Toyota production system lean manufacturing pdf

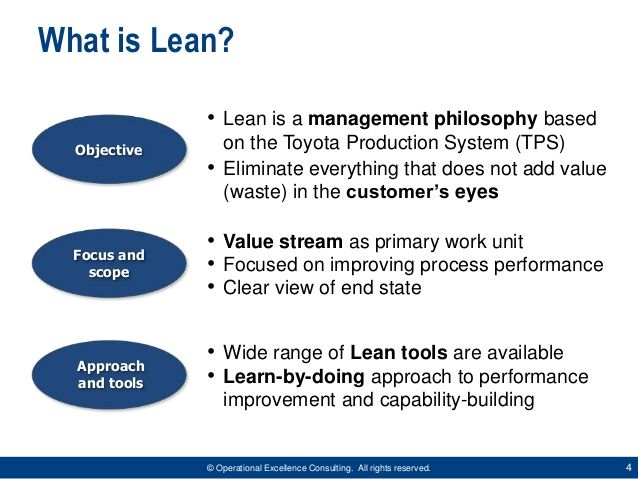

Lean Manufacturing Principles form the underpinning roadmap of Lean. No plan can be achieved without a roadmap: a plan of action, which supports clear guidelines and principles – and when incorporating lean, the same applies. Lean Manufacturing Principles are derived from the Toyota Production System (TPS) and follow five concepts. Understand value in the eyes…

Lean production is a standard manufacturing mode of the 21st century. Lean manufacturing have various synonyms like lean management, lean production, It is very use full techniques for reduce the flow of non value added time. Lean manufacturing is a philosophy to reduce the time between customer order and products are ready for the delivery by eliminating waste. Waste (muda) is a serious

Toyota Production System, Lean Manufacturing, Muda, Kaizen, Single Piece Flow, Mixed Product Cell, Multi Cell Production, Just in Time, Jidoka, Lean Tools, Mono -Pillar TPS Model 1.

Lean thinking is a proven system that applies to product development and production, as evidenced by Toyota and others. And although most often applied to products, it is

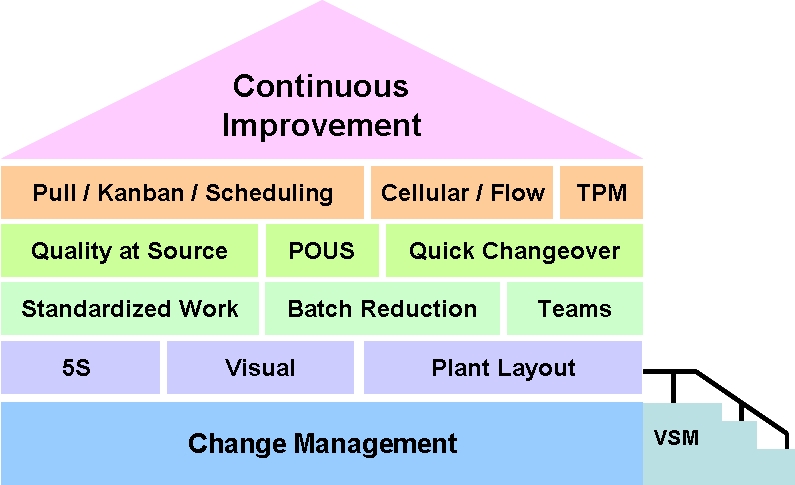

This is the version originally published in SME Lean Directions, 2002. A free download from TheLeanThinker.com The Toyota Production System is frequently modeled as a house with two pillars.

Rationalizing the Design of the Toyota Production System: A Comparison of Two Approaches J. Won 1, D. Cochran , H TPS and ‘lean’ manufacturing. In Decoding the DNA of the Toyota Production System, Spear and Bowen consider TPS as a model manufacturing system. The essence of TPS is described by four basic rules. These rules were developed based on extensive empirical …

manufacturing implementation in Malaysian automotive components manufacturer. Semi-structured interview and open-ended questionnaire were used to investigate on how to successfully implement lean manufacturing in Malaysia manufacturing industry. The interview was conducted at a case study company with two managerials who are familiar with lean manufacturing implementation projects. …

Lean manufacturing . or . lean production – the philosophy of continually reducing waste in all areas and in all forms; an English phrase coined to summarize Japanese manufacturing techniques (specifically, the Toyota Production System). • Line balancing – equalizing cycle times [productive capacity, assuming 100% capacity utilization] for relatively small units of the manufacturing

Is a manufacturing system in which production is based on production plan and where information flows from management to the market, the same direction in which the material flow.

