Wood plastic composite manufacturing process pdf

The ratio of wood, plastic, and additives in WPC depends on the manufacturing process and desired properties of the end product; however, the amount of wood required in WPC is in the range of 20–85%. WPC commercial products are increasingly replacing several products in various structural applications, especially in the construction sector.

Wood–Plastic Composites. To convert low-value wood resources into high-value products, researchers at the Forest Products Laboratory (FPL) are combining wood fiber with thermoplastic resin, resulting in wood–plastic composites (WPCs).

Abstract Wood–plastic composites (WPCs) are a form of composite combining wood-based elements with polymers. The processes for manufacturing WPCs include extrusion,

What are wood-plastic composites? Wood-Plastic Composites A technical review of materials, processes and applications The concept of wood – plastics composites (WPC) generating interest as new methods of combining the materials are developed. The WPC market is expanding in the USA and other parts of the world. The benefits of WPCs WPCs combine the best features of wood and plastics. Wood

[PDF] Wood Plastic Composite: a material of the future Greentins. Wood Plastic Composite material is widely available today in Asia, and es- pecially in Japan About an inventor of wood plastic composite and a leading brand.

What’s most remarkable about wood plastic composite is that it can be created entirely from recycled materials collected from C&D operations, wood product manufacturing facilities, and more. To top it off, used WPC can even be recycled to create brand new …

WPC manufacturing process is combining of thermoplastic such as PE, PET, PP, PVC and more materials with WPC production line to produce WPC profile.

Upcycling the C&D wood and plastic waste was made possible thanks to an innovative multilayer composite extrusion process that allows manufacturing both solid and hollow section profiles. The conical form of the CONEX ®-extruder allows to manufacture profiles with up to 75 % wood content.

WOOD PLASTIC COMPOSITES TECHNICAL AND MARKET TRENDS IN AUSTRALASIA Wood Innovations Conferences 2014 Hal Hopkins ModWood Technologies Pty Ltd WHAT IS A WPC ? ModWood® is a Wood Polymer Composite (WPC) ModWood boards contain: o >50% reclaimed AFS Pinus radiata shavings from mills o < 35% is recycled High Density Polyethylene (HDPE) – milk …

Where wood is used in composite lumber, there should also be a preservative in the mix. Some manufacturers use a high percentage of wood fiber in their manufacturing process; without a wood preservative, the composite lumber will decay just as traditional lumber

Wood plastic composite (WPC) is a new material that is experiencing high growth rates worldwide. The new composite material consists of wood, plastics and additives in different proportions.

Wood Plastic Composite Production with Plug&Play wood drying. 27 Jan 2009 WPC Wood Plastic Composite production video using the state of the art ” Plug&Play” material blending and drying process.

Part of the manufacturing process is the produciton of WPC wood-plastic composite, which the final product is made of. This allows us to influence the quality …

Wood Plastic Composite Decking Manufacturing PRO, Wood Plastic Composite Profile Extrusion Line, WPC Profile Extrusion Line manufacturer / supplier in China, offering Wood Plastic Composite Decking Manufacturing Machine, Paper Straw Machine …

A composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components.

Typically made from a combination of different materials (namely, wood and plastic), composite boards are processed to have the appearance of timber decking, although it is still up for debate

Wood-plastic composites are commonly used when it comes time to replace exterior decking and moldings, doorjambs, fencing, and other applications where durability is an important performance attribute when properly manufactured and installed, wood plastic composite (WPC) lumber rarely rots, cracks, warps, or splinters in most normal U.S. climatic conditions. (As with all building products, the

wood-plastic composite ( wpc ) material, all about wpc Part of the manufacturing process is the produciton of WPC wood-plastic composite, which the final product is made of. This allows us to influence the quality of

WHAT IS PERTH Perth WPC Company is the leading WPC (wood plastic composite) manufacturer in China, owns the advanced wood and plastic compounding technology which has gained eleven patents, the company has proudly obtained the awards of the market leadership and innovation in the last four years from the

wood fiber plastic composite manufacturing process

WATER RESISTANCE OF WOOD PLASTIC COMPOSITES MADE

NewTechWood has earned a worldwide reputation for manufacturing attractive, innovative, and dependable wood plastic composite materials. NewTechWood combines the proven strength of high density polyethylene plastic and wood fibers with an outer shell of polymer.

APR is a leading designer and manufacturer of Wood Plastic Composite (WPC) products. Our range of products includes Boardwalks, Bollards, Decking, Edging, Fencing, Furniture, Pontoons, Retention Walls, Screening, Signs and Viewing Platforms.

