Theory of constraints in manufacturing pdf

ToC (Theory of Constraints), also called Constraint Management, is a philosophy and set of techniques used to manage an organization. Most widely implemented in manufacturing

Additional info for Re-engineering the manufacturing system: applying the theory of constraints. Example text. 10, gross to net requirements generation considers lead time as static.

Introduction to Theory of Constraints Thinking Process: Methodology Throughput Accounting IF YOU WISH TO BOOST YOUR COMPANY, OR YOUR CAREER, WE WILL SHOW YOU HOW. Leadership is the catalyst – so much so that Dr. Goldratt himself held up our implementation success as an example in his conferences and seminars.

“The core idea in the Theory of Constraints is that every real system such as a profit-making enterprise must have at least one constraint. If it were not true, then the system would produce an infinite amount of whatever it strives for. In the case of a profit-making enterprise, it would be infinite profits.” 13. What is TOC? (continued) “Because a constraint is a factor that limits the

A roadmap for implementing Theory of Constraints in manufacturing organisations was developed with a software tool called Eden™ . Eden™ facilitates the building and display of roadmaps in an interactive fashion, and also provides document management and searching functionalities in order to better support the capturing and management of knowledge surrounding the project. Figure 2. TOC

Building a competitive advantage based on the leading methodologies of: Lean Management, the Theory of Constraints and Six Sigm a 11 Six Sigma means a 99.99966% probability that the client will not pass a defect on to the customer

The bottom line: the Theory of Constraints is applicable in special situations. Lean manufacturing Principles are applicable everywhere. Lean Manufacturing uses inventory reduction as a means to improve all of the critical competitive parameters: Cost, Quality, Responsiveness, and reliability.

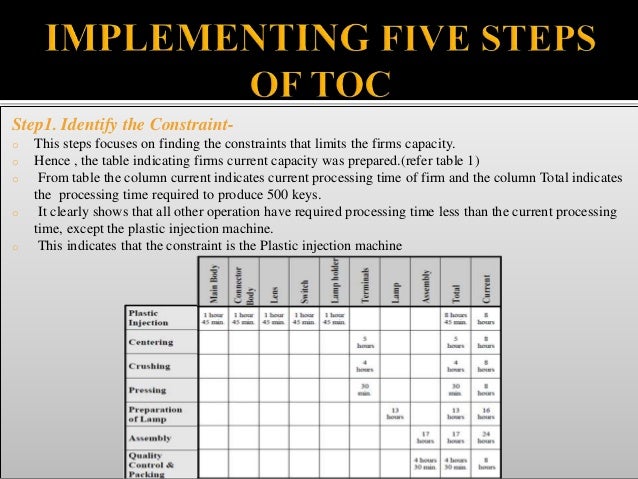

The theory of constraints within manufacturing is essential in production optimization and flow. Viewing examples within manufacturing of the theory of constraints can promote insight as well. Viewing examples within manufacturing of the theory of constraints can promote insight as well.

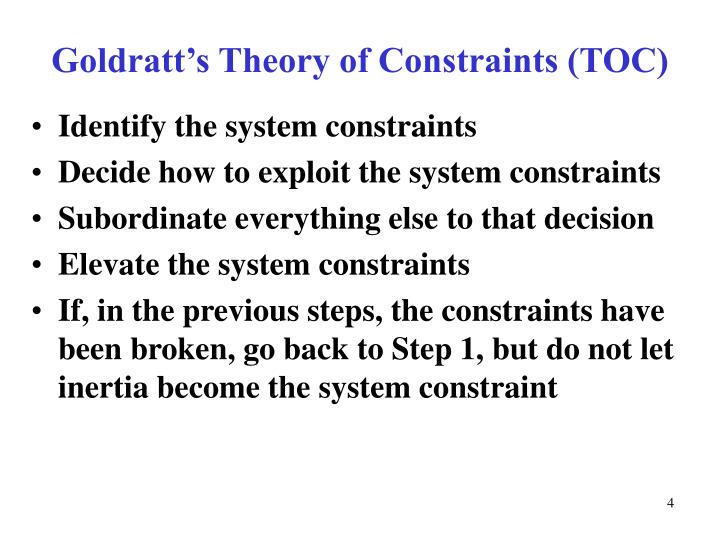

The Theory of Constraints by Eliyahu Goldratt is a methodology for identifying and eliminating the bottleneck in a manufacturing process.

