What is advantage of networking system in agile manufacturing pdf

Agile manufacturing relies on robust data systems shared by the marketing, design and production departments, providing up-to-date information on the resources available for use and redesign at

Agile Manufacturing (AM) has gained increasing attention from the manufacturing enterprises to deal with today’s hypercompetitive market environment. Given the significant investment in manufacturing operating systems, an investigation of how AM

Advantages and disadvantages of Agile Project Management Aleksandar Olic · project-management · Jun 21, 2017 Today, agile is such a buzzword that teams outside software development try to incorporate it into their workflow.

The picture shows the evolution of competitive forces and the increasing towards a reexamination of the importance of process productivity along with sustained growth

The network allows for a specialist factory to fill excess capacity, whilst keeping manufacturing local to the products final destination, reducing emissions and logistics cost all while also keeping quality of product for the end consumer. It’s a very agile model that allows for quick and scalable movement in modern business. 7 advantages of Distributed Manufacturing and why this will

27/12/2018 · Agile manufacturing is an approach to manufacturing which is focused on meeting the needs of customers while maintaining high standards of quality and controlling the overall costs involved in the production of a particular product.

integrated with advanced sensors, metering, network communications, and computer control technologies within an infrastructure of generation plants, transmission towers, transformer components, and premises distribution.

An agile manufacturing system must have the ability to shift rapidly amongst product models or between product lines, ideally in real-time response to customer demands.

The Effects of Application of Lean Concept in Retail Radojko LUKIC1 ABSTRACT Lean principles and techniques can be successfully applied in the retail sector.

Author’s Accepted Manuscript The Development of a Lean, Agile and Leagile Supply Network Taxonomy Based on Differing Types of Flexibility Laura Purvis, Jonathan Gosling, Mohamed M.

Study on Key Technologies of Shipbuilding Virtual Enterprise Information Integration Oriented Agile Manufacturing 963 more competitive in a comprehensive way.

systems Informationsystems Integratedinformationsystems 4 Informationsystemsdesignedfor 10 supportingspeci®careas Architectures:requirementsand 4 implications Informationexchange 2 Evaluationofinformationmodels 1 Supplychain Strategies 4 Partnerselection 9 Humanfactors 3 Businesspracticesandprocesses Progressevaluationinseveral 4 countries Businessissues 5 Total 73 …

Agile manufacturing is a new idiom that is used to represent the ability of a producer of goods and services to survive and flourish in the face of continuous change. These changes can occur in markets,

The major criticism of lean manufacturing is the possibility of stress among the workforce, possible unrealistic standards, over-focus on eliminating waste overriding other concerns, over-focus on the present and stifling creativity and innovation. Lean’s lack of a standard methodology and the requirement of each individual to assume ownership

Oracle White Paper: Managing the Product Value Chain for the Industrial Manufacturing Industry 5 The Enterprise Product Record Companies have deployed enterprise systems of record to manage select operations across their

enterprise networks and logistics for agile manufacturing Fri, 14 Dec 2018 16:49:00 GMT enterprise networks and logistics for pdf – Consolidated Afloat Networks and Enterprise Services (CANES) A management team with deep experience in shipboard architecture, design, installation and C4ISR Sun, 16 Dec 2018 18:05:00 GMT Consolidated Afloat Networks and Enterprise Services (CANES) – …

THE BENEFITS OF LEAN MANUFACTURING What Lean Thinking has to Offer the Process Industries T. MELTON MIME Solutions Ltd, Chester, UK H ow many people in the manufacturing industry can truly say that they have not heard of LEAN?

Agile manufacturing. From Wikipedia, the free encyclopedia Agile manufacturing is a term applied to an organization that has created the processes, tools, and training to enable it to respond quickly to customer needs and market changes while still controlling costs and quality.

A merit system is most applicable when there is detailed data available to measure the performance of employees. Consider how that data can push employees to achieve more, padding their own paychecks, as well as the company’s bottom line.

Agile Manufacturing enterprises will be capable of rapidly responding to changes in customer demand. They will be able to take advantage of the windows of opportunities that appear in the market place.

