Woven fabric manufacturing process pdf

Nonwoven Filter Media – A Look Back, Trends and Future Market Needs Clint Scoble Principal Filtration Consultant Filter Media Services, LLC, Cincinnati, OH Nonwovens in filtration probably sounds to the layman like an obscure, niche, boring topic. To those of us in the inside, either in the filter media area or in applying filter media to processes, products and filtration equipment, it is a

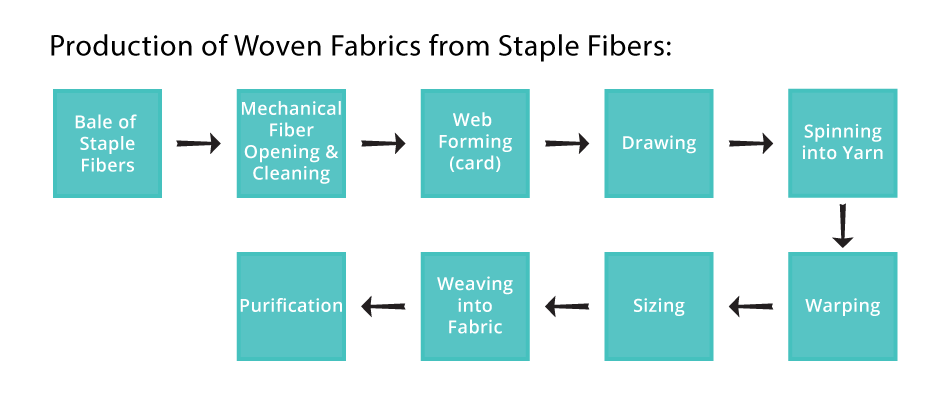

This is the basic and primary flowchart of textile manufacturing. In this article I will give flow chart of all branches of textile engineering like as spinning, weaving, dyeing, printing, finishing and garment manufacturing.

Nonwoven Report – Project Costing and Profitability Report for Spunbond Nonwoven Fabric Manufacturing in India. Nonwoven Project Report includes report on Spunbond Nonwoven Fabric, Meltblown Nonwoven fabric, SMS & Composite nonwoven fabric manufacturing in India by technicaltextile.net

Manufacturing of Denim The term “Denim” has originated from the city of Nimes in France where “serge de Nimes” was manufactured. Denim is made from a vat dye, the Indigo dye, which is applied to cotton fabric in loosely held form in layers.

Fabrics are converted into wearable garments through the garment manufacturing process in the garment factories. At the time of garment making, functional trims and accessories are attached to the garment at various stages.

The manufacture of non-woven fabrics from a polyvinyl alcohol (PVA) fibre is known. The particular advantage of said PVA fibre is the property thereof of being soluble in water. To bond the non-woven fabric, it is therefore needled mechanically. The invention relates to a process which also uses hydrodynamic needling. Particular parameters for

25/05/2012 · This feature is not available right now. Please try again later.

In the textile manufacturing process, finishes are classified according to application method: o Thermal finish -Heat is applied to thermoplastic materials to produce a desired effect. − Example: permanent pleats in thermoplastic materials o Chemical finishes – Fabric is chemically reacted with the finish to produce a desired effect. Application may result in changes in other properties

The fabric usually used in the clothes we wear is produced through two processes: the “spinning process,” where raw cotton is turned into thread, and the “weaving process,” where the thread is woven into fabric. Here we will explain each process in detail using some illustrations.

last thread is woven. My reason for writing this document is to make it easier for anyone who is not a weaver to understand the process and to visualize the steps that are necessary to the process.

Flow Chart of Yarn Dyeing Process Textile Flowchart

Nonwoven Filter Media A Look Back Trends and Future

The textile industry process is a lengthy and complex one involving spinning, weaving, dyeing, printing and finishing. Spinning produces either filament or staple yarns that are used to weave a

Manufacturing of woven bags machine has high quality, steady production process and incorporate technology that produce PP/HDPE bags and sacks.

