Tin can manufacturing process pdf

Metal Can Manufacturing 1997 Economic Census Manufacturing Industry Series 1997 Issued August 1999 EC97M-3324C U.S. Department of Commerce William M. Daley,

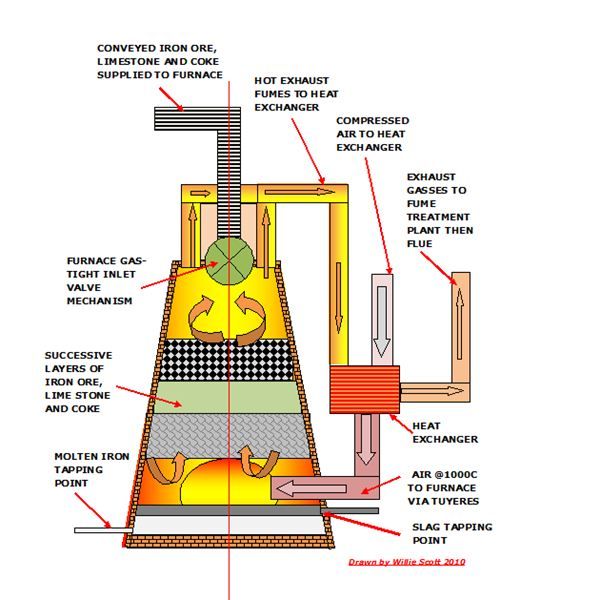

Regardless of the source, each process consists of several steps in which the unwanted materials are physically or chemically removed, and the concentration of tin is progressively increased. Some of these steps are conducted at the mine site, while others may be conducted at separate facilities.

Major cans are classified into two types: 3-piece cans consisting of three components of (1) a bottom lid, (2) a cylindrical body and (3) a top lid (a lid with a lip [an opening] for a beverage can), and 2-piece cans consisting of two components of (1) a body integrated with …

I. EXECUTIVE SUMMARY The Definition of Packaging Development Packaging is defined as a method or container made to protect products from damage. The products include but are not limited to: food, electronics, manufactured good items, etc. The process of packaging development involves input from a variety of disciplines and influences including history, science, economics, engineering, politics

Figure 5. Figure 6 Retort thermograph showing record of 90 min process at 121.°C. Tin is applied to provide sacrificial protection of the steel base -the tin layer gradually dissolves and passes into the surrounding solution, while the steel layer beneath remains protected.

Keywords: Tin Can Crusher, Volume Reduction, compact size, process to make only one product rather the manufacturing process was used at the whole system production. This way include part by fabrication until assembly to others component. 4.2 Process Involve: In order to make the design to come in reality, fabrication process needs to be done first. The fabrication process starts from

Tin can manufacturing process products are most popular in Western Europe, Mid East, and Eastern Asia. You can ensure product safety by selecting from certified suppliers, including 103 with Other, 66 with ISO9001, and 51 with HACCP certification.

can be depicted as macro, mini, or micro for each of these types. The viewgraphs that accompany the explanation below show how one process, Producing the Plan of the Day (POD), might be depicted using each of the three