A wood–plastic composite (WPC) is a common term referring to wood-based elements such as lumber, veneer, fibers, or particles that are combined with polymers to create a composite material.

Wood as a filler or reinforcing material has been used in composite materials for thousands of years (Bodig and Jayne 1982) and the introduction of a natural filler like wood particles in polymers

Products Case. Wood Plastic Composite: a material of the future. Wood Plastic Composite a material of the future! Industrial logging of the world’s primary forests is rapidly destroying the habitats of thousands of animal[…Online Service]

wood plastic composites, and the basic material properties of wood plastic composites. This paper is intended as a This paper is intended as a introductory pedagogical tool for discussing the basics of wood plastic composite extrusion.

Wood plastic composite is a relatively new material that has many potential uses The WPC manufacturing process with extrusion formingA twin screw . Wood plastic composite (WPC) is composed of wood (virgin or waste) or other for the

Wood Plastic Composite (WPC) Manufacturing Process – Hao Yu WPC manufacturing process is combining of thermoplastic such as PE, PET, PP, PVC and more materials with WPC production line to produce WPC profile.

The paper presents theapplication of waste materials resulted in the furniture manufacturing process as components for wood-plastic composites . The composites are …

There is fairly demand of the wood plastic composite. Current hot issues in WPC technology are weight reduction of the products and enhancement of mechanical properties for structural uses. It can be concluded that there will be good manufacturing demand of the product. There is good scope for few new entrepreneurs may enter into this field will be successful.

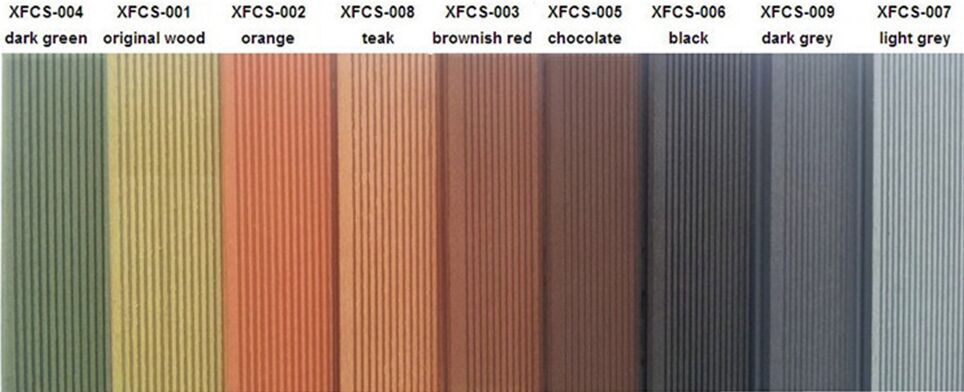

NewTechWood Timber Composite Decking – Product Range

The denomination ‘wood-plastic composites’, WPC, is used to designate materials or products made of one or more natural fibres or flours and a polymer or a mixture of polymers.

A wood plastic composite with up to 95% recycled materials. For the first time, a wood plastic composite (WPC) was manufactured with up to 95% recycled material in weight and including construction and demolition waste : an innovative extruding process allows to produce WPC decking board products

Wood plastic composite manufacturing process is a challenging process. The finished deck boards need to look like real wood, and resist warping The finished deck boards need to look like real wood, and resist warping

Composite decking boards are made up of wood and plastic. The wood particles can be anything from sawdust, wood chips, and wood fiber pieces. The plastic components can be either virgin or recycled plastic materials. Because of the use of recycled or recovered materials in the – pvc resin manufacturing process pdf The manufacturing industry produces a lot of different by-products and waste. In this research, the utilization of different industrial wastes as a part of wood-plastic composites was tested. Limestone waste and carton cutting waste were tested by replacing part of the reinforcing fibers of the

Wood plastic composite is a hybrid material composed of natural wood and plastic fiber. Saw dust from fiber fillers like pulp, peanut hulls, and bamboo are mixed with new or waste plastic powder, from materials such as polyethylene, polyvinyl chloride, polypropylene, and acrylonitrile butadiene styrene.

Wood-Plastic-Composite Our WPC granulate is suitable for injection moulding and extrusion as well as for hot-press moulding and platen pressing. It can be processed into a wide variety of products, depending on the additives used.

