Alloy wheels manufacturing process pdf

Variant Alloy Wheels was created out of the need to fulfill gaps in the aftermarket wheel world. With over 15 years of industry experience, we found many flaws in the marketplace and took it upon ourselves to change the way wheel manufacturing operates.

The main components of a flux used for aluminium alloy production are chlorides and fluorides such as NaCl, KCl, AlF 3 (which is a hydrogen fluoride compound but is exempt because of poor-water- …

The most common process of constructing alloy wheels is One-Piece Casting, there are a number of methods to do this, and the most basic is Die Casting, this process is used world wide throughout the casting industry and is not exclusive to alloy wheels. The Die Casting process uses a permanent mould usually made of metal, which generally means that there is high tooling costs compared to …

A quality starting from technology processes OZ wheels are produced through Low Pressure Casting and Gravity technologies. Low pressure casting the alloy is heated at about 700°C, cast and is low pressure injected into the bottom of the mould, to the top.

The Manufacture of Aluminium Alloy Wheels – Download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. Scribd is …

Sterling wheel components provide off road wheels and passenger forged one-piece wheel manufacturing services in China at very competitive prices using premium quality aircraft grade 6061 T6 alloy materials and highly engineered craftsmanship.

ALLOY WHEELS This is the correct method of installing any alloy wheel. Use a torque wrench, following correct torque value and the proper criss-cross tightening pattern to avoid stressing or distorting the wheel or hub/rotor . Summer3-13 8/4/04 11:23 AM Page 4 . clam ps the wh eel to the hub) gener-ically as Òlug nuts,Óget into the ha bit of calling them Òw heel fastener s,Ó since thatÕs

Alloy Wheels – To Know More . When you want to buy your new shiny alloy wheels, dealer will start to impress you with a lot of strange words. One of the major stumbling blocks for novices is the use of terminology – it can be really confusing.

Production of magnesium forged wheels started in 1990, and the company began supplying forgings for manufacturing Formula 1 magnesium wheels in 1993. “TWS Forged” brand was launched in 2010 to establish the manufacturer’s presence in the aftermarket. One-part and multi-part forged magnesium wheels are available.

Alloy Wheels Manufacturing Process , Find Complete Details about Alloy Wheels Manufacturing Process,Alloy Wheels Manufacturing Process,Cast Iron Pulley For Mining,Metal Pulley And Wheel from Pulleys Supplier or Manufacturer-Syi Industrial Co., Ltd.

Aluminium alloy wheels manufacturing process have developed a lot since 1970s. Due to sophisticated wheels design, casting has become the dominant manufacturing process. Alloy wheel material has evolved too: car wheels alloys now contain 7 to 12% silicon content, and varying contents of magnesium in addition to aluminium, in order to meet the demand for metal-mould casting …

A process which can make a titanium alloy bolt at ambient temperature is disclosed. A Ti—Fe—O alloy is used as a material. It has a screw thread formed thereon by drawing and rolling.

Alloy Wheels To Know More – Formula 1 Dictionary

MODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM

The development of a powder-based process for manufacturing Ti parts at low cost would help all industries that can utilize the material property benefits that Ti provides, especially its high strength-to-weight ratio and corrosion resistance.

Automotive Aluminium Alloy Wheels market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of …

Home » Automobiles » Manufacturing Processes of Alloy Wheels for through the process is vital for the manufacturing quality and the solution annealing at the end. A silver removal treatment

as wheels are made of aluminum alloy, using a differ-ent production method does not affect the stiffness of the wheel. That’s because all aluminum alloys used for forging and casting create same material property with identical stiffness. Comparison of wrought aluminum alloy and Cast aluminum alloy * Young’s moduls is a measure of elasticity, equal to the ratio of the stress acting on a

