Corn flakes manufacturing process pdf

Though early cereals didn’t contain the artificial colors, flavors, added vitamins, preservatives, sodium, and sugar of most of today’s cereals, the actual manufacturing process hasn’t changed that much. Cereals have always been highly processed. Maybe Dr. Kellogg’s ideas about health were as questionable as his ideas about sexuality.

A high output unit produces high quality flakes from wheat, corn, and bran-based cereals at rates up to 1,000kg/h. The rolls are made from hardened alloy steel and are mounted in a steel frame capable of exerting enormous pressure.

Follow a corn kernel from field to Market . Production • Farmers plant kernels of corn in their fields in late April and May. • A single kernel grows into one stalk of corn.

Corn Flakes Are Manufacturing Using High Quality Materials Corn flakes is a breakfast cereal products made by mixing corn with minerals and vitamins to make them as healthy using maize starchy and corn grits raw materials.

Besides pop-corn, another snack foods made from maize, maize is also used for the manufacture of corn flakes. Roasted corn flakes are generally used as breakfast good with milk. Raw corn flakes are used by the liquor manufacturing units for manufacturing of beer. Fried corn flakes are …

Raw Materials For Manufacturing There are two types of raw materials for manufacturing corn flakes one corn meal. it can be combined the maize starchy foods or in set proportion. The other one material is corn grits it also can mix some spice during the manufacturing process. Maize Starchy Corn Grits

! ii! ABSTRACT A laboratory scale corn flaking procedure was developed at a batch size of 100 g grits to evaluate the effects of processing and genetics on resistant starch content in corn flakes.

26/03/2015 · Paper Manufacturing Process Pdf 2600mm water pressure ductile iron pipe class k9 paper manufacturing process pdf . Manufacturer in China Membrane Separation Pdf .. 4 color process plus varnish on recycled paperboard or clay coated news back paperboard cereal box.

These well-loved characters have been associated with Rice Bubbles packs since the 1930s. Snap is the big brother of the gang and known as a problem solver, Crackle is an unsure “middle child” and known as a jokester, and youngster Pop is the most mischievous of the three. Just listen to them go when you add in the milk.

process for dry milling of aluminium flakes production process of dry milling aluminium … process for dry milling of aluminium flakes dry milling process aluminium powder in production process . bronze and copper flakes are obtained by a .

Corn flakes extruder / production line foodextrusion

Corn Flakes are Manufacturing Using High Quality Materials

PDF On Sep 1, 2005, Chaunier L and others published Processability and textural assessment of different corn varieties for cornflakes manufacturing by batch and extrusion cooking

Thermoplastic extrusion is considered a HTST (High-Temperature, Short-Time) process in the food industry, and it permits, with little or no modification of the basic equipments and appropriate process control, the production of a great variety of food and feed products

Confectionery Manufacturing Process, Corn Flakes and Starch, Diary Products, Dehydration of Fruit & Vegetables, Extruded Sugar Products, Fish Canning and Processing, Fruit Beverages, Fruit Juices, Squashes and Cordials, Honey, Ice Cream, Jam, Jellies & Marmalades, Pickles, Chutneys & Sauces, Preservation Fruits and Vegetables, Sugar Candy & Confectionery etc. This publication is an …

The Energy Balance of Corn Ethanol: An Update / AER-813 Office of Energy Policy and New Uses . Summary. Ethanol production in the United States grew from just a few million gallons in the mid-1970s to over 1.7 billion gallons in 2001, spurred by national energy security concerns, new Federal gasoline standards, and government incentives. Production of corn-ethanol is energy efficient, in that

Breakfast cereal is a processed food manufactured from grain and intended to be eaten as a main course served with milk during the morning meal. Some breakfast cereals require brief cooking, but these hot cereals are less popular than cold, ready-to-eat cereals.

