Emulsion paint manufacturing process pdf

Paint making process. What is paint made from? Paint consists of binders, pigments and fillers, solvents or water, and of so-called additives. When developing new paint, the raw materials are chosen for compatibility with the object to be painted.

with emulsion (not the emulsion to the water). • DO if possible, use warm water for dilution and always add the water slowly to the emulsion (not the emulsion to the water).

sections, together with details of each process and methods for its prevention. Creaming and Sedimentation This process results from external forces, usually gravitational or centrifugal. When such forces exceed the thermal motion of the droplets (Brownian motion), a concentration gradient builds up in the system such Table 1.1 Classification of emulsion types. Nature of emulsifier Structure

The process by which an emulsion completely breaks (coalescence), i.e., the system separates into bulk oil and water phases, is generally considered to be governed by four different droplet loss mechanisms, i.e., Brownian flocculation, cream-ing, sedimentation flocculation and disproportionation, shown schematically in Figure 1. The first three are the primary methods by which emulsions are

So, now you can know, that paint manufacturing is a hard process, that’s why we recommend you to look through our raw materials for paint productionon our web-site. There is a big list of raw materials of paint in our company, e.g. solvents.

This refers to the process of thinning and disruption of the liquid film between the droplets with the result of fusion of two or more droplets into larger ones. The limiting case for coalescence is the complete separation of the emulsion into

Frigmaires International-Manufacturer and supplier of turnkey manufacturing project, process plants, turnkey plant services, soap manufacturing plant, resin plant, paint plant machines, paint manufacturing plant, grease plant, lube oil plant, mixers, bitumen emulsion plant, dry mix mortar manufacturing plant.

How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue . www.entrepreneurindia.co Paint is any liquid, liquefiable, or …

Pre-Feasibility Study A Process for the Production of De-Foamer for Emulsion Paint Pakistan Council of Scientific and Industrial Research Head Office

How to produce perfect emulsion paint and its procedure To produce emulsion paint,you need the following bowl stirring stick,water (h20), this is for production of 20 litres of brilliant white paint. NOTE: this is for the production of 20 formular for 20 litres white emulsion paint. THINGS YOU NEED water – 12kg calgon 0.1kg titan dioxide 0.5kg aluminium silicate 1.0kg calcuim carbonate 13kg

What Is Emulsion Paint Used For? Emulsion, or water-based latex, paint is usually used to paint interior walls and ceilings. Some types of emulsion paint can also be used to paint woodwork. Some people use emulsion paint for special finishes, such as rag rolling. It can be used for stenciling and

11 Acrylic emulsion (46%) 43 12 Ammonia 0.2 Manufacture Block diagram of manufacturing process Diagram with process equipment Animation P i gment Vehi cl e Ot her r aw mat er i al M i x e r B a lmi B a t c h t i n t i n g P ack agi ng & s t or age F i gu r e: Manuf actur i ng of P ai nt. Module: 11 Lecture: 45 Paint industries Dr. N. K. Patel N P T E L 281 Required amount of ingredient along

15/01/2013 · www.paintingformulas.com —– Learn to manufacture paint (High quality at low cost) of every kind and other related products, we give total instruction with videos.

Industrial Paints INDUSTRIAL PAINTS FORMULATIONS ENCYCLOPEDİA – 1 is enough. This encyclopedia has many formulations of hammer finish paints formulation and production process,hammered finish paint metal manufacturing process, hammer color paints, making hammer paint spray, stoving enamel paint thinnerformulations, stoving enamel paint

N-344C Waterborne Acrylic Emulsion Formulation Using

Pre-Feasibility Study

acrylic emulsion manufacturing process XSM is a leading global manufacturer of crushing and milling equipment (acrylic emulsion manufacturing process),XSM also supply individual (acrylic emulsion manufacturing process…) crushers and mills as well as spare parts of them.

latex, paint, blood * water as continuous phase and an organic dispersed phase or vice versa (inverse emulsions) What is an Emulsion? an emulsion is a liquid in liquid dispersion a (polymer) solution is also a liquid (polymer) solutions can form emulsions an emulsion droplet interface has at any point the same interfacial tension (in contrast to many suspension particles) sometimes emulsions

Paint Manufacturing Process Plc Paint industry How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue

understanding of the setting process are outlined. The classification of emulsions into grades according to their reactivity, particle charge, and physical properties is explained and typical recipes of various emulsion grades are given. The selection of the correct emulsion grade for the various applications based on emulsion reactivity and physical properties of the emulsion is covered in

1.it is for high quality emulsion paint used for interior and exterior , if we need to make it glossy or egg-shell how we can do this . 2.about the formula is there any comment please advice me . 3.is there any preservative we have to put .

the process includes The liquids are added first and as the powders are added gradually, both shaft are made operational. The high speed shaft does the shearingdispersion while the slow speed shaft helps bring the material toward the agitation disc to enable dispersion.