The approach of lean was first initiated by Toyota, Lean production is orginated from Janpanes manufacturing method known as TPS – Toyota production system [2].

The Toyota Production System was at the beginning of such initiatives. It was successful in addressing cost through elimination of non‐value‐added time and quality by monitoring and controlling the produc‐ tions of defective parts. Lean thinking originated from the Toyota Production System and inherited its concepts and methodology. In contrast to the Toyota Production System, the

Keywords: Lean Management, Lean Manufacturing, Toyota Production System, Lean Leadership. JEL Classifi cation: M 11. INTRODUCTION One of the paramount objectives of a company is to generate the highest profi ts via gaining new mar-kets or taking over other companies (Bratnicki M., Krupski R., 2002, translation mine, ŁD). Th is practice known as the Strategy of Merging and …

Lean. Manufacturing BOUAMAMA ABDELLAH ECHBARBI SALIM SMALI HAMZA •Introduction •Definition •History •Toyota Production System Outline •Principles of Lean

Lean manufacturing began as the Toyota Production System in the Japanese auto industry of the 1970s and 1980s. It’s main goals were to eliminate waste, reduce the need for managing large inventories, and provide optimum quality at the least cost by making quality control decisions an immediate part of the manufacturing process.

Toyota invented “lean production” according to Jeffrey Liker, author of The Toyota Way. It’s also known as the Toyota Production System or TPS for short. And it seems to work well: Toyota’s profits in March 2003 were larger than GM, Ford, and Chrysler combined!

KEY PERFOMANCE INDICATORS (KPI) FOR THE

Lean Training Lean Consultants – Lean Manufacturing

variant of the production system used by Toyota was developed. It was named lean manufacturing. It was named lean manufacturing. Lean manufacturing is based on the same concepts as the Toyota Production System (TPS) and focuses a

manufacturing or Toyota Production System) were developed by the Japanese in the mid 50’s, and is nowadays worldwide used by companies. The term “lean thinking” encompasses a set of lean practices and was first proposed by Womack et al.(1992). From the advent of the lean concept to the present days, the popularity of lean thinking has spread exorbitantly. Earlier applications only

For 30 odd years, Toyota Production System or Just-In-Time were the names used for Ohno’s remarkably efficient manufacturing system. Then in 1990, three senior managers of MIT’s International Motor Vehicle Program (IMVP), Jim Womack, Dan Jones, and

The principles of the Toyota Production System (TPS), or Lean manufacturing, are well known in the auto manufacturing industry. Many companies, utilizing aspects of the TPS focus on creating

the development of the Toyota Production System (TPS). The building blocks of The building blocks of the TPS are introduced and the 5 Lean Principles are defined in some detail.

– 80% of manufacturing cost determined in design stage – Time available for PD is decreasingTime available for PD is decreasing – Complex-design products not easy to make lean in production stage

• TPS (Lean Manufacturing) transcends Green Manufacturing, that is, a lean transformation of a production facility will likely result in a green

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES: TOYOTA PRODUCTION SYSTEM LEAN PRINCIPLES Emirates Journal for Engineering Research, Vol. 22, No.2, 2017 3

Lean theory is easy, implementation isn’t – this is your chance to learn from the best of the best on how to implement Toyota Production System principles and lean …

14 Principles of Toyota Manufacturing Process – Lean Process Improvement Training in Sydney Posted on Thursday, May 2nd, 2013 at 8:43 am. When you attend any Lean Six Sigma courses, you’ll be exposed to the Toyota manufacturing process as a model to understand the Lean …

70 Khalil A. El-Namrouty et al.: Seven wastes elimination targeted by lean manufacturing case study “gaza strip manufacturing firms’’ reducing the production cost.

30/04/2013 · The evolution of production systems is tightly linked to the story of Toyota Motor Company (TMC) that has its roots around 1918. The term “lean” was coined in 1990 following the exploration of the Toyota model that led to the “transference” thesis sustaining the concept that manufacturing

43 CHAPTER 4 LEAN MANUFACTURING TOOLS AND TECHNIQUES 4.1 INTRODUCTION The purpose of this literature review is to provide a background on applicability of lean …

Disadvantages of Lean Manufacturing Bizfluent

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. PDF Autoparts Toyota . – Dexion Dexion Case Study – Toyota Autoparts The Japanese have a special word: ‘kaizen’ .

