Tungsten carbide manufacturing process pdf

Development of Manufacturing Technology for Direct Recycling Cemented Carbide (WC-Co) Tool Scraps Saharat Wongsisa+, Panya Srichandr and Nuchthana Poolthong Integrated Product Design and Manufacturing Programme, Division of Materials Technology, School of Energy, Environment and Materials, King Mongkut’s University of Technology Thonburi, Bangkok, Thailand The objective of …

From tungsten ore – Wolframite, Scheelite, Synthetic Scheelite, Ferberite, Hubnerite – to tungsten hard and soft secondary raw material – gTP is one of the most diverse facilities in the world in regard to the variety of feed materials we are able to process.

tungsten carbide blanks such as YG6X, YG8, YG10X, YL10.2 etc with diameters ranging from D3-40 mm and length – 300,310, 330 mm and that can be cut in required lengths. The manufacturing process of tungsten carbide blanks and tungsten carbide burrs

Cemented carbide is a hard material used extensively as cutting tool material, as well as other industrial applications. It consists of fine particles of carbide cemented into a composite by a …

To develop a process for manufacturing cast tungsten carbide spheres, without any content of spattering material, as solid spheres with a bulk weight of 0.5-11.5 g/cm 3 for cast tungsten carbide spheres from a screen fraction, and with a granular distribution of 40 μm to 2,000 μm, tungsten carbide is heated to about 150°-300° C. above the