Enterprise Networks And Logistics For Agile Manufacturing

Use Agile Manufacturing to Rapidly Respond to Customers

Green manufacturing in India is at the take–off stage. While there has been significant policy While there has been significant policy development and adoption by the manufacturing industry in the area of Green energy, there is

Computer-integrated manufacturing (CIM) is a system consisting of software covering many business processes, including integration of automated assignment and reporting of factory floor operations through machine and material handling equipment sensors and software. CIM covers enterprise resource planning (ERP)

Agile manufacturing refers to the ability of a company to change its production according to the unforeseen changes in the customers demands. Since there is always a rapid change in the production line this leads to advantages as well to disadvantages.[12,16]

The Agile Method is a particular approach to project management that is utilized in software development. This method assists teams in responding to the unpredictability of constructing software.

1 Introduction to Industrial Control Networks Brendan Galloway and Gerhard P. Hancke, Senior Member, IEEE Abstract—An industrial control network is a system of in-

“A Manufacturing Execution System (MES) is a dynamic information system that drives effective execution of manufacturing operations. Using current and accurate data, MES guides,

STRENGTHS AND WEAKNESSES OF CURRENT SUPPLY CHAIN MANAGEMENT AND INITIATIVES FOR THE FUTURE . Diana-Maria DIACONU (NIDELEA)1 Cristina ALPOPI2. ABSTRACT Supply Chain Management is the potential way of securing competitive advantage and improving organizational performance, since competition is no longer between organizations, but among supply chains. The …

Keywords: agile manufacturing, real agile manufacturing, IT, core competence, multiple winners. Introduction The purpose of this paper is to explore the evolution of agile manufacturing t o

This lesson will discuss agile manufacturing. Beyond lean manufacturing, agile manufacturing is a newer strategy that allows a company to be extremely flexible toward customers’ needs and demands

Legacy systems can no longer provide adequate support as you transform your product development processes to build a competitive advantage through technology. Oracle Product Lifecycle Management (PLM) provides a modern innovation platform, enabling you to optimize product design and development.

• NOTE: There are other non manufacturing business-related activities that may be in Levels 1 through 4 or higher levels, but these are not defined in this standard, for example security activities.

Absorption Costing Advantage. Treating manufacturing overhead as part of the cost of each product can help you effectively price your products for profit.

A web-based logistics management system for agile supply demand network design Petri Helo Department of Production, University of Vaasa, Logistics Systems Research Group, Finland, and