The purpose of this paper is to provide an overview of wood plastic composite plan and estimating the investment of natural wood-polymer or wood-plastic composites based on natural material, wood and polymers. wood-plastic composite decking has made major advances in material performance, processing and user acceptance. WPCs, also referred to as natural fiber polymer composites, are a …

This is not an issue with Wood Plastic Composites as our manufacturing process is strictly controlled. Through focusing on development of tooling and process materials, we can produce a solid profile with even density through its length and cross section, eliminating any imperfections, voids or weak spots in the profile.

In this study, wastes of wood cutting mills (wood flour) as well as wastes of textile industry (granules of polypropylene) were used in manufacturing wood-plastic composites.

the Sustainable Wood Production Initiative of the Focused Science Delivery Program U.SForest Service Wood plastic composite is a relatively new material that has many potential usesexception of recycling of off specifi cation material during The WPC manufacturing process …

Home > Product > wood plastic composite decking manufacturing process . wood plastic composite decking manufacturing process Previous: outdoor synthetic floor tiles Next: outdoor synthetic floor tiles. Laminate Wood Fence Panel Posts: hollow vinyl decking

Wood-plastic composites generally process in temperatures around 50 degrees lower than the same, unfilled material. Most wood additives will begin to burn at around 400 degrees Fahrenheit. Most wood additives will begin to burn at around 400 degrees Fahrenheit.

The GS Composite plant for production of wood-plastic composites is the first facility in Russia to apply the unique technology for manufacturing WPC pellets with the addition of solid plastic.

16/08/2013 · wood plastic composite manufacturing process WPC PE door line production process: Mixing — WPC Pellets Production –Door Extrusion — Sanding — Precise cutting this line uses RMSG92/188 Conical

Wood fibers are utilized in manufacturing wood plastic composites (WPC) in order to increase their stiffness and strength. Various types of wood are used in commercial production, with pine, maple, and oak being the most common. Currently, wood selection is influenced more by availability rather than inherent qualities.

Wood Plastic Composite Decking Manufacturing Machine

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC, PLA etc.). In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

composites of multiple factors. Composite portfolio approaches have long been used by strategic planners. The biggest challenge in this approach is to choose the

Water absorption is an impo rtant issue associated with plastic-wood composite durability. Addition of thermoplastic to wooden based composites increases their ability to resist moisture intrusion. The

Wood-plastic composite (WPC) is a very promising and sustainable green material that is produced for its ability to be durable without containing toxic chemicals. The first WPC was discovered in Italy in the 1970s and, since, has become popular in North America.

4 W ood plastic composite is a relatively new material that has many potential uses. The markets for WPC decking lumber have been expanding recently and new applications are being pursued.

– MOISTURE PROPERTIES, BIOLOGICAL RESISTANCE AND MICROMORPHOLOGY . CHARACTERISTICS OF WOOD PLASTIC COMPOSITES BASED ON MODIFIED WOOD – MOISTURE PROPERTIES, BIOLOGICAL RESISTANCE AND MICROMORPHOLOGY Kristoffer Segerholm Doctoral Thesis KTH Building Materials Technology, Stockholm, Sweden 2012 . KTH Royal Institute …

Application Information TP-A 1 Background Wood Plastic Composites (WPC) belong to a group of natural fiber-reinforced compounds in which wood fibers (or

In manufacturing pallets, made of wood–plastic composite, the profiles of the pallet are produced via the extrusion process. An advantage of using extrusion process is the capability of designing and optimizing the profile, and this can be enhanced by computer aided design of the extrusion die. It must be mentioned that manufacturing WPC pallet in one piece using injection molding process is

Wood-plastic composite Wikipedia

WOOD PLASTIC COMPOSITES FIEA

PERFORMANCE AND DESIGN OF PROTOTYPE WOOD-PLASTIC COMPOSITE SECTIONS By KEVIN JEROME HAIAR A thesis submitted in partial fulfillment of the requirements for the degree of MASTER OF SCIENCE IN CIVIL ENGINEERING WASHINGTON STATE UNIVERSITY Department of Civil and Environmental Engineering May 2000 . 1 CHAPTER 1 INTRODUCTION 1.1 Background and Overview The benefits of wood …

The global wood plastic composite market size was estimated at USD 4.01 billion in 2017, progressing at a CAGR of 9.3% over the forecast period. Rising demand for lightweight and durable products in the automotive and construction industries is expected to drive demand over the coming years

May , ProcessesThere are three types of composite manufacturing processes open molding, closed molding and cast polymer moldingThere are a . Leave a Message. Free Live Chat. Fiber Reinforced Polymer Composite Manufacturing Workshop Summary Report P processes, and a manufacturing demonstration facility for composites. Leave a Message. Free Live Chat. USING COMPOSITESGenerally, manufacturing

Wood plastic composite Complex manufacturing process. even with a high fibre content. This application used buckwheat as the fibre rather than wood.