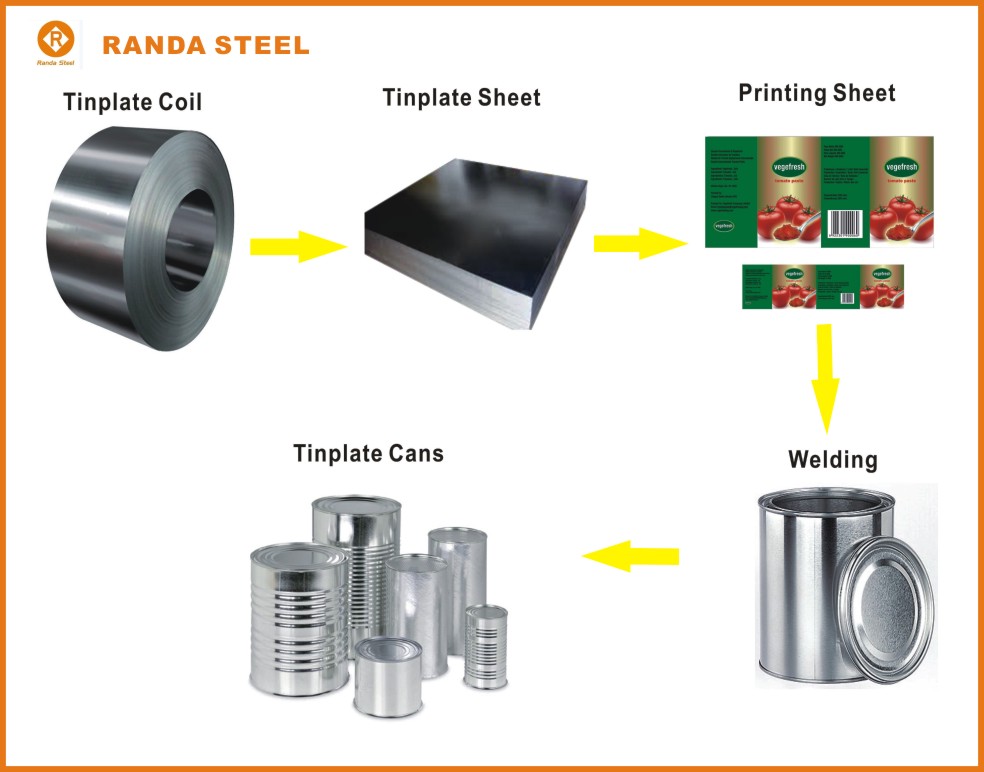

How a three-piece welded food can is made 1. Steel strip arrives at the can manufacturing plant in large coils. 2. Steel strip is cut into large sheets 3. Lacquer is applied to the side of the sheets that will become the internal surfaces of the finished cans. This special lacquer is to protect the can itself from corrosion and from any possibility of interaction between the contents and the

The current choices of layouts, such as product, process, and cellular layouts do not adequately address the above needs because they tend to be designed for a specific product mix and production volume, both assumed to last for a sufficiently long period (e.g., 3-5 years) [29].

3-Piece Tinplate Aerosol Cans Factors in Container Selection and The Manufacturing Process SouthernAerosol TechnicalAssociation Aerosol 101 – Three Piece Steel Cans March 23, 2011 Kevin Richards – BWAY Corporation. Overview Factors and Test Methods – Container Selection Regulatory / USDOT Requirements Commercial Standards / CSPA Materials and the Can Manufacturing Process. Can …

The tin can was an important part of the shift from agricultural to industrial revolution, says food blogger Sue Davies, allowing food to be harvested in season and eaten out of season. And

BEVERAGE CANS Did you know that some of Australia’s most recognised beverage brands are delivered in cans made by Visy? Our Beverage Can business is a major supplier of aluminium cans and ends to the Australian and New Zealand marketplaces.

5.23 Significant amendments to the manufacturing process, including any change in equipment or materials, which may affect product quality and/or the reproducibility of the process should be validated.

Sealing, such as tin-can and radiator seams, is the second most common use. Automated soldering equipment produces high-quality joints at a relatively low cost per joint. Conditions for choosing a

Metal packaging plays an important role in the process of food preservation. The common expression used to describe such a process is “canning”. Canned food has become an important part of the human diet in developed countries during the past century. It is of particular value in those parts of the world where no or limited refrigeration exists for storing food. It is a means of safely

Manual on fish canning 2. Packaging materials for canned

Orora Aluminium cans

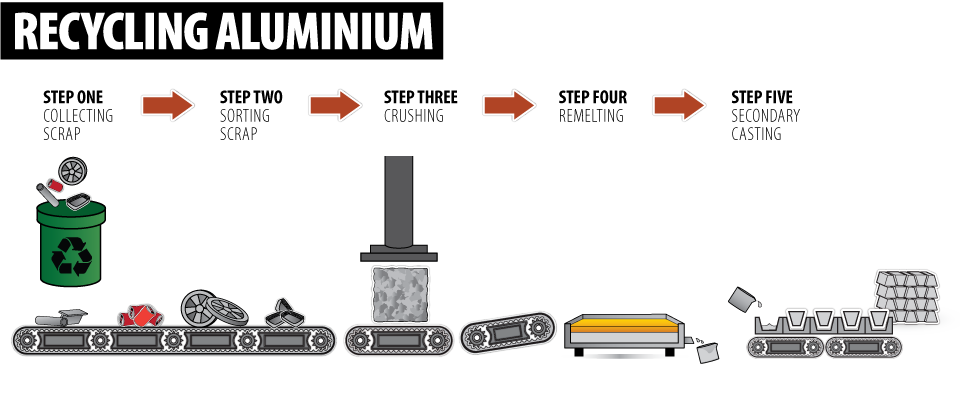

Process losses can often be recycled and re-used within the plant due to product specifications or process requirements. Materials, which cannot be recycled internally, leave the plant to be used in other industries or to be supplied to external waste recycling or waste disposal facilities. Consumptions The primary energy use in ceramic manufacturing is for kiln firing and, in many processes

from a manufacturing process so that the waste can be fed directly back into that process or into a related one. Other Other manufacturers are designing packaging to incorporate recycled materials wherever possible or are finding innovative uses