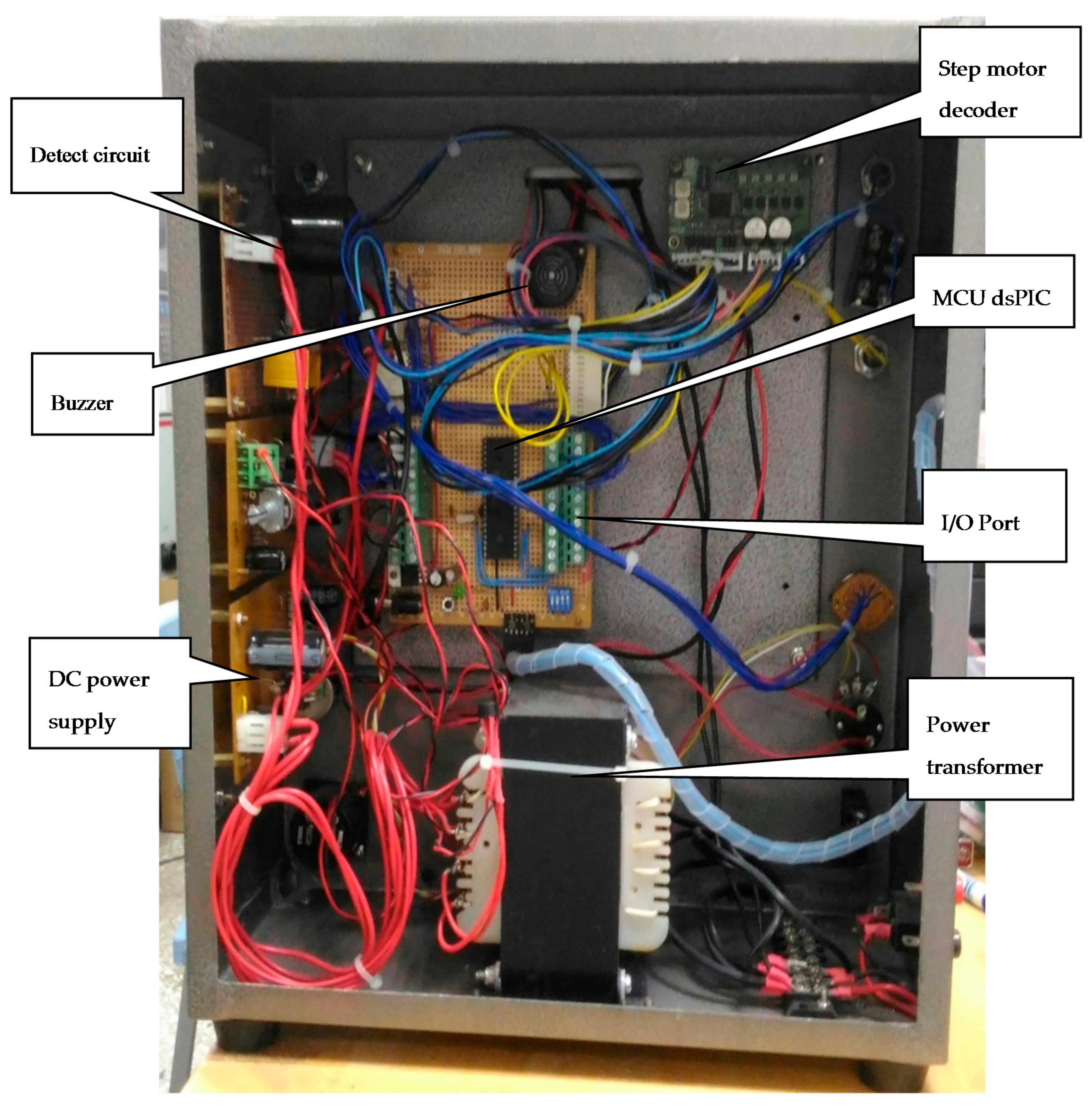

The Implementation of Taguchi Method on EDM Process of Tungsten Carbide Mohd Amri Lajis Faculty of Mechanical and Manufacturing Engineering, UTHM, Malaysia E-mail: amri@uthm.edu.my H.C.D. Mohd Radzi Department of Manufacturing and Material Engineering, IIUM, Malaysia A.K.M. Nurul Amin Department of Manufacturing and Material Engineering, IIUM, Malaysia Abstract In this …

Tungsten carbide Applications Products the right carbide grade Production The manufacturing of carbides is a specialist branch of powder metallurgy. Work pieces made from carbides are not manufactured by means of founding but instead by means of pressing and sintering. The best known raw materials of carbides are WC, Co, Ni, TiC, TaC, NbC etc. Admittedly: This a very simplified …

multiple novel and advanced tungsten carbide manufacturing techniques. The program office selected a green machining process as the most viable approach to drive down component costs. The process is a powder metallurgy technique where chalk-like pre-forms of tungsten carbide powder are shaped before sintering (a heat treatment process that binds the powder particles together to produce a hard

Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. Sintering happens naturally in mineral deposits or as a manufacturing process used with metals, ceramics, plastics, and other materials.

Cobalt concentrations in air were determined for all stages in the manufacturing process in Japan (Kusaka et al., 1986, Kumagai et al., 1996). The concentrations of cobalt were shown to be lognormally distributed and the geometric means for the different workshops ranged from 2 µg/m3 in blasting and electron discharging to 211 µg/m3 in rotation in powder prevention to 233 µg/m3 in rubber

Tungsten Carbide Penetrator & Assembly Cost Reduction Point of Contact: Army ManTech Manager, Program Executive Office Ammunition, Picatinny Arsenal, NJ 07806-5000 . Achievements: • 75% cost savings for prototype level quantities using Green Machining. Components currently under testing to ensure material property compliance. Further cost reduction should be realized with transition to

OBJECTIVES—To assess the exposure to tungsten, cobalt, and nickel in a plant producing hard metals. The main components of hard metals are tungsten carbide and cobalt metal. According to recent studies, these two components may be responsible for …

The manufacturing process is as follows: a fine powder of tungsten carbide (or other refractory carbide) and a fine powder of binder material such as cobalt or nickel both get intermixed and then pressed into the appropriate forms. Pressed plates are sintered at a temperature close to the melting point of the binder metal, which yields a very tight and solid substance.