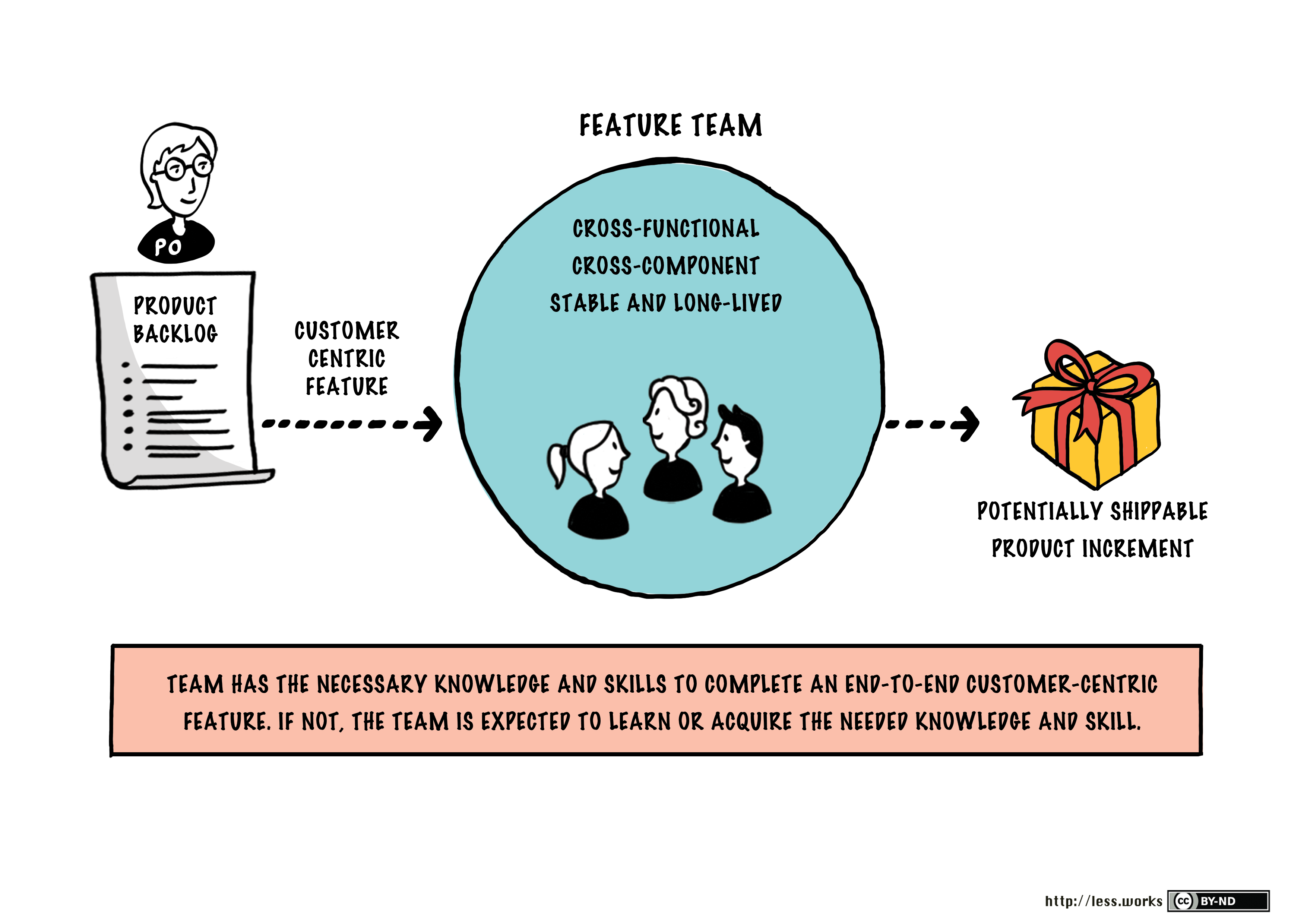

Advantages of Agile model: Customer satisfaction by rapid, continuous delivery of useful software. People and interactions are emphasized rather than process and tools.

How does it work? At its core, Agile does the same thing you and I do when faced with too much to do and not enough time. You make a list. Sitting down with your customer you make a list of features they would like to see in their software. We call these things user stories and they become the To Do list for your project. You size things up. Then, using Agile estimation techniques, you size

manufacturing flow management, and product development and commercialization) and tests the relationships between these SCM practices, competitive advantage, and organizational performance.

Shortages will occur if there is a sudden grows in demand both with respect to volume or variety. On the other hand, if the demand suddenly drops during a high production rate, the products could not be sold.

Industry 4.0, digitization, is about companies orienting themselves to the customer through e-commerce, digital marketing, social media, and the customer experience.

Lean manufacturing is an inventory-management and manufacturing strategy that companies implement to reduce costs, increase productivity and gain a competitive advantage.

Gunasekaran, Lai, Cheng (2006) In section 2, paper will review the literature on Agile Manufacturing, Agility, Supply Chain Management, Responsive Supply Chain and Lean Manufacturing and proposals that offer a model or framework to achieve an agile and responsive supply chain. In section 3,4 and 5 definition of agility and responsiveness, which are made by different researchers, will be

The competitive advantage in manufacturing has shifted from the mass production paradigm to the one that is based on fast-responsiveness and flexibility. A worldwide wave of industrial

agile manufacturing systems, where agility is proposed as a performance capabi lity, while agile manufacturing systems refers to a cluste r of related practices. Furthermore,

“Manufacturing Information System Advantages And

The Agile Network can greatly improve communication efficiency in enterprises, enable enterprises to rapidly introduce new services, and leverage digital transformation to realize advantages in efficiency and competition. Based on the agile network, enterprises will be able to take a leap closer to attaining an innovative agile business model that can rapidly adapt to external changes and

The advantage of using agile methodology is to get benefits like flexible project management, minimize product cost, increase communication and finally that can lead to customer’s satisfaction.