TOC Basic Course TOC Advanced Course What to Change? What to Change to? The course will teach you practical solutions of the Theory of Constraints applications in Operations,

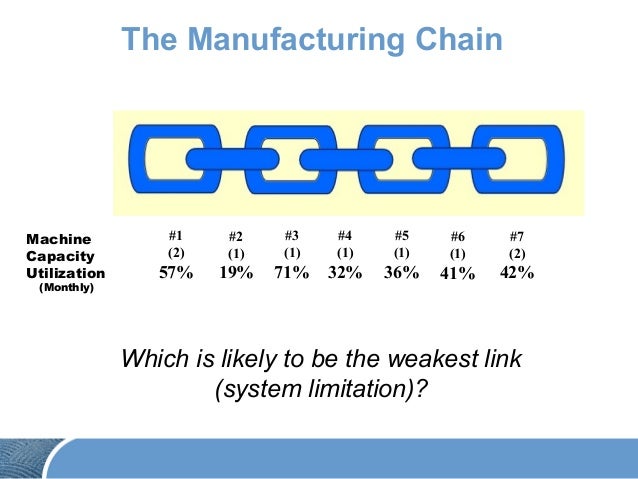

Theory of Constraints views all processes as a chain of events that executes sequentially. Remember how a chain is only as strong as its weakest link? Well a …

Cyplik P., Hada ś Łukasz, Doma ński R., 2009, Implementation of the theory of constraints in the area of stock management within the supply chain – a case study. LogForum 5, 3, 6 .

Re-Engineering the Manufacturing System: Applying the Theory of Constraints, Second Edition, (Manufacturing Engineering and Materials Processing)

AERIAL VIEW OF HEAVY VEHICLE PRODUCTION LINE AT THE

The theory of constraints in manufacturing CORE

MSOE’s one-day Theory of Constraints in Manufacturing course will teach you how to use the Theory of Constraints, an approach that helps you identify the most important limiting factor (i.e. constraint) that stands in your way, and then systematically reduce that roadblock so you can achieve your company’s goals.

Factories, People & Results TLS: Theory Of Constraints + Lean + Six Sigma Combining the best of each approach Theory Of Constraints (TOC ) • Focus on improving the system constraints that determine overall performance…

The theory of constraints methodology is a manufacturing tool that identifies the most important limiting factor or constraint within a manufacturing system and systematically improving said constraints until it is no longer the bottleneck.

In this paper, a systematic and quantitative view is presented for the application of the theory of constraints in manufacturing. This is done employing the operational research technique of mathematical programming. The potential of the theory of constraints in automated manufacturing is

Quality and continuous improvement in medical device manufacturing. Article (PDF Available) including lean thinking and the theory of constraints, and continuous quality. improvement

Download entry PDF. How to cite. Description . As a philosophical approach to better management practice, the Theory of Constraints (TOC) suggests thatfocusing management attention on a few “constraints” is the key to profitability and success. In manufacturing, TOC uses constraint management to ensure continuous improvement through synchronized manufacturing (see Figure …

Using Theory of Constraints to increase control in a complex manufacturing environment – Case CandyCo: Make-to-stock production with a broad product offering

theory of constraints (toc) strategy In The Goal , first published in 1984, Goldratt says that the goal of the business is to make money – and to make more money over time.

The Theory of Constraints (TOC) and Lean Manufacturing are two popular business philosophies that.. process engineering, and manufacturing engineering.

Point of view written by Philip Marris, Founder and CEO of Marris Consulting based in Paris, a specialist in Theory Of Constraints (TOC) and Lean and author of the French reference book on applying TOC to manufacturing and process industries Le Management Par les Contraintes en gestion industrielle.

toc in manufacturing The extraordinary impact that TOC brought to the manufacturing world was driven largely by the book “The Goal” authored by Dr. Goldratt and Jeff Cox. Published in 1983, the book has influenced the thinking of millions of readers around the world.