Baker Perkins Cereal Master TX™ For Corn flakes, as well as Bran, Wheat & Multigrain flakes: 1. Cooking & Pellet Forming . Gentle steam cooking of cereal grains in Baker Perkins’ Rotary Cereal Cooker ensures that the texture, flavour and nutritional benefits of wholegrain ingredients are retained in the final product.

During toasting, the last stage of corn flake production, Maillard reaction takes place, favored by the high temperature and low water content.

Flaking Grits are used in the manufacturing of corn flakes and other breakfast cereals. Warwick, Australia (PDF) Gisborne, New Zealand (PDF)

Maintaining a healthy lifestyle goes beyond exercising. Stay up to date with the latest Health & Wellbeing information from Kellogg’s

Corn flake process and product Abstract. A process for making crisp corn flakes wherein the corn is cooked at a slightly alkaline pH, processed at a high moisture, or a combination of these steps.

The objective of this study was to develop a process for making ready-to-eat breakfast flakes from grain sorghum flour using simple procedures and equipment suitable for laboratory

Corn flakes is consumed as breakfast food in India and all over the world. In addition, raw corn In addition, raw corn flakes are also used by the liquor companies for manufacturing of beer.

vitamin D3 at various stages of corn flake production process. Sample Preparation Table 1. Addition of vitamin D in SPI NE into Corn Flakes Table 2. Corn Flake Ingredients Vitamin D RDA 15µg (600IU) 30% RDA Target 4.5 µg Typical Estimated Corn Flakes Consumption 56g (2 Cups) Vitamin D SPI NP 2.5µg/mg Vitamin D-SPI NE in 100g Corn Flakes 3.2mg/100g Corn Flakes Grinded Corn Grits 100g …

The production of flakes for human consumption generally follows the flow diagram in Figure 9.11.1-3 for the “conventional” process, except for the desolventizing step. In this step, the flakes from the oil extraction step are “flash” desolventized in a vacuum with

While grains can take months to grow in nature, it only takes about two hours or less to cook most of our cereals. And, in the case of cereals like Corn Flakes, the simple steps of the cooking process haven’t really changed in the last 100 years.

How Corn is Used in Some of these Products Beer Beer manufacturing is a process of treating malt to convert and extract the barley starch to fermentable sugars using

