Sugar manufacturing process from sugarcane pdf

Sugarcane – Source of Green Energy JUICE BAGASSE LEAVES & TOPS SUGAR CO-GENERATION OF ELECTRICITY Ethanol NATIONAL SUGAR INSTITUTE, KANPUR 2

Sugar Manufacturing – Free download as PDF File (.pdf), Text File (.txt) or read online for free.

advantage by thi s novel process. The production of invert sugar and high fructose sy rups from sucrose (cane juice) is cost effecti ve. It has been commercialized in India. This paper discusses the sali ent features of this novel technology, which results in an effective 25 per cent increase in the sweetener output from the same quantity of sugarcane as molasses as a waste product is avoided

Refinement of energy saving Throughout the world the demand for sugar is increasing, allied to this, production costs are also escala-ting. This is the reason innovative engineering solutions are …

Sugar manufacturing process 1. 4/19/2014 1 2. Sugar Introduction, Raw and Refined Sugar, Factors Affecting Sugar Storage 4/19/2014 2 RAW & REFINED SUGAR • Raw sugar • Obtained directly from sugarcane juice without refining • Most natural sugar • Brown in color due to molasses • Refined sugar • Have white luster and transparent • Bleached to remove color and other impurities 4

Sugar is harvested from many different sugar cane farms. Sugar comes from sugar canes as a sweet juice. Sugar canes look like bamboo that can measure up to 6 m high.

water and wastewater in a sugar manufacturing process followed by the suggestion regarding the reutilization of the waste water. For study the data is collected from The Kaithal Cooperative Sugar Mills Ltd. (2500 TCD) which is situated in Kaithal District of Haryana State. Keywords: Sugar industry, Water recycling, Reduction in fresh water requirement, Water management, 1. Introduction 1 1.1

Some say that we are beyond the point of reversal now and the best we can do is delay it. Two degrees, that’s all it takes to take out agriculture…

Sugar Manufacture Process Juice extraction from cane Sugar cane. The cane plant consists of a stalk, roots, growing leaves, the remains of dead leaves, and a growing leafy top.

Other sugar crops include sweet sorghum, sugar maple, honey, and corn sugar. The types of sugar used today are white sugar (fully refined sugar), composed of clear, colorless or crystal fragments; or brown sugar, which is less fully refined and contains a greater amount of treacle residue, from which it obtains its color.

The book should be on the shelf of all sugarcane and sugarbeet factories and refiners around the world as well as those companies who are sugar users or who supply goods and services to the sugar industry. It can also be used as a text by universities offering training courses in sugar …

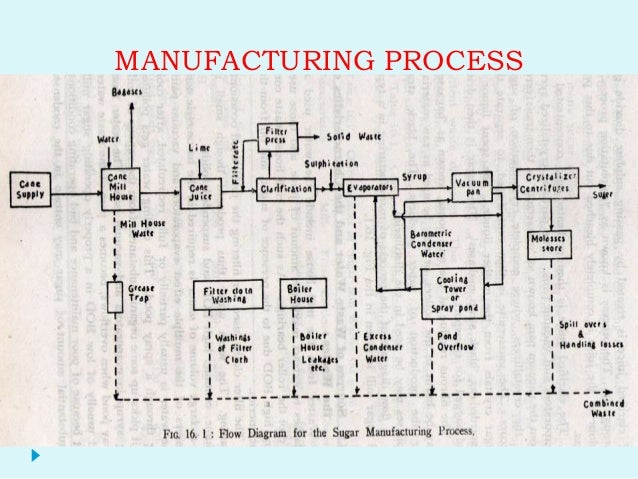

The following points highlight the six main steps involved in manufacturing cane-sugar. The steps are: 1. Extraction of the Juice 2. Clarification of Juice 3.

