and the Manufacturing Systems staff at The University of Michigan’s Office for the Study of Automotive Transportation.

Metalforming Skills Stamping Level III TSSB

double digit growth for sheet metal material and process equipment. Both countries represent tremendous potential buying power as lifestyles improve. At the same time, Asia region sheet metal feed and stamping press OEMs are becoming global leaders. Sheet Metal Panels for a Car Body Sheet metal is a major part of an automobile. There are 40 to 50 major panels required for a typical vehicle …

5350 SheetMetal P&A

Hot Stamping a B-Pillar with Tailored Properties

Hot stamping technology moves on Automotive

The manufacturing process of these steels, and the thermo- mechanical treatment they undergo during hot rolling, result in good structural uniformity and quenchability, ensuring good response to

Determination of the Mechanical Properties of Hot Stamped

When we are discussing the stamping process, invariably the discussion will lead to the dies. It would not be an exaggeration if the die were to be described as the ‘life’ of the stamping. The precision of the die very much decides the quality of the product in the end.

Quality Management Information in Automotive Stamping Process

stamping tool manufacturing is one of the most expens ive fields in car manufacturing, it is of utmost importance to reduce the time and costs for tool d esign and manufacturing and to meet the

Modelling kinetics of phase transformation for the

The terms hot stamping and press hardening are commonly known and used within the automotive industry. The benefits of using ultra-high-strength steels, such as 22MnB5, allow car manufacturers to build lighter, yet stronger and safer vehicles.

Sheet Metal Stamping 101 Part I The Fabricator

Hot stamping and laser processing A hot topic in

Data sheet automotive.arcelormittal.com

Stamping Welding Painting Assembly Cut steel sheets are inserted in a press machine to make vehicle parts such as the hood and door. The “drawing process” utilizes advanced technology to shape the steel sheets in three dimensions. The car body is made by joining many press parts. Various welding methods are used depending on the material and the shape of the part. A primer coat is applied to

Steel Innovations in Hot Stamping Autosteel

The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. Therefore the first step in any sheet metal process is to cut the correct shape and sized ‘blank’from larger sheet. 2 3 Sheet Metal Cutting & Forming Processes -General-Sheet metal processing is an important process

THE HOT STAMPING PROCESS Steinwall

Stamping > ENGINEERING.com

Sheet Metal Stamping Dies & Processes Fundamental Manufacturing Processes Video Series Study Guide – 1 – Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential

THE HOT STAMPING PROCESS Steinwall

Quality Management Information in Automotive Stamping Process Maw Maw Htay1*, the first step in car production is stamping process, which is the process that succeeds the shape designing of the part. Metal stamping is a process employed in manufacturing metal parts with a specific design. Stamping (also known as pressing) includes a variety of sheet-metal forming manufacturing …

5350 SheetMetal P&A

The process of deciding how to manufacture metal parts using either metal stamping or fabrication techniques is an important decision that ultimately affects the design, quality, timing, cost and repeatable performance of the metal components to be produced.

(PDF) Simulation of hot stamping processes ResearchGate

Safety Handbook for Metal Stamping Sheet Metal

When we are discussing the stamping process, invariably the discussion will lead to the dies. It would not be an exaggeration if the die were to be described as the ‘life’ of the stamping. The precision of the die very much decides the quality of the product in the end.

Journal of Materials Processing Technology

Toyota Plant Tour MAP Production Process Company Outline

Surface defects in sheet metal stamping AutoForm

Hot stamping is a well-established process in car manufacturing today. However, the resulting mechanical properties of a hot stamped part and its behaviour during a crash are still open questions.

Quality Management Information in Automotive Stamping Process

Stamping (metalworking) Wikipedia

Hot stamping technology moves on Automotive

Basic hot stamping process chains: (a) direct hot stamping, (b) indirect hot stamping. H. Karbasian, A.E. Tekkaya / Journal of Materials Processing Technology 210 (2010) 2103–2118 2105 Fig. 3.

Automotive Metal Forming Technologies HowStuffWorks

Metal Stamping Market by Process Material Application

Stamping is a cold-forming operation, which means that no heat is introduced into the die or the sheet material intentionally. However, because heat is generated from friction during the cutting and forming process, stamped parts often exit the dies very hot.