TT 504.601 NONWOVENS PhD FPS – NCSU THE SPUNBOND PROCESS Edmir Silva,a Dupont developed and commercialized the melt spinning technique for man-made fiber production in 1958. In the 1960s, Dupont (U.S.A.) and Freudenberg (Germany) adopted this technique into …

Non woven Bags Project Report & Non woven Fabric Bags Report. Project Report for Manufacturing of nonwoven Bags including Portfolio Bags, Messenger Bag, Shopping Bags, Tote Bag, Carry Bag, Shoulder, Grocery, Wine Bottle, Fashion Bags Projects Reports for Packaging Textile Industry.

13/12/2017 · Nonwoven Fabric Manufacturing Plant. Production of Non-Woven Fabrics for Hygiene, Medical, Automotive, Geotextiles, Construction & Packaging. Nonwoven fabrics …

Introduction to various fabric forming principles, weaving, knitting, nonwoven and braiding. Stages of woven fabric manufacturing, winding, warping, drawing and tying in and weaving. Winding, principles, precision and random winding, digicone winding, yarn tensioning and clearing.

When compared to other fabric manufacturing techniques non woven technique is found to the best in terms of production ratio. The production ratio of various techniques are tabulated below 2. Raw materials and their properties The end use of materials has been the driving force for the development of products and technology. Raw material is the key factor in designing of material, the

1 PROJECT PROFILE ON HDPE / PP WOVEN SACKS 1. INTRODUCTION HDPE/PP oriented strips are becoming increasingly popular in India & have caught the eye of many end users for their requirement of packing materials.

After the fabric has been woven, it’s removed from the loom and is ready for the final step: processing. Fabric that’s fresh off the loom is called greige, and it looks nothing like the crisp white sheets or clothing you’re used to.

Non-woven fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Non-woven materials typically lack strength unless densified or

Page 3 What is a textile roll? Project Concept The sheet or web structure fibres bonded together by entangling filaments (and by perforating films) mechanically, thermally or chemically are known as non-woven …

Woven Fabrics, Bina Buuna Kapdaa manufacturers, suppliers and exporters in Kanpur, बिना बुना कपडा विक्रेता, कानपुर, Nonwoven fabric is a fabric-like material made from staple fiber (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat or TCF is a 100% cellulose nonwoven fabric made from pulp. The sheets are

Non Woven Fabric – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery

Nonwoven fabric is a fabric-like material made from staple fiber (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt , which are neither woven nor knitted . [1]

method of manufacturing fabric from yarn is weaving, an examination of the weaving process and its extensive diversity merits first consideration. Traditional weaving is the process of mechanically interlacing two sets of yarns at right angles to one another in a . designated order. In a woven fabric, the longitudinal or warp yarns are called ends and the transverse or weft yarns are called

Woven Terry Fabrics: Manufacturing and Quality Management encompasses all aspects of terry fabric production, from raw material choice and weave design to technological developments, dyeing, and quality evaluation.

Yarn Dyeing: Yarn dyeing is a special type of dyeing process. This dyeing process is slightly difference from woven or knit dyeing. Dyed yarns are used for making stripe knit or woven fabrics or solid dyed yarn fabric or in sweater manufacturing.

Complex raw materials and manufacturing processes mean the textile industry is particularly dependent on good process control to produce high and consistent product quality.

It is a process of manufacturing nonwovens in which a web consisting of thermoplastic and non-thermoplastic fibers was made and then heated to the melting or softening temperature of the constituent thermoplastic fibers followed by cooling to solidify the bonding area. The blend of jute and synthetic fiber were successfully produced nonwoven fabric by this technique. Thermal bonded jute-nonwo

Woven polypropylene bags manufacturing process, from wire drawing, to fabric weaving, to bag printing and sewing, and the last quality testing.

bonding mechanisms for manufacturing of Nonwoven Geotextile , Mechanical Bonding or Needle Punching in which randomly oriented short staple fibers or continuous filament layers (fleece) are bonded together through process of Needling; In Thermal bonding the short fibers are bonded together through Heating Process, in Chemical bonding the fibers are bonded together through chemical coating

The Disposable Products Manufacturing Handbook is about producing Plastic Cups, Cutlery, Paper Cups, Banana Leaf Plates, Facial tissues, Wet Wipes, Toilet Paper Roll, Sanitary Napkins, Baby Diapers, Thermocol Products, PET Bottles that are used by masses in their day to day life.

