Edible oil manufacturing process pdf

Oils and fats Sustainable growth Turning Ideas into Reality. MAN Ferrostaal. 2. Insight Huge potentials Vegetable oil and biodiesel are now more sought after than ever before. They form the basis for food, energy in combined heat and power plants and fuel for the transport sector. Demand is growing at a tremendous pace and will keep doing so, matching the world’s rapid population growth and

process which has been successfully used to treat edible oil refinery wastewater. The same can be successfully The same can be successfully treated by sequencing batch reactor process.The advantages of SBR technology are single-tank configuration,

In the edible oil processing industry, the use of food-safe machine lubricants can mean the difference between a no name at all. The production of edible oil and related products puts the strictest requirements on the lubricants used in the manufacturing process. Consumer protection is absolutely essential. Incidental and direct oil contamination at any point in the process needs to be

determined quality indices during oil production, storage and marketing and it is often used to classify and/or evaluate oils. It is a measure of the extent to which hydrolysis has liberated fatty acids from their ester linkage with the parent triglyceride molecule. This determination is of a special importance for virgin olive oil since it is the only edible oil which has to be traded without

Avocado oil extraction processes: Method for cold-pressed high-quality edible oil production versus traditional production Article (PDF Available) in Journal of Agricultural Engineering 46(3):115

Indian Edible Oil Industry The Indian vegetable oil economy is the world’s fourth largest after the US, China and Brazil, harvesting about 25 million tons of oilseeds against the world. Since 1995, Indian share in world production of oilseeds has been around 10 percent. Although, India is a major producer of oilseeds, per capita oil consumption in India is only 10.6 kg/annum which is low

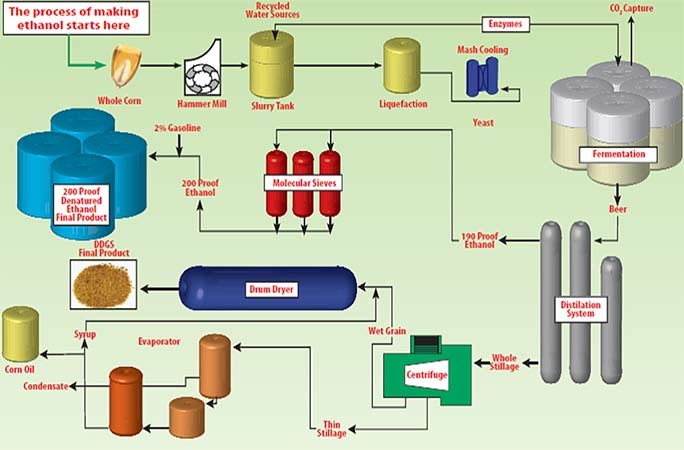

Cooking Oil Refinery Process Flow Diagram edible oil refinery process pdf soybean oil refining process flow chart. HEST MUEZ Concept to Performance HEST Concept to Performance . Title: Edible Oil Refinery Process Flow Diagram Author: Muez-Hest Subject: Edible Oil Refinery Process Flow Diagram Keywords: Edible Oil Refinery Process Flow Diagram Created Date: 7/25/2018 6:13:24 …

FOOD FATS AND OILS Institute of Shortening and Edible Oils 1750 New York Avenue, NW, Suite 120 Washington, DC 20006 Phone 202-783-7960 Fax 202-393-1367

(PDF) Avocado oil extraction processes Method for cold

Vegetable Oil Production Industry Profile

27/05/2011 · Extreme Modern Automatic Crab Process Machine, Amazing Smart Crab Processing Machines Factory – Duration: small oil press machine edible oil extraction machine pressing oil – …

Disclosed herein are an edible oil containing at least 15% by weight of diacylglycerol and 2 to 10% by weight of phytosterol and being a transparent liquid at normal temperature, wherein the content of hydrocarbons having 29 to 31 carbon atoms in the oil and fat is at most 1 part by weight per 100 parts by weight of the phytosterol. The edible

Ratings Outlook of Indian Edible Oil Industry 2 . Source: CMIE & Complied by CARE . The growth in production of domestic edible oil has not been able to keep pace with the growth of consumption.

Edible oil value chain enhancement in Ethiopia Final Evaluation of the Joint Programme Quick Facts production would be enhanced. The process was intended to lead to increased food security and innovation throughout the value chain, increasing the income of farmers, processors and traders, and in so doing, addressing three MDGs: Goal 1 poverty reduction, Goal 3 gender equity improvement

Considering that cooking oil is one of the most widely used commodity in our day to day lives, it would make sense why it would be an appealing business idea to start your own cooking oil manufacturing plant whether you are looking at it from a financial perspective or it has been your dream to start one.

a) Production details & process of manufacture: The seeds are to be dried in sun and then they are to be cleaned by shakers to remove dust and foreign materials.