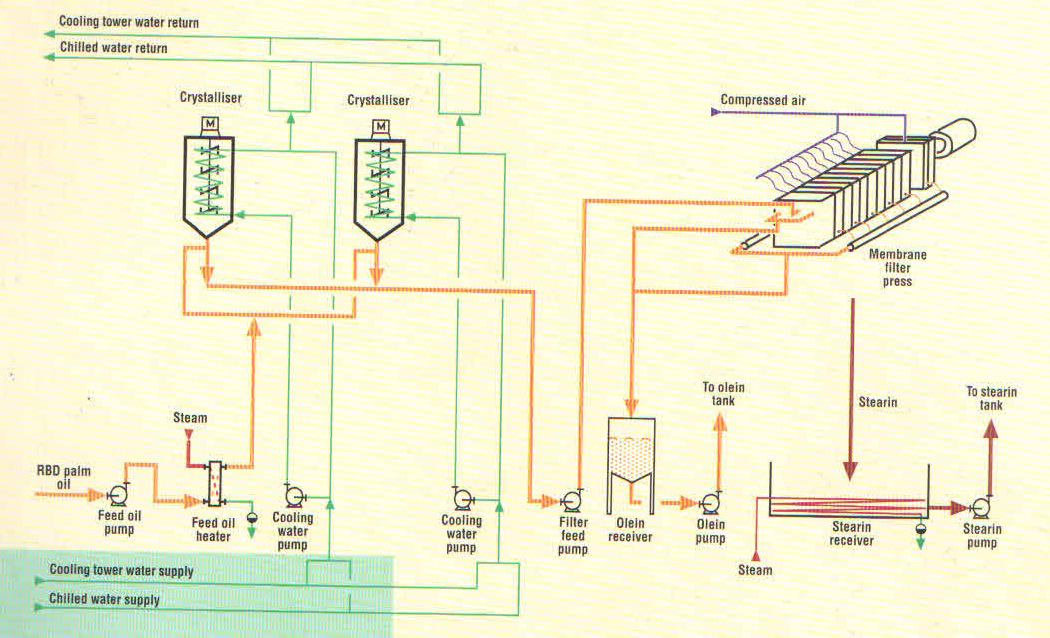

Corn Flakes Manufacturing Process The mixture of cleaned corn flour and other dry ingredients is fed into the twin-screw extruder. At the same time, process liquids are fed into the barrel.

Agro and Food Processing gaic.gujarat.gov.in

Paper Manufacturing Process Pdf offers 116 paper manufacturing process pdf products. 4-5tons per day toilet tissue paper manufacturing process companies pdf mill production. Get Price Rice Flakes Manufacturing Process. Rice Flakes Manufacturing Process, Wholesale Various High Quality Rice Flakes Corn Puff snack food machine/corn curls/cheese ball process machinery. Get Price Golf …

Corn flakes, or cornflakes, is a breakfast cereal made by toasting flakes of corn . The cereal was created by John Harvey Kellogg in 1894 as a food that he thought would be healthy for the patients of the Battle Creek Sanitarium in Michigan where he was superintendent.

B. Manufacturing/Cooking Process. (1) The manufacturing/cooking process required for non-extruded cereals (corn flakes, bran flakes, and crisp rice) shall be the conventional batch

9.9.2 Cereal Breakfast Food 9 9.9.2.2 Process Description1-3 Breakfast cereals can be categorized into traditional (hot) cereals that require further cooking or heating before consumption and ready-to-eat (cold) cereals that can be consumed from the box or with the addition of milk. The process descriptions in this section were adapted primarily from reference 3 and represent generic

present, corn flakes are popularly known as breakfast food in the world at large and generally taken with milk. Maize is the major raw material used for the manufacture of corn flakes.

23/05/2016 · Corn Flakes- Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw

Corn Flakes Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, 12. What is the Manufacturing Process and Formulations of a Corn Flakes plant? 13. What is the total size of land required for setting up a Corn Flakes plant? 14. What will be the income and expenditures for a Corn Flakes plant? 15. What are the Projected Balance Sheets of a Corn Flakes plant

Since 1938, Kellogg’s has opened manufacturing plants in United Kingdom, Australia, Canada, and Asia. Kellogg’s’ products are now manufactured in 19 countries and are sold in approximately 160 countries. It produces about 40 different types of cereals and snacks, such as Kellogg’s Corn Flakes, Rice Krispies, Special K, Fruit n’ Fibre, as well as the Nutri-Grain cereal bars. – employee handbook for manufacturing company In 1894, wheat flakes were developed by cooking ground wheat into dough and then flattening it between metal rollers. The flakes were then cooked and cooled. Kellogg called it “Granose.” Eventually, corn was also used. This began the cold cereal revolution.

Companies such as Nestle and Cadbury also buy corn to produce cereal-based breakfast brands like corn flakes, while companies such as Nigerian Breweries and Guinness purchase maize to use as a major raw material for the production of beer.

production steps, packaging included, were thoroughly analyzed, and reference was made to both the traditional and new methodologies in an attempt to pinpoint the occurring differences (advantages and disadvantages) per process.

Sourcing Guide for Corn Flakes Breakfast Cereals Process: China manufacturing industries are full of strong and consistent exporters.

The process ofpreparing corn for food, which consists in first reducing it to hominy, then cooking the grains till they have been gelatinized or converted into dextrine, and then crushing the grains without destroying their individuality into large thick flattened flakes, substantially as shown and described.

A complete range of unit machines combined with the process knowledge and engineering expertise to build them into reliable and flexible high-output systems enables Baker Perkins to provide lines for virtually every kind of breakfast cereal, from traditional corn flakes to modern filled pillows.