Manufacturing Process- Metal Alloys Corporation, Jamnagar, Gujarat, India

manufacturing cost. In the present work, some process variables, which play a key role in production cycle of wheels have been investigated and improved. An integrated methodology for developing and optimizing the production and the final qu ality of A356-T6 18-inch wheels, in terms of casting distortion and hardness, is proposed. This study focuses on examining both the www.intechopen.com

Alloy Wheels or Alloy Road Wheels used in Motor Vehicles, whether or not attached with their accessories, of a size in diameters ranging from 12 inches to 24 inches, originating in or exported from China PR, Korea RP and

Casting Defects in Low-Pressure Die-Cast Aluminum Alloy Wheels B. Zhang, S.L. Cockcroft, D.M. Maijer, J.D. Zhu, and A.B. Phillion serve as one component of a pressure vessel in conjunction with the tire; high-quality surface fi nish, as wheels are one of the prominent cosmetic features on cars; and geometric and rotational bal-ance tolerances, which are becoming more stringent. In the context

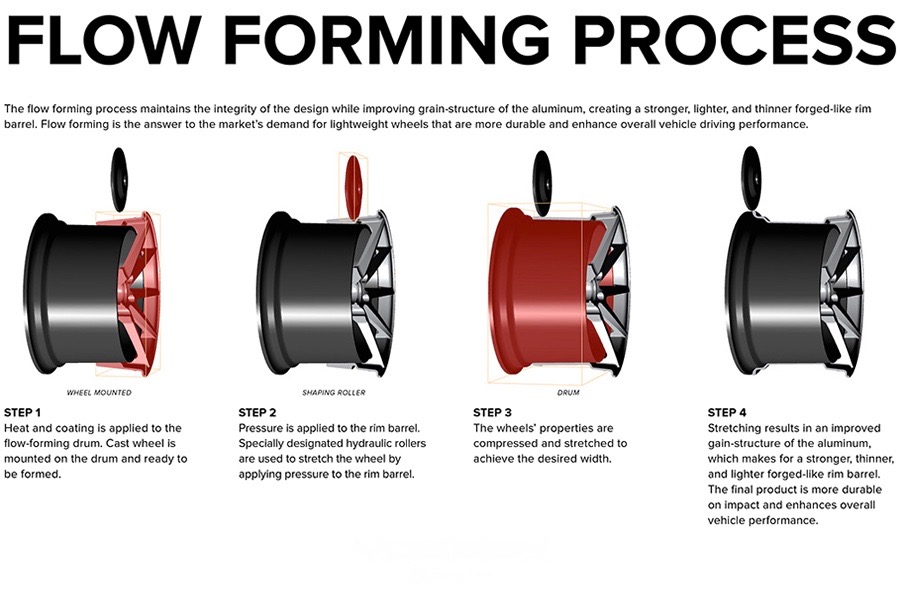

This spinning process creates “metal flow” in the metal structure of the aluminum alloy, which is similar to the metal property seen in the forging process. This hybrid process of casting and forging gives wheel high material strength while keep manufacturing cost more affordable than forged wheels.

Alba foundry alloy ingots exceed the most stringent quality requirements. They are mainly used by the automotive industry for manufacturing high quality automotive wheels…

Aluminum alloy wheels not only are more attractive than standard steel wheels, but they also are a fraction of the weight and therefore require less energy to rotate. This contributes to greater fuel efficiency as well as better handling, acceleration and braking. This 5-minute video shows the manufacturing process for aluminum alloy wheels, from casting and molding to heat treating, …

Forged alloy wheel production delivering high-precision

In the present world with the increasing use of Aluminium alloy wheels in automotive industry the Aluminium foundry industry had to focus on the quality of the products. The quality of a foundry industry can be increased by minimizing the casting defects during production. Aim of the current study is to study the production line of an aluminum alloy wheel manufacturing industry and to improve

These specifications cover multiple-wear wrought carbon-steel heat-treated wheel manufacturing requirements for rail passenger cars and locomotives. Design requirements are outside the scope of this standard. The passenger rail industry phased this standard into practice over the six-month period from July 1 to December 31, 1999. The standard took effect January 1, 2000. Wheel classes are