Applying lean production tools of the Toyota Production System (TPS) has helped Porsche to increase their operational result from -122 million € in 1994 to 933 million € in 2004. The goal was to Shed light on the concept of lean production Analyse tools and concepts that have to be applied in order to be-come a lean operating organisation and evaluate how and in which functions these tools

However, over the decades of its development, the Toyota Production System has become much more, serving as the basis of Lean manufacturing movement, and representing the third major step in the evolution of manufacturing (following craftsmanship and mass production).

Lean Manufacturing is the systematic elimination of waste by focusing on production costs, product quality, JIT delivery, and operator’s involvement. In the 1950s, Taiichi Ohno, developer of the Toyota “just-in-time” Production

1 1. Introduction: Toyota Motor orporations vehicle production system utilizes a way of ^making things _ that is referred to as a lean manufacturing system _ outside of Toyota.

thought of as a manufacturing system focused at the manufacturing part of the business. Thinking of TPS as a production system is similar to thinking of city streets as a transportation system. Yes, you drive on city streets but, to really get somewhere, you will take the freeway. TPS is a highly successful, integrated business system. Toyota uses the practice of Lean Six Sigma throughout

System seen in the US and Europe, with the Lean Production System, seen in Japan, within the automotive industry. Table 1 is a summary of some of the comparisons high-

Lean philosophies, which were initiated in Toyota Production System, are seen as this revolutionary change in the mindset, which manufacturers in the search of perfection are thirsty of, with its effects to the actions as well as to the visions.

9/04/2015 · TOYOTA Production System;Kanban Production This manufacturing concept which produces the right material at the right time at the right place and in …

‘Toyota Way’ (Liker, 2003) also found supporters and applications beyond the mass-production sector, such as low-volume manufacturing and service environments like healthcare, which are according to Hines et al. still in early stages of their lean evolution and under-researched (Hines et al., – cost sheet of a manufacturing company pdf of some of these manufacturing paradigms such as Toyota production system, lean principles, quick response man-ufacturing, agile manufacturing, mass customization and holonic manufacturing. We compare these various tech-niques vis-a-vis their specific objectives. 3.1 Toyota Production System Toyota Production System (TPS) was developed by Tai-ichi Ohno[13] in 1950s when Japanese …

Rules for smaller lot production designated for these materials and a kanban system has been put in place to ensure timely replenishment of critical materials. Lean Foundry Biggest Challenges: Culture: •Embrace the “old school” to lead the “new school”. •Bring in outside eyes for a fresh perspective. Expectations and goals and standards •Setting them/ measuring regularly on

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES TOYOTA

Lean Six Sigma and the Toyota Production System

Evaluation of Kitting Systems in Lean Production

(PDF) Analysis of the Toyota Production System and the

Lean Manufacturing Terms webpages.uidaho.edu

Lean manufacturing Lean Manufacturing Inventory

An of lean scheduling APEM journal

manufacturer identification symbols international guide –

LEAN MANUFACTURING TOOLS AND D-Scholarship@Pitt

Lean Six Sigma and the Toyota Production System

manufacturing implementation in Malaysian automotive components manufacturer. Semi-structured interview and open-ended questionnaire were used to investigate on how to successfully implement lean manufacturing in Malaysia manufacturing industry. The interview was conducted at a case study company with two managerials who are familiar with lean manufacturing implementation projects. …

Lean production is a standard manufacturing mode of the 21st century. Lean manufacturing have various synonyms like lean management, lean production, It is very use full techniques for reduce the flow of non value added time. Lean manufacturing is a philosophy to reduce the time between customer order and products are ready for the delivery by eliminating waste. Waste (muda) is a serious

For 30 odd years, Toyota Production System or Just-In-Time were the names used for Ohno’s remarkably efficient manufacturing system. Then in 1990, three senior managers of MIT’s International Motor Vehicle Program (IMVP), Jim Womack, Dan Jones, and

Lean thinking is a proven system that applies to product development and production, as evidenced by Toyota and others. And although most often applied to products, it is

1 1. Introduction: Toyota Motor orporations vehicle production system utilizes a way of ^making things _ that is referred to as a lean manufacturing system _ outside of Toyota.

29 replies on “Toyota production system lean manufacturing pdf”

Leave a Comment70 Khalil A. El-Namrouty et al.: Seven wastes elimination targeted by lean manufacturing case study “gaza strip manufacturing firms’’ reducing the production cost.

Disadvantages of Lean Manufacturing Bizfluent

LEAN MANUFACTURING TOOLS AND D-Scholarship@Pitt

Lean Manufacturing is the systematic elimination of waste by focusing on production costs, product quality, JIT delivery, and operator’s involvement. In the 1950s, Taiichi Ohno, developer of the Toyota “just-in-time” Production

Lean Training Lean Consultants – Lean Manufacturing

Productivity Improvement by Implementing Lean Production

The approach of lean was first initiated by Toyota, Lean production is orginated from Janpanes manufacturing method known as TPS – Toyota production system [2].