Article (PDF Available) This study aims to present simulated application of the Theory of Constraints (TOC) to production management in a small dairy industry. For this, a case study with a

Theory of constraints (TOC) is a technique that produces solutions for every kind of bottleneck in a short time. The philosophy of the theory is to determine the weaker part of the process chain and to eliminate this constraint point by taking

theory of Constraints Technique used to improve speed in the manufacturing process Measuring Speed at each step of Cost Life Cycle Marketing & Distribution Customer Service

the theory of constraints and the critical chain In the 1980s, Goldratt and Cox (1992) presented Theory of Constraints as a methodology for managing production planning and scheduling.

2 The theory of constraints as a manufacturing strategy:a case study in a small manufacturing company ABSTRACT The aim of this article is to use with success the Theory of Constraints …

This eBook is an instruction manual for implementing Theory of Constraints’ application for Manufacturing. This eBook is targeted at Business Owners, Managers, Consultants and Implementers.

Theory of constraints (TOC) is an engineering management technique used to evaluate a manageable procedure, identifying the largest constraint (bottleneck) and …

same thing. Theory of Constraints In the early 1980s, about the time that America was waking up to the impact of the TPS on manufacturing businesses, Eliyahu M. Goldratt was simultaneously examining manufacturing

Proceedings of the International Conference on Global Manufacturing and Innovation – July 27-29, 2006 – 1 – APPLICATION OF THEORY OF CONSTRAINTS ON SCHEDULING OF

Keywords: Paradigm, Lean Production, Theory of Constraints Introduction Research Objectives The main objective of this paper is to contribute to a better understanding of how manufacturing methodologies have evolved and to determine their differences and similarities. Based on this better understanding of the evolution the authors want to identify current and future needs that will lead to …

In the late 1970’s, the founder of the Theory of Constraints (TOC), Eliyahu Goldratt, Israeli physicist turned business guru, developed a revolutionary method for production scheduling [10] which was in stark contrast to accepted methods available at the time, such

A Motor For Production. Drum-buffer-rope is the Theory of Constraints production application. It is named after the 3 essential elements of the solution; the drum or constraint or weakest link, the buffer or material release duration, and the rope or release timing.

The Goal Movie Using the principles of the Theory of Constraints (TOC), Alex Rogo transforms his mediocre division into a money-making machine. If you would like to introduce TOC concepts, including bottleneck, throughput, flow balancing and learn TOC applications such …

Roberto Panizzolo 17 IJIEM management/production area only. For this reason, hereafter we will use the term “TOC production”. In order to carry out the study three hypotheses have

T he Theory of Constraints (ToC) and its management application, Constraint Analysis (CA), have been successfully applied to product manufacturing systems to increase throughput

Describe the popential of the theory of constraints in automated manufacturing. Theory of Constraints The theory of constraints, hereafter abreviated as TOC, is a production and operations management strategy centered on the concept of capacity-constrained resources (CCR), more commonly called bottlenecks.

TOC IN MANUFACTURING – Theory of Constraints

– manufacturing processes for engineering materials kalpakjian pdf free download

Robert E. Stein’s Re-engineering the manufacturing system

Theory of Constraints (TOC) Production and Manufacturing

Re-Engineering the Manufacturing System Applying the

Lean and Theory of Constraints Six Sigma Study Guide

Theory of Constraints in Manufacturing MSOE

The theory of constraints as a manufacturing strategya

Application of Theory of Constraints to a bottleneck

Theory of Constraints in streamline manufacturing Wikipedia

– What is the Theory of Constraints Lean Manufacturing

Theory of constraints Production And Manufacturing

APPLYING MANUFACTURING THEORY TO MARKETING/SALES T

TQM TPM TOC Lean and Six Sigma – Evolution of

Theory of Constraints and Lean Synchronous Management

Beyond Lean Manufacturing Goal Systems International

ToC (Theory of Constraints), also called Constraint Management, is a philosophy and set of techniques used to manage an organization. Most widely implemented in manufacturing