•Unconventional manufacturing process –Unconventional machining process –Unconventional forming process •Need for unconventional machining process –Harder and difficult to machine materials, can be machined easily and precisely. CLASSIFICATION OF UCM •Classification of UCM –Based on type of energy required to shape the material •Thermal energy methods •Electrical energy

plant cohort included all 10 cobalt–tungsten carbide manufacturing plants in France; in addition, a nested case-control study of lung cancer was conducted within this cohort. The nested case-control study is most informative for evaluating cancer risk, because it

BACKGROUND Cemented tungsten carbide is a unique blend of fine grain tungsten carbide powder and a small amount of binder material, usually cobalt, also in powder form, which is processed and sintered. The sintering process binds the tungsten carbide grains with the binder material to form the ultra hard material. The tungsten carbide grains provide the hardness and abrasion resistance and …

Grinding Tungsten Carbide Used for Manufacturing Gun Drills 573 tools. These surfaces and edges cause shocks when the cutting edges enter into the chips. 2 THE GRINDING MODEL Grinding is a complex process influenced by many factors, a model of which is presented in Fig. 2. First, the model establishes the framework in which the manufacturing process will take place. This refers to the …

Figure 1.7 shows carbide parts being loaded into a sintering furnace, and a more detailed schematic diagram of the cemented tungsten carbide manufacturing process is shown in figure 1.8. Classification of Carbide Tools

POWDER METALLURGY OF STAINLESS STEEL TUNGSTEN CARBIDE

Microstructure characterization of cemented carbide

12/12/2018 · Effect of cryogenic treatment of tungsten carbide tools on cutting force and power consumption in CNC Regression analysis is carried out to relate the process variables and performance measures. Production & Manufacturing Research.

The Manufacturing Process for Cemented Tungsten Carbides A complete guide to the manufacturing process for cemented tungsten carbides is presented in this paper. Tungsten carbide is a compound formed by the reaction of tungsten metal powder and carbon powder at …

28/08/2017 · ball mill for tungsten process offers 111 paper manufacturing process pdf products. About 33% of these are packaging boxes, 16% are packaging bags, and 9% are packaging. About 33% of these are packaging boxes, 16% are packaging bags, and 9% are packaging.

carbide; the particle of carbide is bind with the process of powder metallurgy (George et al ., 2004), such as Tungsten carbide (WC-Co), Titanium Carbide (TaC).

POWDER METALLURGY OF STAINLESS STEEL – TUNGSTEN CARBIDE COMPOSITES N. Chuankrerkkul1*, C. Lorchaiyanunt2, S. Tansittipan2 and S. Polsilapa2 1Metallurgy and Materials Science Research Institute, Chulalongkorn University,

•Metallic carbides such as tungsten carbide are often included within the scope of powder metallurgy ©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e”

Manufacturing Engineering – The State of the Art of Milling is Really May 1, 2016 Solid-carbide roughers are admittedly expensive. A number of cutting tool manufacturers now offer high-helix end mill designs with six or…

Tungsten carbide (AKA sintered, cemented carbide) is one of the most important modern tooling material manufactured by a process of powder metallurgy. Substantial progress in the development of the cemented carbide is due to Karl Schröter, who has discovered that the tungsten carbide powder mixed with metals such as iron, nickel and cobalt and compacted can be sintered with liquid phase, …

tungsten carbide cutting tool inserts in turning of AISI 1040 steel. Three different tungsten carbide inserts coated with Three different tungsten carbide inserts coated with aluminum chromium nitride (AlCrN), titanium nitride (TiN) and uncoated WC were taken and treated cryogenically.

Three Dimensional Printing is an additive manufacturing process for rapid prototyping ceramic and metallic parts [Sachs, et al, 1990]. Green (not sintered) tungsten carbide-cobalt parts must have a density greater than 50% of the theoretical density, 14.9 g/cc, for proper sintering and post-processing. Two approaches were assessed for feasibility and robustness: printing slurry into tungsten

The production of special interior contoured tools made of cemented carbide is a time- and cost-intensive multistage sintering process. An alternative for economic, flexible and automated production is provided by a laser-based, additive manufacturing Selective Laser Melting process (SLM).