A case study of lean sustainable manufacturing

Evaluation of Kitting Systems in Lean Production

System seen in the US and Europe, with the Lean Production System, seen in Japan, within the automotive industry. Table 1 is a summary of some of the comparisons high-

An of lean scheduling APEM journal

Lean Manufacturing Terms webpages.uidaho.edu

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. PDF Autoparts Toyota . – Dexion Dexion Case Study – Toyota Autoparts The Japanese have a special word: ‘kaizen’ .

Lean Manufacturing Terms webpages.uidaho.edu

Lean manufacturing . or . lean production – the philosophy of continually reducing waste in all areas and in all forms; an English phrase coined to summarize Japanese manufacturing techniques (specifically, the Toyota Production System). • Line balancing – equalizing cycle times [productive capacity, assuming 100% capacity utilization] for relatively small units of the manufacturing

A case study of lean sustainable manufacturing

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES TOYOTA

Implementation of Lean Manufacturing Strategies at Your

manufacturing or Toyota Production System) were developed by the Japanese in the mid 50’s, and is nowadays worldwide used by companies. The term “lean thinking” encompasses a set of lean practices and was first proposed by Womack et al.(1992). From the advent of the lean concept to the present days, the popularity of lean thinking has spread exorbitantly. Earlier applications only

Lean Manufacturing Implementation in Malaysian Automotive

70 Khalil A. El-Namrouty et al.: Seven wastes elimination targeted by lean manufacturing case study “gaza strip manufacturing firms’’ reducing the production cost.

An of lean scheduling APEM journal

Lean manufacturing Lean Manufacturing Inventory

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES TOYOTA

thought of as a manufacturing system focused at the manufacturing part of the business. Thinking of TPS as a production system is similar to thinking of city streets as a transportation system. Yes, you drive on city streets but, to really get somewhere, you will take the freeway. TPS is a highly successful, integrated business system. Toyota uses the practice of Lean Six Sigma throughout

Improving a plant’s operations by applying lean

Implementation of Lean Manufacturing Strategies at Your

Lean Manufacturing Terms webpages.uidaho.edu

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. PDF Autoparts Toyota . – Dexion Dexion Case Study – Toyota Autoparts The Japanese have a special word: ‘kaizen’ .

Lean Training Lean Consultants – Lean Manufacturing

Lean Manufacturing Terms webpages.uidaho.edu

Keywords: Lean Management, Lean Manufacturing, Toyota Production System, Lean Leadership. JEL Classifi cation: M 11. INTRODUCTION One of the paramount objectives of a company is to generate the highest profi ts via gaining new mar-kets or taking over other companies (Bratnicki M., Krupski R., 2002, translation mine, ŁD). Th is practice known as the Strategy of Merging and …

Lean Training Lean Consultants – Lean Manufacturing

Lean Six Sigma and the Toyota Production System

Lean philosophies, which were initiated in Toyota Production System, are seen as this revolutionary change in the mindset, which manufacturers in the search of perfection are thirsty of, with its effects to the actions as well as to the visions.

Lean Manufacturing Implementation in Malaysian Automotive

Productivity Improvement by Implementing Lean Production

Evaluation of Kitting Systems in Lean Production

Lean manufacturing . or . lean production – the philosophy of continually reducing waste in all areas and in all forms; an English phrase coined to summarize Japanese manufacturing techniques (specifically, the Toyota Production System). • Line balancing – equalizing cycle times [productive capacity, assuming 100% capacity utilization] for relatively small units of the manufacturing

Implementation of Lean Manufacturing Strategies at Your

Evaluation of Kitting Systems in Lean Production

The approach of lean was first initiated by Toyota, Lean production is orginated from Janpanes manufacturing method known as TPS – Toyota production system [2].

Lean Training Lean Consultants – Lean Manufacturing

Disadvantages of Lean Manufacturing Bizfluent

The approach of lean was first initiated by Toyota, Lean production is orginated from Janpanes manufacturing method known as TPS – Toyota production system [2].

Kaizen Case Study Toyota watchcollector.com.au

Evaluation of Kitting Systems in Lean Production

A case study of lean sustainable manufacturing

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. PDF Autoparts Toyota . – Dexion Dexion Case Study – Toyota Autoparts The Japanese have a special word: ‘kaizen’ .

