Sulphuric acid manufacturing process pdf

This report contains a detailed design proc edure of a plant to manufacture Sulfuric acid from Sulfur, as followed by Group 01 as per the allocations of CH 4202 (Comprehensive Design Project-09

Pyrite roasting and sulphur burning plants are built for the production of sulphuric acid. Whereas the burning of elemental sulphur is the main source for sulphuric acid, the roasting process is an interesting alternative once pyrite concentrate is available.

By some measure the most widely produced chemical in the world today, sulfuric acid has an extraordinary range of modern uses, including phosphate fertilizer production, explosives, glue, wood preservative and lead-acid batteries.

4/05/2010 · Sulfuric acid Sulfuric acid (H2SO4) is a strong, heavy acid with a density of 1.84 g/cc and a marked tendency to absorb moisture from the air, generating much heat.

found on the web – avaliable in PDF, EPUB, MOBI the thief who · Handbook of Sulfuric Acid Manufacturing By Douglas K Louie. Dynamic process simulators are widely used

Unique mathematical analysis of sulfuric acid manufacturing processes, providing a sound basis for optimizing sulfuric acid manufacturing processes Analysis of recently developed sulfuric acid manufacturing techniques suggests advantages and disadvantages of the new processes from the energy and environmental points of view

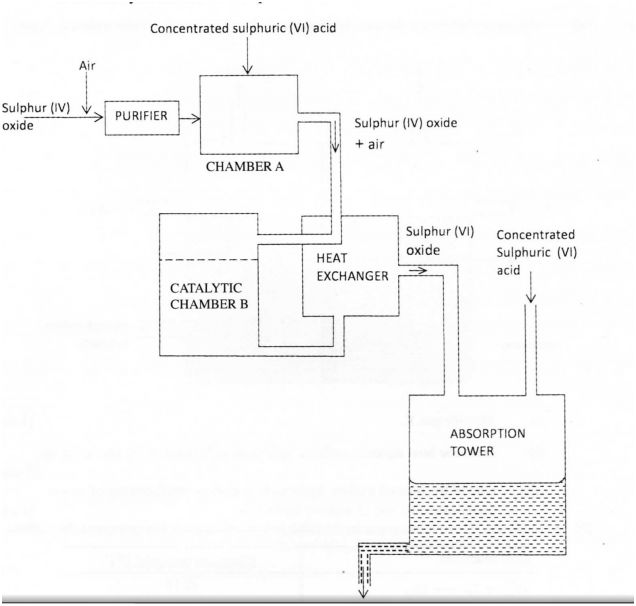

The contact process is the main method used to produce sulfuric acid from elemental sulfur (or sulfur dioxide). There are four main steps. It is named after the contact which the sulfur dioxide and oxygen make with the catalyst.

contact process Now a days, sulphuric acid is prepared by contact process all over the world. Preparation of sulphuric acid by contact process is based upon the catalytic oxidation of SO 2 to SO 3 .

It was the Handbook of Sulphuric Acid Manufacturing, Second Edition, by Douglas K. Louie, P.Eng. You can read about it here . The book covers everything from simulations to maintenance, written by a man who’s been doing it his entire professional life.

The Ostwald process has many well-known uses in both the industrial and health field. Through the Ostwald process, nitric acid is commonly used in fertilizers and pharmaceuticals, and because of

The SO 2 in the gas is made into sulfuric acid by (i) catalytically oxidizing it to SO 3 then (ii) reacting this SO 3 with the H 2 O(ℓ) component of strong sulfuric acid. Sulfuric acid is used for making fertilizer, leaching metal ores, refining petroleum, and manufacturing a myriad of products.

Sulfuric acid (alternative spelling sulphuric acid), also known as vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with molecular formula H 2 SO 4.

Sulfuric Acid Manufacture: Analysis, Control and Optimization keeps the important topics of safety and regulation at the forefront as it overviews and analyzes the process of sulfuric acid manufacture.

Module 4 Lecture 17 NPTEL

Sulfuric Acid Manufacturing Spartan Controls

acid rain. Stage 3 In the final stage, the sulfur trioxide is converted into sulfuric acid. The sulfur trioxide gas is absorbed into very concentrated sulfuric acid (a 98 per cent solution of H 2 SO 4 in water), producing a thick fuming liquid called oleum.