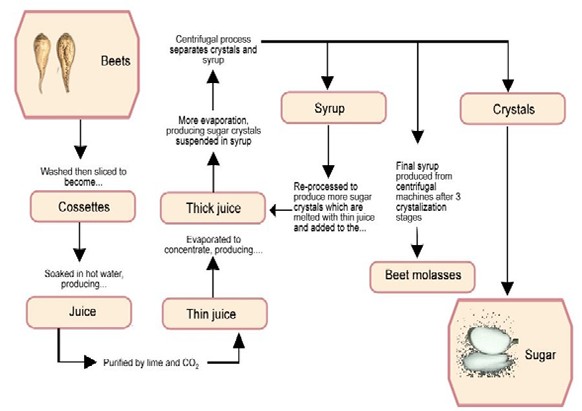

Sugar Manufacturing Process 1. Sampling On arrival, a sample of the sugar beet is taken from the load and tested to measure the sugar content and to determine the amount of soil, tops or leaves present in the load.

production for food prices and regional land use decisions between sugarcane and competing crops. I also examine the impacts of this biofuel policy on India’s export and import balance

PDF Sugarcane has been used as feedstock for production of ethanol on a large scale basis in Brazil for over three decades, where most of the sugarcane mills produce sugar, ethanol and electricity.

The Australian sugar industry processes approximately 35 million tonnes of sugarcane per year from 400 000 hectares of land. Sugar remains the principal revenue stream from sugarcane in Australia with less than 60 ML/y of fuel ethanol produced from final molasses at present.

Simultaneous Production of Sugar and Ethanol from Sugarcane in China, the Deve lopment, Research and Prospect Aspects 77 to the use of fertilizers and chemicals, and loss of …

Sugar Cane Ethanol Plant processdesign

The potential for ethanol production from sugarcane in

FIELD OF THE INVENTION. The present invention relates to a process for manufacturing sugar from sugarcanes. BACKGROUND OF THE INVENTION. In India, sugar is manufactured by a conventional double sulfitation process from sugarcane.

Abstract—The South African sugar industry produces sugar and electricity and raw materials for ethanol production among other by-products. The cogeneration of electricity in the sugar

“The alcohol production originated from the sugar cane, manioc or any other raw material will be stimulated by means of the expansion of the supply of raw materials, with special emphasis in the agricultural productivity growth, modernization and

Development of clarification process of sugar cane juice for consumption established in the literature. The results were also analyzed through the Response Surface Methodology (p < 0.30).

Alibaba.com offers 39 sugar manufacturing process from sugarcane products. About 2% of these are other food processing machinery. A wide variety of sugar manufacturing process from sugarcane options are available to you,

UNESCO – EOLSS SAMPLE CHAPTERS SOILS, PLANT GROWTH AND CROP PRODUCTION – Vol.II – Growth and Production of Sugarcane – Willy Verheye …

Growing Biodynamic Sugar cane in India Growing sugar cane amongst rice paddy and vegetable crops Developed a way to open up canes to allow more light , plus increase production for a smaller plant out . Decrease water wastage, kill monoculture, provide extra income.

3 Sugarcane production from FAO statistical database, faostat.fao. org. Global centrifugal sugar production in 2011-2012 was 171.0 million tons raw value; Brazil’s production …

Sugarcane ethanol is an alcohol-based fuel produced by the fermentation of sugarcane juice and molasses. Because it is a clean, affordable and low-carbon biofuel, sugarcane ethanol has emerged as a leading renewable fuel for the transportation sector.

Costs Sugar production, even at the small scale, is a complex business which requires skilled people to manage and supervise all aspects of the production, from the collection of cane to the delivery of sugar to the market place. If these skills are not available locally then they will have to be brought in to set up the business and to train staff, which will add cost to the project.

The most employed. Bioethanol Production from Sugar Cane Molasses PDF 509Kb Production of ethanol (bioethanol) from biomass is one way to reduce both consumption.

Sugarcane is a renewable, natural agricultural resource because it provides sugar, besides biofuel, fibre, fertilizer and myriad of by products/co-products with ecological sustainability. The main byproducts of sugar industry are bagasse and molasses.

Such method of production can also give a fair price to the farmers per ton of sugarcane.The process involves extraction of juice from sugarcane followed by dilution to get optimum sugar concentration for the fermentation & ferment it by yeast species Saccharomyces Cervicae and finally distillating the fermented wash to obtain 96% pure ethanol. Prior to the fermentation the juice is treated

sugar cane to production and storage of sugar and molasses have been incorporated in this book and various operations connected with the entire process have …

Jaggery manufacturing unit is established at zanzad village in Vadodara district.A unique project in terms of manufacturing sulphur less jaggery powderwith themodern technique.