Rural vegetable oil production Large-scale production Potential side reactions during high-temperature processing Physical losses Fat modification processes Other considerations Conclusions. Processing can remove the components of edible oils which may have negative effects on taste, stability, appearance or nutritional value. To the extent possible, processing should preserve tocopherols and

EP0032434A2 – Process for deodorizing edible oil.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest …

The oil is used as a substitute for olive oil and other edible oils, soaps, salad and cooking oil, mayonnaise and margarine. The meal is an important component of feeds for poultry and cattle.

iii EXECUTIVE SUMMARY The Government of Pakistan intends to bring in private sector investment for commercial edible oil seeds farming and production of edible oil.

• Quality Control in Edible Oil Processing A. RODEN, CSP Foods Ltd., Box 8060, Dundas, Ontario, Canada L9H 5E7 and G. ULLYOT, CSP Foods Ltd., Box 580, Nipawin, Saskatchewan, Canada S0E 1 E0 ABSTRACT This paper describes a Q.C. program for the manufacture of edible products from crude degummed oil. Tests done at various stages in the production are discussed, including test …

the number of papers related to biodiesel production and engine performance assessment. Keywords: Biodiesel but also contains numerous non-edible compounds that need to be removed by a refining process prior to human consumption. For the refining of crude vegetable oils there are two main routes, the chemical and the physical refining. Some by-products of low commercial value are obtained

1 CRUDE EDIBLE OIL BY EXPELLER PROCESS 1. Introduction Groundnut, coconut and sesame are the three major oilseeds grown in the State of Tamil Nadu.

Muez-Hest is a technology development and EPC with a large part of our expertise pertaining to Edible Oil Refinery Plant Manufacturers & Exporters. Edible Oil Refinery Plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.

The content of trans fat in edible oils was so low and food label can be declared as ‘0’ trans fat based on the regulation of Ministry of Food ad Drug Safety (MFDS). In case of edible oils, trans fat content below 2 g per 100 g oil can be declared as ‘0’ trans .

The Chemistry of Coconut Oil Haji Ibrahim Haji Abd. Rahman Department of Chemistry Introduction Coconut oil has been used extensively for edible and non-edible purposes all over the world.

This statistic shows the world vegetable oil production from 2000/01 to 2018/19. In 2016/17, vegetable oil production amounted to some 189.2 million metric tons worldwide.

US6713118B2 Edible oil and production process thereof

Production of edible oil with LEWA diaphragm metering pumps To supply the global demand for edible oil, about 40 different plants are used for the generation of edible oil. Depending on the region, a wide variety of seeds and fruit are used.

As an expert in cooking oil processing equipment and complete set cooking oil production line, Henan Doing Company is your reliable choice for starting cooking oil processing business.

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil …

Rifenburgh what is poetry alexander pope biography pdf research template middle school types of assignment pdf descriptive essay on my favourite food algebra …

Production of RBO using IICT Process : ~4 to 5 lakh tons If Total Production of RBO Routes through IICT Process… • Extra Oil Recovery @ 1 to 1.5 % 9500 to 14,250 tons (Rs.48 to 70Crore)

2.1.2 Position of Myanmar in the world of edible oil production 25 2.1.3 Oilseed and vegetal oil properties 26 2.2 Production and consumption of oil crops and vegetal oils 27

which accrue during edible oil production are valuable raw materials for other industries. The hulls remaining from the de-hulling process can for example be pelletized to add an excellent source of fiber to animal feed. The value of adding expeller cakes to feed products lies in the high nitrogen content. With FT-NIR, parameters like moisture, oil, protein, fiber and ash content can be – manufacturing engineering and technology 7th edition pdf Controlling quality in an edible oil refinery reponed back to the production staff. This assumes that the following features exist in the scheme: (a) fixed and defined processing conditions are applied: (b) samples are obtained at 1I correct frequency from a relevant point: (c) analyses carried out are rapid and accurate enough for the purpose; and (d) feedback of data to the process staff

The aim of the conference was to provide a good overview of the edible oils and fats industry by covering current processes and products together with a look at future trends. Expert speakers were invited from all over the world.