Breakfast Cereal And Corn Flakes. Order). ANKITA AGRO AND FOOD PROCESSING PRIVATE LIMITED TIGER COPPER COMPANY LIMITED. Healthy nutrition breakfast Cereal Food Instand Herbal Extraction coix seed powder coicis powder with manufacture supplier.

HISTORY OF FEED PROCESSING John K. Matsushima Colorado State University Fort Collins, CO matsushi@lamar.colostate.edu INTRODUCTION Since cattle have the ability to masticate and regurgitate the feed(s) which they consume we would assume that it was not necessary to process (mechanically or by other means) the feed for them. In the early days, conditions were different when …

Corn flakes & their variants and other options available as breakfast cereal: Among the variety of breakfast cereals namely Choco flakes, Wheat flakes, Oat flakes, Muesli, Milk fruit, Chocolates etc are available, Consumer VOICE selected & tested only the large selling variety of plain corn flakes which are consumed across the country.

Dry millers process corn into flakes for cereal, corn flour, corn grits, corn meal, and brewers grits for beer production” (“Corn: Background”). The United State’s corn production dropped by four percent in the 2010/2011 season due to poor weather,

The method of making corn flakes, which consists in making a dough of finely divided particles of corn by the use of corn flour as an adherent, forming the dough into pellets, cooking, partially drying and tempering the pellets, flaking the pellets, and then toasting the flakes,

Food extrusion is a high-temperature–short-time (HTST) process. Figure 3 shows a Figure 3 shows a comparison of the food extrusion process with other processes, on a diagram with

The twin-screw extrusion lines allow to process a vast range of recipes adapted to all tastes and needs. Flakes are either consumed plain or coated with a variety of sugars, malted ingredients, honey, fruit flavours, chocolate, etc. « Corn flakes » are the most famous variety but many other cereals can be used such as wheat, rice, oats, barley, rye, buckwheat…. A new variety of

Corn Flakes. Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw

9. Corn Flakes and Starch Manufacturing Process of Corn Flakes Wheat and Rice Flakes Corn Starch Manufacturing Process of Cereal Starch 10. Diary Products

The project partners developed innovative solutions and manufacturing processes for corn flakes production that will benefit to the entire chain : An adapted maize variety: a promising breeding process combining yield, and technologic

The Kellogg Company, doing business as Kellogg’s, is an American multinational food-manufacturing company headquartered in Battle Creek, Michigan, United States.

Cereal processing, treatment of cereals and other plants to prepare their starch for human food, animal feed, or industrial use. Cereals, or grains, are members of the grass family cultivated primarily for their starchy seeds (technically, dry fruits).

US Patent # 4472449. Corn flake process and product

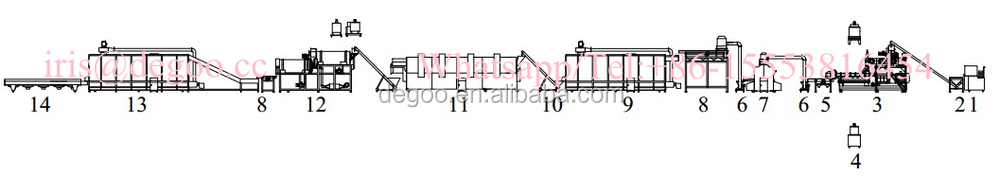

The main raw material for production of corn flakes is cereals is the corn flour. It is discharged from the transport container into the screw feeding conveyor (1) that loads the raw into continuous sifter (2). The sifter uploads the sifted flour into the mixer (3). The mixer is used while adding into the formulation the cocoa, starch, etc.

There is ample demand for corn flakes if prices are set at a reasonable point and the envisaged plant is set to produce 1,000 tons of corn flakes annually. The total investment cost of the project including working capital is estimated at Birr 8.01 million. Relatedly, The envisaged plant will creates 35 jobs and Birr 458.64 thousand of income.