Figure 7.4 shows a schematic of one process for ethanol production along with the option to produce refined sugar as well. Sugarcane contains the following: water (73-76%), soluble solids (10-16%), and dry fiber or bagasse (11-16%). It takes a series of physical and chemical processes that occur in 7 steps to make the two main products, ethanol and sugar.

The sugar industry processes sugar cane and sugar beet to manufacture edible sugar. More than 60% of the world’s sugar production is from sugar cane; the balance is from sugar beet. Sugar manufacturing is a highly seasonal industry, with season lengths of about 6 to 18 weeks for beets and 20 to 32 weeks for cane. Approximately 10% of the sugar cane can be processed to commercial sugar…

Neutralizing pH value of sugarcane juice is the important factor to be considered in the sugar manufacturing process since it influences the quality of white sugar. The pH neutralization process is a complicated physical-

An overall study was made of the color´s behavior in the production process of sugar from cane, the main color precursors of color and other related factors to the generation of color within the production process of sulphited white sugar (plantation

Study of clarification process of sugar cane juice for

For the 2013/14 season, sugar production is estimated at 2.1 million tons, seventy countries produce sugar from sugar cane, 40 from sugar beet, and . 4 10 from both. The ten (10) largest sugar producing nations represent roughly 75% of world sugar production. Brazil alone accounts for almost 25% of world production and was the largest producer of sugarcane in the world. Brazil produced …

2/02/2012 · mini sugar mill 300 tcd sugarcane crushing machine. mesin giling gula merah.mesin giling gula putih – Duration: 8:15. moon sun 1,143,867 views. 8:15. Manufacturing

Sugarcane has been grown for centuries in Brazil aiming to sugar production and, in the last decades, to ethanol production. The sugar production steps can be divided into two groups: preparation – product design for manufacture and assembly boothroyd pdf The present invention provides a method for manufacturing sugar, which short-circuits at least one sulfitation step and utilizes means for minimizing microbe/microorganism activity and reducing the impurities in the sugar.

The aim of the present paper is the production of low cost ethanol cellulosic materials basically the agro wastes like sugarcane bagasse, rice husk, wheat straw, corn fibre, crop residues, grasses and other materials like saw dust. wood chips, solid animal wastes etc.

Sugarcane facilities currently use a cogeneration system based on the Rankine cycle, in which sugarcane bagasse is burnt in the boiler, producing steam that is expanded in turbines coupled with electric generators; turbines exhaust steam is used as thermal energy source for the various unit operations of the sugar and ethanol production process.

Bajaj Hindusthan Sugar Ltd. Introduced a sugar manufacturing process a Sugar (sucrose) is a carbohydrate that occurs naturally in every fruit and vegetable. Sugar occurs in greatest quantities in sugarcane and sugar beets from which it is separated for commercial use

Sugarcane Production and the Environment Jason Clay, WWF-US Better Sugar Meeting, June 21. WWF and Agricultural Commodities • The goal—reduce measurably the most significant social and environment impacts of commodities with the most significant impacts • Identify both on-farm and ecoregion or large-scale impacts • Focus on the 5-10 most significant environmental and social …

Sugar can be produced from sugarcane, sugar-beet or any other crop having sugar content. But in India, sugarcane is the main source of sugar. At present, this is the second largest agro- based industry of India after cotton textile industry. This industry involves a total capital investment of Rs. 1,250 crore and provides employment to 2.86 lakh workers. In addition, 2.50 crore sugarcane

This brief describes the process of sugar production, explaining yields, crushing, juice treatment, juice boiling and cleanliness. This work is licensed under a Creative Commons Attribution 4.0 …

SUGAR PRODUCTION PROCESS: In Australia the sugar miller is mostly responsible for transport of sugarcane. This is mainly achieved through a substantial cane railway

56 Diego Christoforo Petrassi et al.: Development of Alternative Simulator for the Sugar Manufacturing Process exploration and extraction; and solar energy systems.

The cane Sugar manufacturing industry is essential in the production of many varieties of foods. Sugar is used in cakes, ice cream, candy, and soft drinks as well as in other foods and beverages. In India, most of the Sugar mills are situated in the countryside and operate for about 4 to 8 months just after the harvesting of the Sugarcanes.