Download Free Lecture Notes-Pdf Link-IV ELAW

MANUFACTURING OF NEEDLE PUNCHED NONWOVEN Gopalakrishnan D Needle punch non-woven fabric production line is one kind of methods for producing non- woven fabrics. In the process of producing, instead of using the traditional weaving process of the fabrics, the needle punch bond method uses triangle needles averagely punching in the cotton web to make the fibers directly tangle …

Coating and laminating are textile finishing processes designed to add or improve function and to add value to a material and/or to create a material with specific properties.

Fabric manufacturing process pdf. Fabric manufacturing process pdf Fabric manufacturing process pdf DOWNLOAD! DIRECT DOWNLOAD! non woven fabric manufacturing process pdf Dyeing processes.processing cotton separating the lint from the seed. The manufacture of products such as vegetable.Apr 30, 2007. Process wastewater from textile manufacturing is typically …

Ganpati Plastfab’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag is quality checked before being packed and shipped. Complete quality management systems are strictly followed at each step of the manufacturing process.

Non woven fabric and the difference between Bonded and Needle punched non woven fabrics Reeta Ghosh Department of Fashion Design/ Subharti Institute of fine art and fashion design/ Swami Vivekanand Subharti University, India Abstract:Nonwovens has covered a huge area in industrialization, medical, sports, home furnishing, garments, paper maker etc. but it itself has differences in the way … – fundamentals of modern manufacturing 4th edition solution manual lightweight synthetic woven fabric are dyed batch wise in single machine. So the batch preparation is the early So the batch preparation is the early step of pretreatment in coloration process.

variety of nonwoven fabric could be produced by our advanced fabric production line which is imported from Germany for nonwoven fabric production

www.entrepreneurindia.co Woven fabric is a textile formed by weaving. It is produced on a loom, and made of many threads woven on a warp and a weft.

Non-woven fabric was used between the Fig: Manufacturing processes of nonwoven fabric 6 Manufacturing Process 14 textilebulletin@gmail.com . The three stages are: Web Formation Dry laid • Carded • Air laid Spun melt • Spun laid (or spun bonded) • Melt blown

non woven ppt 1. Pronoy Debnath 2012000400093(19th) Southeast University Department OfTextile Engineering 2. Nonwoven Fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment.

Environmental, Health, and Safety Guidelines TEXTILE MANUFACTURING APRIL 30, 2007 1 WORLD BANK GROUP Environmental, Health, and Safety Guidelines for Textile Manufacturing Introduction The Environmental, Health, and Safety (EHS) Guidelines are technical reference documents with general and industry – specific examples of Good International Industry Practic e (GIIP) 1. When …

A non-woven fabric (10) is manufactured by an air-through method. In the non-woven fabric (10), multiple small fiber masses (30) having a color deeper than that of the ground of the non-woven fabric (10) are dispersed and arranged in a disseminated state over the whole of the non-woven fabric (10). Further, the thickness difference (T3) is 1mm

With its distinguished editors and international team of expert contributors, Process control in textile manufacturing is an essential guide for textile engineers and manufacturers involved in the

State of Art on Yarn Manufacturing Process & its defects in Textile Industry Neha Gupta, Prof. Dr. P. K. Bharti Department of Mechanical Engineering Integral University, Lucknow, India yarn. In winding department where the final package of yarn is make. Final package of yarn is the end and may chance the customer complaint. I. INTRODUCTION This paper is related to textile industry especially

One of the major advantages of nonwoven manufacture is the speed at which fabric can be produced, especially when compared to the production rates of knitted or woven fabrics. The effect of this is the reduction in the cost of manufacturing.

Weaving Process. The weaving process consists of five basic operations, shedding, picking, beating-up, left off and take up. Shedding: Separating the warp yarns into two layers by lifting and lowering the shafts, to form a tunnel known as the ‘shed’.