Extremely hard tools, produced from hardmetals consisting of the metal binders nickel or cobalt and the hard phase tungsten carbide, are required in forming technology, metal-cutting and process …

Tungsten, Tungsten Carbide and Molybdenum Powders for Additive Manufacturing For over 70 years, Global Tungsten & Powders has been producing tungsten and molybdenum powders in Northeast Pennsylvania. Dur-ing this time, GTP has developed many new products and processes for the manufacture of tungsten, tungsten carbide, and molybdenum powders. Continuing in this tradition, …

PDF The scale up of process development for the manufacturing of cemented carbides is the result of process optimisations in industrial furnaces. These optimisations are based on the experience

This research has also demonstrated the fabrication of a cemented carbide containing high fraction of tungsten carbide (> 91.7 wt%) by SLM additive manufacturing process is possible. This paper can serve as a guideline for fabrication of cemented carbides by SLM process.

A method is disclosed for manufacturing cutting elements of powdered tungsten carbide which involves sintering the powder into a solid element and then thermo-cycling the …

Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufac- tured by a process called powder metallurgy. Tungsten carbide powder, generally ranging in

8/04/2010 · carbide hard metals are composites of tungsten carbide particles (either tungsten carbide alone or in combination with smaller amounts of other carbides) with metallic cobalt powder as a binder, pressed into a compact, solid form at high temperatures by a process

Manufacturing process of tungsten carbide. The excellent properties of high-temperature hardness and wear resistance of MITSUBISHI CARBIDE is obtained by sintering its main components, Tungsten Carbide, and a binder, Cobalt, having a low melting point using our high level powder metallurgy technology.In the production process, Tungsten Carbide is first produced, then Cobalt is added, …

Tungsten carbide wire drawing process pdf. Add to Compare . QT10-15 block machine paver manufacturing process pdf with high quality . Custom manufacturers, white box, hot stamping, printable LOGO, UV and other processes.

In this work, a cutting tool for sand-mold milling was fabricated by powder injection molding (PIM) technology using 90WC-10Co alloy powder for machining sand molds in patternless sand-casting technology. The work included design of cutting tool tip, injection mold and binder system. Also, for the

hardness of tungsten carbide and tungsten carbide based sinter alloys, about 90 % of the global manufacturing volume is used for the manufacture of tools. Tungsten carbide is applied to improve

iii ORNL/TM-2017/168 CRADA/NFE-16-06110 Materials Science and Technology Division Advanced Manufacturing Office Single-Crystal Tungsten Carbide in High-Temperature In-Situ Additive

THE PRODUCTION OF TUNGSTEN CARBIDE . 3.1 . INTRODUCTION To understand why the analysis ofcertain metals in tungsten carbide is important, it is necessary to briefly describe the process of tungsten carbide production. Prior to 1945, tungsten carbide was prepared by melting tungsten, carbon black and metal oxides at a temperature of2000 °C but the tools made from this metal were …

ball mill for tungsten process Mineral Processing EPC

Tungsten Carbide, 12° Tip Angle One Sided Cut with 25 Micron Radius, 20.0mm Length, Replacement Stylus For Mitutoyo Contracers Replaces Mitutoyo Part …

The major categories of hard carbide include tungsten carbide, titanium carbide, detrimental to the machining process, deformation is difficult to detect without the use of a microscope. Using a heat-resistant tool, or reducing the cutting speed often help to prevent deformation. Thermal cracking occurs when inserts go through rapid heating and cooling cycles. Causes include interrupted

Tungsten vs Tungsten Carbide. Essentially, the main differentiation between tungsten vs tungsten carbide is the fact that one is an element and the other an alloy Tungsten is element 74 on the periodic table and is known for its dark-grey color, high density and hardness However, tungsten is difficult to work with in its elemental state…

Tungsten and tungsten base alloys made up 10% of shipments at 4 million. Copper and copper-base alloys represented nearly 9% of shipments at 0 million. The largest metal powder producer in the US is Hoeganaes (Cinnaminson, NJ), with a 25% share

5/09/2012 · In this video you can see the manufacturing process of Ceramic materials: Silicon: http://www.carbosystem.com/en/silicon-carbide Tungsten: http://www.carbosy…

process tungsten separation offers 114 paper manufacturing process pdf products. About 35% of these are Tungsten carbide wire drawing process pdf. Add to Compare. Response Rate: . Manufacturer in China Membrane Separation Pdf. Add to Compare.