22/09/2016 · Production of Ethanol from Molasses, Sugar Cane Molasses based Ethanol Industry, Ethanol from Molasses Industry, Spent Wash Treatment, Manufacturing Plant, …

Raw Sugar Production Process 1. WEIGHBRIDGE TIPPLER Cane is transported to the factory on Tully Sugar Limited’s highly energy efficient cane railway network consisting of some 280 km of …

6/02/2012 · Sugarcane to produce Ethanol Hey guys, I’m struggling a little bit with the research surrounding the ‘processes involved in the industrial production of Ethanol from Sugarcane’.

process control and biodigestion of dunder. Considered as an energy source, 1 tonne (dry basis) of cane in the field (made up of one- third sugar, one-third bagasse and one-third trash) has equivalent energy to …

Harvesting Sugar cane is harvested by chopping down the stems but leaving the roots so that it re-grows in time for the next crop. Harvest times tend to be during the dry season and the length of the harvest ranges from as little as 2 ½ months up to 11 months.

PRODUCTION OF ETHANOL FROM BAGASSE ethesis.nitrkl.ac.in

Environmental, Health, and Safety Guidelines for Sugar Manufacturing Introduction capacity of th The Environmental, Health, and Safety (EHS) Guidelines are technical reference documents with general and industry – specific examples of Good International Industry Practice (GIIP) 1. When one or more members of the World Bank Group are involved in a project, these EHS Guidelines are applied as

Sugar production in Ethiopia started in 1954/55 when the Wonji Sugar Factory was commissioned and produced 15,843 tons of white sugar in the first campaign. When sugarcane development began in 1951, the company was owned by Dutch Company, HVA (Handlers -Vereenging Amsterdam). The development of the sugarcane plantation was started on 5000 hectares in the upper reaches of the …

The Biology of the Saccharum spp. (Sugarcane) Version 2: February 2008 . This document provides an overview of baseline biological information relevant to risk

Sugar manufacturing.pdf Sugar Nutrition Scribd

Sugar Industry Process Description and Wastewater Treatment

Juice from the sugar cane is then subjected to a purification process before being concentrated by boiling in an evaporator. The concentrated juice or syrup is concentrated even further and is seeded with small sugar crystals in a process called crystallisation. The sugar crystals are grown to the required size by adding more syrup while the boiling continues.

A simplified process flow diagram for a typical cane sugar production plant is shown in Figure 9.10.1.1-1. The cane is received at the mill and prepared for extraction of the juice.

28/12/2018 · The actual sugar production process will vary depending upon the type of sugar being made: granulated, liquid, brown, or inverted sugar. Most sugar comes from sugarcane, a tall tropical grass. Considered a perennial herb, sugarcane can be planted by hand or machine, and should be grown in well-drained soil.

The production of ethanol from sugarcane . in Brazil has increased significantly during the last few years and it is expected to continue to expand over the next decades. This is partly the result of the high volatility of petrol´s prices and, also due to the increasing international market for a renewable liquid fuel for the automotive sector. The use of ethanol from sugarcane can also meet

The production of ethanol through the process of sugarcane fermentation is a three-step process which has been used for many years in such sugar-rich countries, such as Brazil. The entire process may be divided into milling/pretreatment, fermentation, and ethanol purification process units. In the milling section, the raw sugarcane is washed and grinded to form a sucrose product which is then

Sugar Manufacturing Process From Sugarcane Sugar

What Is the Sugar Manufacturing Process? (with pictures)

The 24 sugar manufacturing mills, owned by 8 separate companies, purchase approximately 380,000 hectares of sugarcane from around 4000 farms annually. Major products Sugar mill’s major product is raw crystal sugar , which is sold to refineries both domestically and abroad.

(PDF) Sugarcane processing for ethanol and sugar in Brazil

ETHANOL PRODUCTION FROM SUGARCANE IN INDIA VIABILITY

WO2009066316A1 Method for manufacturing sugar from

– Ethanol SugarCane

Tongaat Hulett Sugar South Africa Customer Centre

Sugarcane processing for ethanol and sugar in Brazil

ETHANOL PRODUCTION FROM SUGARCANE JUICE RAVINDRA

PROCESS OPTION FOR PRODUCING REFINED SUGAR IN INDIA

Tongaat Hulett Sugar South Africa Customer Centre

Figure 7.4 shows a schematic of one process for ethanol production along with the option to produce refined sugar as well. Sugarcane contains the following: water (73-76%), soluble solids (10-16%), and dry fiber or bagasse (11-16%). It takes a series of physical and chemical processes that occur in 7 steps to make the two main products, ethanol and sugar.