The heat generated off sulfuric acid production is used to power phosphate manufacturing plants and extra energy is often sold back to the area electric grid. How is Sulfuric Acid Made? – A Plus Topper . Manufacture of sulphuric acid in industry: In industry, sulphuric acid is manufactured by Contact process. Sulphur, air or oxygen and water are the raw materials for the manufacture of

information on the characteristics of sulfuric acid distributed by NorFalco, as well as on the sulfuric acid manufacturing process, transportation options, storage practices, safe handling and emergency

The gas stream is filtered to remove any traces of sulfuric acid mist and is returned to the atmosphere using a high stack. RELATED TAGS: WHAT IS FORMULA OF SULFURIC ACID,HOW TO USE SULFURIC ACID,WHERE TO USE SULFURIC ACID,FERTILIZERS,MAKING SULFURIC ACID,SULFURIC ACID TO MANUFACTURE,MANUFACTURING SULFURIC ACID,PROCESS OF SULFURIC ACID,USING SULFURIC ACID,SPESIFICATION OF SULFURIC ACID.

Preparation of Sulphuric Acid by Contact process. We will first start by addressing the question of what is sulphuric acid. Well, sulphuric acid is basically an oxidizing agent, a strong mineral acid, and a dehydrating agent. Sulphuric acid has the chemical formula H 2 SO 4. The acid is a colorless liquid. It is soluble in water and generally releases heat on contact. Further, the acid is

DESCRIPTION OF THE MANUFACTURE OF SULFURIC. ACID Sulfuric acid (by mass) is produced world-wide than any other chemical. The superphosphate industry relies on the production of sulfuric acid as one of the primary raw materials.

1.1 Manufacturing processes Isopropyl alcohol has been called the first petrochemical (IARC, 1992). It can be prepared via three different methods: indirect hydration of propylene, direct hydration of propylene, and catalytic hydrogenation of acetone. Indirect hydration, also called the sulfuric-acid process, was the only method used to produce isopro-panol worldwide until the first commercial

• Sulfuric acid treatment process of bones and P minerals (apatite) was patented in mid 1800s. • Today most P fertilizer production is based on acidification of apatite. from phosphate rock (PR) Guano mining, Chincha Islands, Peru, 1860 Guano mining, Chincha Islands, Peru 1860 U.S. phosphate operation, late 1800s. The chemical symbol for the element phosphorus is P. The fertilizer industry

A Practical Guide to the Manufacture of Sulfuric Acid, Oleums, and Sulfonating Agents covers sulfuric acid and derivative chemical plant details from the nuts-and-bolts level to a holistic perspective based on actual field experience. The book is indispensable to anyone involved in implementing a sulfuric acid or related chemical plant.

1 Design Considerations for Sulphuric Acid Plants Short Course Sulphuric Acid Production Technologies Presented by Douglas Louie Cobre-Copper 2010 Hamburg, Germany

Sulfuric acid is used for making fertilizer, leaching metal ores, refining petroleum, and manufacturing a myriad of products. About 200 million tonnes of sulfuric acid are produced/consumed per year.

high concentration (above 70% weight) nitric acid production process is not included. A typical plant of 1,000t.d -1 capacity has been selected for further description but all data are calculated for one tonne of 100% nitric acid because plant size has only a marginal effect

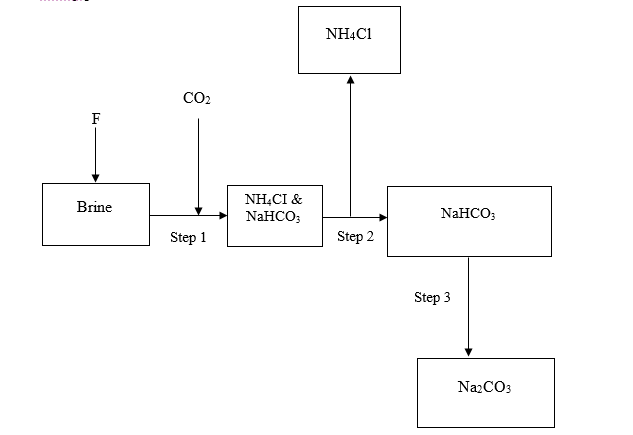

Manufacturing Chemicals. This manufacturing chemicals topic covers how some important chemicals are produced in the chemical industries. This post is going to cover the production of some important inorganic chemicals such as ammonia, sodium hydroxide, and sulfuric acid.