Generally fairly tightly woven fabrics capable of being pulled flat and uniform can be coated by the direct method. Waterproof protective clothing fabric, automotive car seat fabrics, tarpaulins and light weight material for inflatable are produced by the direct method. 3.2. Foamed and Crushed Foam Coating This method can be used to apply polymer to woven fab-rics and knitted fabrics and also

The first stage in the manufacturing process of nonwoven fabrics is “production of web” and another is “bonding of web by using several methods”. Some of

19/09/2011 · The Manufacturing Process For Non-Woven Fabrics Of Needle Punching.

Fashion Design and Technology as a profession includes the entire process of designing and producing fashion apparel for which an understanding of the fibre, yarn and fabric and their properties is essential.

Textile – Fibre to Fabric Processing P R Wadje, Non-member This paper is an attempt to provide all basic information related to textile Industry – in the field of manufacturing, purchasing, promoting, selling and so on. The study may also useful for intermediate level employees engaged in different aspect of textile technology , consumers and home economist s who need sound guidance in the

Cotton fabric manufacturing starts with the preparation of the yarn for weaving or knitting. Annually, textile mills in the U.S. normally produce about eight billion square yards each of woven and three billion square yards of knitted cotton goods.

Nonwoven fabrics: Nonwovens are a sheet, web, or bat of natural and/or man-made fibers or filaments, excluding paper, that have not been converted into yarns, …

Carding Machine Diagram. Note the feed matt or batt is fed in from the left side. The fibers are carried around the large main cylinder over the top by the stationary flats and removed as the card web on the right where it is deposited on a conveyor that leads to nonwoven bonding.

Textiles cdn.vibrantgujarat.com

Technological innovations in woven fabric manufacturing process P K Banerj ee” Department of Textile Technology. Indian Institute of Technology. Hauz Khas, New Delhi II 0 016, India The key to the gradual evolution of woven fabri c manufactu ring process has been traced to the introduction of the gripper shuttle, application of electronics and widespread use of composite materi als in the

Finally part three explores process control in the manufacture of knitted, woven, nonwoven textiles and colouration and finishing, with a final discussion of process control in apparel manufacturing. With its distinguished editors and international team of expert contributors, Process control in textile manufacturing is an essential guide for textile engineers and manufacturers involved in the

Process control in textile manufacturing provides an important overview of the fundamentals and applications of process control methods. Part one introduces key issues associated with process control and principles of control systems in textile manufacturing.

Cotton From Field to Fabric- Fabric Manufacturing

PROJECT PROFILE ON HDPE / PP WOVEN SACKS Sagar

2018-6-1 · Flow Chart of Yarn Dyeing Process stripe knit or woven fabrics or solid dyed yarn fabric or in sweater manufacturing. Process Flow Chart of Textile Process Flow Chart of Textile …

Textile manufacturing is a major industry. It is based on the conversion of fiber into yarn , yarn into fabric . These are then dyed or printed, fabricated into clothes .

Production of fabric Fabric construction involves the conversion of yarns, and sometimes fibres, into a fabric having characteristics determined by the materials and methods employed. Most fabrics are presently produced by some method of interlacing, such as weaving or knitting .

The next process is carding, which involves the transformation of textile fibers into strands of about four centimeters in diameter that are rolled to a length of up to 5,000 meters. During this stretching, long strands are separated from short or broken ones.

C evaporation of solvent from coated fabric after leaving the process.At first we compare garments easy grader pdf dyeing and fabric dyeing process with using. In woven fabric processing generally various types of dyeing process is used.and fabric for

manufacturing process of denim fabric pdf 1 Flaw materials and delivery. 2 Production of yarn and fabric. textile manufacturing process pdf 3 Treatments to fibres, yarns and fabric. fabric production process pdf Dyeing processes.Print Print Friendly and PDF PDF. Textile manufacturing or production eduardo galeano memoria del fuego iii pdf is a very complex process. The range of textile

Nonwoven Fabric Manufacturing Process: Air/Dry Laid and Carding For nonwoven fabric manufacturing, purified cotton webs can be formed using two processes.

Non-woven fabric is a web or sheet which is produced by using natural or man-made fibers or filaments or recycled fibers that have not been converted into yarns.