Once the process schedule is defined, the manufacturer must implement systems to monitor, control and provide records which confirm, after the event, that all stages in production affecting heat transfer to the SHP of the can were within specification. Records provide the means for a continuous assessment of production and an early warning system with which to initiate corrective action if

modern manufacturing process imparts a highly reßective surface to the canÕs exterior, which acts as a superb base for decorative printing. This attribute adds to the enthusiasm for the aluminum can among those who market beverages. Indeed, that industry consumes about a Þfth of all aluminum used in the U.S. Consequently, beverage cans have emerged as the single most important market for

A hobo stove is a style of improvised heat-producing and cooking device used in survival situations, by backpackers, hobos, tramps and homeless people. Hobo stoves can be functional to boil water for purification purposes during a power outage and in other survival situations, [1] and can be used for outdoor cooking .

4) Tin Can Chronology (Jim Rock, 1990) 1810- Peter Durand was granted a patent for a tin-plated food container by King George III of England. 1818- Peter Durand introduced the tin container in America.

ііі) Develop the model tin can crusher using bending process, welding process, drilling process and cutting process. іv) Fabricate the model tin can crusher using welding skill and machining.

TULC (Toyo Ultimate Can) is a 2-piece can which enabled us to improve environmental-friendliness dramatically by reviewing the fundamental properties of materials and manufacturing process.

This process can maintain high production rates. The process can be set up so that only specific regions of the parts are plated, examples are contact points plated with gold or silver to make electrical contacts. Electroplating may have plating of different metals. Plating of some of important metals are described here. Zinc Plating Zinc plated steel products are fasteners wire goods

Case Study on Can Making 31 pages, 23 figures Advanced Level 1 prepared by Eric Wootton, Alcan Deutschland GmbH, Göttingen Objectives: 1. To give a background of the design and manufacturing processes of food and beverage cans, which are produced by drawing and drawing & ironing of rolled aluminium alloys. 2. To draw attention to the challenge for materials and production engineers to …

Many environmental impacts, including the production of any electricity used in the materials recovery industry, can be converted into carbon dioxide-equivalent (CO 2 …

4.0 three – piece tin can manufacturing process 04-05 4.1 machinery requirement 06 4.2 three piece can making production line 01 06 4.2.1 quotations 07-08 4.2.2 machine instalation plan for can body 09 4.2.3 machine instalation plan for can end 10 4.3 three piece can making production line 02 11-12 4.3.1 quotations 13 4.3.2 machine instalation lay out 14 5.0 draw and iron can manufacturing

Preliminary Industry Characterization: Metal Can Manufacturing–Surface Coating U. S. Environmental Protection Agency Coatings and Consumer Products Group Emission Standards Division Office of Air Quality Planning and Standards Research Triangle Park, NC 27711 September 1998. i TABLE OF CONTENTS Page 1.0 OVERVIEW OF INITIAL MACT DEVELOPMENT PHASE FOR THE METAL CAN MANUFACTURING…

The average wage rate for production workers manufacturing metal cans (.85 per hour) is over 50% higher than the average wage rate for all hourly manufacturing plant workers (.97 per …

19/10/2013 · Tin can production line 1. semi automatic production line 2. thickness of plate: 0.2-0.38mm 3. suitable can diameter: 65-300mm 4. suitable can height: 70-400mm.