Sulfuric acid manufacturing processes use different types of reactors. Perhaps the most common type has the reactor divided into adiabatic sections with cooling between the sections (recall Figure 8-8). One such layout is shown in Figure R8.4-2. In the process in Figure R8.4-2, gas is brought out of the converter to cool it between stages, using the hot converter reaction mixture to preheat

Sulfuric Acid Manufacture 2nd Edition

Sulfuric acid – Manufacturing process of Sulfuric acid : Sulfuric acid is the largest-volume industrial chemical produced in the world (200 million tons per year). Concentrated sulfuric acid (93-98 %) is used in the manufacture of fertilizers, explosives, dyes, and petroleum products.

Module 4 Lecture: 17 Sulfuric acid Dr. N. K. Patel N P T E L 107 Module: 4 Lecture: 17 SULFURIC ACID INTRODUCTION Sulfuric acid (H 2 SO 4) is a highly corrosive strong mineral acid. It is a colorless to slightly yellow viscous liquid which is soluble in water at all concentrations. It is one of the most important heavy industrial chemicals due to it has a number of large-scale uses

Fuzzy logic based automation and control simulation of Sulfuric acid manufacturing process: A case www.iosrjen.org 20 P a g e

process sulphuric acid catalyst. Efficient gas cleaning is required for metallurgical Efficient gas cleaning is required for metallurgical and contaminated acid decomposition gases, especially the former.

sulfuric acid manufacturing process, transportation options and storage practices, and safe handling, precautionary and emergency measures. For specific details on sulfuric acid production, characteristics and handling, please refer to appropriate scientific texts. * Please note all specifications and technical information are provided free of charge. This information is intended for guidance

Sulfuric Acid ! This acid should be stored away from water and reducing agents. ! It is safely stored and transported in steel tanks and drums. Any iron that reacts with the acid forms an insoluble coating of iron sulfate on the steel which is is contact with the acid. The layer makes the steel impenetrable to further attack. Industrial Uses of Sulfuric Acid ! Manufacture of fertilisers such – subtractive vs additive manufacturing pdf The process description of the salt-sulfuric acid method of hydrochloric acid production is given hereunder. Hydrochloric or muriatic acid is generally made by the action of sulphuric acid …

Flow diagram for Manufacturing Process of Sulfuric acid by contact shown below clearly illustrates the main steps involved in the process. Figure 2: Flow diagram for Contact Process III. USES OF SULFURIC ACID: Sulfuric Acid has widely varied uses and plays some part in the production of nearly all manufactured goods.Some of the them are industries from fertilis …

14/08/2012 · The manufacturing process for sulphuric acid by the single absorption process and DCDA process are shown in Figure 7–9 and Figure 7–10 respectively. Figure 7–9 . Production of sulfuric acid–single absorption process.

In manufacturing one tonne of sulfuric acid, one tonne of high pressure steam is also produced. (c) Conversion of sulfur dioxide to sulfur trioxide (The Contact Process) A typical plant contains one cylindrical vessel which acts as a fixed bed reactor with four separate beds of catalyst, known as a converter, heated to 700 K, through which the sulfur dioxide and air pass:

COM 2010, Vancouver, Canada, October 3-6, 2010 2 Course Objective Review the fundamentals of the sulphuric acid process, plant design and operation.

semiconductor manufacturing process. There are two types of technology to recover and purity the waste fluid of sulfuric acid: an atmospheric distillation method and a low pressure distillation method. The atmo-spheric distillation method is more commonly used throughout the world, but in Japan only a few recovery and purifica-tion equipment based on this method are in operation1 because Japan