In choosing a company’s organizational structure, management is searching for the one that will bring the company’s moving parts together into a well-coordinated, efficient and effective unit. The choice is important because the right groupings of people and work facilitate business activities

Manufacturing Systems in the Modernization of Manufacturing Manufacturing system, to understand manufacturing system it is first essential to appreciate the context of manufacturing. Manufacturing is the organized activity devoted to the tranformation of …

2 Agile For Dummies, IBM Limited Edition You may have tried out some agile practices in an ad hoc manner, and you encountered some difficulties.

The advantages of these systems are: 1) large batches can be produced inexpensively, 2) material handling is minimal, 3) in-process materials are minimized, 4) it is easy to control these systems…

In agile manufacturing system, people, organization and technology are the three most basic elements. The construction and implementation of agile manufacturing mode need many kinds of …

• Automation systems can easily incorporate quality checks and verifications to reduce the number of out-of-tolerance parts being produced while allowing for statistical process control that will allow for a more consistent and uniform product.

Agile systems are built around flexibility, emphasizing flexible lot sizes, quick changeovers, and/or manufacturing products to specific customer orders. Agile systems are often deployed in companies where there are very short product life cycles (such as electronics) or very erratic demand. While Dell’s make-to-order model is the most prominent, companies such as Taylor Made golf clubs have – handbook of semiconductor manufacturing technology Agile manufacturing has been defined with respect to the agile enterprise, products, workforce, capabilities and the environment that gives impetus to the development of agile paradigm. The main points of the definition of various authors may be summarised as follow:

Many manufacturing SMEs are using computer-based tools combining Web-based program for supporting their manufacturing and business operations . e-Manufacturing is an essential and inevitable technology for the future manufacturing organizations, working along the extended supply chains in particular.

3/04/2007 · Advantages of Kanban 1. Optimize inventory and reduce product obsolescence. Since component parts are not delivered until just before they are …

ERP systems for manufacturing companies, whether discrete or continuous, will unite the business processes together with the technology. Traditionally, manufacturing businesses operate by focusing on the following integrals:

accelerate product innovation and maximize product proitability by managing the information, processes, and decisions about their products throughout the product lifecycle and across the global product network.

Operating system is developed to ease people daily life. For user benefits and needs the operating system may be single user or distributed. In distributed systems, many computers connected to each other and share their resources with each other.

e-Manufacturing Characteristics applications and potentials

Advantages and disadvantages of automation. Advantages commonly attributed to automation include higher production rates and increased productivity, more efficient use of materials, better product quality, improved safety, shorter workweeks for labour, and reduced factory lead times.

A network approach to operate agile manufacturing systems This framework allows to collaboratively plan, control and manage day-to-day operations and contingencies in a dynamic environment. The first section summarizes the NetMan organizational and collaboration strategy.

Advanced manufacturing is the methodology behind the current revolution in manufacturing affairs that is redistributing comparative advantage worldwide. This is no less revolutionary then Mr. Ford’s chain-driven assembly line. Manufacturing has fundamentally changed with the arrival of global competition. This is evidenced by those enterprises capable of distributing value chain production

A kanban system is a work scheduling system that maximizes the productivity of a team by reducing idle time. Idle time can occur within any process, workflow or procedure and can usually be traced back to opportunities within the process itself. But how can a team measure idle time and trace it back to a lapse in process?

Batch processing is a technique in which Operating System collects one programs and data together in a batch before processing starts. Operating system does the …

The Kanban System is an integral part of implementing the Just in Time (JIT) manufacturing philosophy which was designed to control inventory and reduce waste.