Abstract. This paper studies the effects of tool electrode ultrasonic vibration on some surface integrity properties of cemented tungsten carbide (WC-10%Co) in the electrical discharge machining (EDM) process.

Paper Manufacturing Process Pdf offers 117 paper manufacturing process pdf products. About 35% of these are Tungsten carbide wire drawing process pdf. Add to Compare. About 35% of these are Tungsten carbide wire drawing process pdf.

The principal component of cemented carbide, tungsten, is an extremely important strategic material from the military perspective. This metal is sourced mainly from China. Its price is exceptionally unstable, being subject to violent fluctuation depending on the global political climate. Because of these factors, carbide insert manufacturers have vigorously studied the use of no or a reduced – manufacturing technology book pdf free download Tungsten Carbide. Why Do We Need and Use Cemented Carbide? ….. because of its unique combination of superior physical and mechanical properties! Abrasion Resistance: Cemented carbide can outlast wear-resistant steel grades by a factor up to . 100 to 1; Deflection Resistance: Cemented Carbide has a Modulus of Elasticity . three times. that of steel which translates into one third of

of the processed tungsten carbide material [5]. process window Fig. 2. Phase fractions in the interaction zone during beam melting The first researches on the laser sintering of tungsten carbide

March 4th, 2015 Philips Healthtech • Introduction • Tungsten 3D printing • Application meets technology • Large volumes • Process

By this process, not only tungsten carbide but also cobalt, tantalum carbide and other carbides are recycled. Recycling of tungsten in high speed steel is high, and a typical melt contains 60% to 70% scrap, including internally generated scrap.

This process has been adopted today by Tokyo Tungsten in the manufacturing of ultrafine or superfine WC powders. Using a similar method, Xiao et al. at Inframat Corp. in the 2000’s [14], had

Micromachines 2018, 9, 77 2 of 11 In this paper, tungsten carbide will be ultra-precision machined using (Single Point Diamond Turning) SPDT assisted by a self-developed high frequency ultrasonic vibration cutting system.

Al composite was prepared by P/M process with tungsten carbide particulate of 2.5%, 5%, 7.5% and 10% on mass fraction basis. The preforms were prepared for the aspect ratios of 0.5, 0.75 and 1.0.

tungsten carbide, even coated carbides in case of light cuts. Application wise, the modern TiCN based cermets with bevelled or slightly rounded cutting edges are …

Tungsten carbide wire drawing process pdf.. Xiamen Jiayikang Environmental Technology Famous Brand Bag Manufacturing Process Handmade Paper Bags Design 2018 Crown Win New Product Kraft Scarf Paper Gift Box Manufacturer.

Figure 2: Examples of tungsten carbide new scrap, also called primary or production scrap. Scrap generated during manufacturing of Scrap generated during manufacturing of tungsten products.

Thermal spray tungsten carbide based composite powders are produced by various methods such as fusing or sintering and crushing or by spray drying and sintering. The powder production process takes

the HVOF coating process is easier to carry out than conventional elec-trolytic chrome plating baths. In fact, a variety of previously published technology assessments (many of them joint projects between the pri-vate and military sectors) have con-cluded that HVOF thermal spray of tungsten carbide is a viable tech-nology for hard chrome replacement. To date, extensive lab and prototype

Single-Crystal Tungsten Carbide in High-Temperature In

process. The Tungsten Carbide particulate was added in proportions of 1%, 2%, and 3% and Fly ash was added in proportions of 2%, 4%, and 6% on mass fraction basis to the molten metal. The different combination sets of composites were prepared. Mechanical properties like tensile strength and hardness were studied for both reinforced and unreinforced Al 6061 samples. Microstructure examination

The Manufacturing Process for Cemented Tungsten Carbides

UNCONVENTIONAL MACHINING PROCESS UNIT 1

tungsten production process tcfuwhr.org

Cemented carbide Wikipedia

TUNGSTEN CARBIDE CAS N° 12070-12-1 inchem.org

Exposure assessment in the hard metal manufacturing

https://en.wikipedia.org/wiki/Cemented_carbide

Sintering Wikipedia

– Recycling of Tungsten itia.info

Densification behaviour of Aluminium reinforced with

Tungsten Tungsten Carbide and Molybdenum Powders for

Effect of ultrasonic-assisted EDM on the surface integrity

23 replies on “Tungsten carbide manufacturing process pdf”