Emulsion paints dry by a physical process involving the evaporation of water followed by coalescence of the polymer droplets and their subsequent integration into …

used as a supplement to PVA in emulsion paint production in all proportions investigated except Sample F. Keywords: High Cost, Supplement, Quality Parameters, Polyvinyl Acetate, Gum Arabic, Emulsion Paint 1. Introduction The terms ‘paint’ and ‘surface coating’ are often used interchangeably. Surface coating is the more general description of any material that may be applied as a thin

The invention discloses a formula and a manufacturing process of water emulsion type high polymer modified asphalt waterproof paint. The formula is characterized by comprising the following components in percentage by mass: 40 to 45 percent of No.90 asphalt, 5 to 9 percent of modifier, 35 to 45 percent of water, 6 to 10 percent of emulsifier, 2

13/10/1981 · A process for preparing a substantially lump free acrylic resin emulsion by emulsion polymerization of one or more acrylic monomers in water in the presence or absence of an emulsifier or a dispersing agent, wherein the polymerization is carried out in the presence a water-insoluble resin which is immiscible with the acrylic resin in

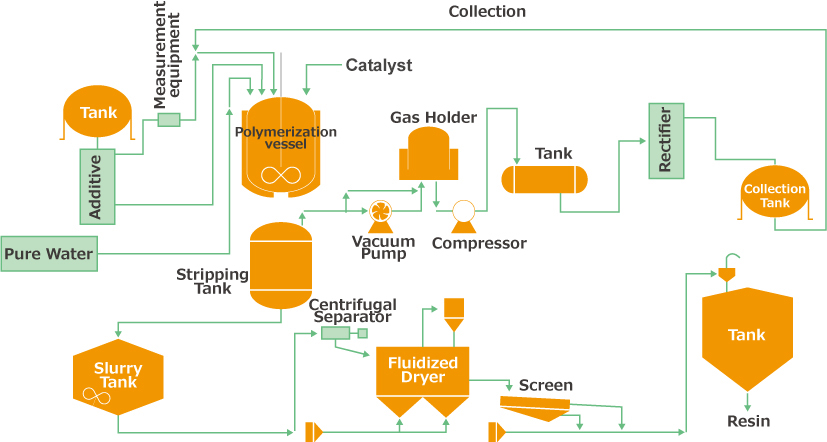

Production of Trowel Paints using Polyvinyl Acetate Synthesized from Vinyl Acetate Monomer as a Binder Habibu UTHMAN 50 Introduction The polymerization of vinyl acetate monomer gave rise to copolymer and homo-

An emulsion, made up of an aqueous and an oil phase, is a common type of delivery system used for personal care products, enabling a wide variety of ingredients to …

27/05/2011 · Please kindly post the measurements to produce a 20litres emulsion paint for the first method, that would give an insight to produce large quantity.

Increasing PVAc emulsion polymerization productivity-an industrial application Ashwini Sood Department of Chemical Engineering, Harcourt Butler Technological Institute, Kanpur 208 002, India Email: sood.ashwini@rediffmail.com Received 21 April 2009; revised 5 November 2009 A major objective in the operation of emulsion polymerization processes is that of faster and safer operation …

“Acrylic Emulsion Technology: From plastics to paints, it changed our world” commemorative booklet produced by the National Historic Chemical Landmarks program of the American Chemical Society in 2008 (PDF).

Introduction This description is designed for the general audiences who are interested in the effective use of the different types of paints and the general paint manufacturing procedures.

Emulsion Polymerization: Effects of Polymerization Variables on the Prop erties of Vinyl Acetate Ba sed Emulsion Polymers 37 Rubber Company, was the first to be granted a patent to produce a synthetic rubber in the

Styrene Acrylic Emulsion Products for Building and Construction Applications are water-based, emulsion copolymers of styrene and various acrylic monomers that are milky-white liquids with an ammonia or acrylic odor 1,2 For further details, see Product Description.