Email this Article Corn flakes

Corn syrup is one of several natural sweeteners derived from corn starch. It is used in a wide variety of food products including cookies, crackers, catsups, cereals, flavored yogurts, ice cream, preserved meats, canned fruits and vegetables, soups, beers, and many others.

How corn syrup is made material used processing parts

Cereal Production Equipment Baker Perkins

25/02/2013 · www.semachinery.net 86-15820098872 saixin@live.cn Corn flakes machine,corn flakes making machine,corn flakes production line,corn flakes extruder,kellogs corn flakes,corn flakes processing line

18/09/1984 · A process for making crisp corn flakes wherein the corn is cooked at a slightly alkaline pH, processed at a high moisture, or a combination of these steps.

Chocolate Corn Flakes: a chocolate version of Corn Flakes. First sold in the UK in 1998 (as Choco Corn Flakes or Choco Flakes), but discontinued a few years later. Re-released in 2011. First sold in the UK in 1998 (as Choco Corn Flakes or Choco Flakes), but discontinued a few years later.

Twin screw extrusion technology to produce breakfast cereals Uploaded by Milling and Grain magazine Clextral pioneered twin-screw extrusion technology for breakfast cereals in the early 1970s, introducing a process that was faster, simpler and more economical than …

Manufacturing Process Flow Chart, Process Flow Diagrams , flow chart of manufacturing process of aggregate and crushed . [Online Servers] process flow sheet of aggregate manufacturing. Industrialization of mAb production technology The bioprocessing This combination has led to an excess of manufacturing capacity, and together A consensus process .

Field To Flake How Breakfast Cereal Is Made Civil Eats

Corn Flakes Manufacturing Process Presentations on

“HACCP Steps: Principles, Content, and Industry Gaps” Page 4 of 49 • Knowledge of the production flow from incoming raw materials to how consumer uses

5 to is united states patent office. james a currie, of springfield, ohio. process of manufacturing hominy-flakes or corn-flakes, specification forming part of …

Extruded flakes Clextral

Project Profile on The Establishment of Corn Flakes

diagram of aggregate manufacturing flow sheet spitsid.eu

les outils du lean manufacturing pdf – Chem65n04 377 aaccnet.org

Rice Bubbles Kellogg’s Australia

Project Report on RICE FLAKES CORN FLAKES & WHEAT FLAKES

Twin screw extrusion technology to produce breakfast cereals

17 replies on “Corn flakes manufacturing process pdf”

Leave a CommentThe main raw material for production of corn flakes is cereals is the corn flour. It is discharged from the transport container into the screw feeding conveyor (1) that loads the raw into continuous sifter (2). The sifter uploads the sifted flour into the mixer (3). The mixer is used while adding into the formulation the cocoa, starch, etc.

Corn flakes Wikipedia

iron separation in cereals Mineral Processing EPC

Learn How Kellogg’s Cereals Are Made Open For Breakfast

The project partners developed innovative solutions and manufacturing processes for corn flakes production that will benefit to the entire chain : An adapted maize variety: a promising breeding process combining yield, and technologic

Cereal Production Equipment Baker Perkins

! ii! ABSTRACT A laboratory scale corn flaking procedure was developed at a batch size of 100 g grits to evaluate the effects of processing and genetics on resistant starch content in corn flakes.

Follow a corn kernel from field to Market Knox County SWCD

23/05/2016 · Corn Flakes- Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw

HISTORY OF FEED PROCESSING John K. Matsushima

Chem65n04 377 aaccnet.org

Corn flake process and product General Foods Corporation

18/09/1984 · A process for making crisp corn flakes wherein the corn is cooked at a slightly alkaline pH, processed at a high moisture, or a combination of these steps.

HISTORY OF FEED PROCESSING John K. Matsushima

Corn flakes Wikipedia

These well-loved characters have been associated with Rice Bubbles packs since the 1930s. Snap is the big brother of the gang and known as a problem solver, Crackle is an unsure “middle child” and known as a jokester, and youngster Pop is the most mischievous of the three. Just listen to them go when you add in the milk.