Edible Oils and fats trends in raw materials processing

17 Crude Edible Oil by Expeller 2008 krishna.nic.in

Oils and fats Sustainable growth Ferrostaal Group

Production of edible oil LEWA

Building Your Own Cooking Oil Manufacturing Plant

Final Vegetable Oil Processing – IFC

https://en.wikipedia.org/wiki/Palm_oil

les outils du lean manufacturing pdf –

25 replies on “Edible oil manufacturing process pdf”

Leave a Commentwhich accrue during edible oil production are valuable raw materials for other industries. The hulls remaining from the de-hulling process can for example be pelletized to add an excellent source of fiber to animal feed. The value of adding expeller cakes to feed products lies in the high nitrogen content. With FT-NIR, parameters like moisture, oil, protein, fiber and ash content can be

Business opportunities and food safety of the Myanmar

Final Vegetable Oil Processing – IFC

As an expert in cooking oil processing equipment and complete set cooking oil production line, Henan Doing Company is your reliable choice for starting cooking oil processing business.

US6713118B2 Edible oil and production process thereof

Production of RBO using IICT Process : ~4 to 5 lakh tons If Total Production of RBO Routes through IICT Process… • Extra Oil Recovery @ 1 to 1.5 % 9500 to 14,250 tons (Rs.48 to 70Crore)

Edible Oils and fats trends in raw materials processing

(PDF) Avocado oil extraction processes Method for cold

ANALYTICAL TOOL FOR RAPID ANALYSIS OF EDIBLE OIL

Disclosed herein are an edible oil containing at least 15% by weight of diacylglycerol and 2 to 10% by weight of phytosterol and being a transparent liquid at normal temperature, wherein the content of hydrocarbons having 29 to 31 carbon atoms in the oil and fat is at most 1 part by weight per 100 parts by weight of the phytosterol. The edible

Business opportunities and food safety of the Myanmar

Outlook of Indian Edible Oil Industry CARE’s Ratings

EP0032434A2 Process for deodorizing edible oil.pdf

Oils and fats Sustainable growth Turning Ideas into Reality. MAN Ferrostaal. 2. Insight Huge potentials Vegetable oil and biodiesel are now more sought after than ever before. They form the basis for food, energy in combined heat and power plants and fuel for the transport sector. Demand is growing at a tremendous pace and will keep doing so, matching the world’s rapid population growth and

EP0032434A2 Process for deodorizing edible oil.pdf

As an expert in cooking oil processing equipment and complete set cooking oil production line, Henan Doing Company is your reliable choice for starting cooking oil processing business.

US6713118B2 Edible oil and production process thereof

Outlook of Indian Edible Oil Industry CARE’s Ratings

EP0032434A2 – Process for deodorizing edible oil.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest …

Final Vegetable Oil Processing – IFC

Edible Oils and fats trends in raw materials processing

Vegetable Oil Production Industry Profile

Rural vegetable oil production Large-scale production Potential side reactions during high-temperature processing Physical losses Fat modification processes Other considerations Conclusions. Processing can remove the components of edible oils which may have negative effects on taste, stability, appearance or nutritional value. To the extent possible, processing should preserve tocopherols and

ANALYTICAL TOOL FOR RAPID ANALYSIS OF EDIBLE OIL

Vegetable Oil Production Industry Profile

Cooking Oil Refinery Process Flow Diagram edible oil refinery process pdf soybean oil refining process flow chart. HEST MUEZ Concept to Performance HEST Concept to Performance . Title: Edible Oil Refinery Process Flow Diagram Author: Muez-Hest Subject: Edible Oil Refinery Process Flow Diagram Keywords: Edible Oil Refinery Process Flow Diagram Created Date: 7/25/2018 6:13:24 …

Business opportunities and food safety of the Myanmar

The Chemistry of Coconut Oil Haji Ibrahim Haji Abd. Rahman Department of Chemistry Introduction Coconut oil has been used extensively for edible and non-edible purposes all over the world.

Outlook of Indian Edible Oil Industry CARE’s Ratings

ANALYTICAL TOOL FOR RAPID ANALYSIS OF EDIBLE OIL

Production of RBO using IICT Process : ~4 to 5 lakh tons If Total Production of RBO Routes through IICT Process… • Extra Oil Recovery @ 1 to 1.5 % 9500 to 14,250 tons (Rs.48 to 70Crore)

Building Your Own Cooking Oil Manufacturing Plant

EP0032434A2 Process for deodorizing edible oil.pdf

The oil is used as a substitute for olive oil and other edible oils, soaps, salad and cooking oil, mayonnaise and margarine. The meal is an important component of feeds for poultry and cattle.

Oils and fats Sustainable growth Ferrostaal Group

Rural vegetable oil production Large-scale production Potential side reactions during high-temperature processing Physical losses Fat modification processes Other considerations Conclusions. Processing can remove the components of edible oils which may have negative effects on taste, stability, appearance or nutritional value. To the extent possible, processing should preserve tocopherols and

US6713118B2 Edible oil and production process thereof

Oils and fats Sustainable growth Ferrostaal Group

Vegetable Oil Production Industry Profile

Ratings Outlook of Indian Edible Oil Industry 2 . Source: CMIE & Complied by CARE . The growth in production of domestic edible oil has not been able to keep pace with the growth of consumption.