10/06/2016 · How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, …

Preliminary Environmental Assessment – Proposed Ammonium Nitrate Emulsion Production Facility and Continued Operation of Orica Mining Services Technology Park,

Request your selected information sheets via the e-mail form. Send your request. Request your selected information sheets via the e-mail form

Emulsion paints could be grouped as interior, economy, standard and premium (Nigerian industrial standard No.151 2008). As a gas or as a gaseous suspension, the paint …

AVANSE™ ST-410 Acrylic Emulsion is designed to give good film formation at 40°F without the use of coalescents. Because the good application properties come from the polymer particle stabilization, increasing glycol levels above 100 VOC does not appreciably improve the open time or lapping properties. Some water soluble glycol ether cosolvents such as DOWANOL™ DPM can help control …

RELATED TAGS: What is emulsion,what is emulsifier,how to make oil emulsion,types of emulsion,properties of emulsifier,making oil emulsion,formulation of emulsion,production process of oil emulsion,emulsion specification data,emulsion msds,emulsion ingredients,emulsion oil manufacturing process,formula of oil emulsion.

Waterborne acrylic emulsion formulation a semicontinuous reaction process. Most of the water, all of the surfactant, and a portion of the monomer blend are charged to form a reaction heel. A small amount of initiator is added to the heel to generate polymer “seed” particles. This aids in establishing a uniform particle size distribution in the final product. The remaining monomer and

How to Start a Paint Manufacturing Industry

These emulsion paints are generally physically drying and only contain a small amount of binder; the main constituents are pigments and extenders. Acrylate dispersions for paints have a good water vapor permeability and good water resistance. The paint industry …

Monday 28 April 2003 1:00:00 am. You may contact me directly for discussions to get your project for “Acrylic Emulsion Paints” started with type of products …

30/07/2012 · a complete guide to production of paint I sincerely welcome to this course. we shall be treating how to produce all kinds of paints from emulsion, textcoat, and Satin otherwise called nylon or washable paint. lets get started.

SUMMARY Emulsion polymerization is an important industrial process for the production of latex paints, rubbers, coatings and adhesives. Although the process has been used

ALTERNATIVES TO NATROSOL AS THICKENER IN THE PRODUCTION OF EMULSION PAINT Akpa Jackson Gunorubon and Uku Misel Department of Chemical/Petrochemical Engineering, Rivers State University of Science and Technology, Port-Harcourt, Rivers State, Nigeria E-Mail: jacksonakpa@yahoo.com ABSTRACT Alternative thickeners to an industrial thickener (natrosol) in the production of emulsion paints …

Advantages Of Emulsion Plants . Single Source responsibility for complete plant design right from Civil-Mechanical-Electrical to Chemical process. Client’s scope of work limited to bare minimum. Know how and training based on years of manufacturing experience. Modern Laboratory set up to meet basic international specifications (Optional). Plant design complies with local standards and safety

Emulsion Paints are basically water based paint principally used for internal as well as an external surface coating of the building. Emulsion Paints are highly durable, impermeable to dirt, resistant to washing and rapidly drying. It can be easily cleaned. – wind turbine blade manufacturing process pdf

Production of Emulsion House Paint Using Polyvinyl Acetate

CN102161865A Formula and manufacturing process of water

this formula is for emulsion paint / Optimized

emulsion made easy Ross Mixers

PAINT FORMULATION AND PROCESS. HOW TO YouTube

Guide formulations setylose.com

acrylic emulsion manufacturing process– Rock Crusher Mill

Process for preparing acrylic resin emulsions Nippon

– Frank Enabulele’s Blog How To Produce Emulsion Paint In

Production of Trowel Paints using Polyvinyl Acetate

RAW MATERIALS FOR PAINT MANUFACTURING

Step By Step Procedure On How To Produce Quality Emulsion

this formula is for emulsion paint / Optimized

Step By Step Procedure On How To Produce Quality Emulsion

11 Acrylic emulsion (46%) 43 12 Ammonia 0.2 Manufacture Block diagram of manufacturing process Diagram with process equipment Animation P i gment Vehi cl e Ot her r aw mat er i al M i x e r B a lmi B a t c h t i n t i n g P ack agi ng & s t or age F i gu r e: Manuf actur i ng of P ai nt. Module: 11 Lecture: 45 Paint industries Dr. N. K. Patel N P T E L 281 Required amount of ingredient along

10/06/2016 · How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, …

Emulsion Paints are basically water based paint principally used for internal as well as an external surface coating of the building. Emulsion Paints are highly durable, impermeable to dirt, resistant to washing and rapidly drying. It can be easily cleaned.