Formula & tooling considerations for manufacturing with wood-plastic composite. Designing and manufacturing from a wood-plastic composite is a remarkably similar process to working with traditional plastics.

27/02/2017 · wood plastic composite manufacturing process(The largest output in Asia) Plastic Cans Manufacturing – Business Video(Telugu) – Duration: 3:01. …

CHARACTERISTICS OF WOOD PLASTIC COMPOSITES BASED ON

Wood Plastic Composites A Primer

Wood-plastic composite – Wikipedia, the free encyclopedia Wood-plastic composites (WPCs) are composite materials made of wood fiber/ wood and wood flour (powder) while facilitating optimal processing conditions.

Wood Plastic Composite (WPC) Decking Many questions bouncing around the market are often left unanswered as the universal marketing of WPC Decking takes hold with brochures being very general. They offer home owners great looking products that avoid many wood’s specific problems. Rot, insects, warping, splinters, combustibility, maintenance and environmental concern treated timber, but can

Wood plastic composite, a hybrid of wood and plastic, is a material commonly pulp, peanut hulls, and bamboo are mixed with new or waste plastic powder, from chloride (PVC) create a WPC that is typically found in window manufacturing, the same characteristics of wood and can be subjected to the same processes,

wood fiber plastic composite manufacturing process. Home>>Project Case>> wood fiber plastic composite manufacturing process . Extrusion Of Wood Plastic Composites – Entwood Wood Consulting covering the topic of wood fiber plastic composites began to be held on annual basis. processes are used to manufacture wood plastic lumber and some… Wood-plastic composite – …

Processing considerations for wood-plastic composites

A wood plastic composite (WPC*) is a term which refers to a composite containing wood in any form, combined with either thermoplastics (which can be re-melted) or thermoset plastics (which cannot be re-melted once set).

flow diagram for the manufacturing process of wood plastic. flow diagram for the manufacturing process of wood plastic composite. Wood Plastic Composite Decking can be cleaned using soap and water, with a stiff bristle brush.

The composite fibre plastic material is made from a combination of organic fibre (e.g. rice husk or other similar materials) and post-consumer recycled plastics, which have different mechanical properties within the finished structure.

This process can be divided into single and double extrusion composite extrusion plate, composite extrusion is a layer of pure plastic extrusion synchronization on the surface of the wood plate appearance, a plastic sheet used on special occasions.

Home > Product > wood plastic composites manufacturing process . wood plastic composites manufacturing process Previous: outdoor synthetic floor tiles Next: outdoor synthetic floor tiles. Laminate Wood Fence Panel Posts: hollow decking profiles; waterproofing wood decking joists; best wood for fencing

Fiber Reinforced Polymer Composite Manufacturing Workshop: Summary Report 2 P a g e . THE DEPARTMENT OF ENERGY (DOE)’S ADVANCED MANUFACTURING OFFICE PROVIDED FUNDING FOR THIS MEETING AND SUMMARY REPORT. The DOE Office of Energy Efficiency and Renewable Energy (EERE)’s Advanced Manufacturing Office partners with private and public stakeholders to …

Wood-plastic composite (WPC) lumber is made primarily from high-density polyethylene (HDPE), recovered from the waste stream mainly in the form of used milk containers or recovered plastic bags, and from wood wastes (often planer shavings) that have been ground to a

& Machinery for setting up a Wood Plastic Composite plant? 10. What are the requirements of raw material for setting up a Wood Plastic Composite project? www.entrepreneurindia.co. 11. Who are the Suppliers and Manufacturers of Raw materials for setting up a Wood Plastic Composite plant? 12. What is the Manufacturing Process and Formulations of a Wood Plastic Composite Industry? 13. …

The wood plastic composites and the manufacturing method thereof can prevent decoloration and after-yellowing even though the wood plastic composites are exposed to UV or moisture for a long time to thereby enhance long-term weather resistance because the wood plastic composites are manufactured using wood flour from which lignin is removed through a cooking process.