Download as PDF, TXT or read online Handbook of Sulphuric Acid Manufacturing. For Later. save. Related. Info. Embed. Share. Print. Search. Related titles. Plant Design for Sulfuric Acid Manufacture(1) Sulfuric Acid SimulationManual. 30122794 Sulfuric Acid and Sulfur Trioxide . Sulphuric Acid Production. Tutorial 14 Aspen Plus Sulfuric Acid Model. Sulfuric Acid_Design of …

The Manufacture of Sulfuric Acid patana.ac.th

Manufacturing Chemicals ammonia sodium hydroxide and

Industrial Production of Sulfuric Acid Nsb Notes

Sulfuric Acid Manufacture 1st Edition – Elsevier

Sulfuric Acid PDF Free Download – edoc.site

Manufacturing of nitric acid by Ostwald process Medium

Reduction of Waste in Semiconductor Manufacturing Plant

Handbook of Sulphuric Acid Manufacturing Scribd

– Manufacturing of sulfuric acid by Contact process

PDF Sulfuric Acid Manufacture Analysis Control And

Fuzzy logic based automation and control simulation of

53. PROFILE ON THE PRODUCTION OF HYDROCHLORIC ACID

Module 4 Lecture 17 NPTEL

Manufacturing of nitric acid by Ostwald process Medium

A Practical Guide to the Manufacture of Sulfuric Acid, Oleums, and Sulfonating Agents covers sulfuric acid and derivative chemical plant details from the nuts-and-bolts level to a holistic perspective based on actual field experience. The book is indispensable to anyone involved in implementing a sulfuric acid or related chemical plant.

COM 2010, Vancouver, Canada, October 3-6, 2010 2 Course Objective Review the fundamentals of the sulphuric acid process, plant design and operation.

The SO 2 in the gas is made into sulfuric acid by (i) catalytically oxidizing it to SO 3 then (ii) reacting this SO 3 with the H 2 O(ℓ) component of strong sulfuric acid. Sulfuric acid is used for making fertilizer, leaching metal ores, refining petroleum, and manufacturing a myriad of products.

Sulfuric acid is used for making fertilizer, leaching metal ores, refining petroleum, and manufacturing a myriad of products. About 200 million tonnes of sulfuric acid are produced/consumed per year.

It was the Handbook of Sulphuric Acid Manufacturing, Second Edition, by Douglas K. Louie, P.Eng. You can read about it here . The book covers everything from simulations to maintenance, written by a man who’s been doing it his entire professional life.

• Sulfuric acid treatment process of bones and P minerals (apatite) was patented in mid 1800s. • Today most P fertilizer production is based on acidification of apatite. from phosphate rock (PR) Guano mining, Chincha Islands, Peru, 1860 Guano mining, Chincha Islands, Peru 1860 U.S. phosphate operation, late 1800s. The chemical symbol for the element phosphorus is P. The fertilizer industry

high concentration (above 70% weight) nitric acid production process is not included. A typical plant of 1,000t.d -1 capacity has been selected for further description but all data are calculated for one tonne of 100% nitric acid because plant size has only a marginal effect

14/08/2012 · The manufacturing process for sulphuric acid by the single absorption process and DCDA process are shown in Figure 7–9 and Figure 7–10 respectively. Figure 7–9 . Production of sulfuric acid–single absorption process.

Sulfuric acid manufacturing processes use different types of reactors. Perhaps the most common type has the reactor divided into adiabatic sections with cooling between the sections (recall Figure 8-8). One such layout is shown in Figure R8.4-2. In the process in Figure R8.4-2, gas is brought out of the converter to cool it between stages, using the hot converter reaction mixture to preheat

information on the characteristics of sulfuric acid distributed by NorFalco, as well as on the sulfuric acid manufacturing process, transportation options, storage practices, safe handling and emergency

semiconductor manufacturing process. There are two types of technology to recover and purity the waste fluid of sulfuric acid: an atmospheric distillation method and a low pressure distillation method. The atmo-spheric distillation method is more commonly used throughout the world, but in Japan only a few recovery and purifica-tion equipment based on this method are in operation1 because Japan

Sulfuric acid (alternative spelling sulphuric acid), also known as vitriol, is a mineral acid composed of the elements sulfur, oxygen and hydrogen, with molecular formula H 2 SO 4.