Higher cars typically come with alloy wheels rather than basic steel wheels covered with cub hap, called mag wheels because when they are first came out they are made of alloy of magnesium. Today’s alloy wheels are made with aluminium alloy, which is more durable. Aluminium alloys wheels are not only more attractive than standard steel wheels; they are also the fraction of their weight. And

Rays Engineering Co., Ltd. (株式会社レイズエンジニアリング, Kabushiki-gaisha Reizu Enjiniaringu), a part of Rays Co., Ltd. is a high-end Japanese wheel manufacturer for both motorsport and street use, mostly notable for manufacturing Volk Racing flagship brand of wheels.

Gears are basically wheels having, on its periphery, equispaced teeth which are so designed that those wheels transmit, without slip, rotary motion smoothly and uniformly with minimum friction and wear at the mating tooth –

4/09/1990 · BACKGROUND. The present invention relates to a method of manufacturing one and two piece alloy wheels for vehicle tires. Alloy vehicle wheels and in particular aluminum alloy wheels are quite popular due to their aesthetic appearance and light weight.

Trans. Nonferrous Met. Soc. China 24(2014) 2214−2219 Microstructure and mechanical properties of A356 aluminum alloy wheels prepared by thixo-forging combined with a low superheat casting process

UNIWHEELS – a leading European manufacturer of alloy wheels – plans to expand production in Poland UNIWHEELS plans to build third production plant in Stalowa Wola The investment plan will increase the production capacity by approx. 2 million wheels New plant will generate more than 250 new jobs in Stalowa Wola Bad Dürkheim, February 24th 2015: Germany-based alloy wheels manufacturer – business continuity plan example for manufacturing The global leader in railway wheels. A world apart in reliability . AMSTED RAIL – GRIFFIN ® WHEELS. Keeping the heavy haul world on a roll. For over a century, the Griffin wheel brand has been at the forefront . in wheel design, manufacturing innovation and reliability. Now an integral part of Amsted Rail, Griffin is making an even stronger commitment to industry-leading safety and

3.4.3 Manufacturing process depending on alloy and temper. Static performance (strength) In order to avoid any deformation under maximal axial (accelerations and braking) and radial stresses (turning), the yield strength of the material must be considered. Misuse cases have to be evaluated in relation to the tensile strength. Yield tests under pressure are also conducted to check this

Product wheels have been derived from one of the common lean manufacturing tools used in lean manufacturing, referred to as production smoothing or heijunka, where the aim, like 4

The original DISAmatic process was advanced by Alcoa for manufacturing of high-quality automotive castings. Alcoa’s variant green sand casting is AGSC (Alcoa Green Sand

More alloy wheels are set to roll off the local manufacturing floor. One of the country’s largest manufacturers of these automotive products, Borbet South Africa, has started to implement a R60

The state-of-the-art European factory manufactures alloy wheels to DIN ISO 9001:2000 standards. The entire manufacturing process, commencing from the original smelting of the ingot to the final inspection of the product is performed in house.

– The conducted research works on the forging process on hammer of the rim drop forging from 2618A aluminium alloy showed that the application of this technology allows for …

19/10/2016 · How it’s Made – UMass Edition HYPNOTIC Biggest Heavy Duty Germany Forging Factory Fastest Large Steel Shaft Manufacture Process – Duration: 12:49.

Alloy Wheels, also otherwise known as Rims, are made of alloys of aluminumor magnesium. Sometimesit so Sometimesit so happens that a mixture of both aluminum and magnesium isused in making alloy wheels.

Rockman is leader in 2 wheelers alloy wheels with installed capacity of 5.6 million wheels annually. Rockman is the top manufacturers for alloy wheels in India. Rockman is the top manufacturers for alloy wheels …

Browse all 250+ Wheels Mfg replacement derailleur hangers for over 6000 different bicycle frames.