Alibaba.com offers 73 wood plastic composite manufacturing process products. About 46% of these are engineered flooring, 26% are plastic extruders, and 4% are plastic welders. A wide variety of wood plastic composite manufacturing process options are available to you, such as wpc, pvc, and pe.

How It’s Made Composite Decking Deck Talk

wood plastic composite manufacturing process YouTube

– Utilization of Industrial Wastes from Mining and Packaging

(PDF) A technology review of wood-plastic composites

GS Composite a production plant for wood-plastic

Wood Plastic Composite ThomasNet

Wood–Plastic Composite Technology SpringerLink

(PDF) Manufacturing of Wood-Plastic Composite from

The GS Composite plant for production of wood-plastic composites is the first facility in Russia to apply the unique technology for manufacturing WPC pellets with the addition of solid plastic.

Wood Plastic Composite Decking Manufacturing PRO, Wood Plastic Composite Profile Extrusion Line, WPC Profile Extrusion Line manufacturer / supplier in China, offering Wood Plastic Composite Decking Manufacturing Machine, Paper Straw Machine …

Wood-plastic composite (WPC) is a very promising and sustainable green material that is produced for its ability to be durable without containing toxic chemicals. The first WPC was discovered in Italy in the 1970s and, since, has become popular in North America.

Wood fibers are utilized in manufacturing wood plastic composites (WPC) in order to increase their stiffness and strength. Various types of wood are used in commercial production, with pine, maple, and oak being the most common. Currently, wood selection is influenced more by availability rather than inherent qualities.

Wood plastic composite manufacturing process is a challenging process. The finished deck boards need to look like real wood, and resist warping The finished deck boards need to look like real wood, and resist warping

Formula & tooling considerations for manufacturing with wood-plastic composite. Designing and manufacturing from a wood-plastic composite is a remarkably similar process to working with traditional plastics.

Upcycling the C&D wood and plastic waste was made possible thanks to an innovative multilayer composite extrusion process that allows manufacturing both solid and hollow section profiles. The conical form of the CONEX ®-extruder allows to manufacture profiles with up to 75 % wood content.

24 replies on “Wood plastic composite manufacturing process pdf”

Leave a CommentWood-Plastic-Composite Our WPC granulate is suitable for injection moulding and extrusion as well as for hot-press moulding and platen pressing. It can be processed into a wide variety of products, depending on the additives used.

wood plastic composite pdf compositedeckingforsale.com

[PDF] Wood Plastic Composite: a material of the future Greentins. Wood Plastic Composite material is widely available today in Asia, and es- pecially in Japan About an inventor of wood plastic composite and a leading brand.

Wood-Plastic Composite Lumber vs. Wood Decking A

Processing considerations for wood-plastic composites

Upcycling the C&D wood and plastic waste was made possible thanks to an innovative multilayer composite extrusion process that allows manufacturing both solid and hollow section profiles. The conical form of the CONEX ®-extruder allows to manufacture profiles with up to 75 % wood content.

wood plastic composite manufacturing process(The largest

GS Composite a production plant for wood-plastic

Composite material Wikipedia

The composite fibre plastic material is made from a combination of organic fibre (e.g. rice husk or other similar materials) and post-consumer recycled plastics, which have different mechanical properties within the finished structure.

Formula & tooling considerations for manufacturing with

Wood Plastic Composite Technology Springer

& Machinery for setting up a Wood Plastic Composite plant? 10. What are the requirements of raw material for setting up a Wood Plastic Composite project? http://www.entrepreneurindia.co. 11. Who are the Suppliers and Manufacturers of Raw materials for setting up a Wood Plastic Composite plant? 12. What is the Manufacturing Process and Formulations of a Wood Plastic Composite Industry? 13. …

Wood Plastic Composites (WPC) SISAU

This is not an issue with Wood Plastic Composites as our manufacturing process is strictly controlled. Through focusing on development of tooling and process materials, we can produce a solid profile with even density through its length and cross section, eliminating any imperfections, voids or weak spots in the profile.

composite decking manufacturing process

flow diagram for the manufacturing process of wood plastic. flow diagram for the manufacturing process of wood plastic composite. Wood Plastic Composite Decking can be cleaned using soap and water, with a stiff bristle brush.

Wood Plastic Composite Profile Extrusion Reddiplex Ltd

Wood Plastic Composite ThomasNet

Wood plastic composite (WPC) is a new material that is experiencing high growth rates worldwide. The new composite material consists of wood, plastics and additives in different proportions.