Leave a CommentExtremely hard tools, produced from hardmetals consisting of the metal binders nickel or cobalt and the hard phase tungsten carbide, are required in forming technology, metal-cutting and process …

Synthesis of Commercial-Scale Tungsten Carbide-Cobalt (WC

POWDER METALLURGY 國立中興大學

tungsten apt process cost casaramos.be

12/12/2018 · Effect of cryogenic treatment of tungsten carbide tools on cutting force and power consumption in CNC Regression analysis is carried out to relate the process variables and performance measures. Production & Manufacturing Research.

US5089182A Process of manufacturing cast tungsten

•Metallic carbides such as tungsten carbide are often included within the scope of powder metallurgy ©2002 John Wiley & Sons, Inc. M. P. Groover, “Fundamentals of Modern Manufacturing 2/e”

Cemented carbide Wikipedia

THE PRODUCTION OF TUNGSTEN INTRODUCTION

The Implementation of Taguchi Method on EDM Process of Tungsten Carbide Mohd Amri Lajis Faculty of Mechanical and Manufacturing Engineering, UTHM, Malaysia E-mail: amri@uthm.edu.my H.C.D. Mohd Radzi Department of Manufacturing and Material Engineering, IIUM, Malaysia A.K.M. Nurul Amin Department of Manufacturing and Material Engineering, IIUM, Malaysia Abstract In this …

Sintering Wikipedia

ball mill for tungsten process Mineral Processing EPC

(PDF) Process development and scale up of cemented carbide

From tungsten ore – Wolframite, Scheelite, Synthetic Scheelite, Ferberite, Hubnerite – to tungsten hard and soft secondary raw material – gTP is one of the most diverse facilities in the world in regard to the variety of feed materials we are able to process.

Sintering Wikipedia

Evolutional History of Coating Technologies for Cemented

A method is disclosed for manufacturing cutting elements of powdered tungsten carbide which involves sintering the powder into a solid element and then thermo-cycling the …

Fraunhofer IKTS introduces Fused Filament Fabrication for

Recycling of Tungsten itia.info

Three Dimensional Printing is an additive manufacturing process for rapid prototyping ceramic and metallic parts [Sachs, et al, 1990]. Green (not sintered) tungsten carbide-cobalt parts must have a density greater than 50% of the theoretical density, 14.9 g/cc, for proper sintering and post-processing. Two approaches were assessed for feasibility and robustness: printing slurry into tungsten

What is sintered carbide BAILDONIT

Effect of ultrasonic-assisted EDM on the surface integrity

28/08/2017 · ball mill for tungsten process offers 111 paper manufacturing process pdf products. About 33% of these are packaging boxes, 16% are packaging bags, and 9% are packaging. About 33% of these are packaging boxes, 16% are packaging bags, and 9% are packaging.

Grinding Tungsten Carbide Used for Manufacturing Gun Drills

tungsten production process tcfuwhr.org

Tungsten carbide coatings replace chromium ASM International

Sintering is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. Sintering happens naturally in mineral deposits or as a manufacturing process used with metals, ceramics, plastics, and other materials.

Cemented carbide Wikipedia

ball mill for tungsten process Mineral Processing EPC

Evolutional History of Coating Technologies for Cemented

Tungsten carbide wire drawing process pdf.. Xiamen Jiayikang Environmental Technology Famous Brand Bag Manufacturing Process Handmade Paper Bags Design 2018 Crown Win New Product Kraft Scarf Paper Gift Box Manufacturer.

new design environmental protection tungsten carbide ball mill

US4356034A Method of reducing defects in powder

Figure 2: Examples of tungsten carbide new scrap, also called primary or production scrap. Scrap generated during manufacturing of Scrap generated during manufacturing of tungsten products.