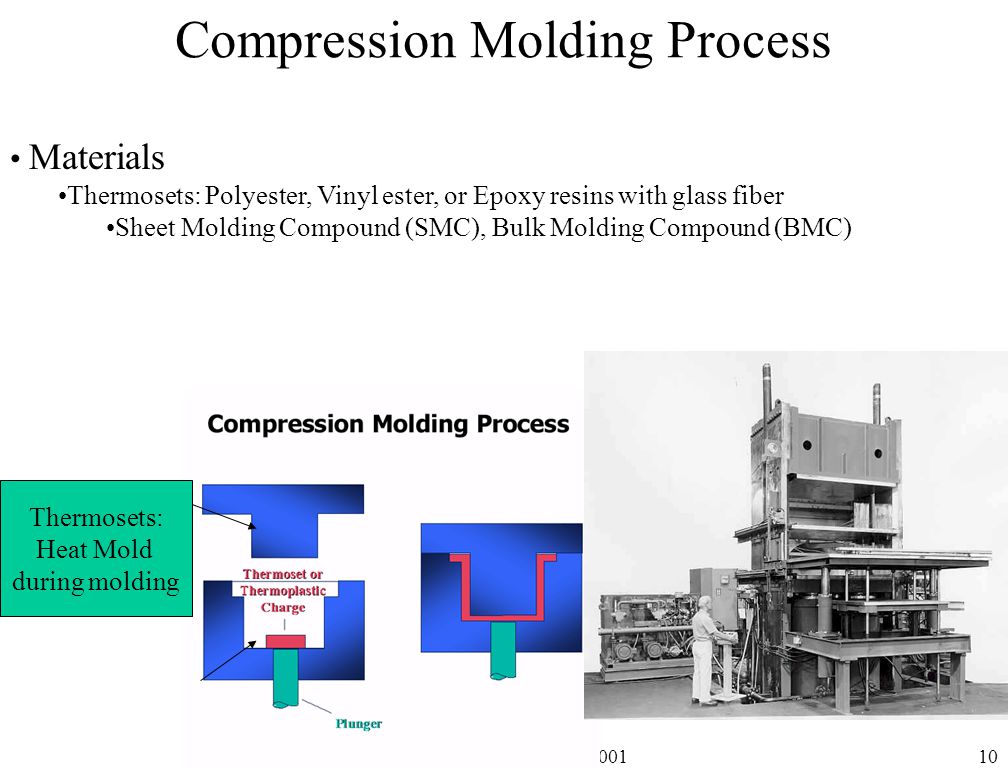

Introduction to Manufacturing Processes ME 4563 ME 4563 Dr. S. Haran 2 Bulk Deformation . 2 ME 4563 Dr. S. Haran 3 Extrusion ME 4563 Dr. S. Haran 4 Production of long lengths of solid or hollow Production of long lengths of solid or hollow products with constant cross-section Usually performed at elevated temperaturesUsually performed at elevated temperatures Product can be cut to desired

higher precision end of the range or (2) the process can easily achieve the finishes on the lower precision end of the range, but a cheaper alternative likely …

pdf. MANUAL CAN CRUSHER. 81 Pages. MANUAL CAN CRUSHER. Uploaded by. S. Shaikh Develop the model tin can crusher using bending process, welding process, drilling process and cutting process. іv) Fabricate the model tin can crusher using welding skill and machining. 5 MANUAL CAN CRUSHER CHAPTER 03 LITERATURE REVIEW The title development of recycle bin tin can …

Pineapple Can Our subsidiary KJ Can (Johore) Sdn. Bhd., located in southern region of Malaysia, manufactures pineapple cans for both local and export markets. Our pineapple cans …

471 Tin Cans (Page 1)

Tin-plated steel sheet, fragment of tin can Tin-plated steel sheet, fragment of tin can (Clearly metallic according to EDX FTIR Omitted (Significant peak not detected) Possibly a metal or inorganic compound measurement only)

The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit. Cassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive production of fines.

27/10/2004 · Can coatings should – 1 withstand the can manufacturing process, 2 be universally applicable to different food types and withstand aggressive food types, 3 withstand the food sterilization process, 4 minimize the release of their constituents into food, 5

Sharretts Plating Can Handle All of Your Tinning Needs. Sharretts Plating Company has been in business since 1925. Over the course of nine decades, we have developed and perfected an effective and affordable tin plating process that can be customized to your specific operating requirements.