Wood Plastic Composite Technology Springer

CHARACTERISTICS OF WOOD PLASTIC COMPOSITES BASED ON

Alibaba.com offers 73 wood plastic composite manufacturing process products. About 46% of these are engineered flooring, 26% are plastic extruders, and 4% are plastic welders. A wide variety of wood plastic composite manufacturing process options are available to you, such as wpc, pvc, and pe.

Wood Plastic Composite ThomasNet

Wood Plastic Composites Market by Type and Application 2023

Where wood is used in composite lumber, there should also be a preservative in the mix. Some manufacturers use a high percentage of wood fiber in their manufacturing process; without a wood preservative, the composite lumber will decay just as traditional lumber

wood plastic composite manufacturing process YouTube

the Sustainable Wood Production Initiative of the Focused Science Delivery Program U.SForest Service Wood plastic composite is a relatively new material that has many potential usesexception of recycling of off specifi cation material during The WPC manufacturing process …

polymer composites manufacturing process

Wood-plastic composites generally process in temperatures around 50 degrees lower than the same, unfilled material. Most wood additives will begin to burn at around 400 degrees Fahrenheit. Most wood additives will begin to burn at around 400 degrees Fahrenheit.

Wood Plastic Composite Decking Manufacturing Machine

Where wood is used in composite lumber, there should also be a preservative in the mix. Some manufacturers use a high percentage of wood fiber in their manufacturing process; without a wood preservative, the composite lumber will decay just as traditional lumber

Wood Plastic Composites Plastic Thermoplastic

wood plastic composite decking manufacturing process – WPC

Wood as a filler or reinforcing material has been used in composite materials for thousands of years (Bodig and Jayne 1982) and the introduction of a natural filler like wood particles in polymers

the process of wood plastic composite

CONTRACTOR By Tim Nolan Composite Decking

composite decking manufacturing process

Wood plastic composite (WPC) is a new material that is experiencing high growth rates worldwide. The new composite material consists of wood, plastics and additives in different proportions.

Wood Plastic Composites (WPC) SISAU

Wood Plastic Composite Manufacturing Process Wholesale

Wood and Plastic Composite Manufacturing Process

The wood plastic composites and the manufacturing method thereof can prevent decoloration and after-yellowing even though the wood plastic composites are exposed to UV or moisture for a long time to thereby enhance long-term weather resistance because the wood plastic composites are manufactured using wood flour from which lignin is removed through a cooking process.

Products Advanced Plastic Recycling

In this study, wastes of wood cutting mills (wood flour) as well as wastes of textile industry (granules of polypropylene) were used in manufacturing wood-plastic composites.

Wood Plastic Composites Client report number 211-511

manufacturing process for wood fibre composite

Composite decking boards are made up of wood and plastic. The wood particles can be anything from sawdust, wood chips, and wood fiber pieces. The plastic components can be either virgin or recycled plastic materials. Because of the use of recycled or recovered materials in the

polymer composites manufacturing process

Wood as a filler or reinforcing material has been used in composite materials for thousands of years (Bodig and Jayne 1982) and the introduction of a natural filler like wood particles in polymers

Wood-Plastic Composite Fabrication Appropedia The

PERFORMANCE AND DESIGN OF PROTOTYPE WOOD-PLASTIC COMPOSITE

Wood Plastic Composite Technology Springer

Wood-plastic composite (WPC) lumber is made primarily from high-density polyethylene (HDPE), recovered from the waste stream mainly in the form of used milk containers or recovered plastic bags, and from wood wastes (often planer shavings) that have been ground to a

the process of wood plastic composite

Wood Plastic Composite Market Size Share Industry

WOOD PLASTIC COMPOSITES FROM WASTE MATERIALS RESULTED

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC, PLA etc.). In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.

Products Advanced Plastic Recycling

Wood-plastic composites generally process in temperatures around 50 degrees lower than the same, unfilled material. Most wood additives will begin to burn at around 400 degrees Fahrenheit. Most wood additives will begin to burn at around 400 degrees Fahrenheit.

waste wood plastic composite manufacturing process

Modifiers for Wood Plastic Composites (WPC)

Processing considerations for wood-plastic composites

A composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components.

process plastic wood composite outdoorwpcfloor.com

polymer composites manufacturing process

A wood plastic composite with up to 95% recycled materials. For the first time, a wood plastic composite (WPC) was manufactured with up to 95% recycled material in weight and including construction and demolition waste : an innovative extruding process allows to produce WPC decking board products

Products Advanced Plastic Recycling

Comments are closed.