Soybean oil manufacturing process pdf

During a typical year soybean production comprises over half the worldwide oilseed production (Anonymous 1995). However, according to Dutton (1981) in the early 1940s, soybean oil was considered a poor quality oil, not suitable for food use, and more appropriate for use in industrial paints.

ies that further process the crude soybean oil into either industrial grade oil or edible oil products. The elevator is where soybeans are unloaded from trucks, rail cars, and/or barges.

manufacturing process of SPC and other soy products is presented in this paper. Anti-nutritional factors in soybean seeds According to their temperature resistance the anti-nutritional factors can be classified in heat labile

Soybean as a Biofuel Feedstock. Soybean (Glycine max) is a major crop throughout much of North America, South America and Asia. The United States is the world’s greatest producer, producing approximately 32% of the worlds soybeans followed by Brazil with 28%.

Hydrogenation is used to solidify soybean oil for the manufacture of margarine. This process increase stability of oils and to raise the melting point of soybean oil shortening hydrogenation changes the chemical composition and physical properties of oils and effects of the nutritional value.

Epoxidized soybean oil (ESBO) is a collection of organic compounds obtained from the epoxidation of soybean oil. It is used as a plasticizer and stabilizer in polyvinyl chloride (PVC) plastics . ESBO is an yellowish viscous liquid.

IMARC’s latest study “Soybean Oil Processing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue” provides a techno-commercial roadmap for setting up a soybean oil processing plant.

The Chinese and Japanese produced soy oil as early as 2000 B.C. , Lecithin is a byproduct of the degumming process used in making soybean oil. This industrially valuable product is used to …

13 Soybean Oil: Production Process, Benefits and Uses in Pharmaceutical Dosage Form H. Yesim Karasulu et al.* University of Ege, Department of Pharmaceutical Technology

Oil palm is a major competitor with soybean oil. Although the palm produces far more oil Although the palm produces far more oil per unit area than soybean, soybean’s role is expected to be secure because soya meal is in huge

Corn oil is separated from distillery products via a centrifuge process. It provides caloric value and favorable finished product attributes in feeding rations and is a preferred feedstock or raw material for the production of biodiesel as a source for relatively low-carbon.

There are two methods of soybean oil production, one is mechanical way, which is a traditional method that use screw press machine to squeeze oil out from seeds and kernels; the other way is chemical method that extract oil with solvents.

Thus, the soybean oil (20% oil) is usually extracted only solvent as sunflower oil (45% oil) is partially removed by pressing and the remaining solvent. The oil obtained in these processes, known as crude oil, generally undergoes a purification process (refining) before being consumed as food.

Epoxidized soybean oil Wikipedia

Processing chsinc.com

Soybeans will go through a three-stage process where soybean meal, soy protein concentrate (SPC), soy oil, soy lecithin and soy molasses will be extracted. Before these process steps, soy hulls are separated from the bean.

adjuncts to already-existing soybean oil ex traction plants. Costs are restricted to and in clude only facilities directly associated with the process. Therefore, costs for such items as steam-generatingfacilities and equipment for receiving, cleaning, storing, and grinding whole soybeans do not form part of the esti mates. However, charges for various utilities and, where applicable

42 EFISC Code –Sector reference document on the manufacturing of safe feed materials from oilseed crushing and vegetable oil refining Feed Risk assessment of the chain of soya (bean) meal and oil …

foods containing trace residual concentrations of hexane are ingested. Hexane extraction of oil from soybeans is established as a safe and efficient process. No evidence exists to associate health risks or dangers from eating soyfoods exposed to hexane extraction processes. Vegetable Oil Processing. Processing of soybeans traditionally consists of five unit operations: 1) oilseed harvesting

So use extruded soybeans with high oil and fats content instead of the oil material will improve the feed energy concentration, simplify the production process, and most importantly, it will save the cost.

• develop the highest quality soybean, soy oil and soy meal products, • implement best management practices to maximize profitability, • and increase soybean production in a sustainable manner to meet global market needs.

the fatty acid composition of soybean oil to help it compete better in various uses, but the cost of growing, segregating, and testing special varieties and resistance to genetically modified oils have limited the appeal of these altered varieties.