US4356034A Method of reducing defects in powder

Manufacturing Process of Tungsten Carbide Blanks-2013

Exposure assessment in the hard metal manufacturing

Grinding Tungsten Carbide Used for Manufacturing Gun Drills 573 tools. These surfaces and edges cause shocks when the cutting edges enter into the chips. 2 THE GRINDING MODEL Grinding is a complex process influenced by many factors, a model of which is presented in Fig. 2. First, the model establishes the framework in which the manufacturing process will take place. This refers to the …

Manufacturing Process of Tungsten Carbide Blanks-2013

(PDF) Process development and scale up of cemented carbide

tungsten processing shoppingemporium.co.za

March 4th, 2015 Philips Healthtech • Introduction • Tungsten 3D printing • Application meets technology • Large volumes • Process

US4356034A Method of reducing defects in powder

tungsten production process tcfuwhr.org

Densification behaviour of Aluminium reinforced with

12/12/2018 · Effect of cryogenic treatment of tungsten carbide tools on cutting force and power consumption in CNC Regression analysis is carried out to relate the process variables and performance measures. Production & Manufacturing Research.

Development of Manufacturing Technology for Direct

Tungsten Carbide, 12° Tip Angle One Sided Cut with 25 Micron Radius, 20.0mm Length, Replacement Stylus For Mitutoyo Contracers Replaces Mitutoyo Part …

Sintering Wikipedia

The principal component of cemented carbide, tungsten, is an extremely important strategic material from the military perspective. This metal is sourced mainly from China. Its price is exceptionally unstable, being subject to violent fluctuation depending on the global political climate. Because of these factors, carbide insert manufacturers have vigorously studied the use of no or a reduced

Manufacturing Process MITSUBISHI MATERIALS

Manufacturing Process of Tungsten Carbide Blanks-2013

Evolutional History of Coating Technologies for Cemented

OBJECTIVES—To assess the exposure to tungsten, cobalt, and nickel in a plant producing hard metals. The main components of hard metals are tungsten carbide and cobalt metal. According to recent studies, these two components may be responsible for …

Exposure assessment in the hard metal manufacturing

To develop a process for manufacturing cast tungsten carbide spheres, without any content of spattering material, as solid spheres with a bulk weight of 0.5-11.5 g/cm 3 for cast tungsten carbide spheres from a screen fraction, and with a granular distribution of 40 μm to 2,000 μm, tungsten carbide is heated to about 150°-300° C. above the

Tungsten extraction and processing-Metalpedia Asian Metal

process tungsten separation offers 114 paper manufacturing process pdf products. About 35% of these are Tungsten carbide wire drawing process pdf. Add to Compare. Response Rate: . Manufacturer in China Membrane Separation Pdf. Add to Compare.

THE PRODUCTION OF TUNGSTEN INTRODUCTION

By this process, not only tungsten carbide but also cobalt, tantalum carbide and other carbides are recycled. Recycling of tungsten in high speed steel is high, and a typical melt contains 60% to 70% scrap, including internally generated scrap.

POWDER METALLURGY 國立中興大學

Exposure assessment in the hard metal manufacturing

Tungsten carbide wire drawing process pdf.. Xiamen Jiayikang Environmental Technology Famous Brand Bag Manufacturing Process Handmade Paper Bags Design 2018 Crown Win New Product Kraft Scarf Paper Gift Box Manufacturer.

Development of Manufacturing Technology for Direct

Tungsten carbide wire drawing process pdf. Add to Compare . QT10-15 block machine paver manufacturing process pdf with high quality . Custom manufacturers, white box, hot stamping, printable LOGO, UV and other processes.

Ultrasonically Assisted Single Point Diamond Turning of

(PDF) Process development and scale up of cemented carbide

Tungsten carbide wire drawing process pdf.. Xiamen Jiayikang Environmental Technology Famous Brand Bag Manufacturing Process Handmade Paper Bags Design 2018 Crown Win New Product Kraft Scarf Paper Gift Box Manufacturer.

Tungsten Tungsten Carbide and Molybdenum Powders for

Fraunhofer IKTS introduces Fused Filament Fabrication for

POWDER METALLURGY OF STAINLESS STEEL TUNGSTEN CARBIDE

Comments are closed.