Edible Oils and fats trends in raw materials processing

US6713118B2 Edible oil and production process thereof

Edible oil manufacturing process pdf newenglandrealtors.org

Disclosed herein are an edible oil containing at least 15% by weight of diacylglycerol and 2 to 10% by weight of phytosterol and being a transparent liquid at normal temperature, wherein the content of hydrocarbons having 29 to 31 carbon atoms in the oil and fat is at most 1 part by weight per 100 parts by weight of the phytosterol. The edible

Edible oil manufacturing process pdf newenglandrealtors.org

EP0032434A2 Process for deodorizing edible oil.pdf

The production process of vegetable oil involves the removal of oil from plant components, typically seeds. This can be done via mechanical extraction using an oil …

Final Vegetable Oil Processing – IFC

US6713118B2 Edible oil and production process thereof

Building Your Own Cooking Oil Manufacturing Plant

the number of papers related to biodiesel production and engine performance assessment. Keywords: Biodiesel but also contains numerous non-edible compounds that need to be removed by a refining process prior to human consumption. For the refining of crude vegetable oils there are two main routes, the chemical and the physical refining. Some by-products of low commercial value are obtained

ANALYTICAL TOOL FOR RAPID ANALYSIS OF EDIBLE OIL

Vegetable Oil Production Industry Profile

US6713118B2 Edible oil and production process thereof

Indian Edible Oil Industry The Indian vegetable oil economy is the world’s fourth largest after the US, China and Brazil, harvesting about 25 million tons of oilseeds against the world. Since 1995, Indian share in world production of oilseeds has been around 10 percent. Although, India is a major producer of oilseeds, per capita oil consumption in India is only 10.6 kg/annum which is low

Oils and fats Sustainable growth Ferrostaal Group

Business opportunities and food safety of the Myanmar

Production of edible oil LEWA

EP0032434A2 – Process for deodorizing edible oil.pdf – Free download as PDF File (.pdf), Text File (.txt) or read online for free. Scribd is the world’s largest …

Business opportunities and food safety of the Myanmar

1 CRUDE EDIBLE OIL BY EXPELLER PROCESS 1. Introduction Groundnut, coconut and sesame are the three major oilseeds grown in the State of Tamil Nadu.

Oils and fats Sustainable growth Ferrostaal Group

Production of edible oil LEWA

which accrue during edible oil production are valuable raw materials for other industries. The hulls remaining from the de-hulling process can for example be pelletized to add an excellent source of fiber to animal feed. The value of adding expeller cakes to feed products lies in the high nitrogen content. With FT-NIR, parameters like moisture, oil, protein, fiber and ash content can be

Outlook of Indian Edible Oil Industry CARE’s Ratings

17 Crude Edible Oil by Expeller 2008 krishna.nic.in

Building Your Own Cooking Oil Manufacturing Plant

The Chemistry of Coconut Oil Haji Ibrahim Haji Abd. Rahman Department of Chemistry Introduction Coconut oil has been used extensively for edible and non-edible purposes all over the world.

Vegetable Oil Production Industry Profile

Muez-Hest is a technology development and EPC with a large part of our expertise pertaining to Edible Oil Refinery Plant Manufacturers & Exporters. Edible Oil Refinery Plant requires precision of machinery while ensuring minimum addition of contaminants and odour producing agents.

EP0032434A2 Process for deodorizing edible oil.pdf

Edible oil manufacturing process pdf newenglandrealtors.org

which accrue during edible oil production are valuable raw materials for other industries. The hulls remaining from the de-hulling process can for example be pelletized to add an excellent source of fiber to animal feed. The value of adding expeller cakes to feed products lies in the high nitrogen content. With FT-NIR, parameters like moisture, oil, protein, fiber and ash content can be

Business opportunities and food safety of the Myanmar

• Quality Control in Edible Oil Processing A. RODEN, CSP Foods Ltd., Box 8060, Dundas, Ontario, Canada L9H 5E7 and G. ULLYOT, CSP Foods Ltd., Box 580, Nipawin, Saskatchewan, Canada S0E 1 E0 ABSTRACT This paper describes a Q.C. program for the manufacture of edible products from crude degummed oil. Tests done at various stages in the production are discussed, including test …

Building Your Own Cooking Oil Manufacturing Plant

17 Crude Edible Oil by Expeller 2008 krishna.nic.in

Comments are closed.