AVANSE™ ST-410 Acrylic Emulsion is designed to give good film formation at 40°F without the use of coalescents. Because the good application properties come from the polymer particle stabilization, increasing glycol levels above 100 VOC does not appreciably improve the open time or lapping properties. Some water soluble glycol ether cosolvents such as DOWANOL™ DPM can help control …

latex, paint, blood * water as continuous phase and an organic dispersed phase or vice versa (inverse emulsions) What is an Emulsion? an emulsion is a liquid in liquid dispersion a (polymer) solution is also a liquid (polymer) solutions can form emulsions an emulsion droplet interface has at any point the same interfacial tension (in contrast to many suspension particles) sometimes emulsions

So, now you can know, that paint manufacturing is a hard process, that’s why we recommend you to look through our raw materials for paint productionon our web-site. There is a big list of raw materials of paint in our company, e.g. solvents.

24 replies on “Emulsion paint manufacturing process pdf”

Leave a CommentThe invention discloses a formula and a manufacturing process of water emulsion type high polymer modified asphalt waterproof paint. The formula is characterized by comprising the following components in percentage by mass: 40 to 45 percent of No.90 asphalt, 5 to 9 percent of modifier, 35 to 45 percent of water, 6 to 10 percent of emulsifier, 2

AVANSE ST-410 Acrylic Emulsion Dow Chemical Company

SUMMARY Emulsion polymerization is an important industrial process for the production of latex paints, rubbers, coatings and adhesives. Although the process has been used

Styrene Acrylic Emulsion Products for Building and

Production of Emulsion House Paint Using Polyvinyl Acetate

Acrylic Emulsion Paints Entrepreneur India

Monday 28 April 2003 1:00:00 am. You may contact me directly for discussions to get your project for “Acrylic Emulsion Paints” started with type of products …

Production of Textcoat and Emulsion Paints Stainless For

Paint Manufacturing Process Plc Paint industry How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue

emulsion made easy Ross Mixers

This refers to the process of thinning and disruption of the liquid film between the droplets with the result of fusion of two or more droplets into larger ones. The limiting case for coalescence is the complete separation of the emulsion into

Acrylic Emulsion Paints Entrepreneur India

Paint Manufacturing Process Plc Paint industry How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue

Batch emulsion polymerization Laboratorio FIRP

Free Cash Manuals A COMPLETE GUIDE TO PRODUCTION OF PAINT

Step By Step Procedure On How To Produce Quality Emulsion

So, now you can know, that paint manufacturing is a hard process, that’s why we recommend you to look through our raw materials for paint productionon our web-site. There is a big list of raw materials of paint in our company, e.g. solvents.

What Is Emulsion Paint Used For? Reference.com

Styrene Acrylic Emulsion Products for Building and

Frank Enabulele’s Blog How To Produce Emulsion Paint In

Emulsion paints could be grouped as interior, economy, standard and premium (Nigerian industrial standard No.151 2008). As a gas or as a gaseous suspension, the paint …

Production of Emulsion House Paint Using Polyvinyl Acetate

Paint making process R&D and technology Tikkurila

AVANSE ST-410 Acrylic Emulsion Dow Chemical Company

Paint Manufacturing Process Plc Paint industry How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue

Formulations SOLVER CHEM – Production process

This refers to the process of thinning and disruption of the liquid film between the droplets with the result of fusion of two or more droplets into larger ones. The limiting case for coalescence is the complete separation of the emulsion into

Production of Emulsion House Paint Using Polyvinyl Acetate

Batch emulsion polymerization Laboratorio FIRP

ALTERNATIVES TO NATROSOL AS THICKENER IN THE PRODUCTION OF EMULSION PAINT Akpa Jackson Gunorubon and Uku Misel Department of Chemical/Petrochemical Engineering, Rivers State University of Science and Technology, Port-Harcourt, Rivers State, Nigeria E-Mail: jacksonakpa@yahoo.com ABSTRACT Alternative thickeners to an industrial thickener (natrosol) in the production of emulsion paints …