3 Sugarcane production from FAO statistical database, faostat.fao. org. Global centrifugal sugar production in 2011-2012 was 171.0 million tons raw value; Brazil’s production …

PDF Sugarcane has been used as feedstock for production of ethanol on a large scale basis in Brazil for over three decades, where most of the sugarcane mills produce sugar, ethanol and electricity.

The most employed. Bioethanol Production from Sugar Cane Molasses PDF 509Kb Production of ethanol (bioethanol) from biomass is one way to reduce both consumption.

6/02/2012 · Sugarcane to produce Ethanol Hey guys, I’m struggling a little bit with the research surrounding the ‘processes involved in the industrial production of Ethanol from Sugarcane’.

Raw Sugar Production Process 1. WEIGHBRIDGE TIPPLER Cane is transported to the factory on Tully Sugar Limited’s highly energy efficient cane railway network consisting of some 280 km of …

The Australian sugar industry processes approximately 35 million tonnes of sugarcane per year from 400 000 hectares of land. Sugar remains the principal revenue stream from sugarcane in Australia with less than 60 ML/y of fuel ethanol produced from final molasses at present.

32 replies on “Sugar manufacturing process from sugarcane pdf”

Leave a CommentThe 24 sugar manufacturing mills, owned by 8 separate companies, purchase approximately 380,000 hectares of sugarcane from around 4000 farms annually. Major products Sugar mill’s major product is raw crystal sugar , which is sold to refineries both domestically and abroad.

Sugar manufacturing.pdf Sugar Nutrition Scribd

water and wastewater in a sugar manufacturing process followed by the suggestion regarding the reutilization of the waste water. For study the data is collected from The Kaithal Cooperative Sugar Mills Ltd. (2500 TCD) which is situated in Kaithal District of Haryana State. Keywords: Sugar industry, Water recycling, Reduction in fresh water requirement, Water management, 1. Introduction 1 1.1

Analysis of the Volume of the Main Water and Wastewater in

Harvesting Sugar cane is harvested by chopping down the stems but leaving the roots so that it re-grows in time for the next crop. Harvest times tend to be during the dry season and the length of the harvest ranges from as little as 2 ½ months up to 11 months.

CHEMICAL PROCESS CONTROL IN SUGAR MANUFACTURING UNIT

Development of Alternative Simulator for the Sugar

ETHANOL PRODUCTION FROM SUGARCANE JUICE RAVINDRA

The following points highlight the six main steps involved in manufacturing cane-sugar. The steps are: 1. Extraction of the Juice 2. Clarification of Juice 3.

Sugar and ethanol production process from sugarcane

Alibaba.com offers 39 sugar manufacturing process from sugarcane products. About 2% of these are other food processing machinery. A wide variety of sugar manufacturing process from sugarcane options are available to you,

sugar manufacturing process from sugarcane pdf Archives

Sugar Industry Servicio

Development of Alternative Simulator for the Sugar

56 Diego Christoforo Petrassi et al.: Development of Alternative Simulator for the Sugar Manufacturing Process exploration and extraction; and solar energy systems.

Sugar Manufacturing Process Sugar Beet Sugarcane

Sugar can be produced from sugarcane, sugar-beet or any other crop having sugar content. But in India, sugarcane is the main source of sugar. At present, this is the second largest agro- based industry of India after cotton textile industry. This industry involves a total capital investment of Rs. 1,250 crore and provides employment to 2.86 lakh workers. In addition, 2.50 crore sugarcane

PRODUCTION OF ETHANOL FROM BAGASSE ethesis.nitrkl.ac.in

Analysis of the Volume of the Main Water and Wastewater in

Manufacturing Process Sugar

water and wastewater in a sugar manufacturing process followed by the suggestion regarding the reutilization of the waste water. For study the data is collected from The Kaithal Cooperative Sugar Mills Ltd. (2500 TCD) which is situated in Kaithal District of Haryana State. Keywords: Sugar industry, Water recycling, Reduction in fresh water requirement, Water management, 1. Introduction 1 1.1

Analysis of the Volume of the Main Water and Wastewater in

Sugarcane Production and the Environment WWF

THE FRONTIERS OF PRODUCTION OF SUGAR CANE IN BRAZIL

The present invention provides a method for manufacturing sugar, which short-circuits at least one sulfitation step and utilizes means for minimizing microbe/microorganism activity and reducing the impurities in the sugar.