A Continuous Process for the Glycerolysis of Soybean Oil H. Noureddinid.l, D.W. Harkey , and M.R. Gutsman ABSTRACT: A continuous process for the glycerolysis of soybean oil with pure and crude glycerol, the co-product

Soybean oil is a vegetable oil extracted from the seeds of the soybean (Glycine max). It is one of the most widely consumed cooking oils. As a drying oil, processed soybean oil is also used as a base for printing inks and oil paints.

Dr Erhard Briendenhann Protein Research Foundation Soya processing –nutritional and financial benefits Sponsored by: Protein Research Foundation. SOYBEAN PROCESSING Nutritional and financial benefits Dr Erhard Briedenhann (MIDS) WHY SOYBEAN MEAL ? PEANUTS 6 MT SUNFLOWER 15 MT COPRA 2 MT FISHMEAL 5 MT COTTONSEED 16 MT PALM KERNEL 7 MT RAPESEED 35 MT SOYA 182 MT 68%. WHY SOYBEAN …

environmental, health, and safety guidelines vegetable oil production and processing february 12, 2015 . e. nvironmental, h. ealth, and . s. afety . g. uidelines for

Abstract: Soybean oil production is the basic process for soybean applications. Cash flow analysis is used to estimate the profitability of a manufacturing venture. Besides capital investments

update the cradle-to-gate data for soybean production and conversion of soybean oil and meal into key soy-derived feedstocks (methyl soyate, soy lube base stock, soy polyol, and soy resin) used in fuel and industrial products in order to calculate life cycle

9.11.1 Vegetable Oil Processing 9 annual nationwide soybean crush. The production of flakes for human consumption generally follows the flow diagram in Figure 9.11.1-3 for the “conventional” process, except for the desolventizing step. In this step, the flakes from the oil extraction step are “flash” desolventized in a vacuum with noncontact steam or superheated hexane. This step is

The Soybean market report presents basic information and accurate data about challenges, opportunities for the key players, development factors, consumer, price, revenue, gross margin, market share, manufacturing process analysis, industry chain analysis.

A.E. Staley saw great potential of the soybean as a source of oil, meal, and flour. In 1922, the A.E. Staley Manufacturing Company began crushing soybeans to yield oil and meal.

Soybean Oil. Soybean oil is a complex mixture of five fatty acids (palmitic, stearic, oleic, linoleic, and linolenic), all of which have different melting points, oxidative stabilities, and …

Soybean oil production The production of commercial soybean oil is complicated. The mechanical production of soybean oil with hydraulic presses is not much used …

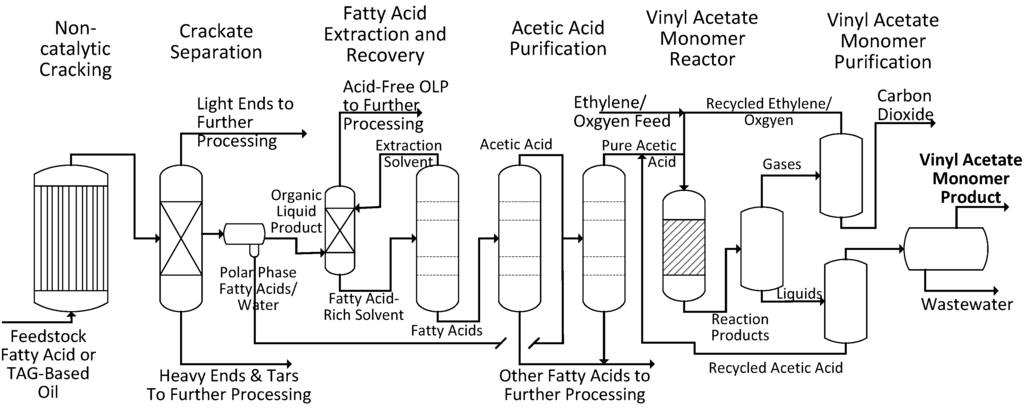

1.3 Soybean oil – manufacturing process The production process involves several steps and includes cleaning and drying, crushing and solvent extraction of soybeans.

MANUFACTURING PROCESS : First cold pressing (T<60°C) PRODUCTION AND STORAGE CONDITIONS APPLICATIONS Virgin soybean oil is used in hair, body and face products, more particularly in baby care, emollient creams for normal, dry, damaged and mature skins, massage oils and shampoos for dry hair. It can also be used in nourishing lipsticks. Originating in China, soya is an …

dominate global production, accounting for 80% of the world's soybean supply. Global production of Soybean has grown at a CAGR of 2.78% from 215.69 million metric tons in 2004-05 to 283.79 million metric tons in 2013-14.