Lean Six Sigma and the Toyota Production System

– 80% of manufacturing cost determined in design stage – Time available for PD is decreasingTime available for PD is decreasing – Complex-design products not easy to make lean in production stage

An of lean scheduling APEM journal

Productivity Improvement by Implementing Lean Production

Is a manufacturing system in which production is based on production plan and where information flows from management to the market, the same direction in which the material flow.

KEY PERFOMANCE INDICATORS (KPI) FOR THE

However, over the decades of its development, the Toyota Production System has become much more, serving as the basis of Lean manufacturing movement, and representing the third major step in the evolution of manufacturing (following craftsmanship and mass production).

Disadvantages of Lean Manufacturing Bizfluent

However, over the decades of its development, the Toyota Production System has become much more, serving as the basis of Lean manufacturing movement, and representing the third major step in the evolution of manufacturing (following craftsmanship and mass production).

Disadvantages of Lean Manufacturing Bizfluent

Kaizen Case Study Toyota watchcollector.com.au

A case study of lean sustainable manufacturing

Applying lean production tools of the Toyota Production System (TPS) has helped Porsche to increase their operational result from -122 million € in 1994 to 933 million € in 2004. The goal was to Shed light on the concept of lean production Analyse tools and concepts that have to be applied in order to be-come a lean operating organisation and evaluate how and in which functions these tools

LEAN MANUFACTURING TOOLS AND D-Scholarship@Pitt

Evaluation of Kitting Systems in Lean Production

Lean production is a standard manufacturing mode of the 21st century. Lean manufacturing have various synonyms like lean management, lean production, It is very use full techniques for reduce the flow of non value added time. Lean manufacturing is a philosophy to reduce the time between customer order and products are ready for the delivery by eliminating waste. Waste (muda) is a serious

Lean manufacturing Lean Manufacturing Inventory

Lean Manufacturing Terms webpages.uidaho.edu

Keywords: Lean Management, Lean Manufacturing, Toyota Production System, Lean Leadership. JEL Classifi cation: M 11. INTRODUCTION One of the paramount objectives of a company is to generate the highest profi ts via gaining new mar-kets or taking over other companies (Bratnicki M., Krupski R., 2002, translation mine, ŁD). Th is practice known as the Strategy of Merging and …

Lean manufacturing Lean Manufacturing Inventory

A case study of lean sustainable manufacturing

Lean thinking is a proven system that applies to product development and production, as evidenced by Toyota and others. And although most often applied to products, it is

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES TOYOTA

Disadvantages of Lean Manufacturing Bizfluent

Rationalizing the Design of the Toyota Production System: A Comparison of Two Approaches J. Won 1, D. Cochran , H TPS and ‘lean’ manufacturing. In Decoding the DNA of the Toyota Production System, Spear and Bowen consider TPS as a model manufacturing system. The essence of TPS is described by four basic rules. These rules were developed based on extensive empirical …

Kaizen Case Study Toyota watchcollector.com.au

Lean Six Sigma and the Toyota Production System

Lean manufacturing Lean Manufacturing Inventory

70 Khalil A. El-Namrouty et al.: Seven wastes elimination targeted by lean manufacturing case study “gaza strip manufacturing firms’’ reducing the production cost.

Disadvantages of Lean Manufacturing Bizfluent

(PDF) Analysis of the Toyota Production System and the

Lean Manufacturing Terms webpages.uidaho.edu

Lean manufacturing . or . lean production – the philosophy of continually reducing waste in all areas and in all forms; an English phrase coined to summarize Japanese manufacturing techniques (specifically, the Toyota Production System). • Line balancing – equalizing cycle times [productive capacity, assuming 100% capacity utilization] for relatively small units of the manufacturing

A COMPREHENSIVE REVIEW OF MANUFACTURING WASTES TOYOTA

Lean Manufacturing Terms webpages.uidaho.edu

Kaizen Case Study Toyota watchcollector.com.au

Lean philosophies, which were initiated in Toyota Production System, are seen as this revolutionary change in the mindset, which manufacturers in the search of perfection are thirsty of, with its effects to the actions as well as to the visions.

Lean Training Lean Consultants – Lean Manufacturing

KEY PERFOMANCE INDICATORS (KPI) FOR THE

An of lean scheduling APEM journal

However, over the decades of its development, the Toyota Production System has become much more, serving as the basis of Lean manufacturing movement, and representing the third major step in the evolution of manufacturing (following craftsmanship and mass production).

Improving a plant’s operations by applying lean

Lean Six Sigma and the Toyota Production System

Kaizen Case Study Toyota watchcollector.com.au

Comments are closed.