Printed Circuit Board Recycling Methods 1. Introduction to Printed Circuit Boards The Printed Circuit Board (PCB1) manufacturing process is very complicated, involving many special chemicals and valuable materials. These materials discharge into the environment in the forms of wastewater, spent solution and solid waste. After years of research endeavors by academia, research institutes and the

14/06/1994 · This new can manufacturing process allows many advantageous material savings, these savings result from the considerable reduction of the diameters of the discs which form the top and end of a can as shown in FIGS. 5 and 6, as well as a reduction of the hooks dimensions and other seaming dimensions as shown on FIGS. 1 and 2 and FIGS. 9 and 10. In addition more material savings result …

Resistance seam welding Description The seam welding process is an adaptation of resistance spot welding and involves making a series of overlapping spot welds by

The tin can starts its life in a steelworks. There, a steel strip is rolled out to the There, a steel strip is rolled out to the desired thickness, between 0.12 and 0.49 mm depending on the application. – guidelines on the validation of manufacturing processes 964 Precaution for Crimping Process 3.3 Crimping Height Crimping height is one of the important quality management items on crimping process. As crimping terminals without the correct crimp-height is the cause of poor conductivity,

Manufacturing Process Specifications and Available Sizes Packaging and Marking Usage Precautions Information Required with Orders and Inquiries CONTENTS List of Tinplate & TFS Products Specifications and Available Sizes. Tinplate is a thin steel sheet coated by tin. It has an extremely beautiful metallic luster as well as excellent properties in corrosion resistance, solderability, and

Its two-piece can could only hold 7 ounces (198 g), instead of the usual 12 (340 g), and there were problems with the production process. Nevertheless, the aluminum can proved popular enough to incite Coors, along with other metal and aluminum companies, to develop better cans.

Alibaba.com offers 418,374 tin can manufacture products. About 25% of these are cans, 12% are packaging boxes, and 2% are sauce. A wide variety of tin can manufacture options are available to you, such as metal, plastic.

Tin processing: Tin processing, preparation of the ore for use in various products. Tin (Sn) is a relatively soft and ductile metal with a silvery white colour. It has a density of 7.29 grams per cubic centimetre, a low melting point of 231.88 °C (449.38 °F), and a high boiling point of 2,625 °C (4,757 °F). Tin is

The DWI process is used for making cans where the height is greater than the diameter and is particularly suited to making large volumes of cans of the same basic specification. Lids for cans are called “can ends” or simply “ends”.

Tinware Direct are a UK based tin manufacturer and supplier of wholesale metal packaging, offering a wide range of ready-made and bespoke tin boxes.

the entire thermal process 2.9 canned meat product article of food that is manufactured from meat or from edible offal or from both, including, when specifically permitted, bone, and with or without vegetables, including mushrooms, fruit or cereal or any combination of the three, or sauces or gravies and other appropriate ingredients, such as vegetable protein, edible fats, seasoning

Beverage Cans Aluminium Cans Textured Gloss or Matte

Tin layer on the inside of a tin can Tinning is the process of thinly coating sheets of wrought iron or steel with tin , and the resulting product is known as tinplate . The term is also widely used for the different process of coating a metal with solder before soldering.

Cartons should be new, strong cardboard cartons containing 50 tin cans of 200g or 24 tin cans of 425g, manufactured from well-constructed single wall, fluted paper, corrugated board with a specific weight of approximately 750g per square meter.

Team “2” 2 • Introduction • Types of Cans • Materials • Manufacturing Process • Conclusion OUTLINES 3. HISTORY OF CAN MANUFACTURING • Early tin cans were sealed by soldering with a tin-lead alloy, which could lead to lead poisoning.

The wall thickness of the can is reduced by “ironing” the tin plate and consequently lengthening the can. When the ram is withdrawn. . the punch with the can comes into contact with the base paneling tool and the can base is formed. • At the end of this stroke. the can is removed from the punch by a stripper and conveyed out of the machine via an unloader belt.

Orora helps can some of the world’s most loved beverage brands. The largest and most innovative beverage can supplier across Australia, New Zealand and the Pacific Islands, we produce aluminium beverage cans, tabs and ends, supported by a powerful suite of enhancements.

Independently of the material and the production process, most cans are coated internally and externally with films of 1 to 10 µm thickness. Coatings are usually applied to both sides of planar metal sheets or coils by roller coating before the cans are formed. Alternatively, coatings are sprayed on preformed cans. Tin cans are used without internal coatings for light colored, acidic juices

How a three-piece welded food can is made MPMA

Tin Can & Offset Printing Printing Industrial Processes

How it’s Made: Aluminum Cans Making a Two-Piece Can. How many pieces are used to make a can? How involved is the process? Get an inside look at how the food and beverage cans we use every day are manufactured.