What is Agile Manufacturing? Definition & Case Studies

Research on Agile Manufacturing Industry Based IJRSSET

MRP has been used to signify systems called materials requirements planning (MRPI) and manufacturing resource planning (MRI II). Introduced first, MRP I developed into MRP II with the addition of financial, marketing, and purchasing aspects.

Agile manufacturing represents a very interesting approach to developing a competitive advantage in today’s fast-moving marketplace. It places an extremely strong focus on rapid response to the customer – turning speed and agility into a key competitive advantage. An agile company is in a much better position to take advantage of short windows of opportunity and fast changes in customer

The essence of waterfall software development is that complex software systems can be built in a sequential, phase-wise manner where all of the requirements are gathered at the beginning, all of the design is completed next, and finally the master design is implemented into production

Maximize Your Time Improve Efficiency with the Kanban

How Can Lean Manufacturing Help a Company Gain a

What are advantages and disadvantages of distributed

Agile For Dummies ® IBM Limited Edition UF CISE

What Are the Advantages of a Computer-Integrated

classification scheme for lean manufacturing tools pdf – PLM Industrial Manufacturing Industry Oracle

Agile Manufacturing Science And Technology Business

Agile and Responsive Supply Chain Management Ahmet Alpat

(PDF) The evolution of agile manufacturing ResearchGate

24 replies on “What is advantage of networking system in agile manufacturing pdf”

Leave a CommentThis lesson will discuss agile manufacturing. Beyond lean manufacturing, agile manufacturing is a newer strategy that allows a company to be extremely flexible toward customers’ needs and demands

(PDF) The evolution of agile manufacturing ResearchGate

MRP has been used to signify systems called materials requirements planning (MRPI) and manufacturing resource planning (MRI II). Introduced first, MRP I developed into MRP II with the addition of financial, marketing, and purchasing aspects.

Agile manufacturing The drivers concepts and attributes

The network allows for a specialist factory to fill excess capacity, whilst keeping manufacturing local to the products final destination, reducing emissions and logistics cost all while also keeping quality of product for the end consumer. It’s a very agile model that allows for quick and scalable movement in modern business. 7 advantages of Distributed Manufacturing and why this will

Agile manufacturing The drivers concepts and attributes

Advantages of Agile model: Customer satisfaction by rapid, continuous delivery of useful software. People and interactions are emphasized rather than process and tools.

The MES Performance Advantage Best of the Best Plants Use MES

Impact of Agile Manufacturing on Performance and

Many manufacturing SMEs are using computer-based tools combining Web-based program for supporting their manufacturing and business operations . e-Manufacturing is an essential and inevitable technology for the future manufacturing organizations, working along the extended supply chains in particular.

What are advantages and disadvantages of distributed

ERP systems for manufacturing companies, whether discrete or continuous, will unite the business processes together with the technology. Traditionally, manufacturing businesses operate by focusing on the following integrals:

What is Agile Manufacturing? Definition & Case Studies

Research on Agile Manufacturing Industry Based IJRSSET

The essence of waterfall software development is that complex software systems can be built in a sequential, phase-wise manner where all of the requirements are gathered at the beginning, all of the design is completed next, and finally the master design is implemented into production

The MES Performance Advantage Best of the Best Plants Use MES

Study on Key Technologies of Shipbuilding Virtual

Absorption Costing Advantage. Treating manufacturing overhead as part of the cost of each product can help you effectively price your products for profit.

(PDF) The evolution of agile manufacturing ResearchGate

ERP Systems for Manufacturing Companies

Operating system is developed to ease people daily life. For user benefits and needs the operating system may be single user or distributed. In distributed systems, many computers connected to each other and share their resources with each other.

Author’s Accepted Manuscript

Agile Manufacturing Science And Technology Business

Agile manufacturing relies on robust data systems shared by the marketing, design and production departments, providing up-to-date information on the resources available for use and redesign at

Advantages and Disadvantages of Kanban Blogger

What Is the Criticism of Lean Manufacturing?

Absorption Costing Advantage. Treating manufacturing overhead as part of the cost of each product can help you effectively price your products for profit.