SCRAP REDUCTION STUDY FOR AUTOMOTIVE STAMPING

double digit growth for sheet metal material and process equipment. Both countries represent tremendous potential buying power as lifestyles improve. At the same time, Asia region sheet metal feed and stamping press OEMs are becoming global leaders. Sheet Metal Panels for a Car Body Sheet metal is a major part of an automobile. There are 40 to 50 major panels required for a typical vehicle …

Steel Innovations in Hot Stamping Autosteel

General Preparing Hot Stamping Artwork Specification

This figure represents the two principal sets of expectations that comprise Level III Stamping Skills. The left-hand The left-hand column is a listing of the duties that are expected to constitute Level III jobs.

TOYOTA MOTOR EAST JAPAN INC. Process until cars are

Metal Stamping or Metal Fabrication Choosing the best

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile’s body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape. Here are some ways that a metal workpiece can be deformed during the automotive manufacturing process:

Automotive Metal Stamping Market Analysis By Technology

Stamping > ENGINEERING.com

Safety Handbook for Metal Stamping A resource guide for the metal stamping and sheet metal industry ment efforts undertaken by PHD Manufacturing Inc., in Columbiana, Ohio. • The company realized that job-related acci- dents were having an impact on its workers’ compensation premiums and hired a third-party administrator. • The company developed a safety team that met monthly. • Pre

Quality Management Information in Automotive Stamping Process

Sheet Metal Stamping Dies & Processes Fundamental Manufacturing Processes Video Series Study Guide – 1 – Training Objectives After watching the video and reviewing this printed material, the viewer will gain knowledge and understanding of the stamping process and the die systems used to form sheet metal. • the terms “ductility” and “formability” are explained • the essential

Sheet Metal Stamping Dies & Processes SeekPart

Quality Management Information in Automotive Stamping Process Maw Maw Htay1*, the first step in car production is stamping process, which is the process that succeeds the shape designing of the part. Metal stamping is a process employed in manufacturing metal parts with a specific design. Stamping (also known as pressing) includes a variety of sheet-metal forming manufacturing …

Automotive Manufacturing industry.siemens.com

(PDF) Simulation of hot stamping processes ResearchGate

Stamping > ENGINEERING.com

Hot stamping technology is a temperature and time dependent process and consists of several steps: heat treatment and austenitisation by continuous- or batch-type furnaces, transfer from the furnace to the press and the deep drawing dies, hot plastic deformation and quenching in closed cool dies.

Surface defects in sheet metal stamping AutoForm

Stamping is a process in which thin walled metal parts are shaped by punches and dies. The punches and dies are mounted on mechanical or hydraulic presses and they perform two functions during the stamping process: shearing and bending.

Advanced Stamping for High Strength Steels autosteel.org

Steel Innovations in Hot Stamping Autosteel

Hot Stamping a B-Pillar with Tailored Properties

Stamping Process Capability and Implications for Design, Die Tryout and Process Control,” updates ongoing research activities by the Body Systems Analysis Team and the Manufacturing Systems staff at The University of Michigan’s Office for the Study of Automotive Transportation.

Stamping Process Variation University of Michigan

Automotive Metal Forming Technologies HowStuffWorks

Determination of the Mechanical Properties of Hot Stamped

tion, manufacturing of lightweight body parts from ultrahigh-strength steels (UHSS) is rapidly increasing. Forming of UHSS at room tempera- ture is limited by low formability and consid-erable springback. Therefore, hot stamping is accepted as a viable alternative solution and widely used (Fig. 7.1). “Hot stamping is a non-isothermal forming process for sheet metals, where forming and

Hot stamping technology moves on Automotive

THE HOT STAMPING PROCESS Hot stamping is a permanent marking process used to label plastic parts. The hot stamping process utilizes a heated metal or …

Hot stamping and laser processing A hot topic in

be printed using process colour. 1 PDF file for reverse side (If applicable) Prepare 1 PDF file for the artwork on the reverse side. (Reminder: Hot stamping can only be applied on 1 side of the product.) Upload file online (Back) DONOT delete the ‘Full Bleed’ box; change the line colour to WHITE Double check preparation then upload file online (Front) Zip all PDF files together or Combine and

Data sheet automotive.arcelormittal.com

Stamping (metalworking) Wikipedia

Comments are closed.