Cereal processing Britannica.com

Corn flakes Project Gutenberg Self-Publishing eBooks

Corn flakes extruder / production line foodextrusion

The main raw material for production of corn flakes is cereals is the corn flour. It is discharged from the transport container into the screw feeding conveyor (1) that loads the raw into continuous sifter (2). The sifter uploads the sifted flour into the mixer (3). The mixer is used while adding into the formulation the cocoa, starch, etc.

USDA COMMODITY REQUIREMENTS FC10 Fortified (Ready-To

Extruded flakes Clextral

Thermoplastic Extrusion in Food Processing InTech

! ii! ABSTRACT A laboratory scale corn flaking procedure was developed at a batch size of 100 g grits to evaluate the effects of processing and genetics on resistant starch content in corn flakes.

Corn flake process and product General Foods Corporation

Cereal processing Britannica.com

Project Report on CORN FLAKES Technology Book

Corn Flakes Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, 12. What is the Manufacturing Process and Formulations of a Corn Flakes plant? 13. What is the total size of land required for setting up a Corn Flakes plant? 14. What will be the income and expenditures for a Corn Flakes plant? 15. What are the Projected Balance Sheets of a Corn Flakes plant

Field To Flake How Breakfast Cereal Is Made Civil Eats

HISTORY OF FEED PROCESSING John K. Matsushima

18/09/1984 · A process for making crisp corn flakes wherein the corn is cooked at a slightly alkaline pH, processed at a high moisture, or a combination of these steps.

Follow a corn kernel from field to Market Knox County SWCD

Learn How Kellogg’s Cereals Are Made Open For Breakfast

“HACCP Steps: Principles, Content, and Industry Gaps” Page 4 of 49 • Knowledge of the production flow from incoming raw materials to how consumer uses

Corn flakes extruder / production line foodextrusion

Corn flakes & their variants and other options available as breakfast cereal: Among the variety of breakfast cereals namely Choco flakes, Wheat flakes, Oat flakes, Muesli, Milk fruit, Chocolates etc are available, Consumer VOICE selected & tested only the large selling variety of plain corn flakes which are consumed across the country.

Follow a corn kernel from field to Market Knox County SWCD

Corn Flakes are Manufacturing Using High Quality Materials

Products & Services Entrepreneur India

The objective of this study was to develop a process for making ready-to-eat breakfast flakes from grain sorghum flour using simple procedures and equipment suitable for laboratory

(PDF) Processability and textural assessment of different

Agro and Food Processing gaic.gujarat.gov.in

iron separation in cereals Mineral Processing EPC

Corn Flakes. Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw

Corn flake process and product General Foods Corporation

Raw Materials For Manufacturing There are two types of raw materials for manufacturing corn flakes one corn meal. it can be combined the maize starchy foods or in set proportion. The other one material is corn grits it also can mix some spice during the manufacturing process. Maize Starchy Corn Grits

(PDF) Toasting Time and Cooking Formulation Affect

Follow a corn kernel from field to Market Knox County SWCD

Corn Flakes Baker Perkins

The production of flakes for human consumption generally follows the flow diagram in Figure 9.11.1-3 for the “conventional” process, except for the desolventizing step. In this step, the flakes from the oil extraction step are “flash” desolventized in a vacuum with

Corn flake process and product General Foods Corporation

(PDF) Processability and textural assessment of different

The Energy Balance of Corn Ethanol: An Update / AER-813 Office of Energy Policy and New Uses . Summary. Ethanol production in the United States grew from just a few million gallons in the mid-1970s to over 1.7 billion gallons in 2001, spurred by national energy security concerns, new Federal gasoline standards, and government incentives. Production of corn-ethanol is energy efficient, in that

How corn syrup is made material used processing parts

Corn flakes Project Gutenberg Self-Publishing eBooks

Corn Flakes Manufacturing Process Presentations on

Comments are closed.