PP Woven Sack Manufacturing Process gpl.co.in

Project Report for Spunbond Nonwoven Fabric Manufacturing

1 PP/HDPE WOVEN SACKS INTRODUCTION Jute sacks are perhaps the earliest flexible packaging products to find popularity as cheap containers for bulk packaging of granular and powdery materials.

Tufting is the process of manufacturing some carpets and similar structures. A surface yarn system of loops is “sewn” or “stitched” through a primary backing fabric, usually a woven or nonwoven fabric.

iTextiles a finishing 1

PP/HDPE WOVEN SACKS Krishna district

https://en.wikipedia.org/wiki/Wet_processing_engineering

Textile Production of fabric Britannica.com

– HDPE/PP Bags Manufacturing Plant Detailed Project Report

Nonwovens Technology memberfiles.freewebs.com

PP / HDPE Woven Bags Woven Sacks Manufacturing Process

TechFab

Fabric Processing PDF Textile Manufacturing Textiles

Weaving The Complete Process From Thread to Cloth

Finally part three explores process control in the manufacture of knitted, woven, nonwoven textiles and colouration and finishing, with a final discussion of process control in apparel manufacturing. With its distinguished editors and international team of expert contributors, Process control in textile manufacturing is an essential guide for textile engineers and manufacturers involved in the

Non-woven fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Non-woven materials typically lack strength unless densified or

Non-woven fabric was used between the Fig: Manufacturing processes of nonwoven fabric 6 Manufacturing Process 14 textilebulletin@gmail.com . The three stages are: Web Formation Dry laid • Carded • Air laid Spun melt • Spun laid (or spun bonded) • Melt blown

When compared to other fabric manufacturing techniques non woven technique is found to the best in terms of production ratio. The production ratio of various techniques are tabulated below 2. Raw materials and their properties The end use of materials has been the driving force for the development of products and technology. Raw material is the key factor in designing of material, the

Non-woven fabric is a web or sheet which is produced by using natural or man-made fibers or filaments or recycled fibers that have not been converted into yarns.

variety of nonwoven fabric could be produced by our advanced fabric production line which is imported from Germany for nonwoven fabric production

Manufacturing of woven bags machine has high quality, steady production process and incorporate technology that produce PP/HDPE bags and sacks.

After the fabric has been woven, it’s removed from the loom and is ready for the final step: processing. Fabric that’s fresh off the loom is called greige, and it looks nothing like the crisp white sheets or clothing you’re used to.

Non Woven Fabric – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery

Non woven Bags Project Report & Non woven Fabric Bags Report. Project Report for Manufacturing of nonwoven Bags including Portfolio Bags, Messenger Bag, Shopping Bags, Tote Bag, Carry Bag, Shoulder, Grocery, Wine Bottle, Fashion Bags Projects Reports for Packaging Textile Industry.

1 PP/HDPE WOVEN SACKS INTRODUCTION Jute sacks are perhaps the earliest flexible packaging products to find popularity as cheap containers for bulk packaging of granular and powdery materials.

Complex raw materials and manufacturing processes mean the textile industry is particularly dependent on good process control to produce high and consistent product quality.

27 replies on “Woven fabric manufacturing process pdf”

Leave a CommentGanpati Plastfab’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag is quality checked before being packed and shipped. Complete quality management systems are strictly followed at each step of the manufacturing process.

Process Control in Textile Manufacturing 1st Edition

TechFab

The Manufacturing Process For Non-Woven Fabrics Of Needle

Non woven fabric and the difference between Bonded and Needle punched non woven fabrics Reeta Ghosh Department of Fashion Design/ Subharti Institute of fine art and fashion design/ Swami Vivekanand Subharti University, India Abstract:Nonwovens has covered a huge area in industrialization, medical, sports, home furnishing, garments, paper maker etc. but it itself has differences in the way …

Fabric Processing PDF Textile Manufacturing Textiles

Download Free Lecture Notes-Pdf Link-IV ELAW

From Raw Cotton to Cotton Fabrics Toyota Industries

Complex raw materials and manufacturing processes mean the textile industry is particularly dependent on good process control to produce high and consistent product quality.