Manufacturing Chemicals. This manufacturing chemicals topic covers how some important chemicals are produced in the chemical industries. This post is going to cover the production of some important inorganic chemicals such as ammonia, sodium hydroxide, and sulfuric acid.

4/05/2010 · Sulfuric acid Sulfuric acid (H2SO4) is a strong, heavy acid with a density of 1.84 g/cc and a marked tendency to absorb moisture from the air, generating much heat.

The heat generated off sulfuric acid production is used to power phosphate manufacturing plants and extra energy is often sold back to the area electric grid. How is Sulfuric Acid Made? – A Plus Topper . Manufacture of sulphuric acid in industry: In industry, sulphuric acid is manufactured by Contact process. Sulphur, air or oxygen and water are the raw materials for the manufacture of

30 replies on “Sulphuric acid manufacturing process pdf”

Leave a CommentThe Ostwald process has many well-known uses in both the industrial and health field. Through the Ostwald process, nitric acid is commonly used in fertilizers and pharmaceuticals, and because of

Preparation of Sulphuric Acid by Contact process Chemistry

ISOPROPYL ALCOHOL MANUFACTURE BY THE STRONG-ACID PROCESS

PDF Sulfuric Acid Manufacture Analysis Control And

COM 2010, Vancouver, Canada, October 3-6, 2010 2 Course Objective Review the fundamentals of the sulphuric acid process, plant design and operation.

Manufacturing of nitric acid by Ostwald process Medium

Preparation of Sulphuric Acid by Contact process Chemistry

Sulfuric acid – Manufacturing process of Sulfuric acid

Sulfuric Acid ! This acid should be stored away from water and reducing agents. ! It is safely stored and transported in steel tanks and drums. Any iron that reacts with the acid forms an insoluble coating of iron sulfate on the steel which is is contact with the acid. The layer makes the steel impenetrable to further attack. Industrial Uses of Sulfuric Acid ! Manufacture of fertilisers such

Manufacturing of sulfuric acid by Contact process

(PDF) Design of a Plant to Manufacture Sulfuric Acid from

Download as PDF, TXT or read online Handbook of Sulphuric Acid Manufacturing. For Later. save. Related. Info. Embed. Share. Print. Search. Related titles. Plant Design for Sulfuric Acid Manufacture(1) Sulfuric Acid SimulationManual. 30122794 Sulfuric Acid and Sulfur Trioxide . Sulphuric Acid Production. Tutorial 14 Aspen Plus Sulfuric Acid Model. Sulfuric Acid_Design of …

The Manufacture of Sulfuric Acid patana.ac.th

Design Considerations for Sulphuric Acid Plants

Sulfuric Acid PDF Free Download – edoc.site

Module 4 Lecture: 17 Sulfuric acid Dr. N. K. Patel N P T E L 107 Module: 4 Lecture: 17 SULFURIC ACID INTRODUCTION Sulfuric acid (H 2 SO 4) is a highly corrosive strong mineral acid. It is a colorless to slightly yellow viscous liquid which is soluble in water at all concentrations. It is one of the most important heavy industrial chemicals due to it has a number of large-scale uses

Preparation of Sulphuric Acid by Contact process Chemistry

AP-42 CH 8.9 Phosphoric Acid

Sulphuric acid- Contact process- industrial preparation of

Module 4 Lecture: 17 Sulfuric acid Dr. N. K. Patel N P T E L 107 Module: 4 Lecture: 17 SULFURIC ACID INTRODUCTION Sulfuric acid (H 2 SO 4) is a highly corrosive strong mineral acid. It is a colorless to slightly yellow viscous liquid which is soluble in water at all concentrations. It is one of the most important heavy industrial chemicals due to it has a number of large-scale uses

Sulfuric Acid Manufacture 2nd Edition

The Manufacture of Sulfuric Acid patana.ac.th

This report contains a detailed design proc edure of a plant to manufacture Sulfuric acid from Sulfur, as followed by Group 01 as per the allocations of CH 4202 (Comprehensive Design Project-09

Handbook of Sulphuric Acid Manufacturing Scribd

PRODUCTION OF NITRIC ACID Fertilizers Europe

information on the characteristics of sulfuric acid distributed by NorFalco, as well as on the sulfuric acid manufacturing process, transportation options, storage practices, safe handling and emergency