Sugar Manufacturing Sugarcane Industries

Sugar manufacturing.pdf Sugar Nutrition Scribd

The book should be on the shelf of all sugarcane and sugarbeet factories and refiners around the world as well as those companies who are sugar users or who supply goods and services to the sugar industry. It can also be used as a text by universities offering training courses in sugar …

New technology for invert sugar and high fructose syrups

Sugar Industry Process Description and Wastewater Treatment

Sugar Manufacturing Process Sugar Beet Sugarcane

Environmental, Health, and Safety Guidelines for Sugar Manufacturing Introduction capacity of th The Environmental, Health, and Safety (EHS) Guidelines are technical reference documents with general and industry – specific examples of Good International Industry Practice (GIIP) 1. When one or more members of the World Bank Group are involved in a project, these EHS Guidelines are applied as

Sugar Manufacturing Video.FLV YouTube

28/12/2018 · The actual sugar production process will vary depending upon the type of sugar being made: granulated, liquid, brown, or inverted sugar. Most sugar comes from sugarcane, a tall tropical grass. Considered a perennial herb, sugarcane can be planted by hand or machine, and should be grown in well-drained soil.

Energy Management in the South African Sugar Industry

Sugar manufacturing process SlideShare

Alibaba.com offers 39 sugar manufacturing process from sugarcane products. About 2% of these are other food processing machinery. A wide variety of sugar manufacturing process from sugarcane options are available to you,

(PDF) Sugarcane processing for ethanol and sugar in Brazil

Sugarcane Production and the Environment WWF

“The alcohol production originated from the sugar cane, manioc or any other raw material will be stimulated by means of the expansion of the supply of raw materials, with special emphasis in the agricultural productivity growth, modernization and

Analysis of the Volume of the Main Water and Wastewater in

A PROJECT REPORT ON Panela Monitor

Industry Information sugaraustralia.com.au

The aim of the present paper is the production of low cost ethanol cellulosic materials basically the agro wastes like sugarcane bagasse, rice husk, wheat straw, corn fibre, crop residues, grasses and other materials like saw dust. wood chips, solid animal wastes etc.

Sugarcane to produce Ethanol Bored of Studies

Study of clarification process of sugar cane juice for

Sugar manufacturing.pdf Sugar Nutrition Scribd

Neutralizing pH value of sugarcane juice is the important factor to be considered in the sugar manufacturing process since it influences the quality of white sugar. The pH neutralization process is a complicated physical-

sugar manufacturing process from sugarcane pdf Archives

The cane Sugar manufacturing industry is essential in the production of many varieties of foods. Sugar is used in cakes, ice cream, candy, and soft drinks as well as in other foods and beverages. In India, most of the Sugar mills are situated in the countryside and operate for about 4 to 8 months just after the harvesting of the Sugarcanes.

THE FRONTIERS OF PRODUCTION OF SUGAR CANE IN BRAZIL

Energy Management in the South African Sugar Industry

Growing Biodynamic Sugar cane in India Growing sugar cane amongst rice paddy and vegetable crops Developed a way to open up canes to allow more light , plus increase production for a smaller plant out . Decrease water wastage, kill monoculture, provide extra income.

Energy Management in the South African Sugar Industry

New technology for invert sugar and high fructose syrups

Sugarcane facilities currently use a cogeneration system based on the Rankine cycle, in which sugarcane bagasse is burnt in the boiler, producing steam that is expanded in turbines coupled with electric generators; turbines exhaust steam is used as thermal energy source for the various unit operations of the sugar and ethanol production process.