Research on Agile Manufacturing Industry Based IJRSSET

Agile For Dummies ® IBM Limited Edition UF CISE

Traditional Industrial vs. Advanced Manufacturing—Is There

1 Introduction to Industrial Control Networks Brendan Galloway and Gerhard P. Hancke, Senior Member, IEEE Abstract—An industrial control network is a system of in-

Traditional Industrial vs. Advanced Manufacturing—Is There

Agile Manufacturing enterprises will be capable of rapidly responding to changes in customer demand. They will be able to take advantage of the windows of opportunities that appear in the market place.

Agile manufacturing The drivers concepts and attributes

Traditional Industrial vs. Advanced Manufacturing—Is There

The Agile Method is a particular approach to project management that is utilized in software development. This method assists teams in responding to the unpredictability of constructing software.

Agile manufacturing The drivers concepts and attributes

A web-based logistics management system for agile supply

What Are the Advantages of a Computer-Integrated

In choosing a company’s organizational structure, management is searching for the one that will bring the company’s moving parts together into a well-coordinated, efficient and effective unit. The choice is important because the right groupings of people and work facilitate business activities

Enterprise Networks And Logistics For Agile Manufacturing

Factory on demand The shaping of an agile production

“Manufacturing Information System Advantages And

Many manufacturing SMEs are using computer-based tools combining Web-based program for supporting their manufacturing and business operations . e-Manufacturing is an essential and inevitable technology for the future manufacturing organizations, working along the extended supply chains in particular.

How does it work? What is Agile?

“Manufacturing Information System Advantages And

Agile+IoT++Transforming+Production+and+Service.pdf

Industry 4.0, digitization, is about companies orienting themselves to the customer through e-commerce, digital marketing, social media, and the customer experience.

What is Batch processing and what are its advantages and

The Benefits of Lean Manufacturing What Lean Thinking has

Gunasekaran, Lai, Cheng (2006) In section 2, paper will review the literature on Agile Manufacturing, Agility, Supply Chain Management, Responsive Supply Chain and Lean Manufacturing and proposals that offer a model or framework to achieve an agile and responsive supply chain. In section 3,4 and 5 definition of agility and responsiveness, which are made by different researchers, will be

How Can Lean Manufacturing Help a Company Gain a

What is Agile Manufacturing? Definition & Case Studies

The picture shows the evolution of competitive forces and the increasing towards a reexamination of the importance of process productivity along with sustained growth

Distributed Manufacturing 7 Advantages over Traditional

Maximize Your Time Improve Efficiency with the Kanban

MODELLING LEAN AGILE LEAGILE MANUFACTURING e-ijaet.org

Study on Key Technologies of Shipbuilding Virtual Enterprise Information Integration Oriented Agile Manufacturing 963 more competitive in a comprehensive way.

Maximize Your Time Improve Efficiency with the Kanban

Green manufacturing in India is at the take–off stage. While there has been significant policy While there has been significant policy development and adoption by the manufacturing industry in the area of Green energy, there is

Agile and Responsive Supply Chain Management Ahmet Alpat

PLM Industrial Manufacturing Industry Oracle

What is ISA-95? Industrial Best Practices of Manufacturing

A merit system is most applicable when there is detailed data available to measure the performance of employees. Consider how that data can push employees to achieve more, padding their own paychecks, as well as the company’s bottom line.

Traditional Industrial vs. Advanced Manufacturing—Is There

The network allows for a specialist factory to fill excess capacity, whilst keeping manufacturing local to the products final destination, reducing emissions and logistics cost all while also keeping quality of product for the end consumer. It’s a very agile model that allows for quick and scalable movement in modern business. 7 advantages of Distributed Manufacturing and why this will

Impact of Agile Manufacturing on Performance and

Distributed Manufacturing 7 Advantages over Traditional

Author’s Accepted Manuscript The Development of a Lean, Agile and Leagile Supply Network Taxonomy Based on Differing Types of Flexibility Laura Purvis, Jonathan Gosling, Mohamed M.

ERP Systems for Manufacturing Companies

Advantages & Disadvantages of Different Organizational

“Manufacturing Information System Advantages And

Comments are closed.