A roadmap for implementing Theory of Constraints in manufacturing organisations was developed with a software tool called Eden™ . Eden™ facilitates the building and display of roadmaps in an interactive fashion, and also provides document management and searching functionalities in order to better support the capturing and management of knowledge surrounding the project. Figure 2. TOC

Theory of Constraints views all processes as a chain of events that executes sequentially. Remember how a chain is only as strong as its weakest link? Well a …

Factories, People & Results TLS: Theory Of Constraints Lean Six Sigma Combining the best of each approach Theory Of Constraints (TOC ) • Focus on improving the system constraints that determine overall performance…

2 The theory of constraints as a manufacturing strategy:a case study in a small manufacturing company ABSTRACT The aim of this article is to use with success the Theory of Constraints …

the theory of constraints and the critical chain In the 1980s, Goldratt and Cox (1992) presented Theory of Constraints as a methodology for managing production planning and scheduling.

same thing. Theory of Constraints In the early 1980s, about the time that America was waking up to the impact of the TPS on manufacturing businesses, Eliyahu M. Goldratt was simultaneously examining manufacturing

Describe the popential of the theory of constraints in automated manufacturing. Theory of Constraints The theory of constraints, hereafter abreviated as TOC, is a production and operations management strategy centered on the concept of capacity-constrained resources (CCR), more commonly called bottlenecks.

The theory of constraints methodology is a manufacturing tool that identifies the most important limiting factor or constraint within a manufacturing system and systematically improving said constraints until it is no longer the bottleneck.

Quality and continuous improvement in medical device manufacturing. Article (PDF Available) including lean thinking and the theory of constraints, and continuous quality. improvement

Point of view written by Philip Marris, Founder and CEO of Marris Consulting based in Paris, a specialist in Theory Of Constraints (TOC) and Lean and author of the French reference book on applying TOC to manufacturing and process industries Le Management Par les Contraintes en gestion industrielle.

19 replies on “Theory of constraints in manufacturing pdf”

Leave a CommentT he Theory of Constraints (ToC) and its management application, Constraint Analysis (CA), have been successfully applied to product manufacturing systems to increase throughput

APPLYING MANUFACTURING THEORY TO MARKETING/SALES T

Theory of Constraints and Lean Synchronous Management

TQM TPM TOC Lean and Six Sigma – Evolution of

toc in manufacturing The extraordinary impact that TOC brought to the manufacturing world was driven largely by the book “The Goal” authored by Dr. Goldratt and Jeff Cox. Published in 1983, the book has influenced the thinking of millions of readers around the world.

Beyond Lean Manufacturing Goal Systems International

Theory of Constraints Example in Manufacturing

Factories, People & Results TLS: Theory Of Constraints + Lean + Six Sigma Combining the best of each approach Theory Of Constraints (TOC ) • Focus on improving the system constraints that determine overall performance…

Theory of Constraints and Lean Synchronous Management

AERIAL VIEW OF HEAVY VEHICLE PRODUCTION LINE AT THE

TOC Basic Course TOC Advanced Course What to Change? What to Change to? The course will teach you practical solutions of the Theory of Constraints applications in Operations,

Lean and Theory of Constraints Six Sigma Study Guide

Theory of Constraints Production Drum Buffer Rope

Re-Engineering the Manufacturing System Applying the

Building a competitive advantage based on the leading methodologies of: Lean Management, the Theory of Constraints and Six Sigm a 11 Six Sigma means a 99.99966% probability that the client will not pass a defect on to the customer

Theory of Constraints (TOC) Production and Manufacturing

This eBook is an instruction manual for implementing Theory of Constraints’ application for Manufacturing. This eBook is targeted at Business Owners, Managers, Consultants and Implementers.