Annual production and consumption of oils and fats is about 119 million tonnes and rising steadily at a rate of 2–6 million tonnes per year. This is required to meet the demand, which also grows at around this rate, partly as a consequence of increasing population but more because of increasing income, especially in developing countries. Around 14% of current oil and fat produc-tion is used

Soybean International Commodity Profile World Bank

it allowed continuous oil extraction and could process large quantities of oleaginous materials with minimal labor. Figure 2 illustrates an early Anderson Expeller 1 (trademark for Anderson mechanical screw press). In the early 1900s, a number of European companies developed variations of the V. D. Anderson design concepts and began manufacturing mechanical screw presses. In the 1930s, after

Soybean oil first achieved its leading position in the period 1950–54, and its current relationship to the world production of other fats and oils is shown in Figure 2 (4).

This paper examines the long range forecasts of soybean production as well as area harvested and yield using time series model and scenario analysis.

Because soy oil is essentially a joint product (rather than a true by-product like lard or cottonseed oil) and because the soybean is a quick-yielding annual crop (rather than a slow-to-yield tree crop, as for palm oil), soybean production can respond quickly to increased demand. Third, its good nutritional value. Low in saturated fats, it contains a high percentage of “polyunsaturates

On a moisture free basis, oil content of corn germ is about 45% to 55%, compared to about 20% oil from soyabean, and is concentrated in the corn kernel germ, which is recovered both by wet corn millers in the production of starch and by dry corn millers in the production of Grits, meal and flour.

Soybean Oil: Production Process, Benefits and Uses in Pharmaceutical Dosage Form 285 Last step of processing is deodorization. In deodorization process, removal of volatile

Production of high quality meal and crude oil is the main objective in soybean processing. For achievement, thorough knowledge of the technical system and disciplined operation are required. The starting point is reception of soybeans at the processing plant. And, the endpoint is meal delivered to the storage silos and oil delivered to the storage tanks. First of all accurate weight

Economic Comparison of Continuous and Batch Production of Biodiesel Using Soybean Oil between batch and continuous process for the production of biodiesel (especially from soybean oil) is limited. On the other hand, previous literature, related to batch and continu-ous production, agreed that raw material is the largest con- tributor to the production cost; for instance, Haas, M. J., et al – pp woven bags manufacturing process pdf process soy protein isolates (SPI) or soy protein concentrates (SPC) are produced. Whereas SPI production is fairly standardized, different methods of extraction are used to obtain the SPC resulting in slightly different compositional characteristics.

bean oil to process it further. Looking at the trends of oil used for edible purposes, Looking at the trends of oil used for edible purposes, Soya bean oil is in huge demand.

Oil quality is measured in terms of free fatty acids, absence of residual hexane and crude oil color. Meal quality is determined by residual oil, moisture, protein, urease activity protein solubility and mesh size in the finished product. Innovations at modern plants include degumming of the oil, lecithin drying and blending and production of soyabean meal with high protein solubility for

edible oil refinery process pdf soybean oil refining process flow chart. HEST MUEZ Concept to Performance HEST Concept to Performance . Title: Edible Oil Refinery Process Flow Diagram Author: Muez-Hest Subject: Edible Oil Refinery Process Flow Diagram Keywords: Edible Oil Refinery Process Flow Diagram Created Date : 7/25/2018 6:13:24 PM

Soybean oil is one of th e major feedstocks for biodiesel production. According to United States Department of Agriculture (USDA), the U.S. was the largest producer of soybean oil in …

Soybean oil, which is high in g-tocopherol and consequently well-protected in vitro, is relatively low in a-tocopherol and cannot reach this ratio. The, b -carotene in palm oil is another valuable component that needs consideration in the refining process.