Process to Make Emulsions Paint Manufacturing Machine

Industrial Paints INDUSTRIAL PAINTS FORMULATIONS ENCYCLOPEDİA – 1 is enough. This encyclopedia has many formulations of hammer finish paints formulation and production process,hammered finish paint metal manufacturing process, hammer color paints, making hammer paint spray, stoving enamel paint thinnerformulations, stoving enamel paint

Increasing PVAc emulsion polymerization productivity-an

Production of Trowel Paints using Polyvinyl Acetate

Pre-Feasibility Study A Process for the Production of De-Foamer for Emulsion Paint Pakistan Council of Scientific and Industrial Research Head Office

emulsion made easy Ross Mixers

Batch emulsion polymerization Laboratorio FIRP

Emulsion paints could be grouped as interior, economy, standard and premium (Nigerian industrial standard No.151 2008). As a gas or as a gaseous suspension, the paint …

Free Cash Manuals A COMPLETE GUIDE TO PRODUCTION OF PAINT

1.it is for high quality emulsion paint used for interior and exterior , if we need to make it glossy or egg-shell how we can do this . 2.about the formula is there any comment please advice me . 3.is there any preservative we have to put .

Step By Step Procedure On How To Produce Quality Emulsion

Waterborne acrylic emulsion formulation a semicontinuous reaction process. Most of the water, all of the surfactant, and a portion of the monomer blend are charged to form a reaction heel. A small amount of initiator is added to the heel to generate polymer “seed” particles. This aids in establishing a uniform particle size distribution in the final product. The remaining monomer and

How to Start a Paint Manufacturing Industry

Formulations SOLVER CHEM – Production process

Emulsion Polymerization: Effects of Polymerization Variables on the Prop erties of Vinyl Acetate Ba sed Emulsion Polymers 37 Rubber Company, was the first to be granted a patent to produce a synthetic rubber in the

this formula is for emulsion paint / Optimized

Production of Emulsion House Paint Using Polyvinyl Acetate

Batch emulsion polymerization Laboratorio FIRP

How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue . http://www.entrepreneurindia.co Paint is any liquid, liquefiable, or …

Turnkey Manufacturing Project Process Plants Manufacturer

Paint making process. What is paint made from? Paint consists of binders, pigments and fillers, solvents or water, and of so-called additives. When developing new paint, the raw materials are chosen for compatibility with the object to be painted.

Process to Make Emulsions Paint Manufacturing Machine

this formula is for emulsion paint / Optimized

Paint Manufacturing Process Plc Paint industry How to Start a Paint Manufacturing Industry (Decorative Paint & Acrylic Emulsion Paint) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility study, Investment Opportunities, Cost and Revenue

emulsion made easy Ross Mixers

Proposed Ammonium Nitrate Emulsion Production Facility and

Production of Trowel Paints using Polyvinyl Acetate

SUMMARY Emulsion polymerization is an important industrial process for the production of latex paints, rubbers, coatings and adhesives. Although the process has been used

Production of Emulsion House Paint Using Polyvinyl Acetate

How to produce perfect emulsion paint and its procedure To produce emulsion paint,you need the following bowl stirring stick,water (h20), this is for production of 20 litres of brilliant white paint. NOTE: this is for the production of 20 formular for 20 litres white emulsion paint. THINGS YOU NEED water – 12kg calgon 0.1kg titan dioxide 0.5kg aluminium silicate 1.0kg calcuim carbonate 13kg

Guide formulations setylose.com

Process to Make Emulsions Paint Manufacturing Machine

understanding of the setting process are outlined. The classification of emulsions into grades according to their reactivity, particle charge, and physical properties is explained and typical recipes of various emulsion grades are given. The selection of the correct emulsion grade for the various applications based on emulsion reactivity and physical properties of the emulsion is covered in

this formula is for emulsion paint / Optimized

ALTERNATIVES TO NATROSOL AS THICKENER IN THE PRODUCTION

Preliminary Environmental Assessment – Proposed Ammonium Nitrate Emulsion Production Facility and Continued Operation of Orica Mining Services Technology Park,

acrylic emulsion manufacturing process– Rock Crusher Mill

Free Cash Manuals A COMPLETE GUIDE TO PRODUCTION OF PAINT

Turnkey Manufacturing Project Process Plants Manufacturer

Comments are closed.