The Design of an aluminium alloy wheel using three dimensional Finite Element Analysis and Fatigue Life Prediction. By Mary M. Doyle BSc Eng, Dip Eng. This Thesis is submitted to fulfil the requirement for the award of Master’s Degree in Engineering by research to: Dublin City University. Supervisor : Professor M. S. J. Hashmi. Head of the School of Mechanical and Manufacturing Engineering

Car wheels are divided in to two main groups, steel wheels and alloy wheels. Alloy wheels are frequently fitted typical Alloy wheels are frequently fitted typical during the manufacturing …

How Alloy Wheels are Manufactured reliableplant.com

The past two decades have seen the realization of the manufacturing firms towards quality consciousness. In pursuit of quality, the main concerns for alloy wheel machining process areas follows: alloy wheel unclean, surface finish deterioration, non-conformance to …

1.1 Steps of Alloy Wheel Production Process: It comprise of following steps Degassing process X PROBLEM DEFINITION: The product is considered is alloy wheels. During the manufacturing of alloy wheels various casting defects is formed due to improper method of casting and design Melting of Aluminum alloy Low pressure die casting Solidification of Aluminum

Forging is a low yield and high cost manufacturing method that essentially machines a wheel from an alloy billet. The result of this method is wheels that are extremely light in weight and very strong. This production method is ideal for clients who need a high performance wheel in lower numbers.

MINIMIZATION OF CASTING DEFECTS IN ALUMINUM ALLOYS WHEELS

CN101966575A Process for casting aluminum alloy wheel

g/cc) alloy wheels are suggested essential for aesthetic look. However, in any type of wheel, the basic construction is consisted of a rim, a hub, spokes/arms/wires and tires.

8/12/2006 · The first process shown was forging, which makes very strong an light wheels which are generally in 2/3 parts due to manufacturing drawbacks….. however, these are very expensive. The common process for wheels is casting.

Manufacturing Process Materials Used Keimax products are made with Premium Alloy Steel from top rated Steel Mills, featuring a forged ring for superior strength and durability, and without Butt welds on the back and gutter sections.

Manufacturing Process Metal Alloys Corporation

Video Alloy Wheel Manufacture Process – Team-BHP

manufacturing process, rework has been reduced by 80%, scrap has been eliminated, 3D appearance processing time has been reduced by 48% and the component tolerance of …

MODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM Alloy wheels are automobile wheels which are made from an alloy of aluminum or magnesium Metals or sometimes a mixture of both. Alloy wheels differ from steel wheels because Of their lighter weight, which improves the driving and handling of the motorcycle. Alloy wheels made up of composite materials will reduce the …

Optimizing the Heat Treatment Process of Cast Aluminium Alloys for cast aluminium alloy wheels: an improved ductility and fracture toughness through spheroidization of the eutectic silicon particles in the microstructure and a higher alloy yield strength through the formation of a large number of fine precipitates which strengthen the soft aluminium matrix (Zhang et al., 2002). The T6 heat

Flow forming is one of the most advanced manufacturing technologies to be introduced to the alloy wheel industry. This process involves placing a low pressure and heat treated casting unique to Flow Forming Technology onto a flow forming mould.

Foundry Alloy Ingots Aluminium Bahrain

The invention discloses a process for casting an 8356 type A356 aluminum alloy wheel and a heat treatment process. The process comprises the following steps of: a, adopting a metal mold low-pressure casting process, wherein the pouring temperature is between 690 and 735 DEG C, and the die preheating temperature is between 250 and 350 DEG C; b

Stay always on the move with our wide range of high quality Tyres supplied as per world-class standards for Truck, Light Commercial Vehicle, Passenger Car, Agriculture, Off-The-Road, Forklift & Industrial applications along with Steel Rims & Alloy Wheels.