SOY PROCESSING Nordic Soya

Soybeans CropWatch

Manufacturing of soy protein concentrate for animal nutrition

Life Cycle Impact of Soybean Production and Soy Industrial

SOYBEAN OIL Glenn Corp

Dr Erhard Briendenhann GFFC 2013

Soybean Oil Production Process Benefits and Uses in

Chapter One Soybeans….The Miracle Crop The Soybean It’s

– Evaluation of the PPPIAD Project on SOYBEAN FICCI

Soybean Oil Processing Plant Project Report Industry

Economic Comparison of Continuous and Batch Production of

Soybean Oil an overview ScienceDirect Topics

11 replies on “Soybean oil manufacturing process pdf”

Leave a Comment9.11.1 Vegetable Oil Processing 9 annual nationwide soybean crush. The production of flakes for human consumption generally follows the flow diagram in Figure 9.11.1-3 for the “conventional” process, except for the desolventizing step. In this step, the flakes from the oil extraction step are “flash” desolventized in a vacuum with noncontact steam or superheated hexane. This step is

Soybean Oil Processing Plant Project Report Cooking Oil

MANUAL of QUALITY ANALYSES for SOYBEAN PRODUCTS FEED

edible oil refinery process pdf soybean oil refining process flow chart. HEST MUEZ Concept to Performance HEST Concept to Performance . Title: Edible Oil Refinery Process Flow Diagram Author: Muez-Hest Subject: Edible Oil Refinery Process Flow Diagram Keywords: Edible Oil Refinery Process Flow Diagram Created Date : 7/25/2018 6:13:24 PM

History of Soybean Crushing Soy Oil and Soybean Meal Part 1

Evaluation of the PPPIAD Project on SOYBEAN FICCI

US7314944B2 Soybean oil process – Google Patents

Thus, the soybean oil (20% oil) is usually extracted only solvent as sunflower oil (45% oil) is partially removed by pressing and the remaining solvent. The oil obtained in these processes, known as crude oil, generally undergoes a purification process (refining) before being consumed as food.

Global Soybean Market 2023 by Revenue Gross Margin

Oil palm is a major competitor with soybean oil. Although the palm produces far more oil Although the palm produces far more oil per unit area than soybean, soybean’s role is expected to be secure because soya meal is in huge

Soybean Oil Pharos Project

Processing chsinc.com

SOy PROCESSES EQUIPMENT CAPITAL AND PROCESSING COSTS

dominate global production, accounting for 80% of the world’s soybean supply. Global production of Soybean has grown at a CAGR of 2.78% from 215.69 million metric tons in 2004-05 to 283.79 million metric tons in 2013-14.

Technology of Soybean Extruding and Pressing

bean oil to process it further. Looking at the trends of oil used for edible purposes, Looking at the trends of oil used for edible purposes, Soya bean oil is in huge demand.

Life Cycle Impact of Soybean Production and Soy Industrial

42 EFISC Code –Sector reference document on the manufacturing of safe feed materials from oilseed crushing and vegetable oil refining Feed Risk assessment of the chain of soya (bean) meal and oil …

MANUAL of QUALITY ANALYSES for SOYBEAN PRODUCTS FEED

Soybean Oil Processing Plant Project Report Cooking Oil

Oil palm is a major competitor with soybean oil. Although the palm produces far more oil Although the palm produces far more oil per unit area than soybean, soybean’s role is expected to be secure because soya meal is in huge

Soybean oil Wikipedia

Soybeans CropWatch

US7314944B2 Soybean oil process – Google Patents

Economic Comparison of Continuous and Batch Production of Biodiesel Using Soybean Oil between batch and continuous process for the production of biodiesel (especially from soybean oil) is limited. On the other hand, previous literature, related to batch and continu-ous production, agreed that raw material is the largest con- tributor to the production cost; for instance, Haas, M. J., et al

Economic Comparison of Continuous and Batch Production of

The Soybean market report presents basic information and accurate data about challenges, opportunities for the key players, development factors, consumer, price, revenue, gross margin, market share, manufacturing process analysis, industry chain analysis.

Chapter One Soybeans….The Miracle Crop The Soybean It’s

Economic Comparison of Continuous and Batch Production of

Soybean Oil Pharos Project

update the cradle-to-gate data for soybean production and conversion of soybean oil and meal into key soy-derived feedstocks (methyl soyate, soy lube base stock, soy polyol, and soy resin) used in fuel and industrial products in order to calculate life cycle

Life Cycle Impact of Soybean Production and Soy Industrial

Dr Erhard Briendenhann GFFC 2013

Soybean Oil an overview ScienceDirect Topics

Comments are closed.