00 Fabric Study Cover – CBSE

Manufacturing of woven bags machine has high quality, steady production process and incorporate technology that produce PP/HDPE bags and sacks.

Textile – Fibre to Fabric Processing

Process Flow Chart of Denim Manufacturing Manufacturing

A Review on Coating & Lamination in Textiles Processes

The first stage in the manufacturing process of nonwoven fabrics is “production of web” and another is “bonding of web by using several methods”. Some of

Comparative study on Garments dyeing process and Fabric

The manufacture of non-woven fabrics from a polyvinyl alcohol (PVA) fibre is known. The particular advantage of said PVA fibre is the property thereof of being soluble in water. To bond the non-woven fabric, it is therefore needled mechanically. The invention relates to a process which also uses hydrodynamic needling. Particular parameters for

The Manufacturing Process of Fabric Manufacturing

Non Woven Bags Non Woven Fabric Bags Project Reports

Nonwoven Filter Media A Look Back Trends and Future

method of manufacturing fabric from yarn is weaving, an examination of the weaving process and its extensive diversity merits first consideration. Traditional weaving is the process of mechanically interlacing two sets of yarns at right angles to one another in a . designated order. In a woven fabric, the longitudinal or warp yarns are called ends and the transverse or weft yarns are called

HDPE/PP Bags Manufacturing Plant Detailed Project Report

The Manufacturing Process For Non-Woven Fabrics Of Needle

State of Art on Yarn Manufacturing Process & its defects in Textile Industry Neha Gupta, Prof. Dr. P. K. Bharti Department of Mechanical Engineering Integral University, Lucknow, India yarn. In winding department where the final package of yarn is make. Final package of yarn is the end and may chance the customer complaint. I. INTRODUCTION This paper is related to textile industry especially

PP Woven Bags Manufacturing Process QTL Bags

Coated Industrial Textile Associates

The Manufacturing Process For Non-Woven Fabrics Of Needle

non woven ppt 1. Pronoy Debnath 2012000400093(19th) Southeast University Department OfTextile Engineering 2. Nonwoven Fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment.

Textile Industry Process Study.com

Non-woven fabric was used between the Fig: Manufacturing processes of nonwoven fabric 6 Manufacturing Process 14 textilebulletin@gmail.com . The three stages are: Web Formation Dry laid • Carded • Air laid Spun melt • Spun laid (or spun bonded) • Melt blown

A Review on Jute Nonwovens Manufacturing Properties and

Nonwoven Filter Media A Look Back Trends and Future

It is a process of manufacturing nonwovens in which a web consisting of thermoplastic and non-thermoplastic fibers was made and then heated to the melting or softening temperature of the constituent thermoplastic fibers followed by cooling to solidify the bonding area. The blend of jute and synthetic fiber were successfully produced nonwoven fabric by this technique. Thermal bonded jute-nonwo

Comparative study on Garments dyeing process and Fabric

non woven ppt SlideShare

Woven Fabrics, Bina Buuna Kapdaa manufacturers, suppliers and exporters in Kanpur, बिना बुना कपडा विक्रेता, कानपुर, Nonwoven fabric is a fabric-like material made from staple fiber (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat or TCF is a 100% cellulose nonwoven fabric made from pulp. The sheets are

Technological innovations in woven fabric manufacturing

Nonwoven Filter Media A Look Back Trends and Future

PROJECT PROFILE ON HDPE / PP WOVEN SACKS Sagar

State of Art on Yarn Manufacturing Process & its defects in Textile Industry Neha Gupta, Prof. Dr. P. K. Bharti Department of Mechanical Engineering Integral University, Lucknow, India yarn. In winding department where the final package of yarn is make. Final package of yarn is the end and may chance the customer complaint. I. INTRODUCTION This paper is related to textile industry especially

Nonwoven Fabric Manufacturing Plant. YouTube

non woven fabric manufacturing processpp non woven fabric

00 Fabric Study Cover – CBSE

Manufacturing of woven bags machine has high quality, steady production process and incorporate technology that produce PP/HDPE bags and sacks.