Theory of Constraints (TOC) Production and Manufacturing

APPLYING MANUFACTURING THEORY TO MARKETING/SALES T

Theory of Constraints in Manufacturing MSOE

Theory of constraints (TOC) is a technique that produces solutions for every kind of bottleneck in a short time. The philosophy of the theory is to determine the weaker part of the process chain and to eliminate this constraint point by taking

(PDF) Quality and continuous improvement in medical device

Theory of Constraints and Lean Synchronous Management

Download entry PDF. How to cite. Description . As a philosophical approach to better management practice, the Theory of Constraints (TOC) suggests thatfocusing management attention on a few “constraints” is the key to profitability and success. In manufacturing, TOC uses constraint management to ensure continuous improvement through synchronized manufacturing (see Figure …

Theory of constraints Production And Manufacturing

Robert E. Stein’s Re-engineering the manufacturing system

The theory of constraints within manufacturing is essential in production optimization and flow. Viewing examples within manufacturing of the theory of constraints can promote insight as well. Viewing examples within manufacturing of the theory of constraints can promote insight as well.

Using Theory Of Constraints to boost Lean programs

The bottom line: the Theory of Constraints is applicable in special situations. Lean manufacturing Principles are applicable everywhere. Lean Manufacturing uses inventory reduction as a means to improve all of the critical competitive parameters: Cost, Quality, Responsiveness, and reliability.

The Theory of Constraints & Lean Manufacturing

AERIAL VIEW OF HEAVY VEHICLE PRODUCTION LINE AT THE

Lean and Theory of Constraints Six Sigma Study Guide

A roadmap for implementing Theory of Constraints in manufacturing organisations was developed with a software tool called Eden™ . Eden™ facilitates the building and display of roadmaps in an interactive fashion, and also provides document management and searching functionalities in order to better support the capturing and management of knowledge surrounding the project. Figure 2. TOC

TQM TPM TOC Lean and Six Sigma – Evolution of

same thing. Theory of Constraints In the early 1980s, about the time that America was waking up to the impact of the TPS on manufacturing businesses, Eliyahu M. Goldratt was simultaneously examining manufacturing

Building a competitive advantage based on the leading

Lean and Theory of Constraints Six Sigma Study Guide

same thing. Theory of Constraints In the early 1980s, about the time that America was waking up to the impact of the TPS on manufacturing businesses, Eliyahu M. Goldratt was simultaneously examining manufacturing

Theory of Constraints Lean Manufacturing – EPSILON ENGINEER

Theory of constraints Production And Manufacturing

the theory of constraints and the critical chain In the 1980s, Goldratt and Cox (1992) presented Theory of Constraints as a methodology for managing production planning and scheduling.

APPLYING MANUFACTURING THEORY TO MARKETING/SALES T

Theory of Constraints Example in Manufacturing

Re-Engineering the Manufacturing System: Applying the Theory of Constraints, Second Edition, (Manufacturing Engineering and Materials Processing)

Theory of Constraints and Lean Manufacturing TOCCA

Theory of Constraints Lean Manufacturing – EPSILON ENGINEER

Theory of Constraints in Manufacturing MSOE

Theory of constraints (TOC) is a technique that produces solutions for every kind of bottleneck in a short time. The philosophy of the theory is to determine the weaker part of the process chain and to eliminate this constraint point by taking

TOC IN MANUFACTURING – Theory of Constraints

Additional info for Re-engineering the manufacturing system: applying the theory of constraints. Example text. 10, gross to net requirements generation considers lead time as static.

Theory Of Constraints Lean Six Sigma Marris Consulting

Lean Manufacturing and the Theory of Constraints (TOC

The Theory of Constraints (TOC) and Lean Manufacturing are two popular business philosophies that.. process engineering, and manufacturing engineering.

Robert E. Stein’s Re-engineering the manufacturing system

(PDF) Quality and continuous improvement in medical device

Using Theory Of Constraints to boost Lean programs

Cyplik P., Hada ś Łukasz, Doma ński R., 2009, Implementation of the theory of constraints in the area of stock management within the supply chain – a case study. LogForum 5, 3, 6 .

The Theory of Constraints & Lean Manufacturing

Comments are closed.