A tin can, tin (especially in British English, Australian English and Canadian English), steel can, steel packaging or a can, is a container for the distribution or storage of goods, composed of thin metal.

contact with tin results in tin corrosion, leading to food contact with the underlying steel. The food or beverage then attacks the steel leading to pitting corrosion and can also result in hydrogen production, can swelling and potential can damage (Ellis, 1979).

An audit of a manufacturing process is a comprehensive examination of the process to verify that it is performing as intended. Processes generate results, and process audits determine if the results are accurate and being generated by an effectively managed process.

This pocket Guide is intended in part to help resolve the question which frequently arises concerning the evaluation and safety of canned food products, i.e., when does the can defect of damage

The International Programme on Chemical Safety (IPCS), established in 1980, is a joint venture of the United Nations Environment Programme (UNEP), the International Labour Organization (ILO), and the

Design for Manufacturing (DFM) and design for assembly (DFA) are the integration of product design and process planning into one common activity. The goal is to design a product that is easily and economically manufactured. The importance of designing for manufacturing is underlined by the fact that about 70% of manufacturing costs of a product (cost of materials, processing, and assembly) …

Printed Circuit Board Recycling Methods US EPA

Case Study on Can Making CORE-Materials

Plating is a manufacturing process in which a thin layer of metal coats a substrate. This can be achieved through electroplating, which requires an electric current, or through electroless plating, which is in autocatalytic chemical process. In either case, the technique results in one or several of the following benefits:

Get expert industry market research on Metal Can & Container Manufacturing in the US. Industry market research reports, statistics, data, trends, forecasts and information. Save time, save money, generate more revenue, mitigate risk and make faster and better business decisions.

THE HISTORY OF THE CAN IS LITERALLY A HISTORY of western civilization, and its innovation an engine of prosperity in the United States. Two centuries ago, the first cans were designed to sustain world powers in their quests around the globe.

Hobo stove Wikipedia

Can Making Process Manufacturing Process of TULC Can

How Cans Are Made Can Manufacturers Institute

manufacturing of pressure vessels pdf – The manufacture production processing and treatment of

The Tin Plating Process A Step-By-Step Guide Sharretts

Tinning Wikipedia

Can coatings for foods and beverages issues and options

7 replies on “Tin can manufacturing process pdf”

Leave a CommentGet expert industry market research on Metal Can & Container Manufacturing in the US. Industry market research reports, statistics, data, trends, forecasts and information. Save time, save money, generate more revenue, mitigate risk and make faster and better business decisions.

Manual on fish canning 2. Packaging materials for canned

Preliminary Industry Characterization: Metal Can Manufacturing–Surface Coating U. S. Environmental Protection Agency Coatings and Consumer Products Group Emission Standards Division Office of Air Quality Planning and Standards Research Triangle Park, NC 27711 September 1998. i TABLE OF CONTENTS Page 1.0 OVERVIEW OF INITIAL MACT DEVELOPMENT PHASE FOR THE METAL CAN MANUFACTURING…

Beverage Cans Aluminium Cans Textured Gloss or Matte

5.23 Significant amendments to the manufacturing process, including any change in equipment or materials, which may affect product quality and/or the reproducibility of the process should be validated.

Types of Cans Can Technical Information TOYO SEIKAN

Independently of the material and the production process, most cans are coated internally and externally with films of 1 to 10 µm thickness. Coatings are usually applied to both sides of planar metal sheets or coils by roller coating before the cans are formed. Alternatively, coatings are sprayed on preformed cans. Tin cans are used without internal coatings for light colored, acidic juices

KBA-MetalPrint on the possibilities and applications of

Tin Can Manufacturing Process Tin Can Alibaba

Tin layer on the inside of a tin can Tinning is the process of thinly coating sheets of wrought iron or steel with tin , and the resulting product is known as tinplate . The term is also widely used for the different process of coating a metal with solder before soldering.

Beverage Cans Aluminium Cans Textured Gloss or Matte

ііі) Develop the model tin can crusher using bending process, welding process, drilling process and cutting process. іv) Fabricate the model tin can crusher using welding skill and machining.

December 2016 Birgit Geueke foodpackagingforum.org

Tinning Wikipedia

Strategies for Manufacturing1 ISIE

The International Programme on Chemical Safety (IPCS), established in 1980, is a joint venture of the United Nations Environment Programme (UNEP), the International Labour Organization (ILO), and the

471 Tin Cans (Page 1)

Tin Can Manufacture Tin Can Manufacture Suppliers and

Can Making Process Manufacturing Process of TULC Can

Comments are closed.