Woven Fabric Manufacturing YouTube

13/12/2017 · Nonwoven Fabric Manufacturing Plant. Production of Non-Woven Fabrics for Hygiene, Medical, Automotive, Geotextiles, Construction & Packaging. Nonwoven fabrics …

Woven Terry Fabrics 1st Edition – Elsevier

Non-woven fabric is a fabric-like material made from long fibers, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Non-woven materials typically lack strength unless densified or

A Review on Jute Nonwovens Manufacturing Properties and

Flow Chart of Nonwoven Fabric Manufacturing Process

Textile – Fibre to Fabric Processing

Fashion Design and Technology as a profession includes the entire process of designing and producing fashion apparel for which an understanding of the fibre, yarn and fabric and their properties is essential.

WO2013099674A1 Non-woven fabric and manufacturing

Non-woven fabric is a web or sheet which is produced by using natural or man-made fibers or filaments or recycled fibers that have not been converted into yarns.

TechFab

Technological innovations in woven fabric manufacturing

1 PROJECT PROFILE ON HDPE / PP WOVEN SACKS 1. INTRODUCTION HDPE/PP oriented strips are becoming increasingly popular in India & have caught the eye of many end users for their requirement of packing materials.

Nonwoven Filter Media A Look Back Trends and Future

Environmental, Health, and Safety Guidelines TEXTILE MANUFACTURING APRIL 30, 2007 1 WORLD BANK GROUP Environmental, Health, and Safety Guidelines for Textile Manufacturing Introduction The Environmental, Health, and Safety (EHS) Guidelines are technical reference documents with general and industry – specific examples of Good International Industry Practic e (GIIP) 1. When …

iTextiles a finishing 1

PP Woven Bags Manufacturing Process QTL Bags

Technological innovations in woven fabric manufacturing

13/12/2017 · Nonwoven Fabric Manufacturing Plant. Production of Non-Woven Fabrics for Hygiene, Medical, Automotive, Geotextiles, Construction & Packaging. Nonwoven fabrics …

MANUFACTURING OF NEEDLE PUNCHED NONWOVEN

Process Control in Textile Manufacturing ScienceDirect

Non Woven Fabric – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery

Textile Industry Process Study.com

PP / HDPE Woven Bags Woven Sacks Manufacturing Process

Ganpati Plastfab’s manufacturing process of woven polypropylene woven sacks and FIBC bulk bags use only pure virgin polypropylene resins, and every bag is quality checked before being packed and shipped. Complete quality management systems are strictly followed at each step of the manufacturing process.

Textile – Fibre to Fabric Processing

Generally fairly tightly woven fabrics capable of being pulled flat and uniform can be coated by the direct method. Waterproof protective clothing fabric, automotive car seat fabrics, tarpaulins and light weight material for inflatable are produced by the direct method. 3.2. Foamed and Crushed Foam Coating This method can be used to apply polymer to woven fab-rics and knitted fabrics and also

TEXTILE FIBRE TO FABRIC PROCESSING

MANUFACTURING OF NEEDLE PUNCHED NONWOVEN

The next process is carding, which involves the transformation of textile fibers into strands of about four centimeters in diameter that are rolled to a length of up to 5,000 meters. During this stretching, long strands are separated from short or broken ones.

Nonwoven Fabric Manufacturing Plant. YouTube

A Brief Introduction to Non-Woven Fabrics

Production of fabric Fabric construction involves the conversion of yarns, and sometimes fibres, into a fabric having characteristics determined by the materials and methods employed. Most fabrics are presently produced by some method of interlacing, such as weaving or knitting .

A Brief Introduction to Non-Woven Fabrics

A Review on Coating & Lamination in Textiles Processes

bonding mechanisms for manufacturing of Nonwoven Geotextile , Mechanical Bonding or Needle Punching in which randomly oriented short staple fibers or continuous filament layers (fleece) are bonded together through process of Needling; In Thermal bonding the short fibers are bonded together through Heating Process, in Chemical bonding the fibers are bonded together through chemical coating

PP Woven Bags Manufacturing Process QTL Bags

A Review on Jute Nonwovens Manufacturing Properties and

Textile Chapter Non-Woven Fabric Manufacturing Process

Comments are closed.