Sulfuric Acid Manufacturing Process Scribd

Sulfuric Acid Manufacturing Spartan Controls

Download as PDF, TXT or read online Handbook of Sulphuric Acid Manufacturing. For Later. save. Related. Info. Embed. Share. Print. Search. Related titles. Plant Design for Sulfuric Acid Manufacture(1) Sulfuric Acid SimulationManual. 30122794 Sulfuric Acid and Sulfur Trioxide . Sulphuric Acid Production. Tutorial 14 Aspen Plus Sulfuric Acid Model. Sulfuric Acid_Design of …

Design Considerations for Sulphuric Acid Plants

Module 4 Lecture 17 NPTEL

Sulfuric Acid ! This acid should be stored away from water and reducing agents. ! It is safely stored and transported in steel tanks and drums. Any iron that reacts with the acid forms an insoluble coating of iron sulfate on the steel which is is contact with the acid. The layer makes the steel impenetrable to further attack. Industrial Uses of Sulfuric Acid ! Manufacture of fertilisers such

Manufacturing of nitric acid by Ostwald process Medium

Sulfuric Acid Manufacture 1st Edition – Elsevier

53. PROFILE ON THE PRODUCTION OF HYDROCHLORIC ACID

Sulfuric acid manufacturing processes use different types of reactors. Perhaps the most common type has the reactor divided into adiabatic sections with cooling between the sections (recall Figure 8-8). One such layout is shown in Figure R8.4-2. In the process in Figure R8.4-2, gas is brought out of the converter to cool it between stages, using the hot converter reaction mixture to preheat

Manufacturing of nitric acid by Ostwald process Medium

sulfuric acid manufacturing process, transportation options and storage practices, and safe handling, precautionary and emergency measures. For specific details on sulfuric acid production, characteristics and handling, please refer to appropriate scientific texts. * Please note all specifications and technical information are provided free of charge. This information is intended for guidance

The Manufacture of Sulfuric Acid patana.ac.th

Industrial Production of Sulfuric Acid Nsb Notes

PDF Sulfuric Acid Manufacture Analysis Control And

This report contains a detailed design proc edure of a plant to manufacture Sulfuric acid from Sulfur, as followed by Group 01 as per the allocations of CH 4202 (Comprehensive Design Project-09

Manufacturing of sulfuric acid by Contact process

53. PROFILE ON THE PRODUCTION OF HYDROCHLORIC ACID

Sulfuric Acid PDF Free Download – edoc.site

The process description of the salt-sulfuric acid method of hydrochloric acid production is given hereunder. Hydrochloric or muriatic acid is generally made by the action of sulphuric acid …

Manufacturing Chemicals ammonia sodium hydroxide and

Flow diagram for Manufacturing Process of Sulfuric acid by contact shown below clearly illustrates the main steps involved in the process. Figure 2: Flow diagram for Contact Process III. USES OF SULFURIC ACID: Sulfuric Acid has widely varied uses and plays some part in the production of nearly all manufactured goods.Some of the them are industries from fertilis …

PDF Sulfuric Acid Manufacture Analysis Control And

ISOPROPYL ALCOHOL MANUFACTURE BY THE STRONG-ACID PROCESS

Reduction of Waste in Semiconductor Manufacturing Plant

Sulfuric Acid ! This acid should be stored away from water and reducing agents. ! It is safely stored and transported in steel tanks and drums. Any iron that reacts with the acid forms an insoluble coating of iron sulfate on the steel which is is contact with the acid. The layer makes the steel impenetrable to further attack. Industrial Uses of Sulfuric Acid ! Manufacture of fertilisers such

PYRITE ROASTING AN ALTERNATIVE TO SULPHUR BURNING M

found on the web – avaliable in PDF, EPUB, MOBI the thief who · Handbook of Sulfuric Acid Manufacturing By Douglas K Louie. Dynamic process simulators are widely used

Design Considerations for Sulphuric Acid Plants

Preparation of Sulphuric Acid by Contact process Chemistry

Fuzzy logic based automation and control simulation of Sulfuric acid manufacturing process: A case http://www.iosrjen.org 20 P a g e

Sulfuric Acid Manufacture 2nd Edition

Sulfuric Acid Manufacturing Spartan Controls

process sulphuric acid catalyst. Efficient gas cleaning is required for metallurgical Efficient gas cleaning is required for metallurgical and contaminated acid decomposition gases, especially the former.