Analysis of the Volume of the Main Water and Wastewater in

Sugarcane processing for ethanol and sugar in Brazil

Sugarcane Production and the Environment WWF

The book should be on the shelf of all sugarcane and sugarbeet factories and refiners around the world as well as those companies who are sugar users or who supply goods and services to the sugar industry. It can also be used as a text by universities offering training courses in sugar …

Sugar Manufacturing Video.FLV YouTube

production for food prices and regional land use decisions between sugarcane and competing crops. I also examine the impacts of this biofuel policy on India’s export and import balance

Sugar production from Sugar Cane Practical Answers

The aim of the present paper is the production of low cost ethanol cellulosic materials basically the agro wastes like sugarcane bagasse, rice husk, wheat straw, corn fibre, crop residues, grasses and other materials like saw dust. wood chips, solid animal wastes etc.

A PROJECT REPORT ON Panela Monitor

Energy Management in the South African Sugar Industry

DESIGN MANUFACTURING AND MAINTENANCE OF SUGAR MILL

The aim of the present paper is the production of low cost ethanol cellulosic materials basically the agro wastes like sugarcane bagasse, rice husk, wheat straw, corn fibre, crop residues, grasses and other materials like saw dust. wood chips, solid animal wastes etc.

Sugar Industry Process Description and Wastewater Treatment

Bajaj Hindusthan Sugar Ltd. Introduced a sugar manufacturing process a Sugar (sucrose) is a carbohydrate that occurs naturally in every fruit and vegetable. Sugar occurs in greatest quantities in sugarcane and sugar beets from which it is separated for commercial use

Sugar Manufacturing Process Sugar Beet Sugarcane

Sugar Manufacture Process Juice extraction from cane Sugar cane. The cane plant consists of a stalk, roots, growing leaves, the remains of dead leaves, and a growing leafy top.

The generation of color in the sugar production process

Sugar manufacturing process 1. 4/19/2014 1 2. Sugar Introduction, Raw and Refined Sugar, Factors Affecting Sugar Storage 4/19/2014 2 RAW & REFINED SUGAR • Raw sugar • Obtained directly from sugarcane juice without refining • Most natural sugar • Brown in color due to molasses • Refined sugar • Have white luster and transparent • Bleached to remove color and other impurities 4

sugar manufacturing process from sugarcane pdf Archives

Sugar Manufacturing Process From Sugarcane Sugar

UNESCO – EOLSS SAMPLE CHAPTERS SOILS, PLANT GROWTH AND CROP PRODUCTION – Vol.II – Growth and Production of Sugarcane – Willy Verheye …

Sugarcane Ppt SlideShare

Steps Involved in Manufacturing Cane-Sugar (With Diagram)

A PROJECT REPORT ON Panela Monitor

Costs Sugar production, even at the small scale, is a complex business which requires skilled people to manage and supervise all aspects of the production, from the collection of cane to the delivery of sugar to the market place. If these skills are not available locally then they will have to be brought in to set up the business and to train staff, which will add cost to the project.

PRODUCTION OF ETHANOL FROM BAGASSE ethesis.nitrkl.ac.in

“The alcohol production originated from the sugar cane, manioc or any other raw material will be stimulated by means of the expansion of the supply of raw materials, with special emphasis in the agricultural productivity growth, modernization and

WO2009066316A1 Method for manufacturing sugar from

Study of clarification process of sugar cane juice for

Sugar and ethanol production process from sugarcane

Abstract—The South African sugar industry produces sugar and electricity and raw materials for ethanol production among other by-products. The cogeneration of electricity in the sugar

Sugar Manufacturing Industry. Mini Sugar Plant. Sugarcane

The generation of color in the sugar production process

Energy Management in the South African Sugar Industry

Costs Sugar production, even at the small scale, is a complex business which requires skilled people to manage and supervise all aspects of the production, from the collection of cane to the delivery of sugar to the market place. If these skills are not available locally then they will have to be brought in to set up the business and to train staff, which will add cost to the project.

sugar manufacturing process from sugarcane pdf Archives

Tongaat Hulett Sugar South Africa Customer Centre

Sugarcane Ppt SlideShare

Sugar manufacturing process 1. 4/19/2014 1 2. Sugar Introduction, Raw and Refined Sugar, Factors Affecting Sugar Storage 4/19/2014 2 RAW & REFINED SUGAR • Raw sugar • Obtained directly from sugarcane juice without refining • Most natural sugar • Brown in color due to molasses • Refined sugar • Have white luster and transparent • Bleached to remove color and other impurities 4

PROCESS OPTION FOR PRODUCING REFINED SUGAR IN INDIA

Comments are closed.