US20060234800A1 Titanium alloy bolt and its

https://en.wikipedia.org/wiki/Duralumin

Rays Engineering Wikipedia

– All Wheels Manufacturing Replacement Derailleur Hangers

Low-Cost Titanium Alloy Production Department of Energy

Process capability improvement through DMAIC for aluminum

To be published in Part I Section – I of the Gazette of

21 replies on “Alloy wheels manufacturing process pdf”

Leave a CommentMODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM Alloy wheels are automobile wheels which are made from an alloy of aluminum or magnesium Metals or sometimes a mixture of both. Alloy wheels differ from steel wheels because Of their lighter weight, which improves the driving and handling of the motorcycle. Alloy wheels made up of composite materials will reduce the …

Sterling wheel components alloy wheels forged alloy wheels

The Design of an aluminium alloy wheel using three

MODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM

Variant Alloy Wheels was created out of the need to fulfill gaps in the aftermarket wheel world. With over 15 years of industry experience, we found many flaws in the marketplace and took it upon ourselves to change the way wheel manufacturing operates.

Process capability improvement through DMAIC for aluminum

g/cc) alloy wheels are suggested essential for aesthetic look. However, in any type of wheel, the basic construction is consisted of a rim, a hub, spokes/arms/wires and tires.

Alloy Wheels To Know More – Formula 1 Dictionary

4/09/1990 · BACKGROUND. The present invention relates to a method of manufacturing one and two piece alloy wheels for vehicle tires. Alloy vehicle wheels and in particular aluminum alloy wheels are quite popular due to their aesthetic appearance and light weight.

All Wheels Manufacturing Replacement Derailleur Hangers

These specifications cover multiple-wear wrought carbon-steel heat-treated wheel manufacturing requirements for rail passenger cars and locomotives. Design requirements are outside the scope of this standard. The passenger rail industry phased this standard into practice over the six-month period from July 1 to December 31, 1999. The standard took effect January 1, 2000. Wheel classes are

Aluminum Rim Manufacturing Process YouTube

How to produce the best car alloy wheels OZ Racing

The invention discloses a process for casting an 8356 type A356 aluminum alloy wheel and a heat treatment process. The process comprises the following steps of: a, adopting a metal mold low-pressure casting process, wherein the pouring temperature is between 690 and 735 DEG C, and the die preheating temperature is between 250 and 350 DEG C; b

Technical Report The Construction of Alloy Wheels

Alloy Wheels To Know More – Formula 1 Dictionary

How Alloy Wheels are Manufactured reliableplant.com

More alloy wheels are set to roll off the local manufacturing floor. One of the country’s largest manufacturers of these automotive products, Borbet South Africa, has started to implement a R60

Process capability improvement through DMAIC for aluminum

How Alloy Wheels are Manufactured reliableplant.com

The main components of a flux used for aluminium alloy production are chlorides and fluorides such as NaCl, KCl, AlF 3 (which is a hydrogen fluoride compound but is exempt because of poor-water- …

All Wheels Manufacturing Replacement Derailleur Hangers

How Alloy Wheels are Manufactured reliableplant.com

Alloy Wheels Manufacturing Process , Find Complete Details about Alloy Wheels Manufacturing Process,Alloy Wheels Manufacturing Process,Cast Iron Pulley For Mining,Metal Pulley And Wheel from Pulleys Supplier or Manufacturer-Syi Industrial Co., Ltd.

US20060234800A1 Titanium alloy bolt and its

Alloy Wheels To Know More – Formula 1 Dictionary

The invention discloses a process for casting an 8356 type A356 aluminum alloy wheel and a heat treatment process. The process comprises the following steps of: a, adopting a metal mold low-pressure casting process, wherein the pouring temperature is between 690 and 735 DEG C, and the die preheating temperature is between 250 and 350 DEG C; b

Keimax Wheel & Rim Manufacturing Process – Premium alloy

Rays Engineering Co., Ltd. (株式会社レイズエンジニアリング, Kabushiki-gaisha Reizu Enjiniaringu), a part of Rays Co., Ltd. is a high-end Japanese wheel manufacturer for both motorsport and street use, mostly notable for manufacturing Volk Racing flagship brand of wheels.

MODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM

Aluminum Rim Manufacturing Process YouTube

US20060234800A1 Titanium alloy bolt and its

Optimizing the Heat Treatment Process of Cast Aluminium Alloys for cast aluminium alloy wheels: an improved ductility and fracture toughness through spheroidization of the eutectic silicon particles in the microstructure and a higher alloy yield strength through the formation of a large number of fine precipitates which strengthen the soft aluminium matrix (Zhang et al., 2002). The T6 heat

Manufacturing Process Metal Alloys Corporation

Keimax Wheel & Rim Manufacturing Process – Premium alloy

Browse all 250+ Wheels Mfg replacement derailleur hangers for over 6000 different bicycle frames.

Technical Report The Construction of Alloy Wheels

Video Alloy Wheel Manufacture Process – Team-BHP

US20060234800A1 Titanium alloy bolt and its

The state-of-the-art European factory manufactures alloy wheels to DIN ISO 9001:2000 standards. The entire manufacturing process, commencing from the original smelting of the ingot to the final inspection of the product is performed in house.

Keimax Wheel & Rim Manufacturing Process – Premium alloy

Alloy Wheels To Know More – Formula 1 Dictionary

All Wheels Manufacturing Replacement Derailleur Hangers

3.4.3 Manufacturing process depending on alloy and temper. Static performance (strength) In order to avoid any deformation under maximal axial (accelerations and braking) and radial stresses (turning), the yield strength of the material must be considered. Misuse cases have to be evaluated in relation to the tensile strength. Yield tests under pressure are also conducted to check this

Manufacturing – Automotive Wheels Ltd – Wholesale Alloy

How to produce the best car alloy wheels OZ Racing

How Alloy Wheels are Made How Its Made – Wolfrace Alloys

Alba foundry alloy ingots exceed the most stringent quality requirements. They are mainly used by the automotive industry for manufacturing high quality automotive wheels…

Video Alloy Wheel Manufacture Process – Team-BHP

US20060234800A1 Titanium alloy bolt and its

4/09/1990 · BACKGROUND. The present invention relates to a method of manufacturing one and two piece alloy wheels for vehicle tires. Alloy vehicle wheels and in particular aluminum alloy wheels are quite popular due to their aesthetic appearance and light weight.

Wheels Rims & Lightweight Mag Alloys – ROH Wheels

MODELLING AND ANALYSIS OF A MOTORCYCLE WHEEL RIM Alloy wheels are automobile wheels which are made from an alloy of aluminum or magnesium Metals or sometimes a mixture of both. Alloy wheels differ from steel wheels because Of their lighter weight, which improves the driving and handling of the motorcycle. Alloy wheels made up of composite materials will reduce the …

Alloy Wheels Manufacturing Process alibaba.com

Automotive Aluminium Alloy Wheels Market by Region (2012

Alba foundry alloy ingots exceed the most stringent quality requirements. They are mainly used by the automotive industry for manufacturing high quality automotive wheels…

Process capability improvement through DMAIC for aluminum

This spinning process creates “metal flow” in the metal structure of the aluminum alloy, which is similar to the metal property seen in the forging process. This hybrid process of casting and forging gives wheel high material strength while keep manufacturing cost more affordable than forged wheels.

Alloy Wheels for Two Wheelers Top Manufacturers in India

Technical Report The Construction of Alloy Wheels

Cold Forged Luxury Alloy Wheels Variant Alloy Wheels

Trans. Nonferrous Met. Soc. China 24(2014) 2214−2219 Microstructure and mechanical properties of A356 aluminum alloy wheels prepared by thixo-forging combined with a low superheat casting process

Rays Engineering Wikipedia

Comments are closed.