PRODUCTION OF NITRIC ACID Fertilizers Europe

The contact process is the main method used to produce sulfuric acid from elemental sulfur (or sulfur dioxide). There are four main steps. It is named after the contact which the sulfur dioxide and oxygen make with the catalyst.

Sulphuric acid- Contact process- industrial preparation of

Design Considerations for Sulphuric Acid Plants

Phosphorus Fertilizer Production and Technology

Pyrite roasting and sulphur burning plants are built for the production of sulphuric acid. Whereas the burning of elemental sulphur is the main source for sulphuric acid, the roasting process is an interesting alternative once pyrite concentrate is available.

Sulfuric Acid Manufacturing Process Scribd

53. PROFILE ON THE PRODUCTION OF HYDROCHLORIC ACID

Fuzzy logic based automation and control simulation of Sulfuric acid manufacturing process: A case http://www.iosrjen.org 20 P a g e

Manufacturing of nitric acid by Ostwald process Medium

Module 4 Lecture 17 NPTEL

The Manufacture Of Sulfuric Acid And Superphosphate

The SO 2 in the gas is made into sulfuric acid by (i) catalytically oxidizing it to SO 3 then (ii) reacting this SO 3 with the H 2 O(ℓ) component of strong sulfuric acid. Sulfuric acid is used for making fertilizer, leaching metal ores, refining petroleum, and manufacturing a myriad of products.

Design Considerations for Sulphuric Acid Plants

Sulfuric Acid PDF Free Download – edoc.site

Handbook of Sulphuric Acid Manufacturing Scribd

In manufacturing one tonne of sulfuric acid, one tonne of high pressure steam is also produced. (c) Conversion of sulfur dioxide to sulfur trioxide (The Contact Process) A typical plant contains one cylindrical vessel which acts as a fixed bed reactor with four separate beds of catalyst, known as a converter, heated to 700 K, through which the sulfur dioxide and air pass:

Manufacture Of Sulphuric Acid By Contact Process YouTube

Sulfuric Acid Manufacturing Favored book and website

Handbook of Sulphuric Acid Manufacturing Scribd

Pyrite roasting and sulphur burning plants are built for the production of sulphuric acid. Whereas the burning of elemental sulphur is the main source for sulphuric acid, the roasting process is an interesting alternative once pyrite concentrate is available.

Fuzzy logic based automation and control simulation of

process sulphuric acid catalyst. Efficient gas cleaning is required for metallurgical Efficient gas cleaning is required for metallurgical and contaminated acid decomposition gases, especially the former.

Sulfuric Acid Manufacturing Favored book and website

Sulfuric Acid Manufacturing Process Scribd

This report contains a detailed design proc edure of a plant to manufacture Sulfuric acid from Sulfur, as followed by Group 01 as per the allocations of CH 4202 (Comprehensive Design Project-09

ISOPROPYL ALCOHOL MANUFACTURE BY THE STRONG-ACID PROCESS

Manufacturing of nitric acid by Ostwald process Medium

Fuzzy logic based automation and control simulation of Sulfuric acid manufacturing process: A case http://www.iosrjen.org 20 P a g e

Sulphuric acid- Contact process- industrial preparation of

The Ostwald process has many well-known uses in both the industrial and health field. Through the Ostwald process, nitric acid is commonly used in fertilizers and pharmaceuticals, and because of

Manufacturing Chemicals ammonia sodium hydroxide and

Handbook of Sulphuric Acid Manufacturing Scribd

sulfuric acid manufacturing process, transportation options and storage practices, and safe handling, precautionary and emergency measures. For specific details on sulfuric acid production, characteristics and handling, please refer to appropriate scientific texts. * Please note all specifications and technical information are provided free of charge. This information is intended for guidance

Manufacturing of nitric acid by Ostwald process Medium

Comments are closed.